BCT Ceramic Slurry Pumps

Advantages of Ceramic Pumps

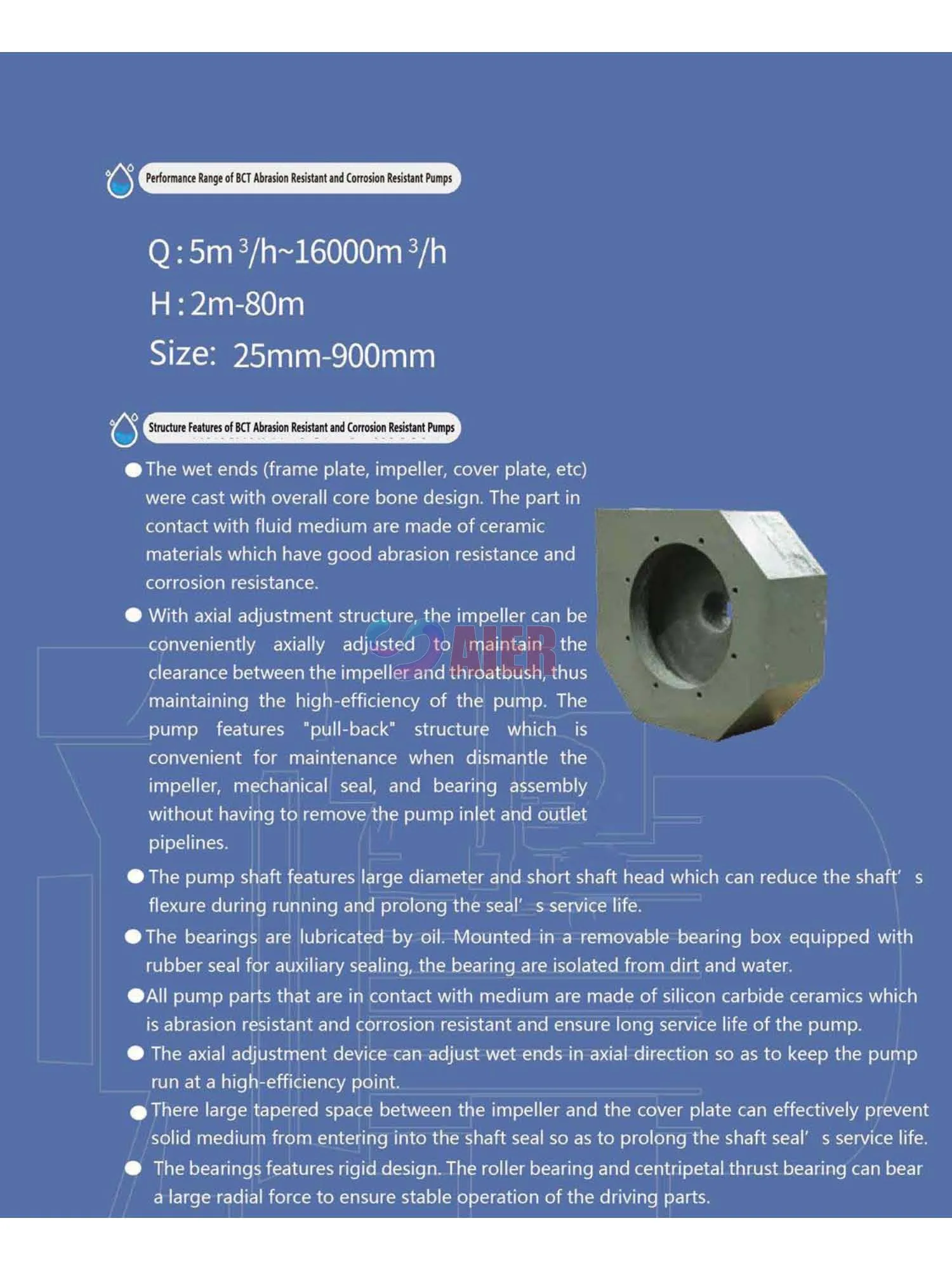

SPECIFICATIONS:

Size: 4" to 24"

Capacity: 50-6000 m3/h

Head: 5-45 m

Handing solids: 0-130mm

Concentration: 0%-70%

Materials: Ceramic

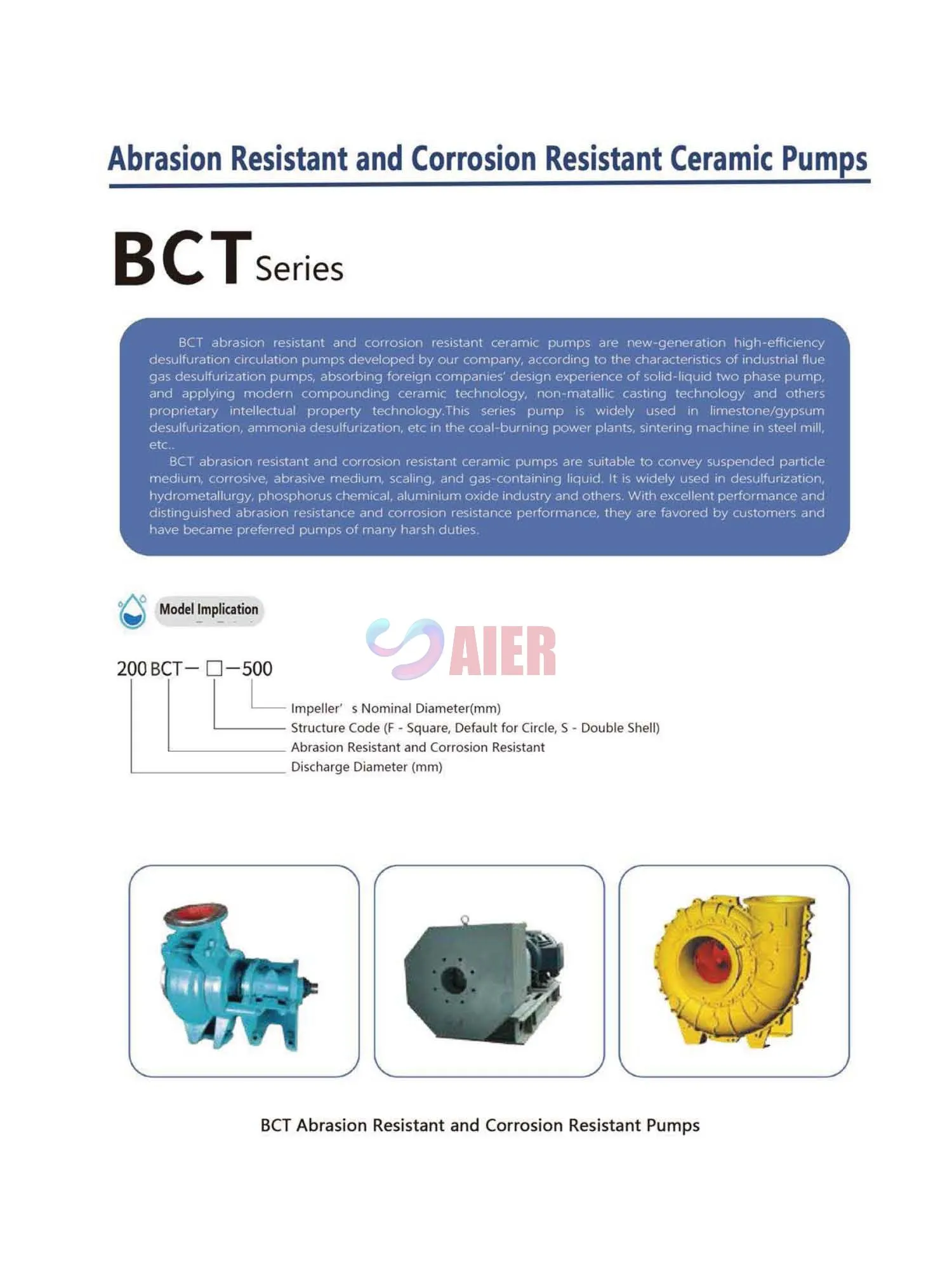

AIER® BCT Abrasion Resistant, Corrosion Reistant Ceramic Slurry Pump

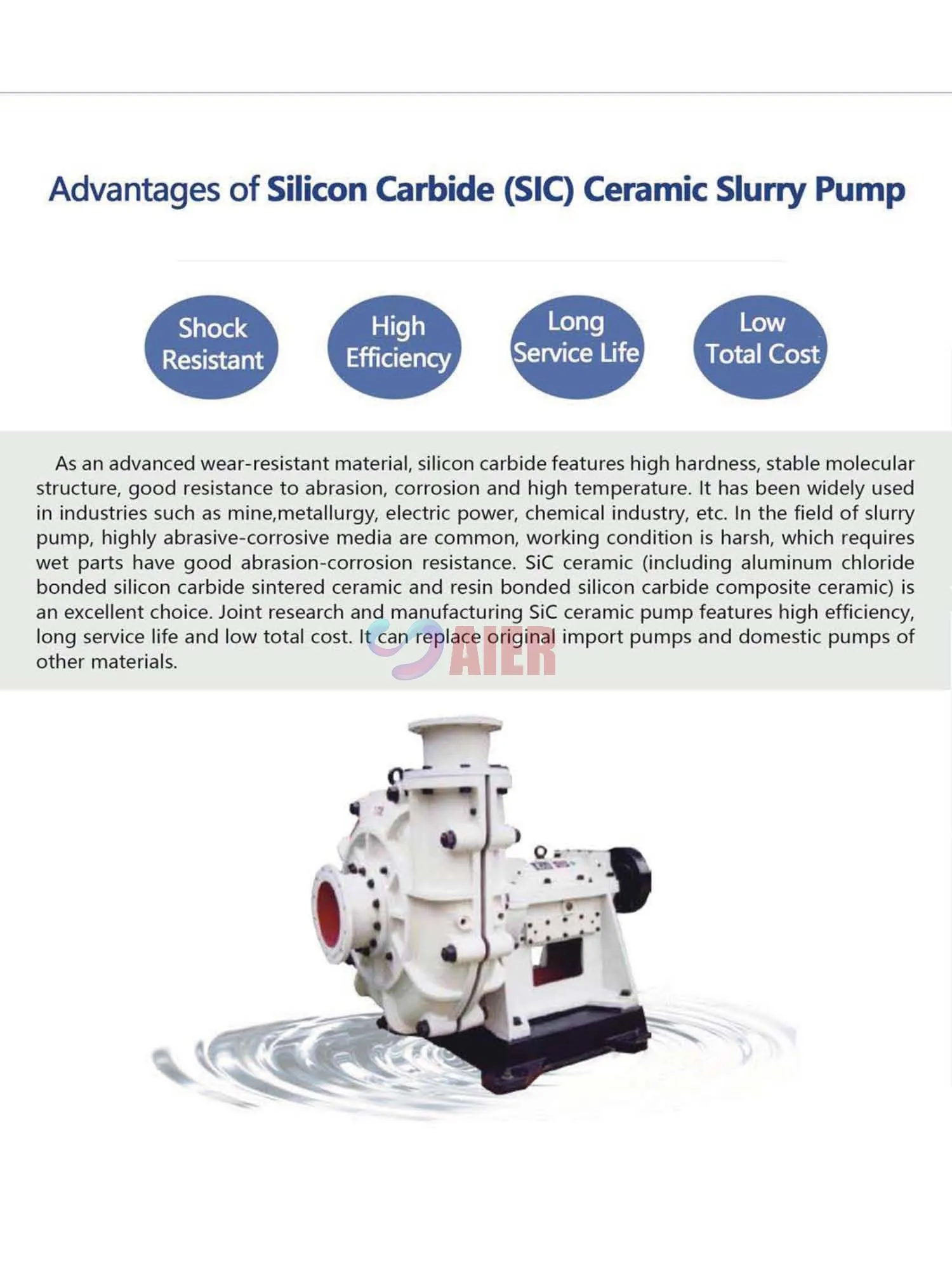

Advantages of Silicon Carbide (SIC) Ceramic Slurry Pump

Shock resistant

High efficiency

Long service time

Low total Cost

As an advanced wear-resistant material, silicon carbide features high hardness, stable molecular structure, good resistance to abrasion, corrosion, and high temperature. It has been widely used in industries such as mining, metallurgy, electric power, chemical industry, etc. In the field of slurry pump, highly abrasive-corrosive media are common, and working condition is adverse, which requires wet parts to have good abrasion-corrosion resistance. SiC ceramic (including aluminum chloride-bonded silicon carbide sintered ceramic and resin-bonded silicon carbide composite ceramic) is an excellent choice. Joint research and manufacturing of SiC ceramic pumps feature high efficiency, long service time and low total cost. It can replace original import pumps and domestic pumps of other materials.

Strong corrosion resistance of SiC

Good chemical stability. Silicon carbide resists most inorganic acids, organic acids, bases and oxidizing media.

Strong wear resistance. The abrasive resistance of silicon carbide is 3 ~ 5 times more than high chrome antiwear steel

Excellent corrosion resistance. Silicon carbide can stand various acids, bases, chemicals except hydrofluoric acid and hot concentrated caustic.

Good impact resistance. Silicon carbide can resist the impact of large particles and steel balls.

Wide range of temperature resistance. Silicon carbide can be used for a long time at -40°C ~ 90°C, up to 110°

Excellent wear resistance of SiC

The crystal structure of silicon carbide is close to the diamond tetrahedron. This compound is linked by strong covalent bonds. The hardness is second only to diamond. According to the contrast experiment conducted by Xi’an Jiaotong University, the wear resistance of silicon carbide is 3.51 times more than Cr30 antiwear steel.

Strong impact resistance of SiC

Application

|

Industry |

Station |

Product |

|

Mineral processing Tailings |

Mill pump, Cyclone feed pump, Tailing pump, Flotation/ concentration pump, Thickener underflow pump, Filer press feed pump |

ACT(ZCT) ceramic pump STP vertical pump |

|

Environment protection Coal power generation Steelmaking Metallurgy |

Desulfurizing slurry-circling pump, Mill slurry pump, Lime seriflux cycling pump, Gypsum discharge pump, Emergency pump, Hydrometallurgy slurry pump |

BCT ceramic pump SCT pump YCT vertical pump |

|

Chemical industry |

Salt chemical engineering, Process pump for highly corrosive chemical minerals |

BCT ceramic pump YCT vertical pump |

Product Description

Features

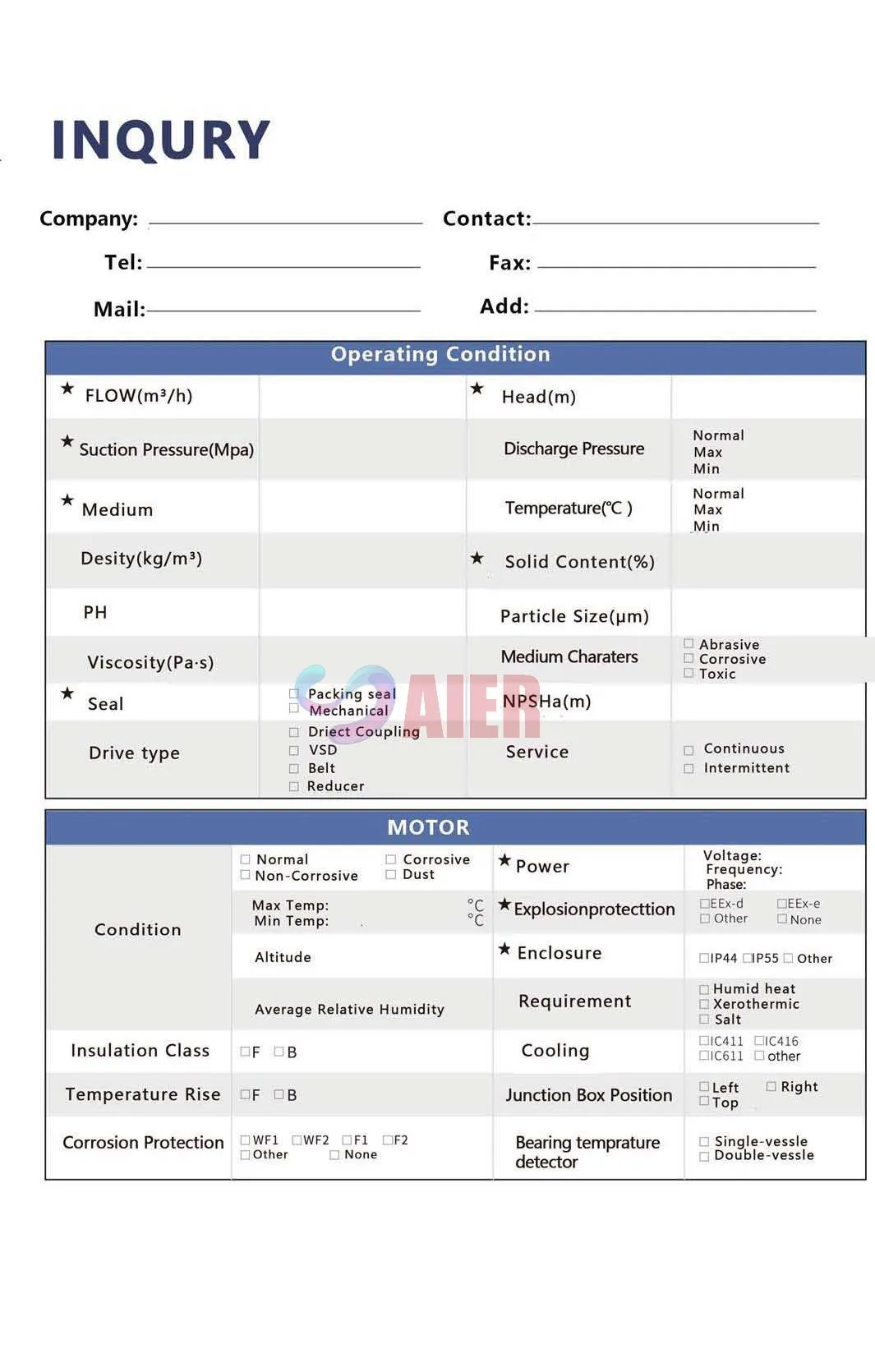

Inquiry Form

Energy Efficiency of Ceramic Slurry Pumps in Large-Scale Operations

Energy efficiency is a major concern for industrial operations, and ceramic slurry pumps offer significant advantages in this area. By reducing friction and maintaining optimal hydraulic performance, a high efficiency ceramic slurry pump can lower energy consumption while handling abrasive and corrosive slurries. This is particularly important in large-scale operations such as mining, metallurgical plants, chemical processing, and wastewater treatment, where pumps often operate continuously under demanding conditions.

The smooth, hard surfaces of ceramic components minimize internal resistance and allow slurry to flow more easily through the pump. Compared with metal or rubber-lined pumps, an energy saving ceramic slurry pump can operate at a lower power requirement without compromising flow rate or pressure. In addition, superior wear resistance reduces efficiency loss over time, as ceramic linings maintain their shape and hydraulic characteristics even after prolonged use.

Optimizing industrial slurry pump performance also involves selecting the right pump size, impeller design, and operational parameters. A well-matched pump ensures that the system operates near its best efficiency point, reducing excess energy use. Many china ceramic slurry pump manufacturers now provide computational fluid dynamics (CFD) simulations to predict hydraulic performance and energy consumption, enabling clients to choose pumps that maximize efficiency while maintaining durability.

Another factor contributing to energy savings is reduced maintenance downtime. Durable ceramic materials minimize erosion and corrosion, decreasing the frequency of repairs or replacements. Less downtime translates into continuous operation, further improving overall energy efficiency and productivity. Additionally, improved pump reliability helps industrial operators avoid overcompensation with multiple pumps running simultaneously, reducing unnecessary energy usage.

In conclusion, high efficiency ceramic slurry pumps provide an excellent solution for large-scale industrial operations looking to reduce energy costs while maintaining reliable slurry transport. By choosing an energy saving ceramic slurry pump designed to fit specific operational conditions, industries can achieve sustainable, cost-effective, and long-term operational benefits, making these pumps a preferred choice for demanding slurry handling applications.

Troubleshooting Common Issues in Ceramic Slurry Pumps

Despite their durability and high performance, ceramic slurry pumps can experience operational problems if not properly maintained or operated. Understanding ceramic slurry pump troubleshooting techniques helps industrial operators identify and resolve issues quickly, minimizing downtime and preventing costly damage. Common slurry pump problems include seal leaks, excessive vibration, reduced flow, cavitation, and unusual noise. Each of these issues can indicate underlying problems with installation, alignment, or operational conditions.

Seal leakage is one of the most frequent concerns in ceramic slurry pumps. Mechanical seals can wear due to abrasive slurry particles, misalignment, or excessive pressure. Regular inspection and timely replacement of seals and gaskets are essential. Using genuine ceramic pump spare parts ensures compatibility and prevents premature failure.

Excessive vibration and noise often indicate bearing wear, misaligned shafts, or an imbalance in the impeller. Proper installation, alignment, and lubrication of bearings are crucial. Checking for buildup in the pump casing and discharge lines can also resolve vibration issues. Reduced flow or head may result from clogged suction lines, worn impellers, or air entrainment. Periodically cleaning the pump and monitoring slurry concentration can prevent performance decline.

Another common problem is cavitation, which occurs when local pressure drops below the slurry vapor pressure. This can cause pitting on ceramic surfaces and reduce pump efficiency. Ensuring proper suction conditions and operating within design parameters can mitigate cavitation risks. Ceramic slurry pump maintenance tips include regular inspection of wear parts, monitoring operating conditions, flushing the pump after use, and maintaining correct alignment and lubrication.

By following systematic ceramic slurry pump troubleshooting and preventive maintenance practices, industrial operators can extend pump life, reduce repair costs, and maintain consistent performance. Partnering with a knowledgeable ceramic slurry pump manufacturer or supplier also ensures access to technical support, spare parts, and expert advice, enhancing overall reliability in mining, chemical, and metallurgical applications.

Innovations in Ceramic Slurry Pump Materials: Improving Wear and Corrosion Resistance

In modern industrial operations, the choice of pump materials directly impacts the efficiency, reliability, and longevity of slurry handling systems. Ceramic slurry pump materials have undergone significant innovations in recent years, enabling pumps to operate in increasingly harsh conditions. Advanced materials such as high-purity alumina, zirconia, and silicon carbide are now commonly used for critical components like impellers, liners, and throat bushes. These materials provide exceptional wear resistance and chemical stability, making them ideal for applications in mining, chemical processing, metallurgy, and wastewater treatment.

A wear resistant ceramic slurry pump offers several advantages over traditional metal or rubber-lined pumps. The high hardness of ceramic components ensures minimal abrasion when pumping slurries containing sharp or coarse particles. This reduces the frequency of replacement parts, minimizes downtime, and lowers maintenance costs. In addition, ceramic materials are chemically inert, meaning they can handle acidic, alkaline, or otherwise corrosive slurries without degradation. This combination of mechanical strength and chemical stability makes advanced ceramics a superior choice for long-term industrial applications.

Technological improvements in advanced ceramic pump technology have also enhanced the bonding and sintering processes, ensuring stronger adhesion between ceramic liners and metal pump bodies. This prevents cracking or detachment under high-pressure or high-velocity operations. Modern manufacturing techniques also allow for precision shaping of ceramic components, optimizing hydraulic performance and reducing energy losses. By maintaining smooth surfaces and tight tolerances, these pumps operate more efficiently and quietly while extending service life.

Moreover, manufacturers can now customize ceramic slurry pump materials to match specific operational conditions. For example, silicon carbide can be selected for extremely abrasive slurries, while zirconia is ideal for applications involving strong chemical corrosion. By leveraging these material innovations, industrial operators can improve pump reliability, reduce operating costs, and maintain consistent performance even in highly challenging environments.

In summary, innovations in ceramic slurry pump materials have revolutionized industrial slurry handling. Through the use of high-quality alumina, zirconia, and silicon carbide, combined with precision manufacturing and advanced sintering techniques, wear resistant ceramic slurry pumps deliver enhanced durability, chemical resistance, and efficiency. These advancements ensure that industries can meet operational demands while minimizing maintenance, downtime, and overall costs.