WS, WSG Gravel Sand Pump

Product Description

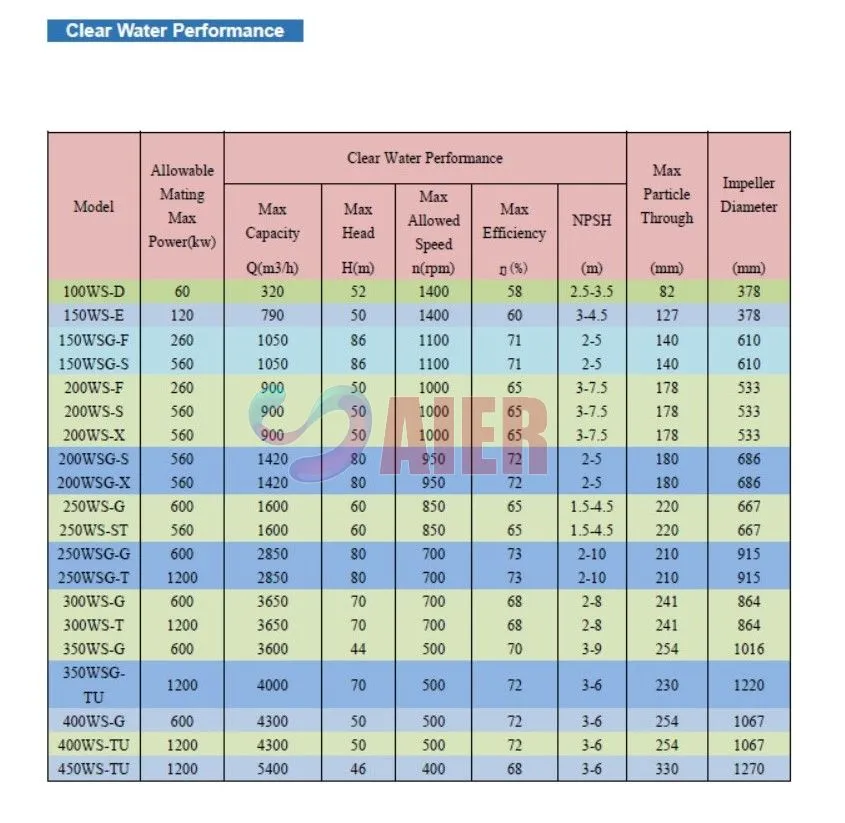

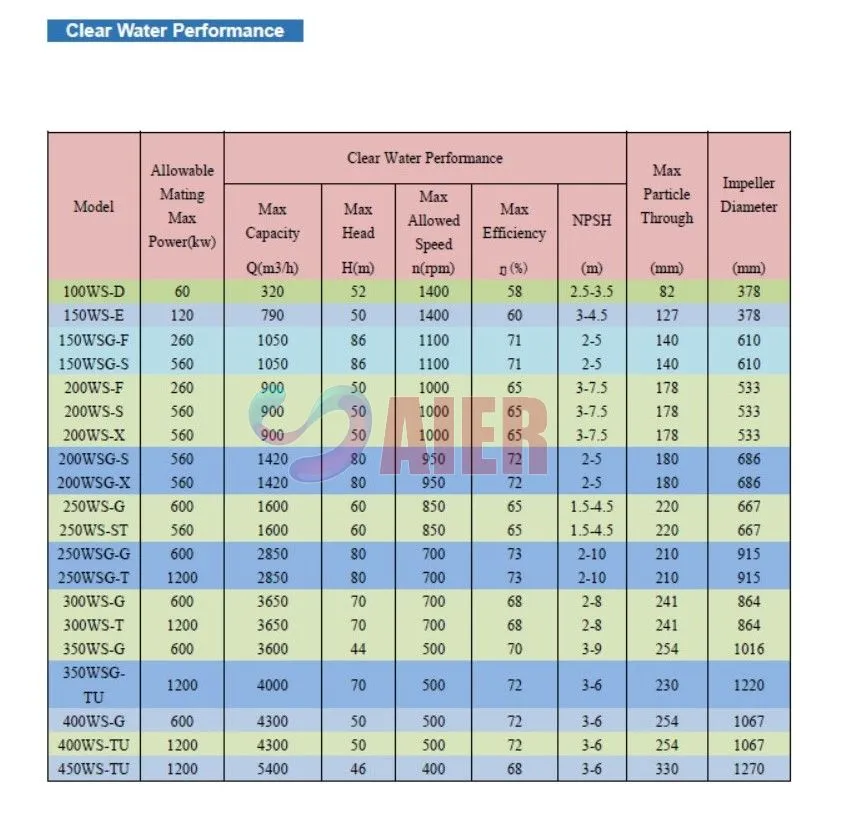

SPECIFICATIONS:

Size (discharge): 4" to 18"

Capacity: 36-4320m3/hr

Head: 5m-80 m

Handling solids: 0-260mm

Concentration: 0%-70%

Material: High chrome alloy, Cast iron, Stainless steel etc

AIER® WS, WSG Gravel Sand Pump

Pump Introduction

WS/WSG gravel pumps are designed for continuously handling the most difficult higher abrasive slurry which contain too big solids to be pumped by a common pump. They are suitable for delivering slurry in mining, explosive sludge in metal smelting, dredging in dredger and course of rivers, and other fields. Type WSG pump are of high head ones.

Typical Applications

Tailings, sugar beet, dredging, slag granulation, cyclone feed, slag granulation, suction hopper dredging, barge loading, mill discharge, sand reclamation, booster pumping, sand waste, material transfer, etc.

Features

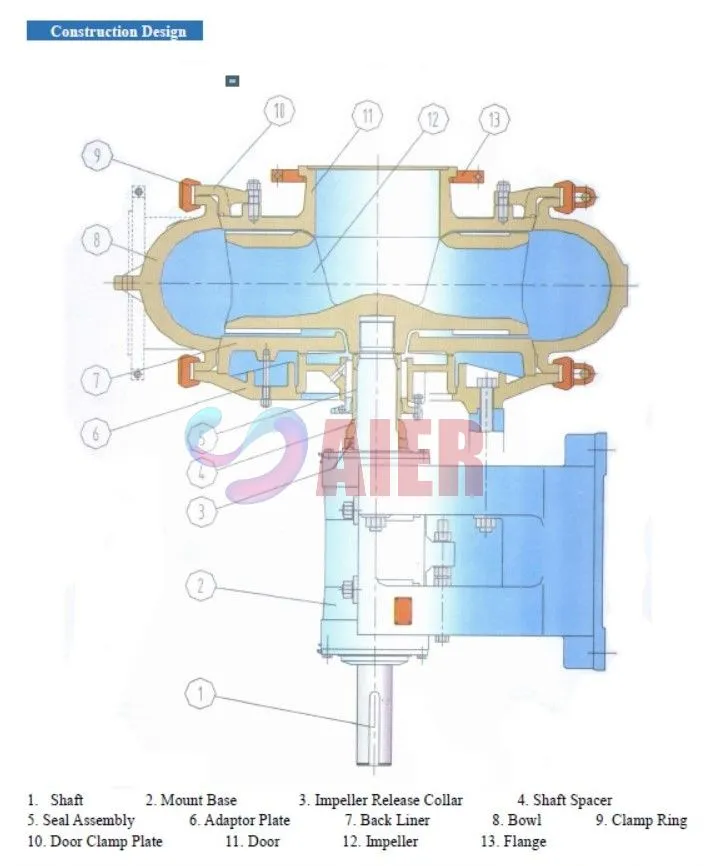

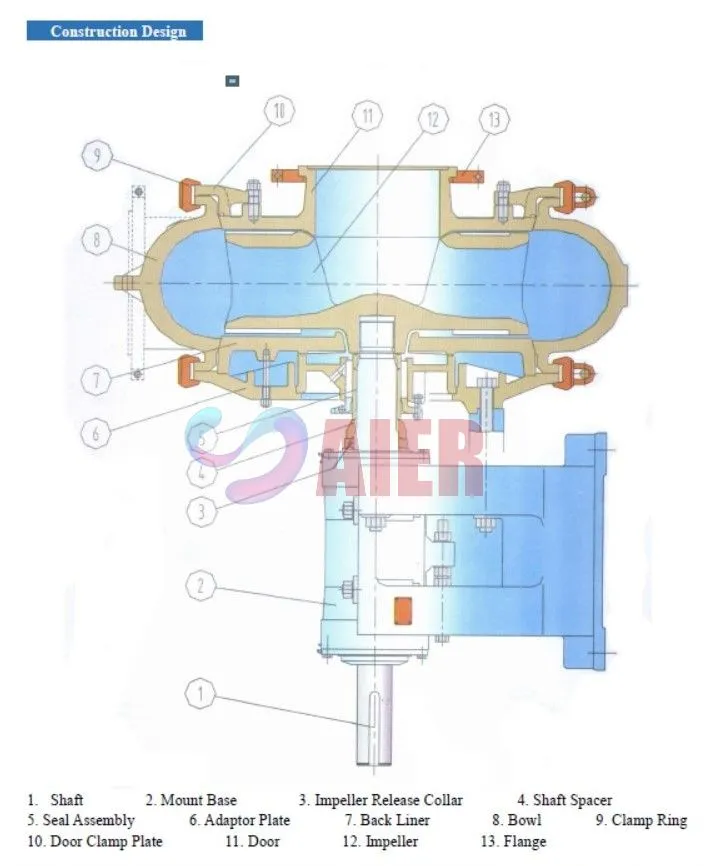

Construction of this pump is of single casing connected by means of clamp bans and wide wet-passage. The wet-parts are made of Ni-hard and high chromium abrasion-resistance alloys. The discharged direction of pump can be oriented in any direction of 360°.

The type of pump possess the advantage of easy installing and operation, good performance of NPSH and abrasion-resistance.

Types of driver: V belt driver, gearbox driver, elastic coupling driver, fluid coupling driver, frequency conversion driver, silicon controlled rectifier speed regulation etc.

Pump Notation

200WS-F

200: Outline Diameter: mm

WS: Pump Type: Gravel Pump

F: Frame type

Construction Design

Pump Part Material

| Part Name | Material | Specification | HRC | Application | OEM Code |

| Liners & Impeller | Metal | AB27: 23%-30% chrome white iron | ≥56 | Used for higher wear conditions with pH between 5 and 12 | A05 |

| AB15: 14%-18% chrome white iron | ≥59 | Used for higher wear condition | A07 | ||

| AB29: 27%-29% chrome white iron | 43 | Used for lower pH conditions, especially for FGD. It also can be used for low-sour condition and desulfuration installation with pH no less than 4 | A49 | ||

| AB33: 33%-37% chrome white iron | It can transport oxygenated slurry with a pH of not less than 1 such as phosphor-plaster, nitric acid, vitriol, phosphate, etc. | A33 | |||

| Expeller & expeller ring | Metal | B27: 23%-30% chrome white iron | ≥56 | Used for higher wear conditions with pH between 5 and 12 | A05 |

| Grey iron | G01 | ||||

| Stuffing Box | Metal | AB27: 23%-30% chrome white iron | ≥56 | Used for higher wear conditions with pH between 5 and 12 | A05 |

| Grey iron | G01 | ||||

| Frame/Cover plate, bearing house & base | Metal | Grey iron | G01 | ||

| Ductile iron | D21 | ||||

| Shaft | Metal | Carbon steel | E05 | ||

| Shaft sleeve, lantern ring/restrictor, neck ring, gland bolt | Stainless steel | 4Cr13 | C21 | ||

| 304 SS | C22 | ||||

| 316 SS | C23 | ||||

| Joint rings & seals | Rubber | Butyl | S21 | ||

| EPDM rubber | S01 | ||||

| Nitrile | S10 | ||||

| Hypalon | S31 | ||||

| Neoprene | S44/S42 | ||||

| Viton | S50 |

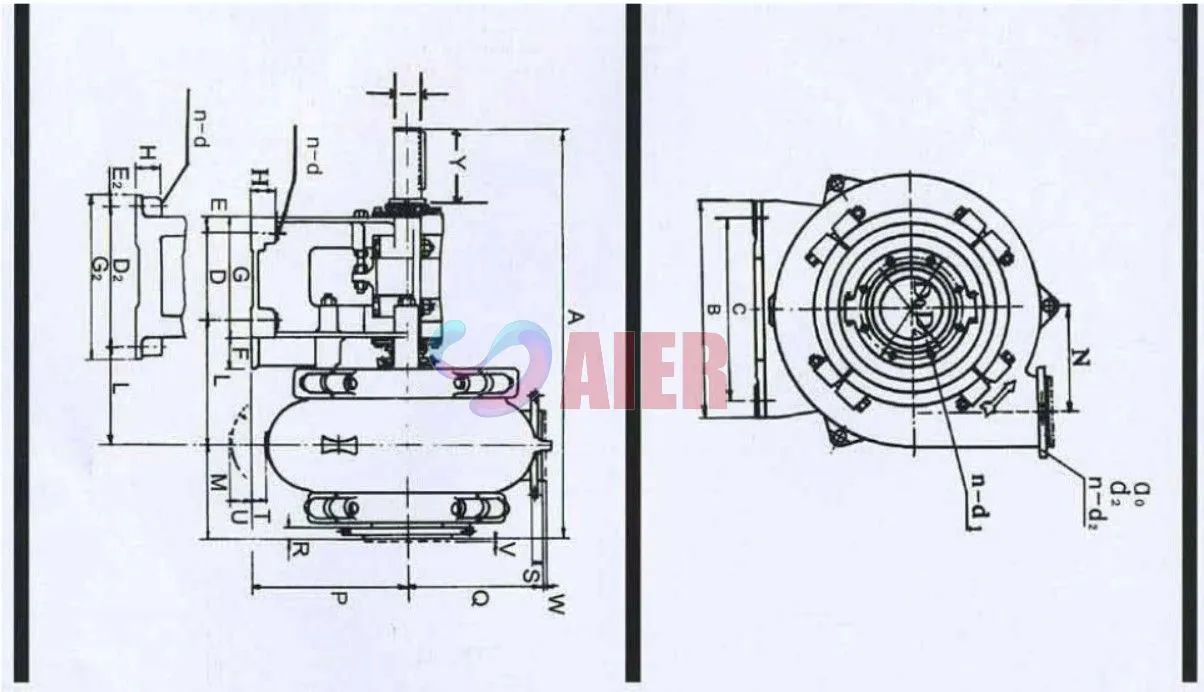

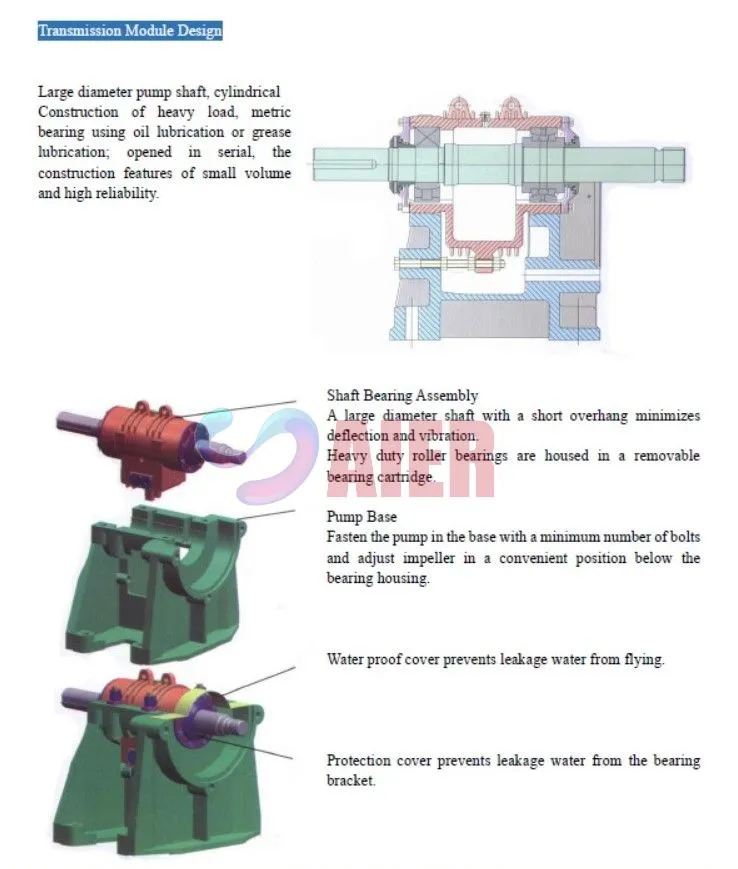

Transmission Module Design

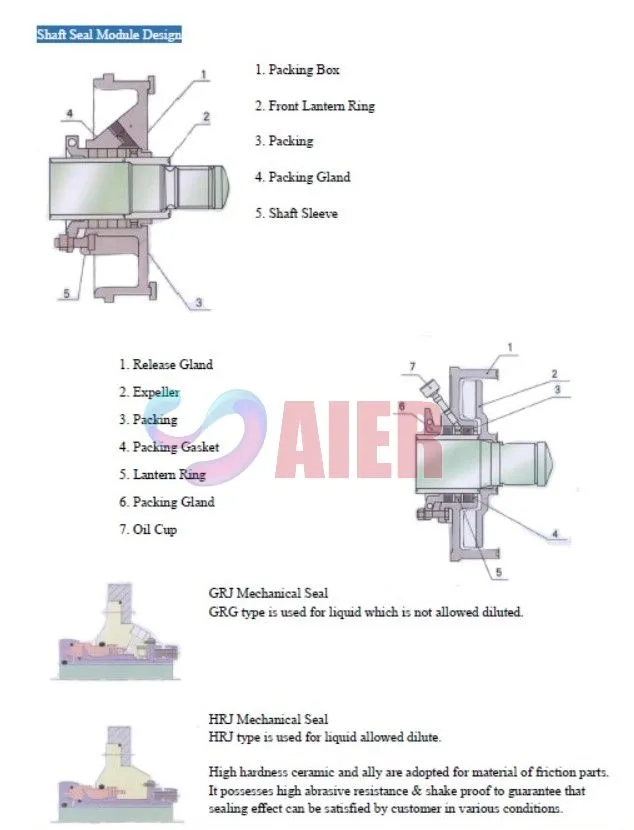

Shaft Seal Module Design