WS, WSH Solution Pump

Aier WS, WSH Solution Pump, 100% interchangeable with Warman S, SH solution pump

Product Description

SPECIFICATIONS:

Size: 1.5'' - 16"

Capacity: 15 - 930m3/h

Head: 10m - 120 m

Materials: Cast Iron, Stainless steel, etc.

AIER® WS, WSH Solution Pump

GENERAL DESCRIPTION

Series WS, WSH solution pump is a new type, high efficiency, energy-saving product manufactured by Aier Machinery Hebei Co., Ltd.

APPLICATION

Series WS, WSH solution pump is mainly used for delivering solution fluids in processing such as mill circuit water, thickener overflows, industrial waste, tailings dam return water, filtrate return, plant cooling water, dredge pump priming and spray water, etc. This series solution pump has been specially designed for those duties where both an ordinary water pump and slurry pump are not suitable, but the most reasonable selection is to use a solution pump that can operate reliably in arduous conditions.

CONSTRUCTION FEATURES

The construction of this series of pumps is a single casing. The pumps are provided with Spheroidal Graphite (S.G.) Cast Iron casings and impellers. When required, casing and impeller can be provided in any machinable alloy. All bearing assembly, frame, drive, and gland sealing components are interchangeable with Warman slurry pump.

Discharge can be positioned at intervals of 45° by request and oriented to any eight positions to suit installations and applications. The advantages of this pump are as follows:

Simple Maintenance, easy assembly and disassembly, easy operation, etc.

Type Notation:

e.g.: 100WS (or WSH) -D

100 - Suction Diameter (mm)

WS - Solution Pump

WSH - High Head Solution Pump

D - Frame Type

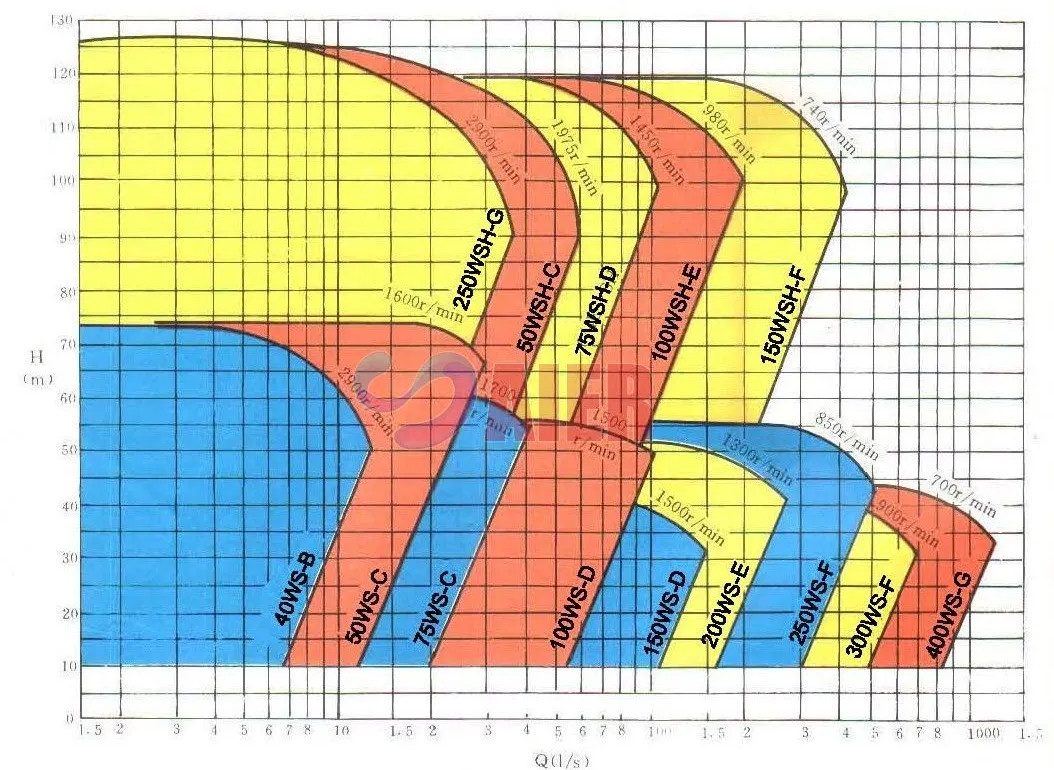

Performance Range

SOLUTION PUMP SELECTION CHART

Note: Approximate performance for clean water for primary selection only.

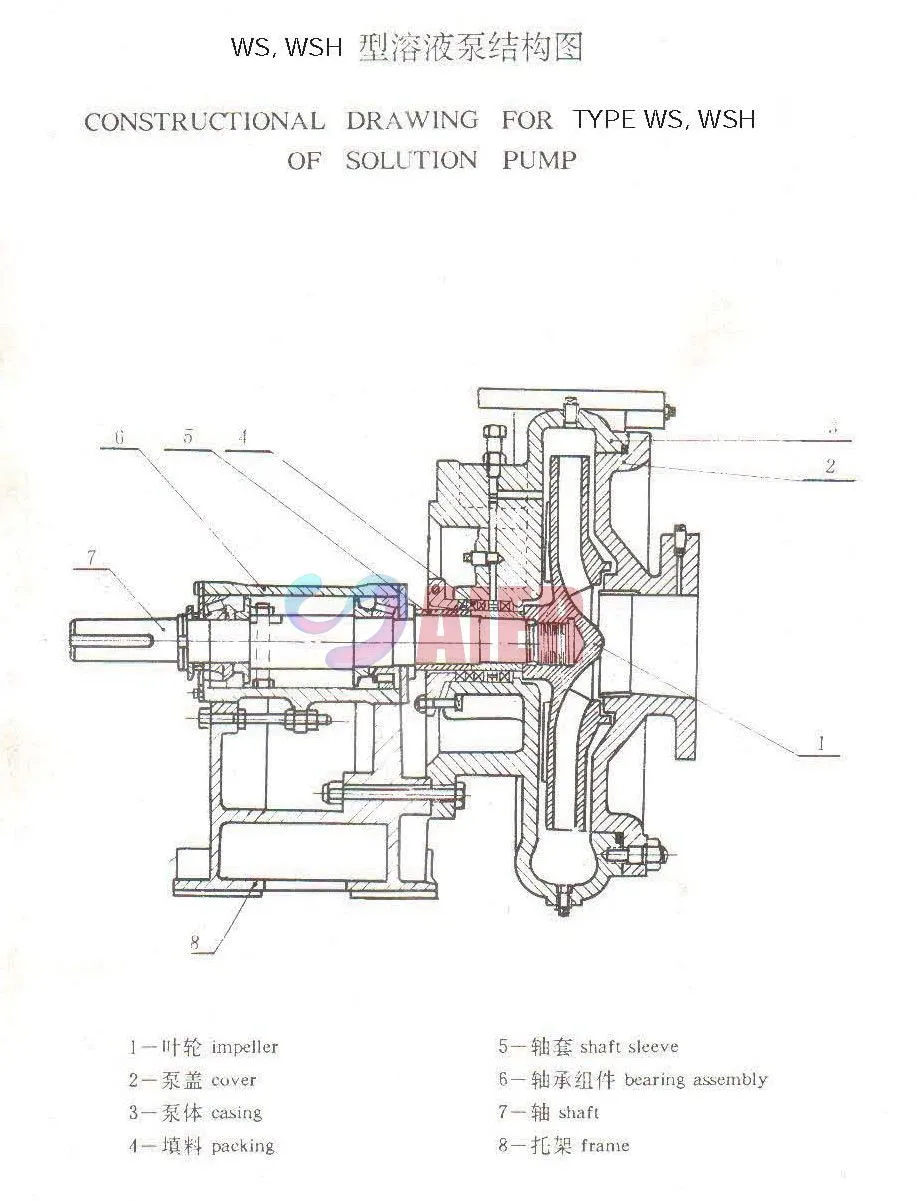

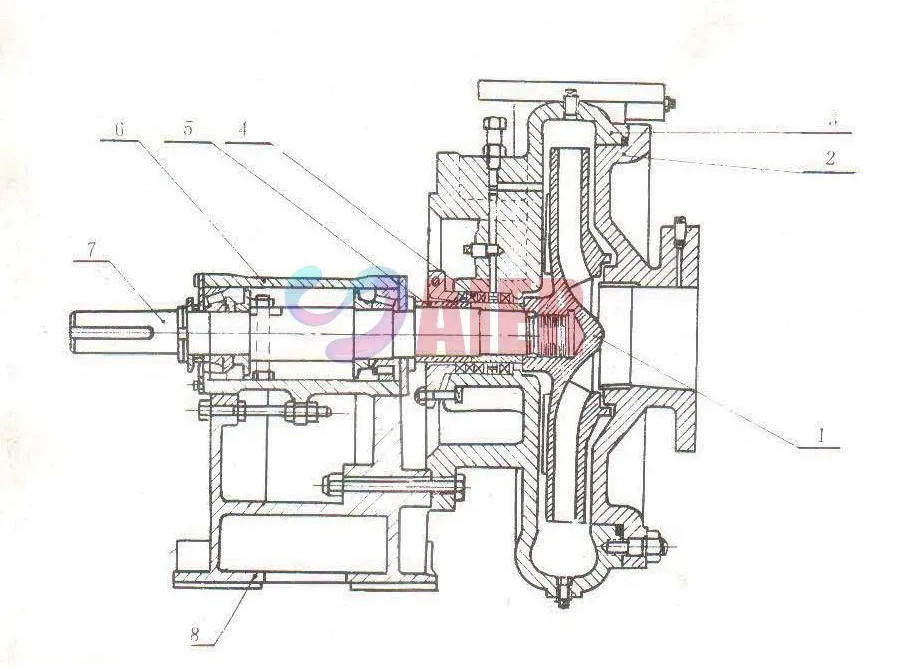

Construction Diagram

CONSTRUCTIONAL DRAWING FOR TYPE WS, WSH OF SOLUTION PUMP

1. impeller 2. pump cover 3. pump casing 4. packing 5. shaft sleeve 6. bearing assembly 7. shaft 8. frame

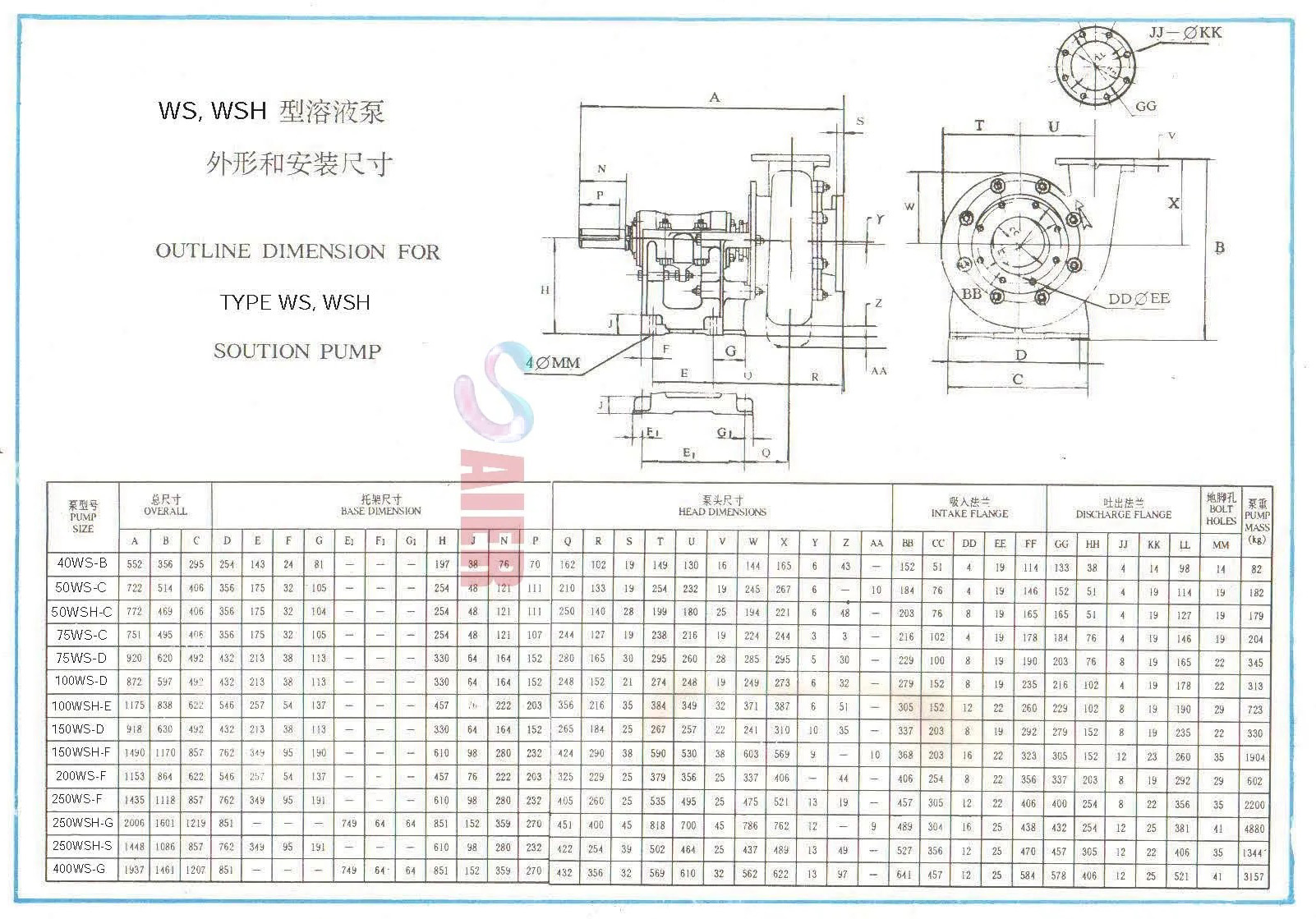

Outline Dimensions