TL, TLR FGD Pump

Product Description

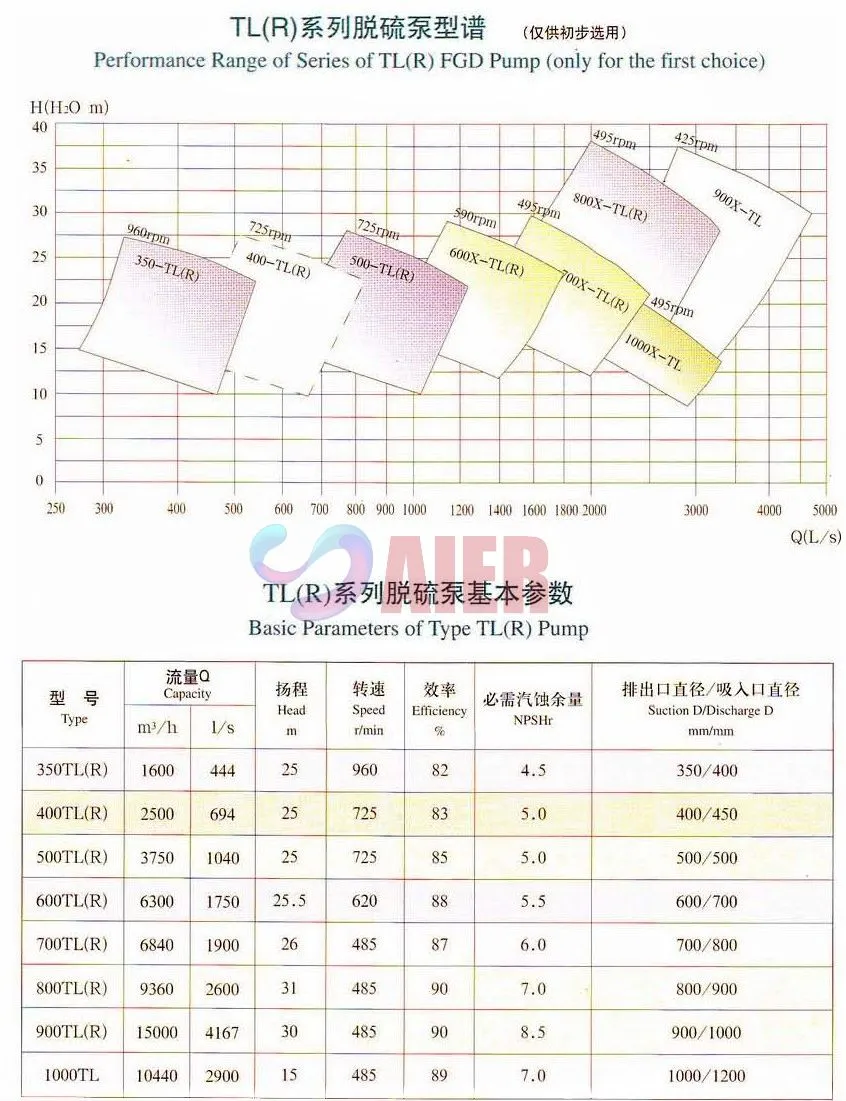

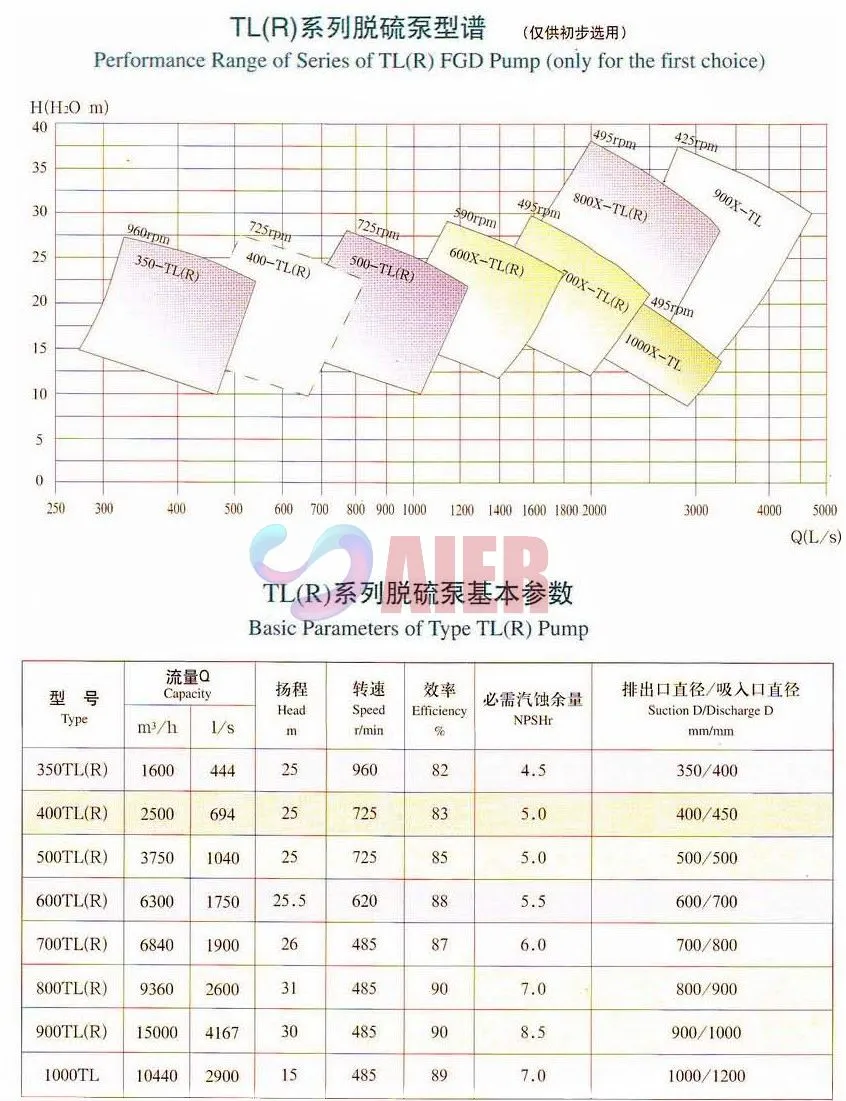

SPEFICATIONS:

Size: 350-1000mm

Capacity: 1500-14000m3/h

Head: 10-33m

Max.particles: 180mm

Temperature Range: ≤80°C

Materials: Hyperchrome, Natural Rubber, etc

AIER® TL, TLR FGD Pump

General

Series of TL FGD pump is a single stage single suction horizontal centrifugal pump. It is mainly used as the circulation pump for absorbent tower in FGD applications. It has such features: wide range flowing capacity, high efficiency, high saving power. This series of pump is matched by tight structure X bracket which can save much space. Meanwhile our company develops many kinds of material targeted on the pumps for FGD.

Technology Features

The pump wet parts are designed by advanced CFD Flowing Simulating Analysis Techniques to ensure design reliable and its working effective.

It can change the impeller’s position in pump casing by adjusting the bearing assembly to keep the pump working high efficiently all the time.

This kind of pump adopts back pull-out structure, keeping it easy construction and easy maintenance. It doesn’t need disassemble inlet & outlet pipeline.

Two sets of taper roller bearing is fixed in the end of the pump, the column roller bearing is equipped at driving end. The bearing is lubricated by oil. All these can improve the bearing working condition and greatly enhance it life.

Integrating mechanical seal which is specialized in FGD technology to ensure its operation is adopted.

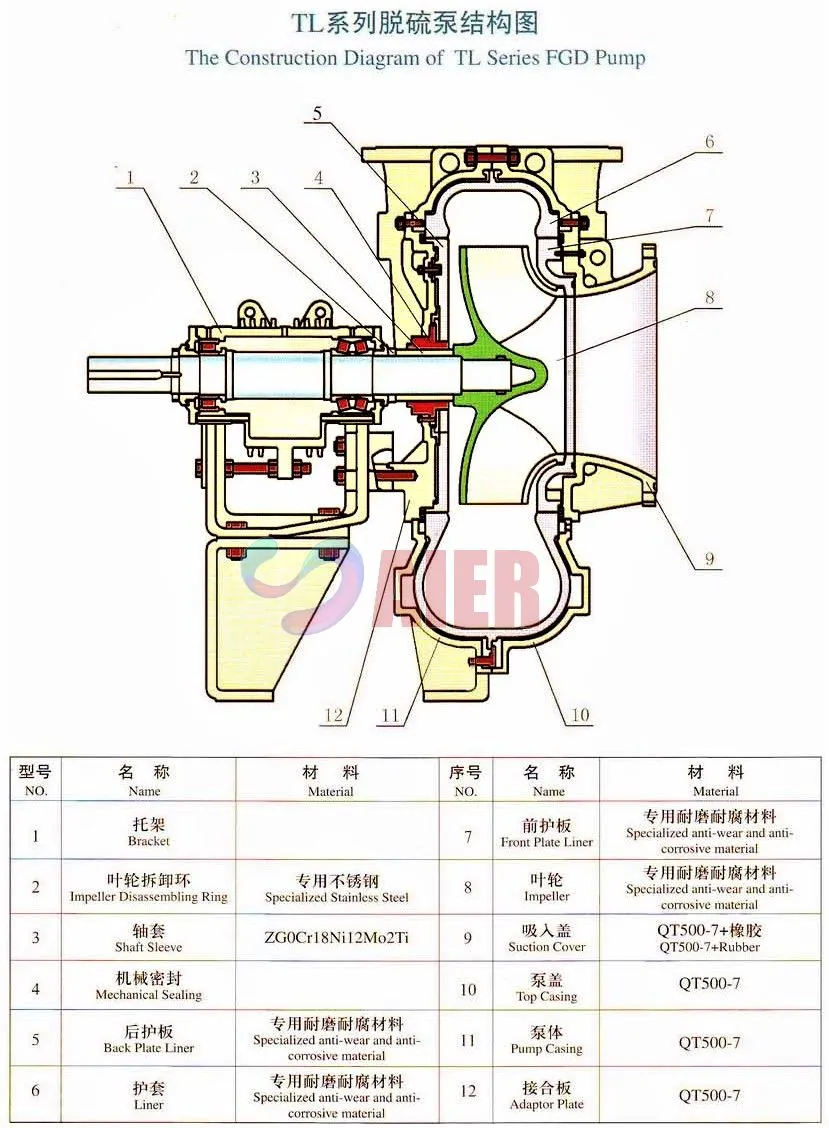

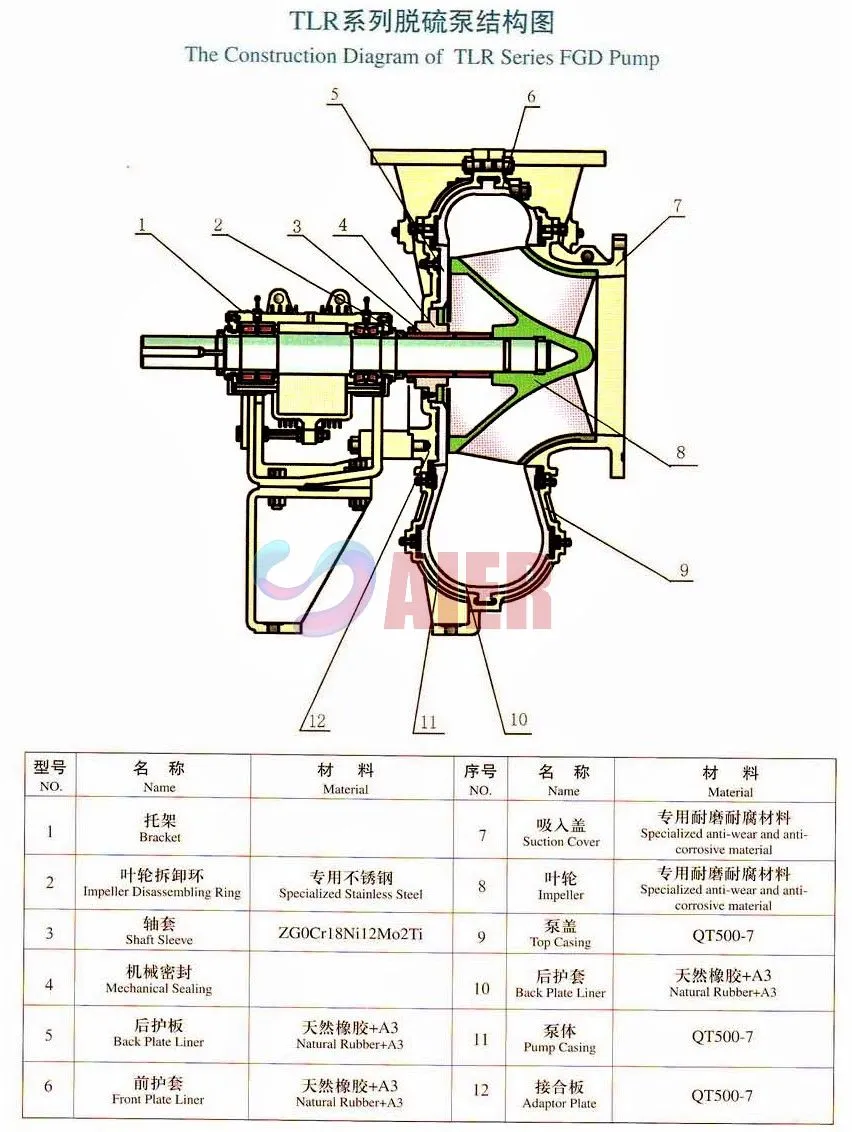

Material Selection

AIER has developed a new kind of specialized anti-wear and anti-corrosive material which possess the duplex stainless steel’s anti-corrosive property and the high chrome white iron’s anti-abrasive property in FGD process.

In the rubber pump casing, impeller, suction cover/cover plate are all made of specialized anti-wear and anti-corrosive material; the material of front liner, back liner and back liner insert are natural rubber with light weight and having excellent anti-corrosive property and low cost.

In metal pump casing, impeller, volute liner, suction plate and back plate are all made of specialized anti-wear and anti-corrosive material, the suction cover are made of ductile iron with rubber.

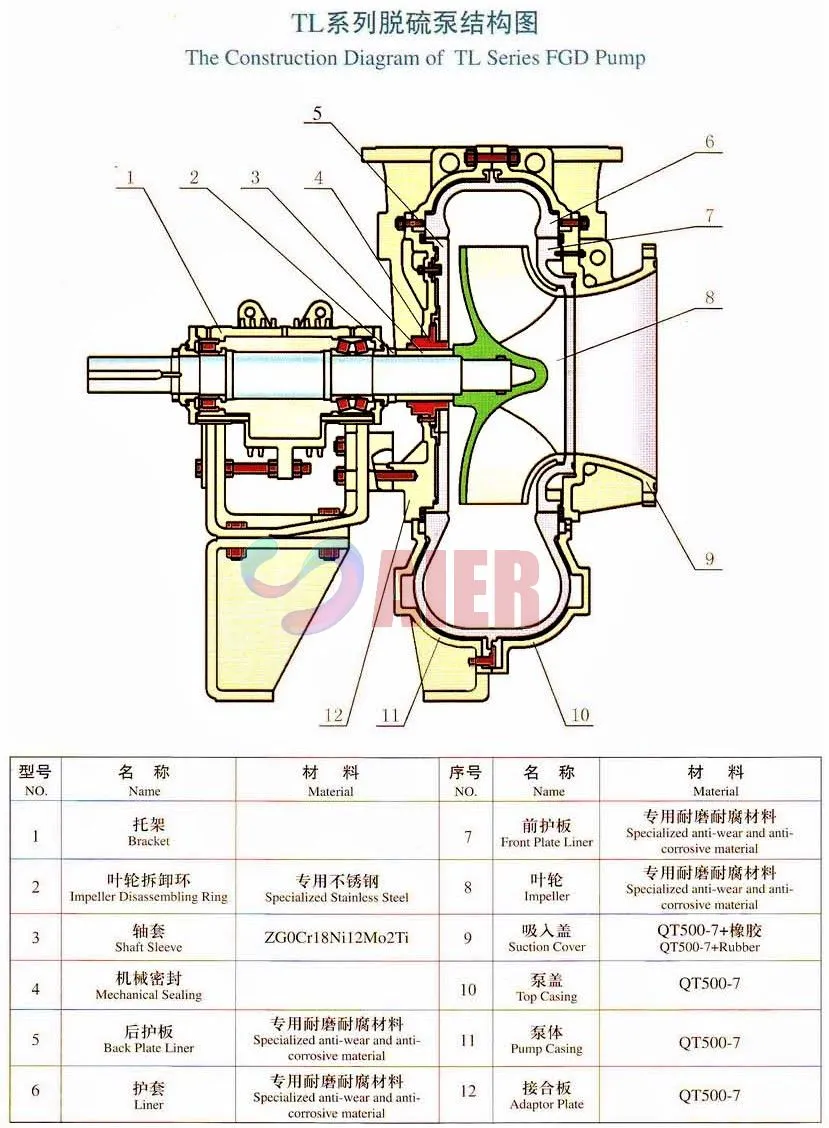

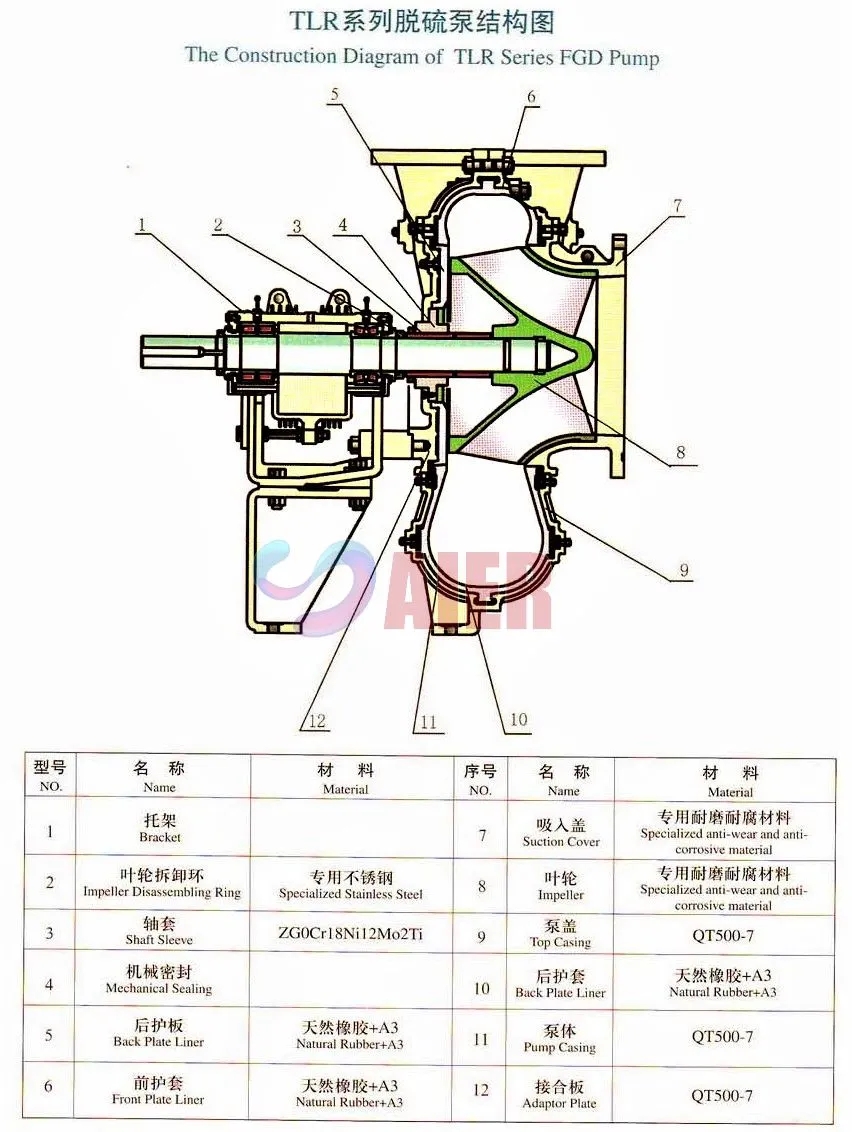

Construction Diagram

Performance Range and Main Parameters

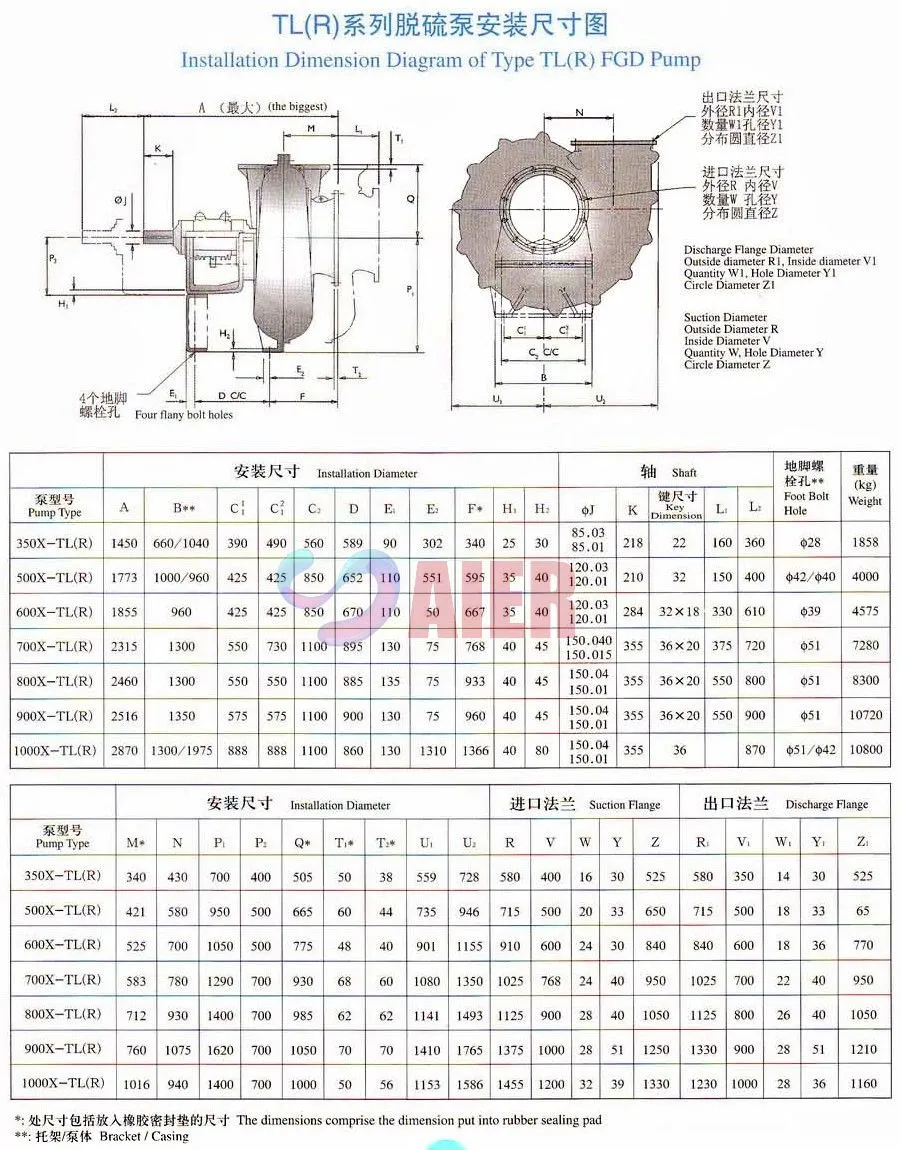

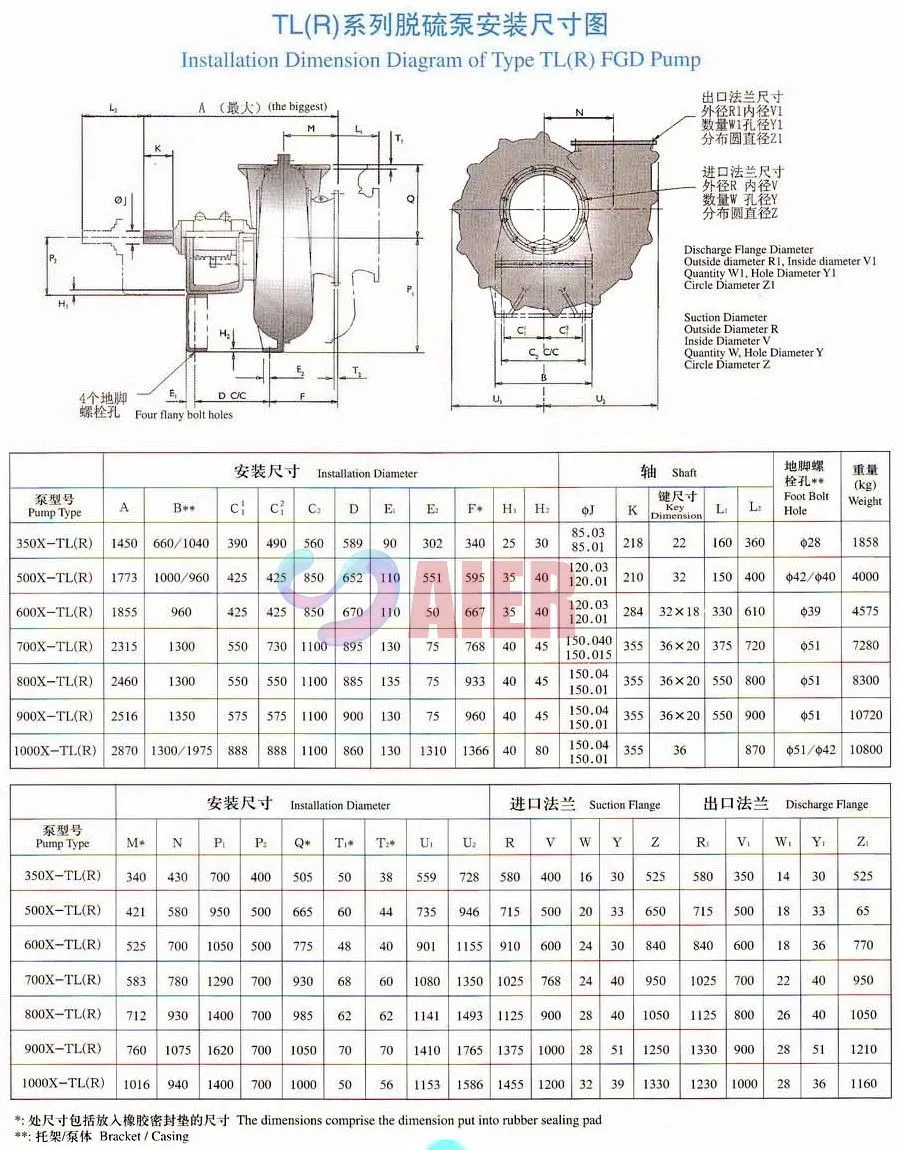

Outline Dimensions

How to Choose the Right FGD Pump Manufacturer for Your Project

Selecting the right FGD pump manufacturer is a critical step for ensuring the success of flue gas desulfurization projects. An FGD pump is a highly specialized piece of equipment, designed to handle abrasive and corrosive slurries efficiently. Choosing a reliable manufacturer guarantees long-term performance, minimal maintenance, and compliance with environmental standards.

First, consider the experience and expertise of the manufacturer. Leading FGD pump manufacturers like Aier Machinery Hebei Co., Ltd. have decades of experience producing pumps for industrial and power plant applications. Their knowledge of slurry characteristics, materials engineering, and hydraulic design ensures that every high quality FGD pump is optimized for both durability and efficiency.

Next, examine the product range and customization capabilities. Different FGD systems have unique requirements in terms of flow rate, head, and slurry composition. A reputable OEM FGD pump manufacturer can provide tailored solutions, from horizontal to vertical designs, and can adjust material composition, impeller design, and wear-resistant linings according to project demands. This customization ensures optimal performance in specific industrial conditions.

Another key factor is quality assurance and testing procedures. High-quality FGD pumps must withstand continuous operation with abrasive and corrosive materials. Look for manufacturers who implement rigorous quality control at every stage, including casting, machining, assembly, and performance testing. Certifications and adherence to international standards indicate a manufacturer’s commitment to reliability.

After-sales support is equally important. A trusted FGD pump manufacturer should offer technical guidance, spare parts availability, and maintenance support. This ensures minimal downtime and quick troubleshooting in case of operational issues.

Finally, consider global experience and references. Companies like Aier Machinery, a renowned OEM FGD pump manufacturer, have delivered pumps worldwide, providing solutions for thermal power plants and industrial projects across different environments. Their proven track record demonstrates reliability and technical competence.

In summary, choosing the right FGD pump manufacturer involves evaluating experience, product range, customization capabilities, quality assurance, and after-sales support. Partnering with a reputable OEM FGD pump manufacturer ensures that your project benefits from a high quality FGD pump that is efficient, durable, and reliable under demanding conditions.

Maintenance and Troubleshooting Tips for FGD Pumps

Proper maintenance is essential for ensuring the longevity and performance of an FGD pump. As these pumps handle abrasive and corrosive slurries in flue gas desulfurization systems, regular inspection and maintenance can prevent downtime and reduce operational costs. Aier Machinery Hebei Co., Ltd., a leading FGD pump manufacturer, offers solutions and guidance for extending pump life.

The first maintenance tip is regular inspection of wear parts. Impellers, casings, liners, and seals are constantly exposed to abrasive slurry. Using high-quality materials, as found in a high quality FGD pump, reduces wear, but regular visual inspections are still necessary. Replace worn parts promptly to avoid damage to other components.

Next, monitor pump performance parameters, including flow rate, pressure, vibration, and noise. Any deviation from normal operating conditions may indicate impeller erosion, blockage, or misalignment. Addressing these issues early prevents further damage. Working with an OEM FGD pump manufacturer ensures that spare parts and technical support are readily available for troubleshooting.

Lubrication and bearing maintenance are also critical. Bearings support the pump shaft and impeller, and insufficient lubrication can lead to overheating or failure. Follow manufacturer recommendations for lubrication intervals and types of lubricants. High-quality pumps from experienced FGD pump manufacturers often include advanced bearing assemblies designed for extended service life.

For chemical corrosion protection, check the integrity of lining and coatings. Acidic or chemically aggressive slurries can degrade the pump over time. Maintaining the lining and promptly repairing any damage ensures consistent operation of your FGD pump.

Finally, implement a preventive maintenance schedule. Document inspections, part replacements, and performance checks. An organized maintenance program, supported by guidance from a trusted OEM FGD pump manufacturer, significantly improves reliability and reduces unexpected downtime.

In conclusion, proper maintenance of an FGD pump includes monitoring wear parts, performance parameters, lubrication, and corrosion protection. Partnering with a reputable FGD pump manufacturer ensures access to high-quality pumps, spare parts, and technical support, keeping operations safe, efficient, and uninterrupted.

Comparing Horizontal and Vertical FGD Pumps for Power Plants

In power plants, FGD pumps are critical for transporting abrasive slurries in flue gas desulfurization systems. Selecting between horizontal and vertical pump designs impacts efficiency, maintenance, and overall operational performance. Aier Machinery Hebei Co., Ltd., a leading FGD pump manufacturer, provides both types, tailored to specific industrial requirements.

Horizontal FGD pumps are widely used for their simplicity, ease of installation, and maintenance accessibility. Their shaft and bearings are typically easier to service, and the modular design allows for quick replacement of wear parts. A high quality FGD pump in horizontal configuration is ideal for applications with moderate suction lift and space availability. Horizontal pumps are especially suitable when continuous monitoring and maintenance access are important.

In contrast, vertical FGD pumps are preferred in deep sump or confined-space installations. The vertical design allows the pump to operate directly from a slurry sump, reducing the need for a long suction pipeline. Vertical pumps from an experienced OEM FGD pump manufacturer like Aier Machinery are engineered to handle high head and abrasive slurries efficiently. They are often more compact and better suited for deep installations, although they may require specialized maintenance procedures.

Both horizontal and vertical FGD pumps feature wear-resistant materials, including high chrome alloys and stainless steel, ensuring long service life in corrosive and abrasive environments. Advanced hydraulic design optimizes flow efficiency and reduces energy consumption, providing cost-effective operation for power plants.

Another consideration is installation and space constraints. Horizontal pumps need more floor space but allow easier maintenance, while vertical pumps save space but may require overhead access for certain servicing tasks. A trusted FGD pump manufacturer can help determine the best configuration based on site layout and operational requirements.

In summary, both horizontal and vertical FGD pumps have distinct advantages. Horizontal pumps offer accessibility and simplicity, while vertical pumps are ideal for deep or confined installations. Partnering with a reputable FGD pump manufacturer ensures you receive a high quality FGD pump designed to meet your plant’s specific operational demands