QJ Submersible PUMP

Product Description

General Description

The QJ submersible pump is mainly used for carrying water from a deep well and boosting and is widely used in farmland irrigation, water draining in urban and rural areas and mines and industrial enterprises and water conservancy works including reservoir, fountain, cooling system and spa etc. The main features are as follows: With easy to use, easy installation, easy maintenance, environmental protection etc. Advantages, the electric diving pump which collects the motor and water pump could work in the water and it is convenient to use and repair.

Submersible Water Pump Manufacturers

We are a professional manufacturer of submersible pumps in China. In addition to water pumps, we also supply various slurry pumps, gravel pumps, desulfurization pumps, etc. According to different requests, we could provide products with different materials like stainless steel casting, stainless press-welding, bronze casting, plain iron casting, corrosion resistant special material casting. The pump must be strict with outside diameter, so the situations such as motor seal leaks and water pollution will not occur.

Specifications

Size (discharge): 4" to 16"

Capacity: 2-500m3/hr

Head: 10m-500 m

Housepower: 0.75-450kw

Material: Cast Iron, Bronze, Stainless steel etc

AIER® QJ Submersible Pump

Conditions Of Usage

①Power: 380V/3-phase AC, 50Hz

②Water quality:

A. The temperature of water is below 20℃(high temperature resistance 80℃)

B. The solid content is less than 0.01% (depends on the quality)

C. PH 6.5-8.5

D. The content of hydrogen sulfide is less than 1.15mg/l

E. The content of oxide ion is less than 400mg/l

③The inner part of the submersible motor must be full of clean water and submersible pump must sefely submerge to work.

④Mounting depth shall not exceed 20% of water pump rated head and well face must be smooth and straight.

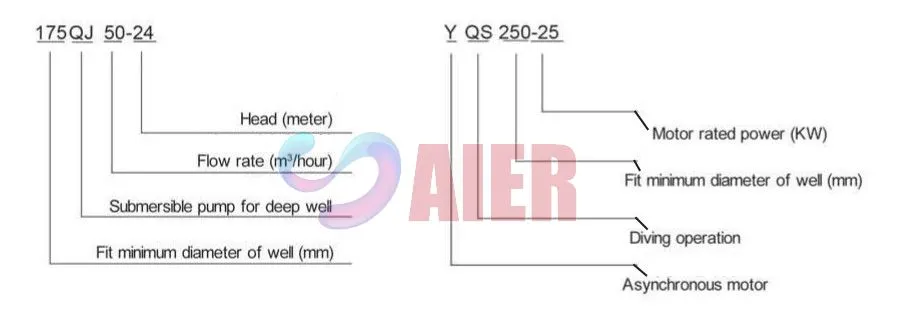

Type Notation

Main Features

1. The motor is wet submersible motor. The motor chamber must be filled with clean water which is used for cooling motor and lubricating bearing. The voltage regulating film on the base or motor is used for adjusting pressure difference and dilation of water in the inner part of motor caused by motor temperate changes.

2. In order to prevent the sand grains from a well from enter into the inner part of motor, upper shall extension is installed two seals oils which are installed backward and one sand off ring is installed.

3. To prevent water pump shaft from jumping, water pump shaft and motor shaft are connected by coupling and a thrust bearing should be installed in the under parts of motor.

4. The water lubricates the motor and water pump bearing.

5. The submersible motor winding wires are used for the stator winding. So it insulates well

6. The centrifugal impeller and vertical blower inlet casing are used for target="_blank">water pump and the structure is simple.

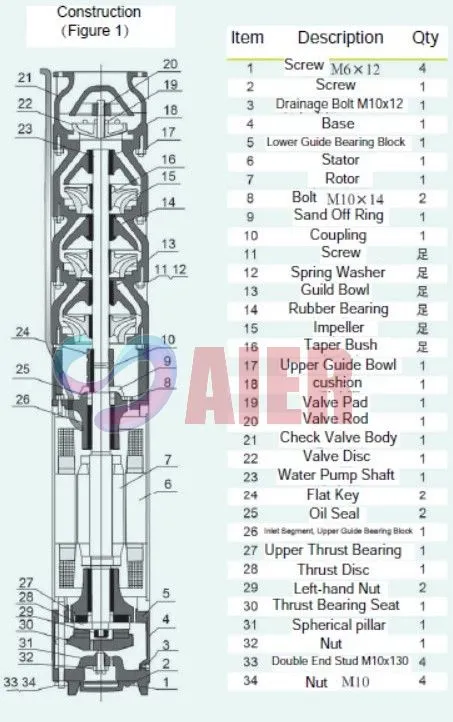

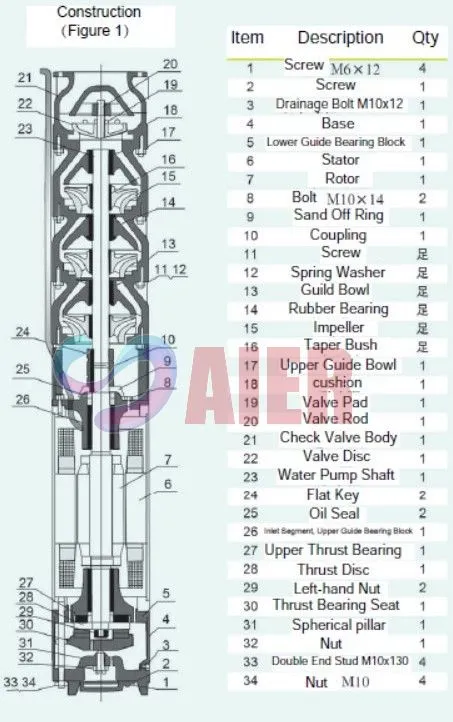

Construction Diagram

QJ submersible pump mainly consists of feed point, water pump shaft, impeller, blower inlet casing, rubber bearing, check valve (option) etc. The submersible motor consists of base, voltage regulating film, thrust bearing, thrust disc, lower guide bearing block, stator, stator winding, rotor, upper guide, bearing block, sand off ring, outlet cable, etc.

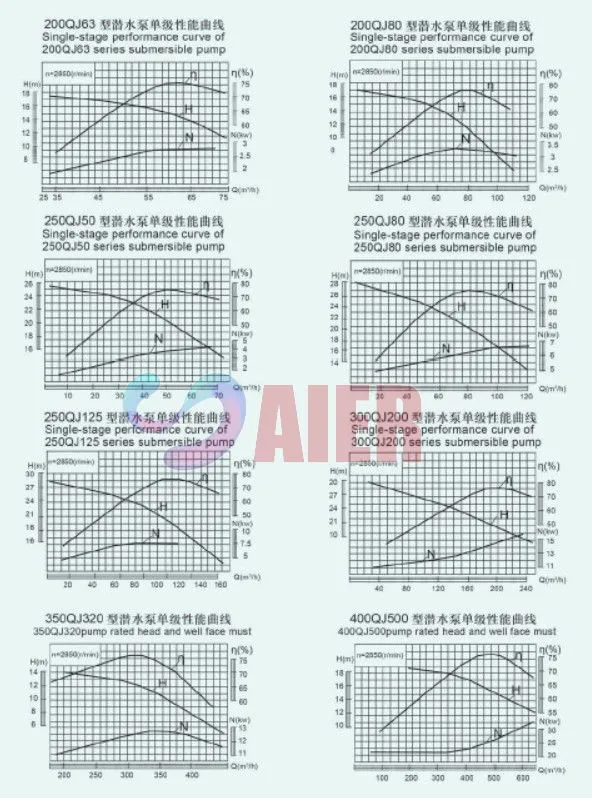

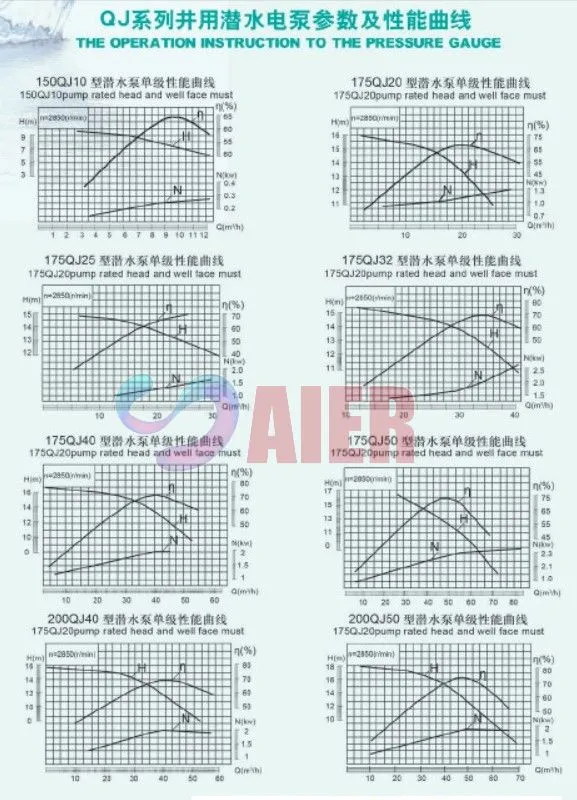

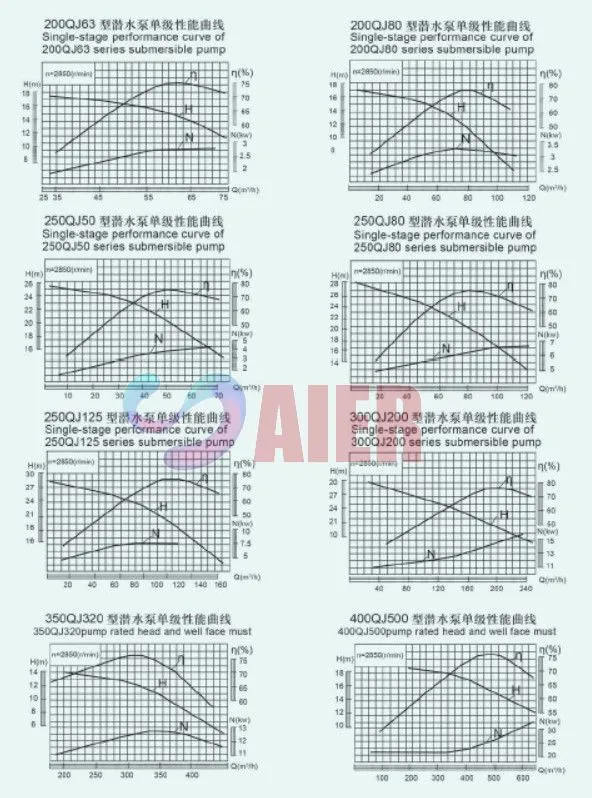

Performance Curve

Advantages of Using Submersible Water Pumps for Continuous Operation

A submersible water pump is a highly efficient and durable pumping solution designed to work entirely underwater, making it ideal for applications requiring continuous operation. Unlike surface-mounted pumps that rely on suction, a submersible pump pushes water upward through direct contact with the liquid, resulting in higher efficiency, less energy loss, and better performance in harsh environments.

One of the most significant advantages of submersible water pumps is their energy efficiency. Because they operate directly in the fluid, there is no air leakage or suction head loss, which means the pump converts more motor energy into hydraulic power. This makes submersible pumps extremely effective in deep wells, reservoirs, and dewatering systems where long-term operation is essential. Leading submersible water pump manufacturers often equip their pumps with advanced motors featuring high-efficiency windings and low energy consumption for round-the-clock operation.

Another major benefit is the quiet and vibration-free operation. Since the entire pump is submerged underwater, the surrounding fluid dampens sound and vibration. This makes submersible pumps suitable for residential, municipal, and industrial applications where noise control is important—such as building basements, urban drainage systems, and cooling water circulation.

In addition, submersible water pumps are known for their excellent anti-cavitation properties. Because they operate below the water surface, the risk of air bubbles forming at the impeller is greatly reduced. This prevents vapor lock, improves hydraulic stability, and minimizes wear on internal components. The constant immersion of the pump also ensures natural cooling for the motor, extending its service life even during extended operation.

Finally, submersible pumps are easy to install and maintain. Most modern models are designed with modular components, corrosion-resistant casings, and advanced sealing systems. This ensures long-lasting reliability in environments such as wastewater treatment, agriculture, mining, and chemical processing. When you choose a product from a reputable submersible water pump manufacturer, you can expect superior performance, reduced maintenance costs, and reliable operation—day after day.

Maintenance and Troubleshooting Tips for Submersible Water Pumps

Proper maintenance of a submersible water pump is essential for ensuring consistent performance, preventing failures, and maximizing operational lifespan. Since these pumps work entirely underwater, they must endure high pressure, varying temperatures, and possible contact with sediments or chemicals. Following a proactive maintenance plan can significantly extend the efficiency and reliability of your system.

The first step is routine inspection. Regularly check the power cable for cracks, fraying, or water ingress, as damaged insulation can cause short circuits. Next, examine the pump’s exterior for corrosion or debris buildup. Sediment accumulation can restrict water flow and reduce pump efficiency. Cleaning the suction strainer and impeller housing every few months helps maintain optimal performance.

A common issue in submersible pumps is reduced discharge flow. This can be caused by impeller wear, clogged intake screens, or partial blockage in the discharge line. If this happens, disconnect the pump, clean the impeller, and inspect for wear or imbalance. Replacing worn impellers or seals promptly prevents more serious mechanical damage.

The mechanical seal is one of the most critical components of a submersible water pump. It prevents water from entering the motor housing. Any leakage or oil contamination in the seal area indicates the need for immediate replacement. Additionally, monitor the bearing temperature and listen for unusual noises—these can signal excessive friction or bearing wear.

Leading submersible water pump manufacturers recommend checking motor insulation resistance periodically to prevent electrical faults. For pumps used in wastewater or industrial environments, schedule quarterly performance tests to track flow, head, and power consumption. If overheating occurs, it could be due to low voltage or excessive solids in the fluid; cleaning the pump and verifying electrical connections typically resolves these problems.

By maintaining your submersible water pump properly—keeping it clean, well-lubricated, and regularly inspected—you can reduce downtime, prevent costly repairs, and ensure reliable operation for years, even in continuous-use applications.

Key Features of High Quality Submersible Water Pumps

A high-quality submersible water pump is engineered for durability, efficiency, and versatility, making it suitable for use in various industries including construction, mining, agriculture, and wastewater management. Understanding the key features that define a superior submersible pump can help users select the best equipment for long-term operation.

The most important feature is robust material construction. Reputable submersible water pump manufacturers use stainless steel, cast iron, or high-chrome alloys to ensure resistance to corrosion, abrasion, and chemical attack. These materials protect the pump body and impeller from harsh conditions such as sewage, slurry, or seawater exposure. A well-built submersible pump can operate continuously even in environments with high sediment or chemical content.

Another key aspect is the advanced mechanical sealing system. Double mechanical seals made of silicon carbide or tungsten carbide prevent leakage and protect the electric motor from water intrusion. Combined with oil-filled motor chambers for cooling and lubrication, these systems ensure long-lasting reliability and smooth operation.

Efficiency is also a hallmark of a top-tier submersible water pump. Precision-engineered impellers and high-efficiency motors minimize energy consumption while delivering consistent flow and head performance. Built-in overload protection and thermal sensors help prevent damage from overheating or voltage fluctuations, ensuring safety in continuous-use environments.

In addition, modern submersible pumps feature modular and service-friendly designs. Easy-to-remove components allow for quick maintenance without dismantling the entire system, reducing downtime. Anti-clog impeller designs and self-cleaning flow channels further enhance reliability, especially in wastewater or industrial slurry applications.

Finally, certified submersible water pump manufacturers perform rigorous quality control and performance testing to guarantee every unit meets global efficiency and safety standards. When you choose a high-quality submersible pump, you’re investing in a machine that provides stable output, reduced maintenance costs, and decades of dependable operation across multiple industries.