ZJQ Submersible Slurry Pumps

Product Description

Aier® Submersible Slurry Pumps

The submersible slurry pump is a pump designed for pumping liquids containing solid particles. Aier® ZJQ series submersible slurry pump is a kind of hydraulic machinery, the motor and the pump of which are coaxially submerged in medium to work. The wet parts of the pump are made from high alloy wear-resistant material, so the pump has good wear resistance and large flowing passage. It is applicable for conveying medium such as sand, sludge, ore slurry, coal slurry, sand, stones containing big solid particles. It with wide range of applications in the industrial fields.

As one of the manufacturers of robust submersible pumps, Aier® is a market leader in terms of product quality. We have a full range of high quality submersible slurry pumps for dewatering, de-friction, abrasive media with high solids content (e.g. sand) in quarries and mining. The user-friendly design and ease of use of heavy submersible mortar pumps make them the first choice for submersible pumps.

Heavy-duty submersible slurry pump spefications

1. Size: 50-400mm

2. Capacity: 10-2000m3/h

3. Head: 8-80m

4. Max.particles: 60mm

5. Temperature Range: ≤80°C

6. Materials: High chrome alloy, Cast iron, SS304, SS316L etc.

ZJQ submersible slurry pumps features

1. Vertical, centrifugal, submersible pump design.

2. Besides the main impeller, there is the agitation impeller which can agitate the sludge deposited on the water bottom into turbulent flow and pump the sludge out.

3. The wet parts such as the impeller and the agitation impeller are made from high-hardness high chromium cast steel, have wear resistance, corrosion resistance and strong drainage capacity, and allow big solid particles to pass.

4. The motor is submerged in water, is not limited by suction stroke, and has high sludge suction rate and thorough desilting.

5. The integral device is simplified, needs no auxiliary stirrer device or ejector device, and has simple and convenient operation and low total investment of the unit.

6. The agitation impeller directly approaches the depositional surface, and controls the concentration through submerged depth. Under the condition of large medium proportion, an auxiliary device can be arranged to increase the concentration of the medium.

7. Various parameter configurations of slurry pumps can be customized.

8. Reliable and long-lasting, the highest quality construction and materials ensure long service life.

How to choose a suitable slurry pump?

The following can help you understand the pump specifications so that you need to take into account the size, strength, volume, and routine of the submersible pump. If you don't understand anything, you can target="_blank">contact us, we will have a professionals to solve it.

1. Size

2. Power

3. Volume

4. Head etc.

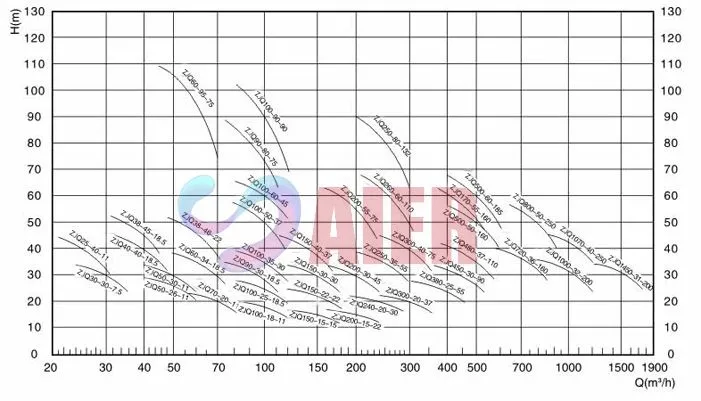

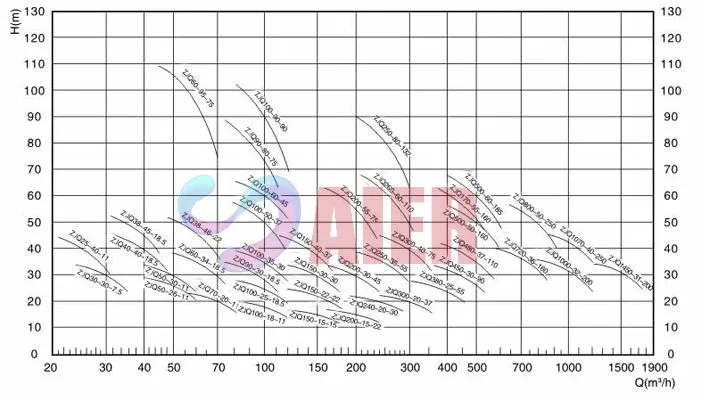

Performance Chart

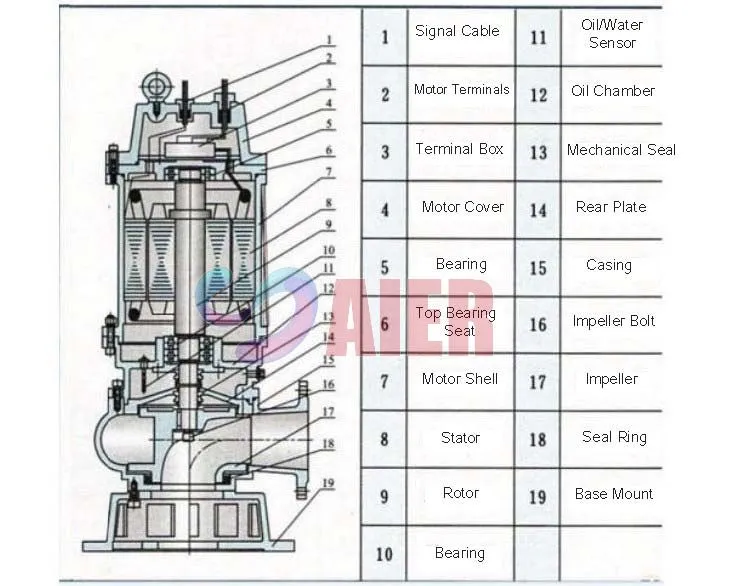

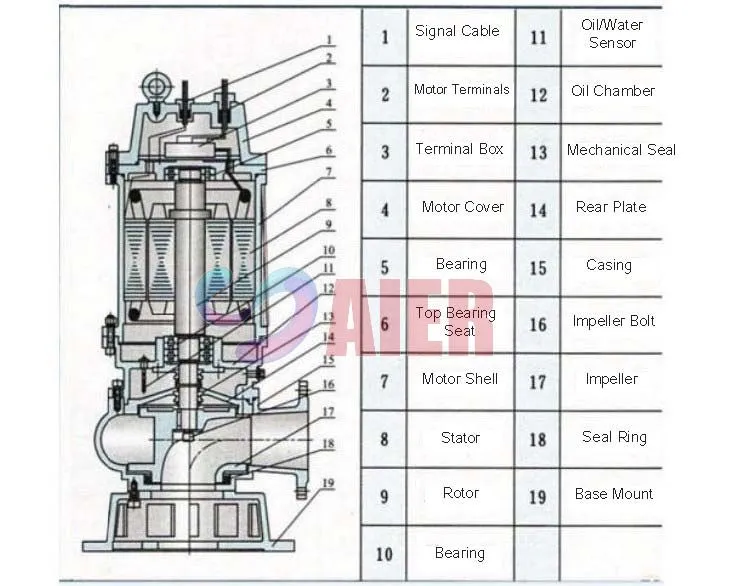

Construction Diagram

Performance Parameters

| Aier® ZJQ Submersible Slurry Pumps Performance Parameters: | |||||||||

| No. | Model | Size (mm) | Capacity Q (m3/h) | Head H (m) | Power P (kw) | Eff. η (%) | Speed n (r/min) | Max. particles (mm) | Weight (kg) |

| 1 | 50ZJQ10-20-3 | 50 | 10 | 20 | 3 | 37 | 1460 | 8 | 110 |

| 2 | 50ZJQ15-18-3 | 50 | 15 | 18 | 3 | 46 | 1460 | 8 | 110 |

| 3 | 50ZJQ20-15-3 | 50 | 20 | 15 | 3 | 52 | 1460 | 8 | 110 |

| 4 | 50ZJQ25-12-3 | 50 | 25 | 12 | 3 | 58 | 1460 | 8 | 110 |

| 5 | 65ZJQ30-12-3 | 65 | 30 | 12 | 3 | 60 | 1460 | 8 | 110 |

| 6 | 65ZJQ35-10-3 | 65 | 35 | 10 | 3 | 64 | 1460 | 8 | 110 |

| 7 | 65ZJQ40-8-3 | 65 | 40 | 8 | 3 | 66 | 1460 | 8 | 110 |

| 8 | 50ZJQ15-22-4 | 50 | 15 | 22 | 4 | 43 | 1460 | 10 | 113 |

| 9 | 50ZJQ18-20-4 | 50 | 18 | 20 | 4 | 46 | 1460 | 10 | 113 |

| 10 | 50ZJQ20-18-4 | 50 | 20 | 18 | 4 | 50 | 1460 | 10 | 113 |

| 11 | 50ZJQ25-20-4 | 50 | 25 | 20 | 4 | 52 | 1460 | 10 | 113 |

| 12 | 65ZJQ30-16-4 | 65 | 30 | 16 | 4 | 52 | 1460 | 10 | 113 |

| 13 | 65ZJQ35-15-4 | 65 | 35 | 15 | 4 | 60 | 1460 | 10 | 113 |

| 14 | 65ZJQ40-12-4 | 65 | 40 | 12 | 4 | 63 | 1460 | 10 | 113 |

| 15 | 65ZJQ45-10-4 | 65 | 45 | 10 | 4 | 66 | 1460 | 10 | 113 |

| 16 | 80ZJQ20-30-5.5 | 80 | 20 | 30 | 5.5 | 42 | 1460 | 13 | 205 |

| 17 | 80ZJQ30-20-5.5 | 80 | 30 | 20 | 5.5 | 54 | 1460 | 13 | 205 |

| 18 | 80ZJQ45-15-5.5 | 80 | 45 | 15 | 5.5 | 41 | 1460 | 13 | 205 |

| 19 | 80ZJQ15-20-5.5 | 80 | 15 | 20 | 5.5 | 33 | 1460 | 13 | 205 |

| 20 | 80ZJQ50-10-5.5 | 80 | 50 | 10 | 5.5 | 44 | 1460 | 13 | 205 |

| 21 | 80ZJQ15-20-7.5 | 80 | 15 | 20 | 7.5 | 34 | 1460 | 13 | 210 |

| 22 | 80ZJQ20-25-7.5 | 80 | 20 | 25 | 7.5 | 35 | 1460 | 13 | 210 |

| 23 | 80ZJQ25-20-7.5 | 80 | 25 | 20 | 7.5 | 36 | 1460 | 13 | 210 |

| 24 | 80ZJQ25-30-7.5 | 80 | 25 | 30 | 7.5 | 36 | 1460 | 13 | 210 |

| 25 | 80ZJQ30-30-7.5 | 80 | 30 | 30 | 7.5 | 37 | 1460 | 13 | 210 |

| 26 | 80ZJQ32-20-7.5 | 80 | 32 | 20 | 7.5 | 37 | 1460 | 13 | 210 |

| 27 | 80ZJQ45-15-7.5 | 80 | 45 | 15 | 7.5 | 41 | 1460 | 13 | 210 |

| 28 | 100ZJQ100-10-7.5 | 100 | 100 | 10 | 7.5 | 48 | 1460 | 21 | 220 |

| 29 | 80ZJQ25-40-11 | 80 | 25 | 40 | 11 | 36 | 1460 | 13 | 300 |

| 30 | 80ZJQ40-25-11 | 80 | 40 | 25 | 11 | 38 | 1460 | 13 | 240 |

| 31 | 80ZJQ50-21-11 | 80 | 50 | 21 | 11 | 40 | 1460 | 13 | 240 |

| 32 | 80ZJQ50-26-11 | 80 | 50 | 26 | 11 | 40 | 1460 | 13 | 240 |

| 33 | 80ZJQ70-20-11 | 80 | 70 | 20 | 11 | 43 | 1460 | 13 | 240 |

| 34 | 100ZJQ100-18-11 | 100 | 100 | 18 | 11 | 48 | 1460 | 21 | 240 |

| 35 | 80ZJQ25-40-15 | 80 | 25 | 40 | 15 | 37 | 1460 | 13 | 330 |

| 36 | 80ZJQ50-26-15 | 80 | 50 | 26 | 15 | 40 | 1460 | 13 | 260 |

| 37 | 80ZJQ50-28-15 | 80 | 50 | 28 | 15 | 40 | 1460 | 13 | 260 |

| 38 | 100ZJQ60-30-15 | 100 | 60 | 30 | 15 | 41 | 1460 | 13 | 265 |

| 39 | 80ZJQ70-24-15 | 80 | 70 | 24 | 15 | 42 | 1460 | 13 | 260 |

| 40 | 100ZJQ75-25-15 | 100 | 75 | 25 | 15 | 43 | 1460 | 13 | 260 |

| 41 | 100ZJQ100-18-15 | 100 | 100 | 18 | 15 | 49 | 1460 | 21 | 270 |

| 42 | 100ZJQ150-15-15 | 100 | 150 | 15 | 15 | 51 | 1460 | 21 | 270 |

| 43 | 150ZJQ150-18-18.5 | 150 | 150 | 18 | 18.5 | 49 | 980 | 32 | 550 |

| 44 | 150ZJQ200-12-18.5 | 150 | 200 | 12 | 18.5 | 53 | 980 | 45 | 550 |

| 45 | 150ZJQ150-22-22 | 150 | 150 | 22 | 22 | 47 | 980 | 32 | 600 |

| 46 | 150ZJQ200-15-22 | 150 | 200 | 15 | 22 | 50 | 980 | 45 | 600 |

| 47 | 150ZJQ60-46-30 | 150 | 60 | 46 | 30 | 41 | 980 | 14 | 550 |

| 48 | 150ZJQ70-38-30 | 150 | 70 | 38 | 30 | 42 | 980 | 21 | 710 |

| 49 | 150ZJQ100-35-30 | 150 | 100 | 35 | 30 | 44 | 980 | 21 | 710 |

| 50 | 150ZJQ108-30-30 | 150 | 108 | 30 | 30 | 44 | 980 | 21 | 710 |

| 51 | 150ZJQ150-30-30 | 150 | 150 | 30 | 30 | 46 | 980 | 21 | 710 |

| 52 | 150ZJQ150-35-30 | 150 | 150 | 35 | 30 | 46 | 980 | 21 | 710 |

| 53 | 150ZJQ200-20-30 | 150 | 200 | 20 | 30 | 52 | 980 | 21 | 710 |

| 54 | 150ZJQ240-20-30 | 150 | 240 | 20 | 30 | 55 | 980 | 21 | 710 |

| 55 | 200ZJQ300-15-30 | 200 | 300 | 15 | 30 | 56 | 980 | 28 | 700 |

| 56 | 150ZJQ100-50-37 | 150 | 100 | 50 | 37 | 44 | 980 | 21 | 850 |

| 57 | 200ZJQ300-20-37 | 200 | 300 | 20 | 37 | 56 | 980 | 28 | 775 |

| 58 | 200ZJQ400-15-37 | 200 | 400 | 15 | 37 | 58 | 980 | 28 | 775 |

| 59 | 150ZJQ150-35-45 | 150 | 150 | 35 | 45 | 47 | 980 | 36 | 1000 |

| 60 | 150ZJQ200-30-45 | 150 | 200 | 30 | 45 | 49 | 980 | 36 | 1110 |

| 61 | 200ZJQ500-15-45 | 200 | 500 | 15 | 45 | 59 | 980 | 46 | 1100 |

| 62 | 150ZJQ150-45-55 | 150 | 150 | 45 | 55 | 46 | 980 | 21 | 1140 |

| 63 | 150ZJQ250-35-55 | 150 | 250 | 35 | 55 | 51 | 980 | 36 | 1140 |

| 64 | 250ZJQ600-15-55 | 250 | 600 | 15 | 55 | 60 | 980 | 46 | 1220 |

| 65 | 150ZJQ200-45-75 | 150 | 200 | 45 | 75 | 49 | 980 | 21 | 1540 |

| 66 | 150ZJQ200-50-75 | 150 | 200 | 50 | 75 | 48 | 980 | 14 | 1550 |

| 67 | 200ZJQ350-35-75 | 200 | 350 | 35 | 75 | 53 | 980 | 28 | 1550 |

| 68 | 200ZJQ400-25-75 | 200 | 400 | 25 | 75 | 58 | 980 | 25 | 1550 |

| 69 | 200ZJQ500-20-75 | 200 | 500 | 20 | 75 | 59 | 980 | 25 | 1550 |

| 70 | 150ZJQ200-60-90 | 150 | 200 | 60 | 90 | 48 | 980 | 14 | 1550 |

| 71 | 200ZJQ400-40-90 | 200 | 400 | 40 | 90 | 54 | 980 | 28 | 1550 |

| 72 | 200ZJQ500-25-90 | 200 | 500 | 25 | 90 | 60 | 980 | 25 | 1550 |

| 73 | 200ZJQ400-50-110 | 200 | 400 | 50 | 110 | 53 | 980 | 28 | 1970 |

| 74 | 250ZJQ600-30-110 | 250 | 600 | 30 | 110 | 61 | 980 | 28 | 1970 |

| 75 | 300ZJQ780-26-110 | 300 | 780 | 26 | 110 | 62 | 980 | 50 | 1970 |

| 76 | 300ZJQ1000-18-110 | 300 | 1000 | 18 | 110 | 64 | 980 | 50 | 1970 |

| 77 | 200ZJQ400-60-132 | 200 | 400 | 60 | 132 | 53 | 980 | 28 | 2000 |

| 78 | 200ZJQ500-45-132 | 200 | 500 | 45 | 132 | 56 | 980 | 28 | 2000 |

| 79 | 200ZJQ500-55-132 | 200 | 500 | 55 | 132 | 55 | 980 | 28 | 2000 |

| 80 | 300ZJQ800-35-132 | 300 | 800 | 35 | 132 | 63 | 980 | 42 | 2000 |

| 81 | 300ZJQ1000-22-132 | 300 | 1000 | 22 | 132 | 64 | 980 | 50 | 2000 |

| 82 | 200ZJQ650-52-160 | 200 | 650 | 52 | 160 | 58 | 980 | 28 | 2650 |

| 83 | 300ZJQ780-50-185 | 300 | 780 | 50 | 185 | 60 | 980 | 38 | 3330 |

| 84 | 250ZJQ600-55-200 | 250 | 600 | 55 | 200 | 62 | 980 | 28 | 4080 |

| 85 | 300ZJQ800-55-220 | 300 | 800 | 55 | 220 | 60 | 980 | 38 | 3400 |

| 86 | 350ZJQ1250-35-220 | 350 | 1250 | 35 | 220 | 65 | 980 | 45 | 3400 |

| 87 | 350ZJQ1750-30-250 | 350 | 1750 | 30 | 250 | 70 | 980 | 55 | 3750 |

| 88 | 350ZJQ1500-35-250 | 350 | 1500 | 35 | 250 | 70 | 980 | 50 | 3750 |

| 89 | 350ZJQ1750-40-315 | 350 | 1750 | 40 | 315 | 70 | 980 | 55 | 4200 |

| 90 | 400ZJQ2000-35-315 | 400 | 2000 | 35 | 315 | 72 | 980 | 60 | 3800 |

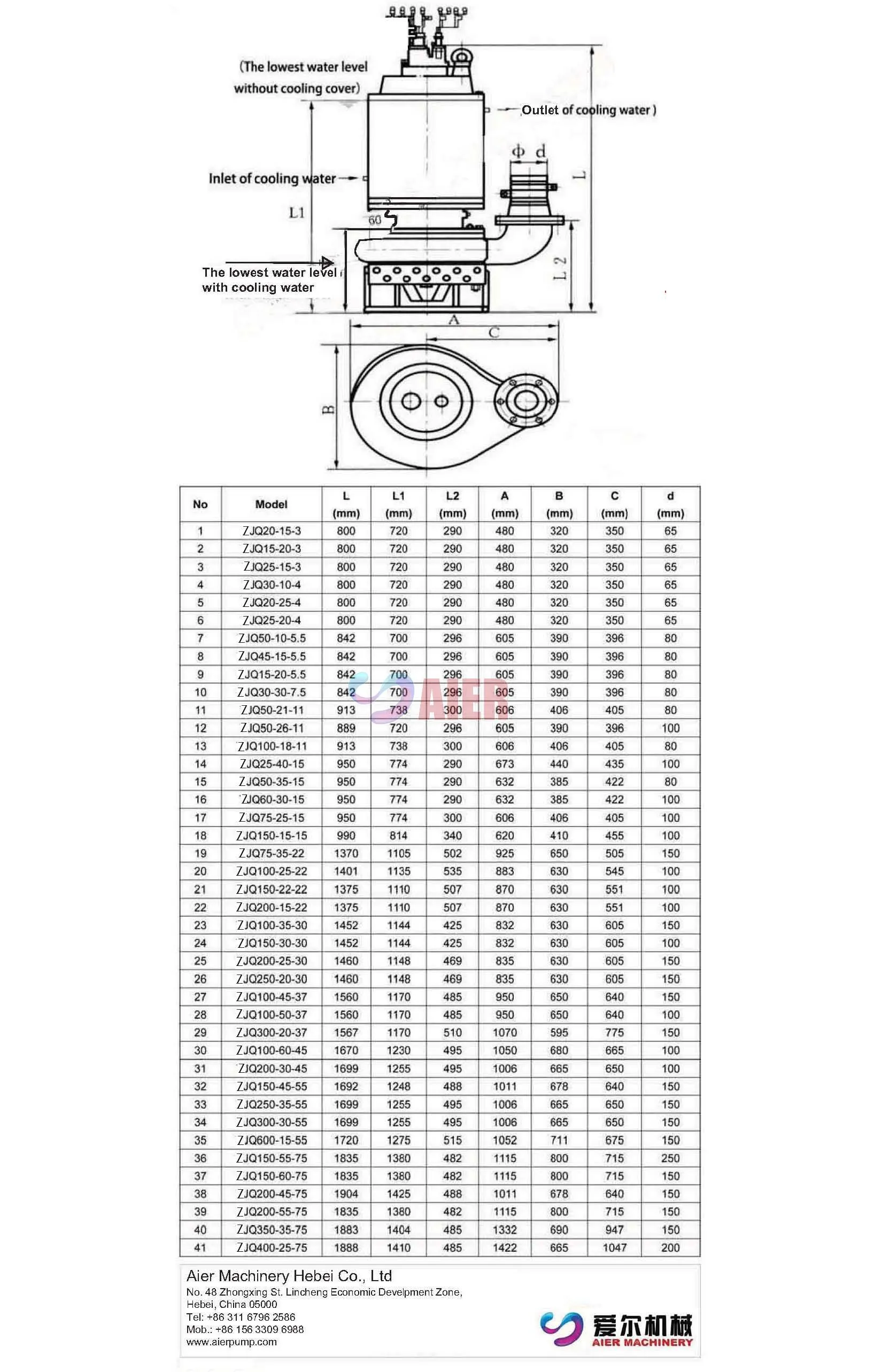

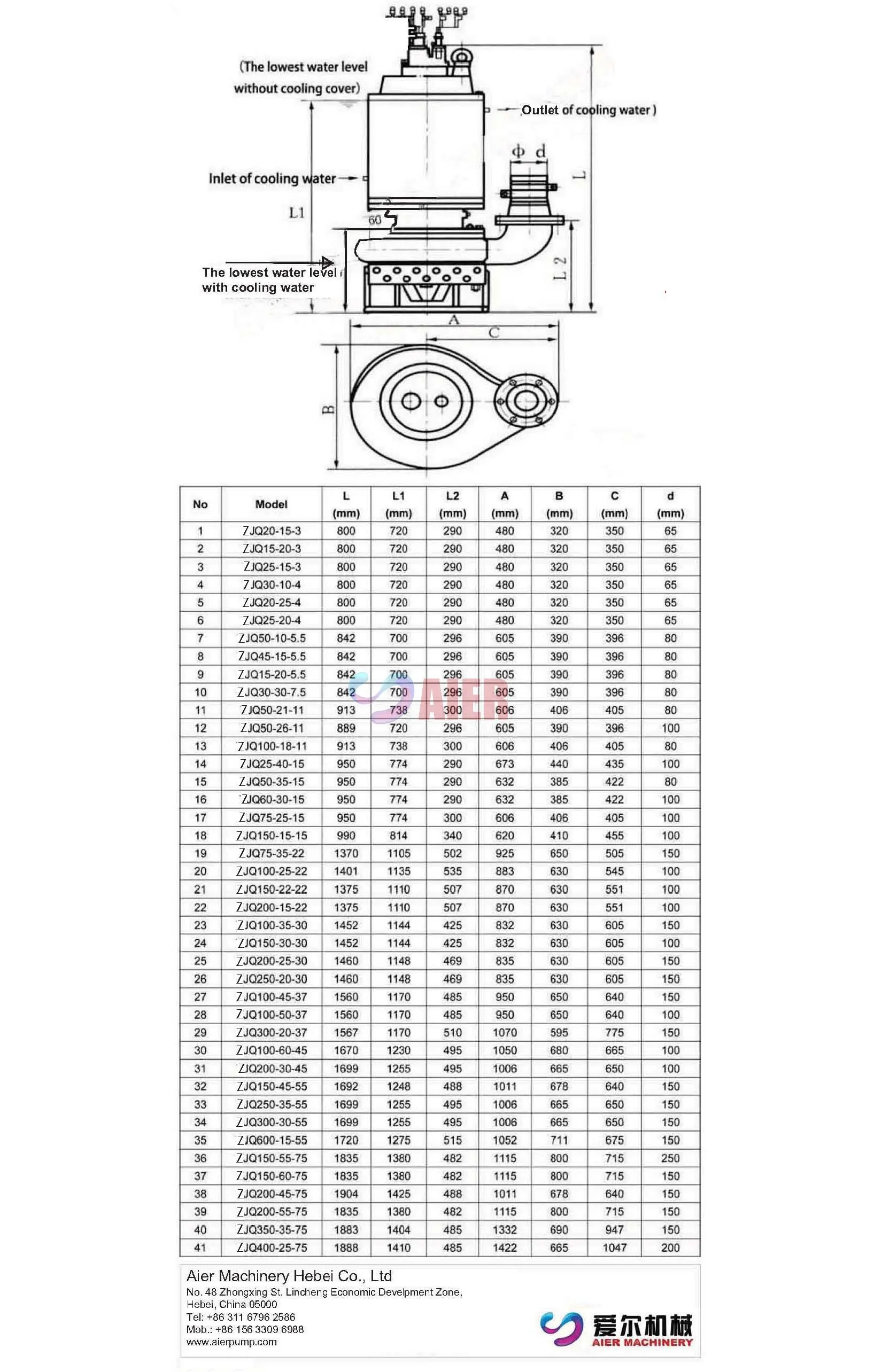

Outline Dimensions

Materials Used in Submersible Slurry Pumps

The performance and durability of a submersible slurry pump largely depend on the materials used in its construction. These pumps operate in challenging environments, handling abrasive, solid-laden, and sometimes corrosive fluids, which can quickly degrade standard materials. Selecting the right materials is essential for achieving long-term operational efficiency and reducing maintenance costs.

A high quality submersible slurry pump typically uses high-chrome alloy, stainless steel, or other wear-resistant metals for the impeller, casing, and wear plates. High-chrome alloys provide excellent resistance to abrasion and erosion caused by solid particles in the slurry. Stainless steel offers both corrosion resistance and moderate wear protection, making it suitable for chemical slurries or industrial fluids containing corrosive components.

For applications requiring extreme durability, some manufacturers offer high head submersible slurry pumps with specialized alloys or composite liners. These materials are engineered to resist the combined effects of high pressure, abrasive solids, and corrosive fluids, ensuring stable performance in demanding conditions. High-head models are particularly common in mining, dredging, and heavy industrial operations where reliability and long-term service life are critical.

Bearings, shafts, and seals are also constructed with robust materials to withstand the unique stresses of submersible operation. Mechanical seals are often reinforced with corrosion-resistant ceramics or carbon materials to maintain integrity under pressure and prevent slurry infiltration into the motor housing. Proper material selection in these components ensures smooth pump operation and minimizes downtime.

Many wholesale submersible slurry pump suppliers provide customization options, allowing clients to select materials based on slurry composition, temperature, and operating conditions. This flexibility is crucial for industrial clients who require pumps tailored to specific operational challenges.

In conclusion, the choice of materials in a submersible slurry pump directly impacts its wear resistance, corrosion resistance, and service life. High-quality construction, combined with materials optimized for abrasive and corrosive conditions, makes these pumps reliable solutions for mining, industrial, and wastewater applications. Partnering with a reputable wholesale submersible slurry pump supplier ensures access to durable, high-performance pumps suitable for demanding environments.

Can Submersible Slurry Pumps Handle Corrosive Fluids?

Yes, submersible slurry pumps can handle corrosive fluids, provided they are designed and constructed with appropriate materials and protective features. Handling corrosive liquids requires a combination of high-quality engineering, chemical-resistant materials, and precise sealing to maintain performance and prevent premature wear.

A high quality submersible slurry pump designed for corrosive applications typically uses stainless steel, high-chrome alloys, or specialized coatings on the impeller, casing, and wear plates. These materials resist chemical attack and maintain structural integrity even when continuously exposed to acidic or alkaline solutions. For example, in chemical plants, mining operations, or industrial wastewater treatment, these pumps can transfer corrosive slurries without risk of rapid erosion or failure.

High head submersible slurry pumps designed for demanding environments can operate under both high pressure and chemically aggressive conditions. The combination of robust construction and chemically resistant materials ensures that the pump maintains efficiency and reliability over extended periods, even in highly abrasive and corrosive fluids. The seals and bearings are also reinforced, often using ceramic or carbon materials, to prevent leakage and damage from chemical exposure.

Many wholesale submersible slurry pump suppliers offer pumps specifically engineered for chemical or corrosive slurry handling. These pumps are often tested for resistance to specific chemical compositions, temperature ranges, and pH levels, ensuring they meet the operational requirements of industrial clients.

Furthermore, submersible design itself provides advantages when handling corrosive fluids. By keeping the pump fully submerged, exposure to air and potential oxidation is minimized, reducing the risk of chemical degradation of components. This design also supports safe and efficient handling of hazardous fluids, making these pumps suitable for industrial, mining, and wastewater applications.

In conclusion, with proper materials, sealing, and engineering, submersible slurry pumps can effectively handle corrosive fluids. High-quality, heavy-duty designs from reputable wholesale submersible slurry pump suppliers provide long-term durability, reliable performance, and chemical resistance for demanding industrial and mining applications.

How Deep Can a Submersible Pump Work?

The operating depth of a submersible slurry pump depends on its design, motor power, and intended application. Submersible pumps are built to operate fully underwater, which allows them to lift slurry from pits, sumps, tanks, or dredging sites efficiently. High-performance models, especially high head submersible slurry pumps, are designed to operate at considerable depths while maintaining hydraulic efficiency and mechanical reliability.

Depth capabilities are influenced by the pump’s motor size and pressure rating. A high quality submersible slurry pump typically includes a sealed motor designed to withstand water pressure at the pump’s operating depth. For most industrial applications, submersible slurry pumps can work effectively at depths ranging from a few meters to over 50 meters. Heavy-duty pumps for mining, dredging, and industrial slurry transport can even exceed these depths when properly engineered.

Submersible pumps are equipped with reinforced housings and seals to prevent water or slurry ingress into the motor. This is particularly important for pumps operating at greater depths, where hydrostatic pressure increases. High-quality designs ensure reliable operation even under continuous immersion, enabling the pump to handle dense, abrasive, or corrosive slurries efficiently.

Many wholesale submersible slurry pump suppliers provide guidance on selecting pumps based on sump depth, flow rate, and slurry characteristics. By choosing the correct model, operators can ensure optimal pump efficiency, longevity, and safety. Additionally, modular designs allow for flexible installation and maintenance, even in deep sump or pit applications.

In conclusion, submersible slurry pumps can operate at significant depths, with high-quality models designed for industrial and heavy-duty applications capable of handling depths exceeding 50 meters. Partnering with reputable submersible slurry pump manufacturers ensures the selection of pumps that meet depth, flow, and slurry-handling requirements while maintaining long-term reliability and operational efficiency.