WP Vertical Froth Pump

Product Description

SPECIFICATIONS:

Size: 2" to 8"

Capacity: 18-620 m3/h

Head: 5-28 m

Efficiency: up to 55%

Materials: Hyper chrome alloy, Rubber, Polyurethane, Ceramic, Stainless steel, etc.

AIER® WP Vertical Froth Pump

WP Series of Froth Pumps is an efficiency pump product which is manufactured by Aier Machinery Hebei Co., Ltd under the advanced manufacturing technology introduced by one famous Australian company.

Typical Applications

WP vertical froth pumps are suitable for handling solids-liquid mixtures, special for delivering frothy pulp generated in flotation machines in metalliferous and coal flotation circuits.

Features

The basic principle of the pump is much higher than that of other types of slurry pumps without shaft seal and sealing water. The froth pump is a perfect pump for handling frothy pulp indeed.

The Construction of the pump head is double casing which is similar to the standard construction of Warman slurry pump. All wet parts can be supplied in Ni-hard, high chrome alloy iron, and pressure-molded natural or synthetic rubber. The drive end can be exchanged with that of type WY (equivalent to Warman SP) & WYJ (equivalent to Warman SPR) pumps. The hopper tank is fabricated with a steel plate. The inner wall of the tank can be covered with liner according to different medium pumped. The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications.

The advantages of the pump are of excellent performance, easy assembly & disassembly, high reliability, and etc.

Type Notation

Example:50WP-Q

50 - Discharge Diameter(mm)

Q - Frame Type

WP - Froth Pump

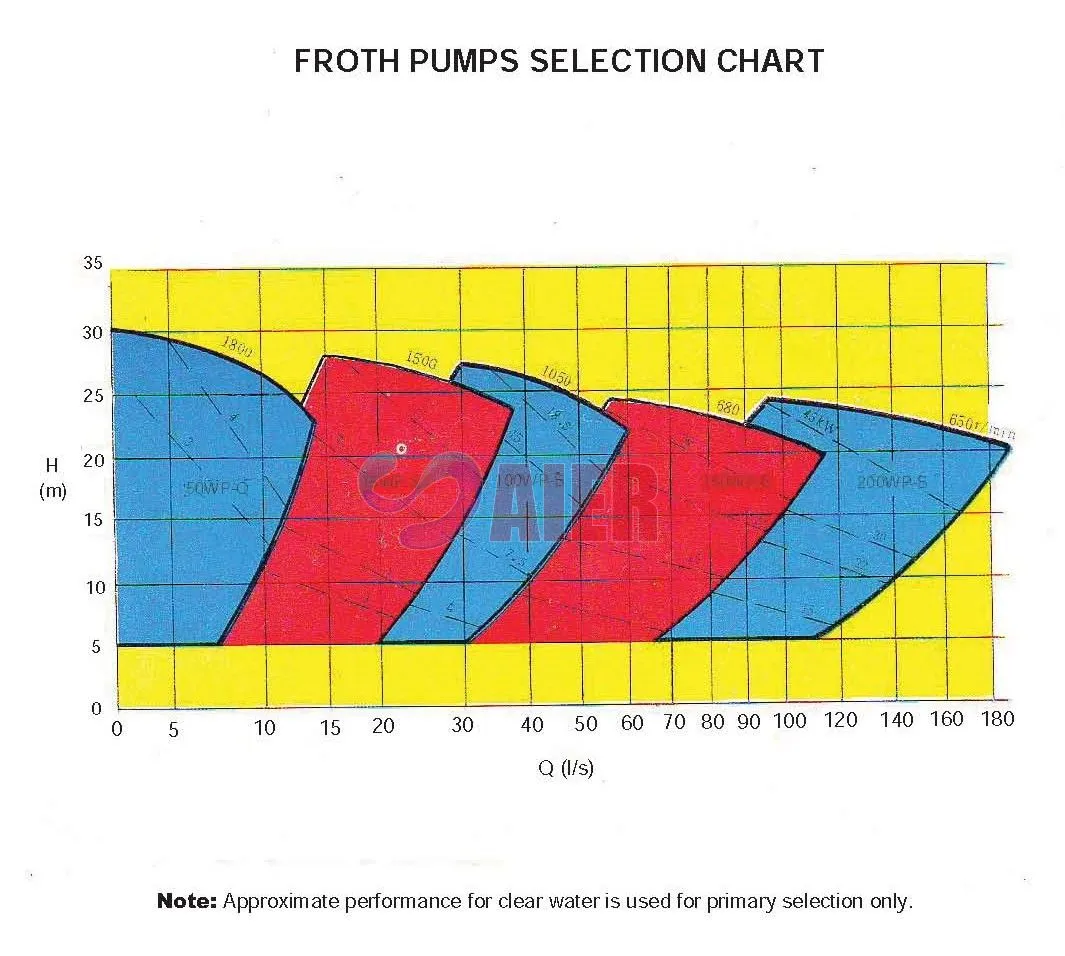

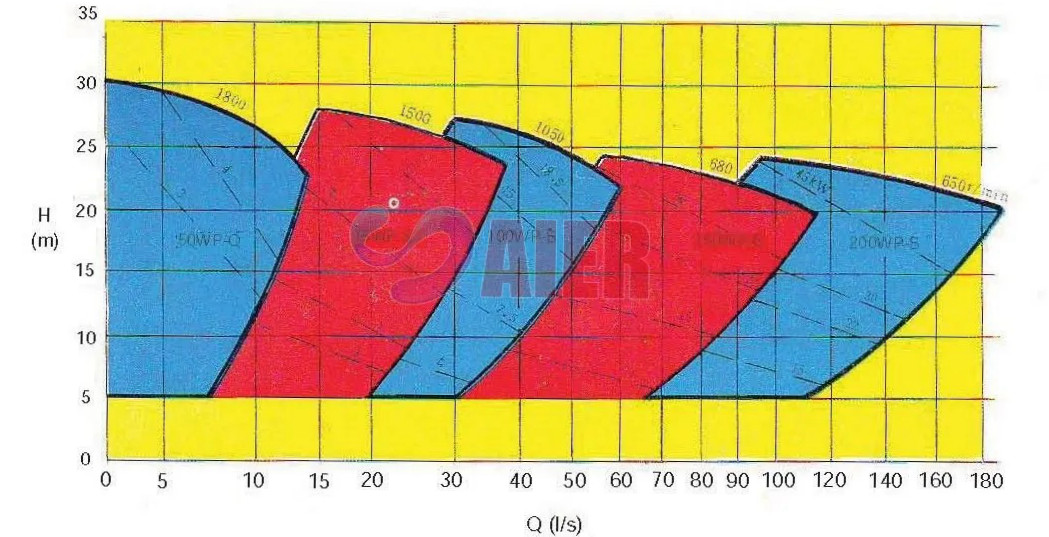

Performance Chart

Froth PUMP SELECTION CHART

Note: Approximate performance for clear water is used for primary selection.

Note: Approximate performance for clear water is used for primary selection.

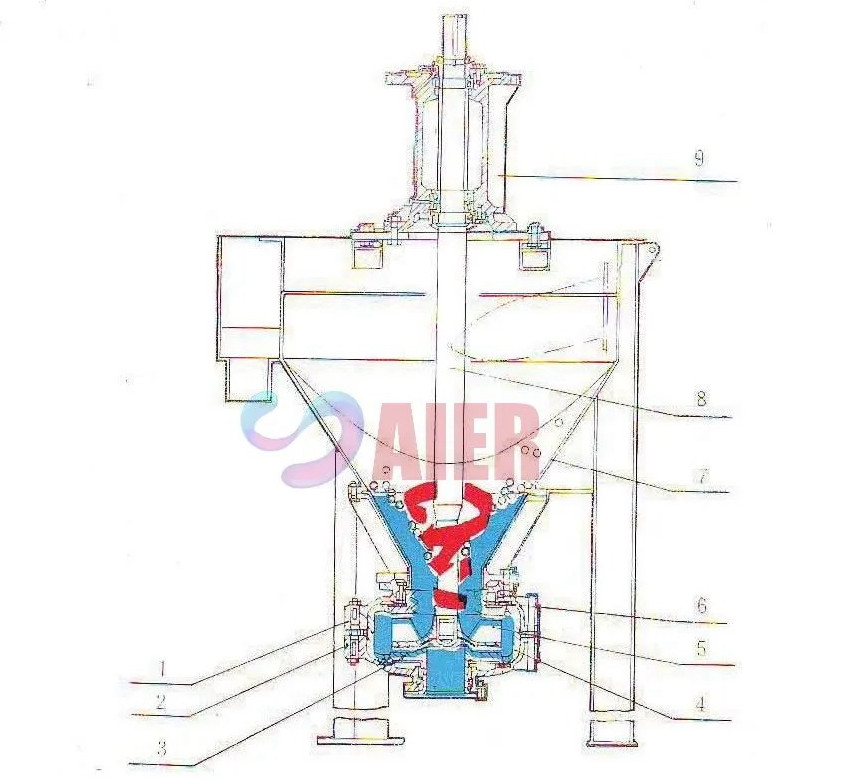

Construction Drawing

| 1 | Frame Plate | 6 | Frame Plate Liner Insert |

| 2 | Cover Plate | 7 | Tank |

| 3 | Cover Plate Liner Insert | 8 | Shaft |

| 4 | Volute Liner | 9 | Bearing Housing |

| 5 | Impeller |

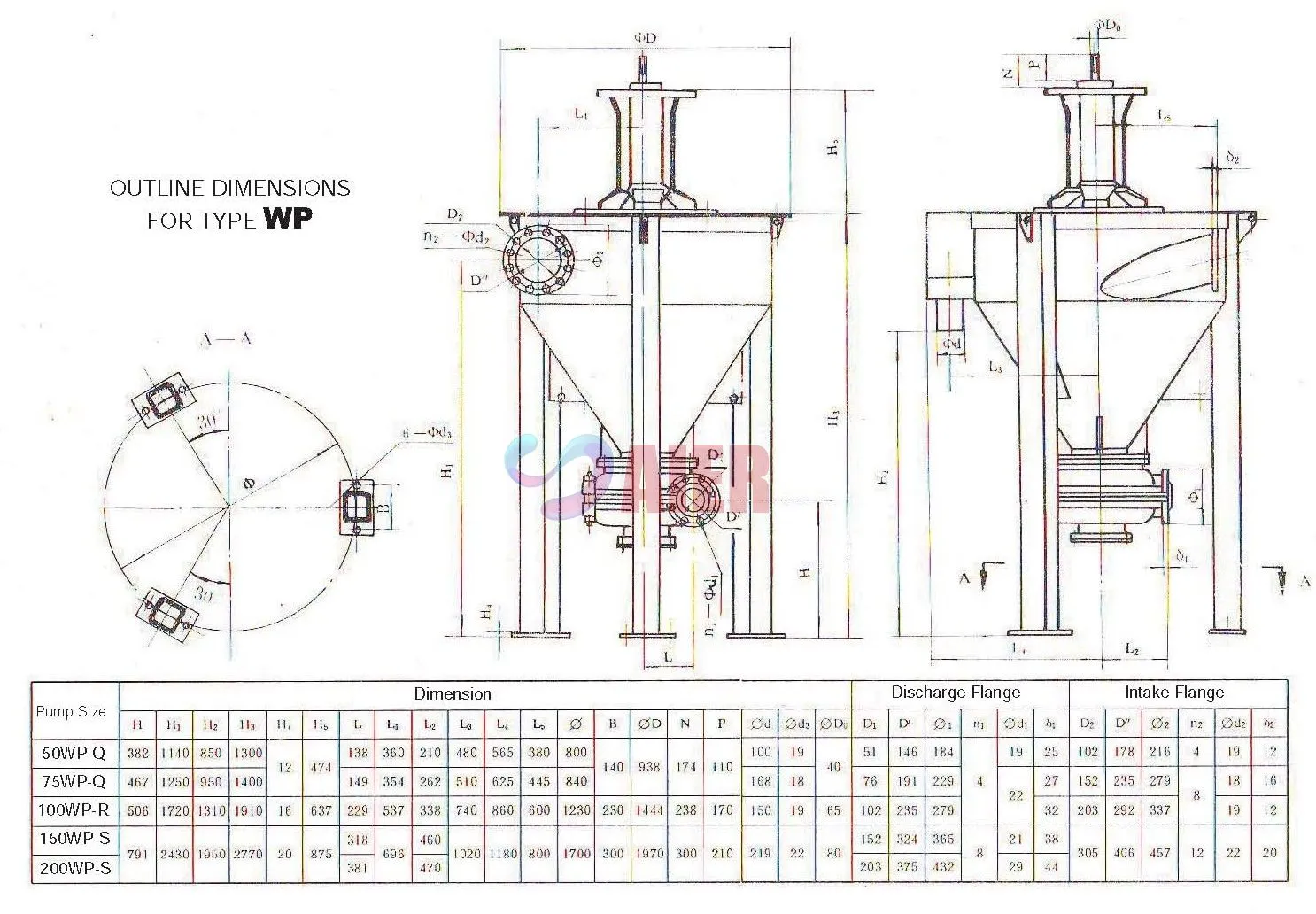

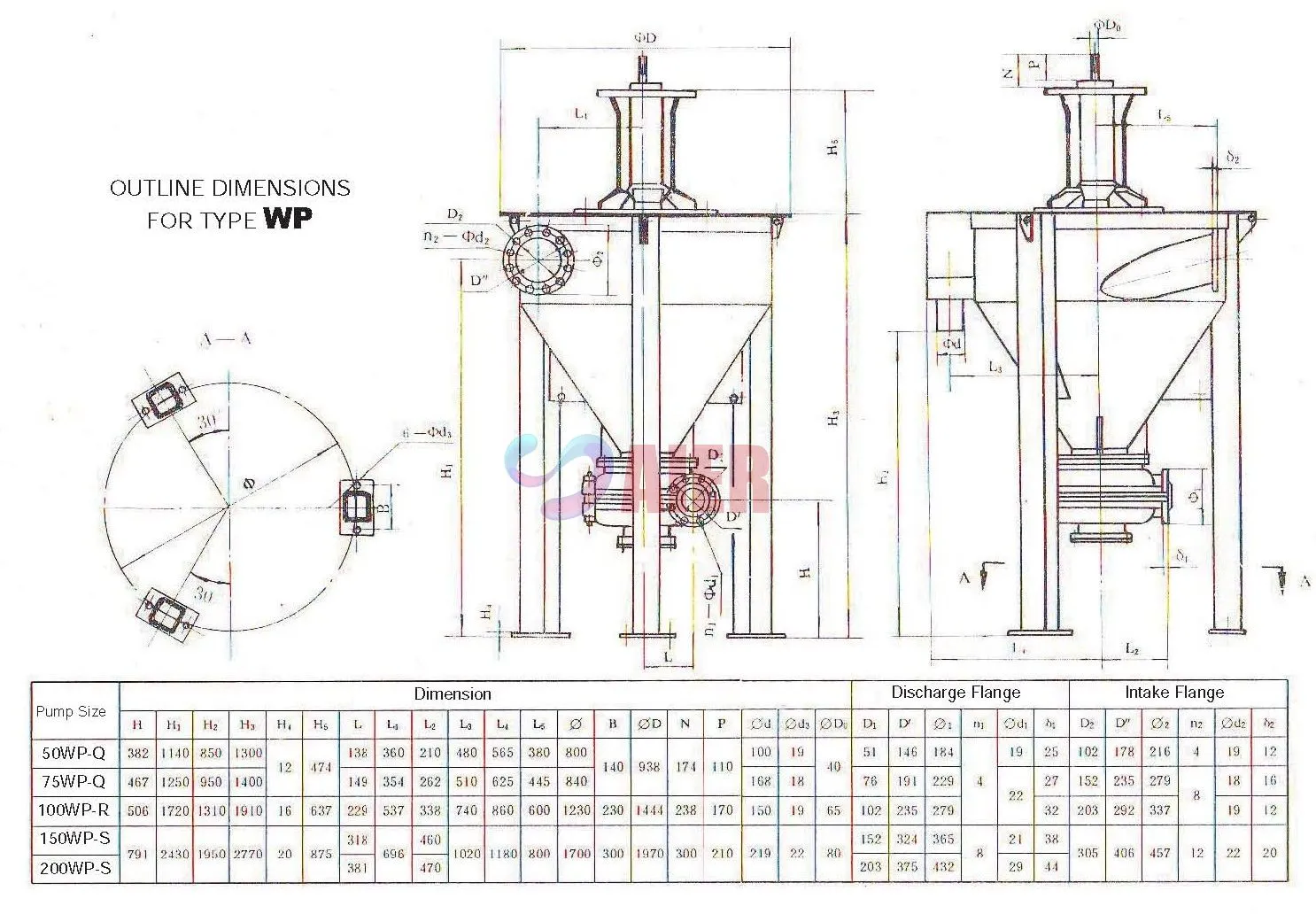

Outline Dimensions

Maintenance and Troubleshooting Tips for Froth Slurry Pumps

Proper maintenance and timely troubleshooting are essential for maximizing the performance and longevity of a froth pump. Froth slurry pumps handle highly aerated, abrasive, and sometimes corrosive slurries, which can put significant stress on pump components. As an experienced froth pump manufacturer, Aier Machinery Hebei Co., Ltd. emphasizes engineering solutions that minimize downtime and simplify maintenance for industrial and mining operations.

One of the most critical maintenance tips is regular inspection of wear parts. The impeller, volute, and liner are constantly exposed to abrasive particles and foam, which can accelerate wear. Replacing these components before they fail prevents more serious damage to the pump and ensures continuous operation. A high quality froth slurry pump from a reliable manufacturer will use durable materials like high chrome alloy or stainless steel to extend service life.

Monitoring pump performance is another key factor. Variations in flow rate, pressure, vibration, or unusual noise can indicate problems such as impeller erosion, clogging, or misalignment. Addressing these issues early prevents further damage and maintains operational efficiency.

Proper lubrication and bearing maintenance are also essential. Bearings support the pump shaft and impeller, and inadequate lubrication can lead to overheating or failure. High-quality froth pumps often include advanced bearing assemblies designed for heavy-duty operation, ensuring reliability even in challenging conditions.

Another important aspect is preventive maintenance scheduling. Documenting inspections, part replacements, and performance checks allows operators to anticipate potential issues, reduce unplanned downtime, and extend the service life of the froth pump. Trusted froth pump manufacturers often provide detailed maintenance manuals and technical support to guide operators.

In addition, chemical exposure from abrasive or corrosive slurries can degrade pump materials. Checking liners and coatings regularly and replacing them when necessary ensures that the high quality froth slurry pump remains reliable over long-term operation.

In conclusion, maintaining and troubleshooting a froth pump involves monitoring wear parts, maintaining bearings, performing regular inspections, and adhering to preventive maintenance schedules. Partnering with a reputable froth pump manufacturer guarantees access to durable pumps, replacement parts, and technical support, minimizing downtime and ensuring reliable performance in demanding industrial applications.

Wholesale Heavy Duty Vertical Froth Pumps: Industrial Applications and Benefits

Wholesale heavy duty vertical froth pumps are widely used in mining, mineral processing, and industrial applications where handling highly aerated, abrasive, or corrosive slurries is required. As a leading froth pump manufacturer, Aier Machinery Hebei Co., Ltd. offers vertical pumps that deliver exceptional performance, durability, and operational reliability.

Vertical froth pumps are ideal for applications where space constraints prevent the use of horizontal pumps. They can operate directly from a slurry pit, eliminating the need for long suction piping and reducing the risk of clogging. A wholesale heavy duty vertical froth pump from Aier Machinery features reinforced shafts, heavy-duty bearings, and wear-resistant liners to withstand continuous operation under extreme conditions.

These pumps are particularly beneficial in flotation processes, where aerated slurry with a high froth content must be transferred efficiently. The design of a high quality froth slurry pump allows for smooth handling of frothy liquids, minimizing energy loss and preventing cavitation. This ensures stable, continuous operation and consistent processing efficiency.

Another advantage of vertical froth pumps is their maintenance efficiency. Despite their vertical configuration, modular designs enable easy replacement of wear parts such as impellers and liners. Aier Machinery, as a professional froth pump manufacturer, provides pumps with standardized components, making maintenance straightforward and reducing downtime.

The versatility of a wholesale heavy duty vertical froth pump also makes it suitable for large-scale industrial applications, including chemical processing, wastewater treatment, and ore slurry handling. These pumps are engineered to handle highly abrasive or corrosive slurries without compromising performance or service life.

In summary, vertical froth pumps combine durability, space efficiency, and reliable operation for demanding industrial applications. Aier Machinery, as a reputable froth pump manufacturer, delivers high quality froth slurry pumps designed for long-term performance, efficient maintenance, and operational reliability, making them a cost-effective choice for industrial operators.

Material Selection and Wear-Resistance in Froth Slurry Pumps

Material selection is a critical factor when designing a froth pump, particularly for applications involving abrasive, aerated, or corrosive slurries. As a leading froth pump manufacturer, Aier Machinery Hebei Co., Ltd. focuses on producing high quality froth slurry pumps with materials engineered for maximum wear resistance and durability.

The most exposed components of a froth slurry pump—impeller, casing, and liner—must withstand constant impact from solid particles and foam. High chrome alloys are commonly used because of their excellent hardness and resistance to erosion. Stainless steel and duplex alloys are selected for applications with corrosive chemicals, providing long-term reliability in challenging industrial environments.

Rubber linings are another option for abrasion-prone slurries with low-density froth. They reduce friction, absorb impact, and prevent rapid wear, while maintaining the hydraulic efficiency of the froth pump. Material selection is critical to extending service life and minimizing maintenance costs, especially for pumps operating continuously in mining or flotation processes.

Wear-resistant coatings and surface treatments further enhance durability. A high quality froth slurry pump from Aier Machinery integrates advanced hydraulic design with superior materials to ensure smooth slurry flow, reduce turbulence, and minimize energy loss. This combination of design and material engineering ensures consistent performance and reduces the frequency of component replacements.

For industrial operators, partnering with a reliable froth pump manufacturer guarantees access to pumps optimized for specific slurry characteristics. Customized OEM froth pumps can be manufactured to suit different flow rates, slurry abrasiveness, and chemical composition, ensuring maximum efficiency and durability.

In conclusion, selecting appropriate materials is essential for a froth pump to withstand abrasive and corrosive environments. With carefully engineered wear-resistant materials, high quality froth slurry pumps provide long-lasting performance, reduced downtime, and optimized energy efficiency. Trusted froth pump manufacturers like Aier Machinery deliver durable, reliable, and customizable solutions for demanding industrial applications.