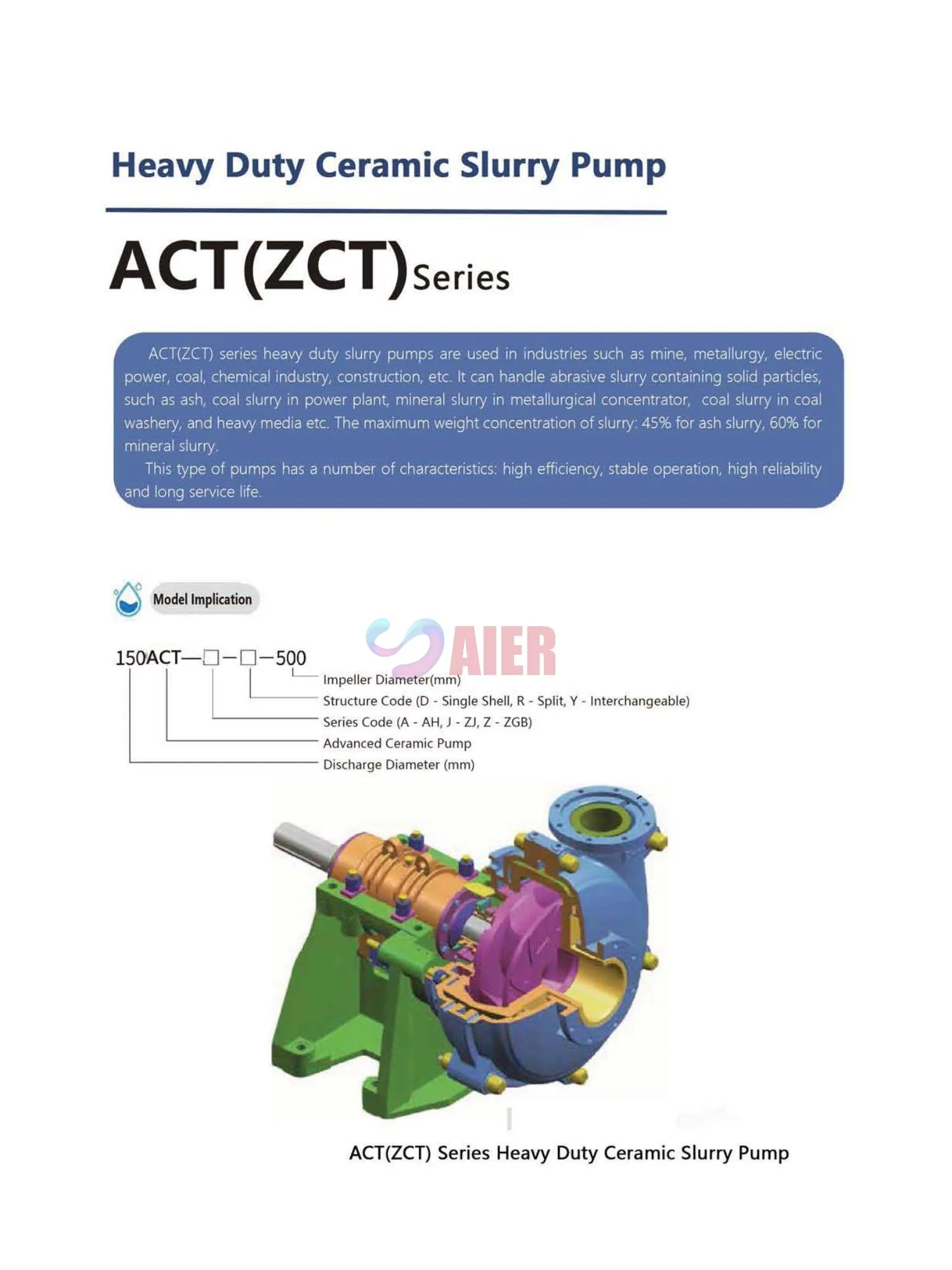

ACT (ZCT) Ceramic Slurry Pumps

Advantages of Ceramic Slurry Pumps

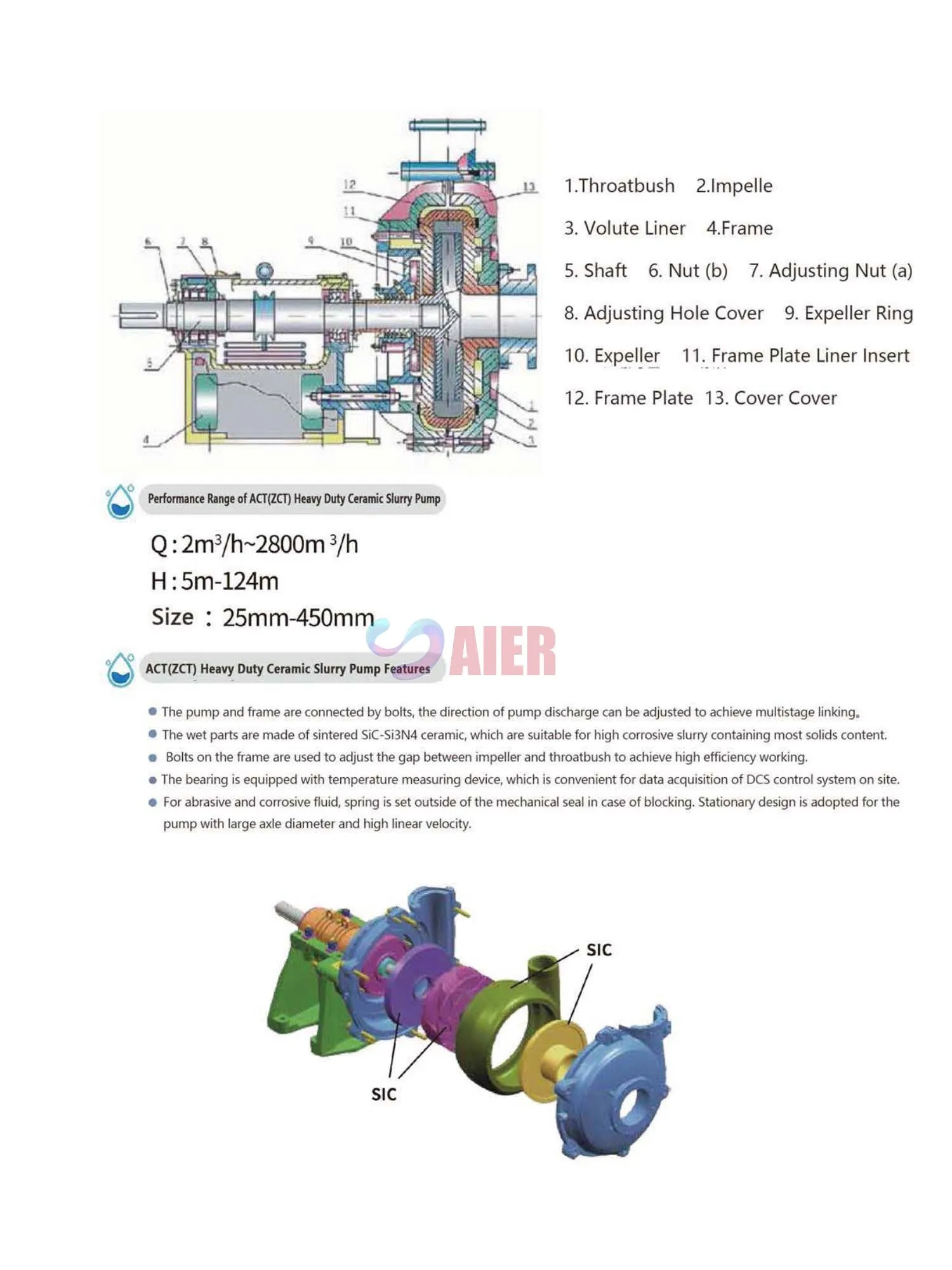

SPECIFICATIONS:

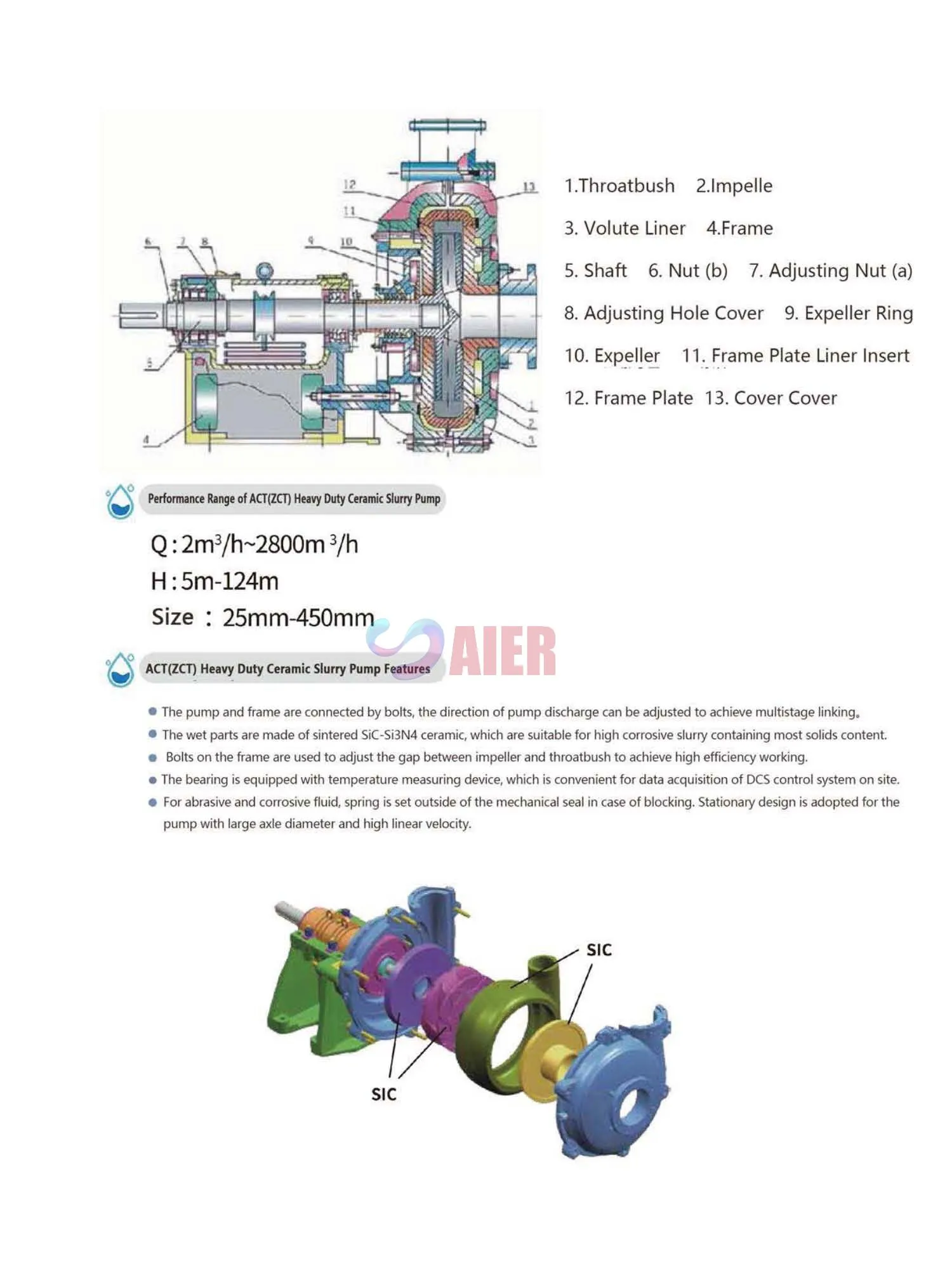

Size: 1" to 18"

Capacity: 2-2800 m3/h

Head: 5-124 m

Handing solids: 0-110mm

Concentration: 0%-70%

Materials: Ceramic

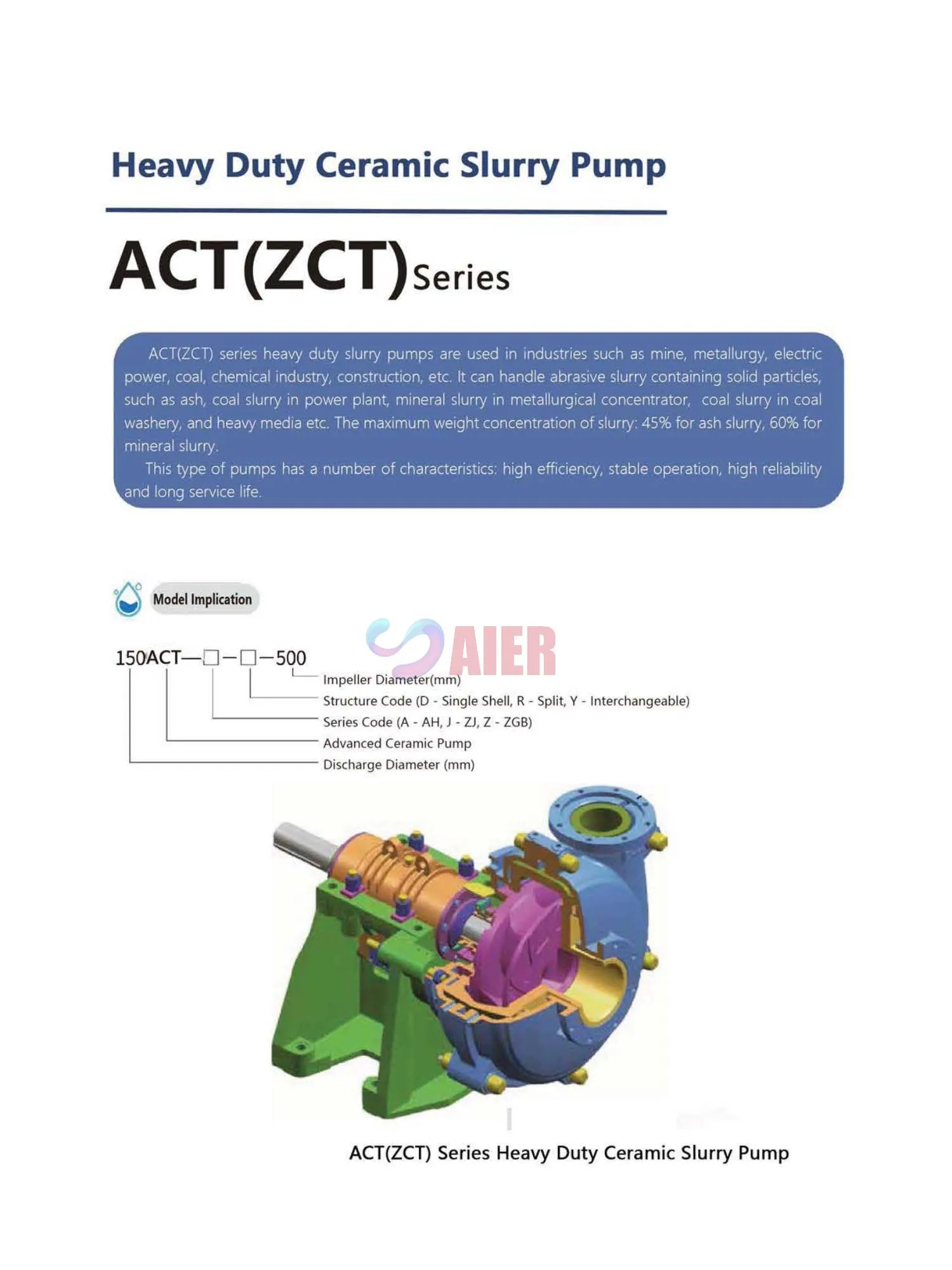

AIER® ACZ (ZCT) Heavy Duty Ceramic Slurry Pump

Advantages of Silicon Carbide (SIC) Ceramic Slurry Pump

Shock resistant

High efficiency

Long service time

Low total Cost

As an advanced wear-resistant material, silicon carbide features high hardness, stable molecular structure, good resistance to abrasion, corrosion, and high temperature. It has been widely used in industries such as mining, metallurgy, electric power, chemical industry, etc. In the field of slurry pump, highly abrasive-corrosive media are common, and working condition is adverse, which requires wet parts to have good abrasion-corrosion resistance. SiC ceramic (including aluminum chloride-bonded silicon carbide sintered ceramic and resin-bonded silicon carbide composite ceramic) is an excellent choice. Joint research and manufacturing of SiC ceramic pumps feature high efficiency, long service time and low total cost. It can replace original import pumps and domestic pumps of other materials.

Strong corrosion resistance of SiC

Good chemical stability. Silicon carbide resists most inorganic acids, organic acids, bases and oxidizing media.

Strong wear resistance. The abrasive resistance of silicon carbide is 3 ~ 5 times more than high chrome antiwear steel

Excellent corrosion resistance. Silicon carbide can stand various acids, bases, chemicals except hydrofluoric acid and hot concentrated caustic.

Good impact resistance. Silicon carbide can resist the impact of large particles and steel balls.

Wide range of temperature resistance. Silicon carbide can be used for a long time at -40°C ~ 90°C, up to 110°

Excellent wear resistance of SiC

The crystal structure of silicon carbide is close to the diamond tetrahedron. This compound is linked by strong covalent bonds. The hardness is second only to diamond. According to the contrast experiment conducted by Xi’an Jiaotong University, the wear resistance of silicon carbide is 3.51 times more than Cr30 antiwear steel.

Strong impact resistance of SiC

Application

|

Industry |

Station |

Product |

|

Mineral processing

Tailings |

Mill pump, Cyclone feed pump, Tailing pump, Flotation/ concentration pump, Thickener underflow pump, Filer press feed pump |

ACT(ZCT) ceramic pump STP vertical pump |

|

Environment protection Coal power generation Steelmaking Metallurgy |

Desulfurizing slurry-circling pump, Mill slurry pump, Lime seriflux cycling pump, Gypsum discharge pump, Emergency pump, Hydrometallurgy slurry pump |

BCT ceramic pump SCT pump YCT vertical pump |

|

Chemical industry |

Salt chemical engineering, Process pump for highly corrosive chemical minerals |

BCT ceramic pump YCT vertical pump |

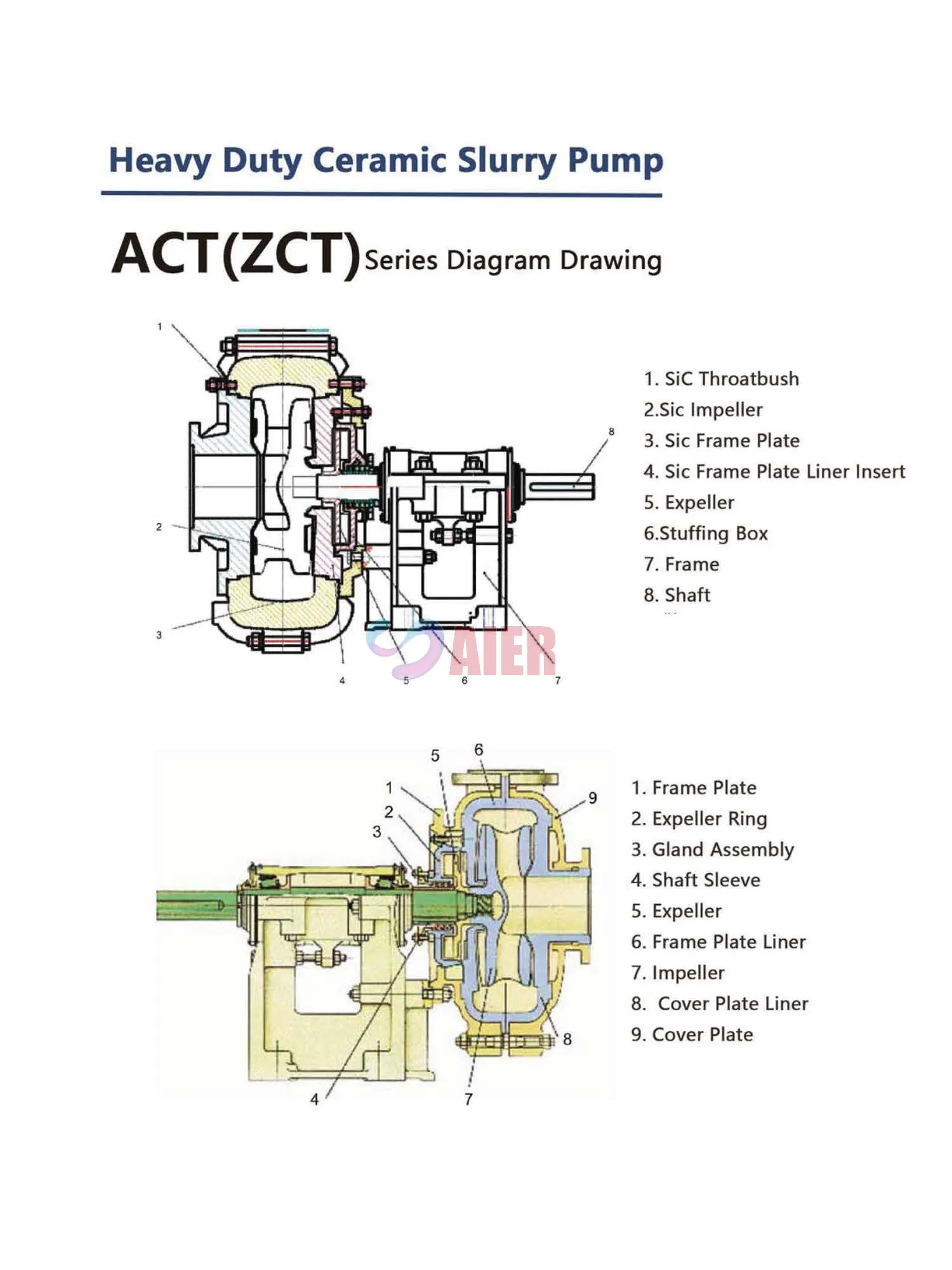

General Description

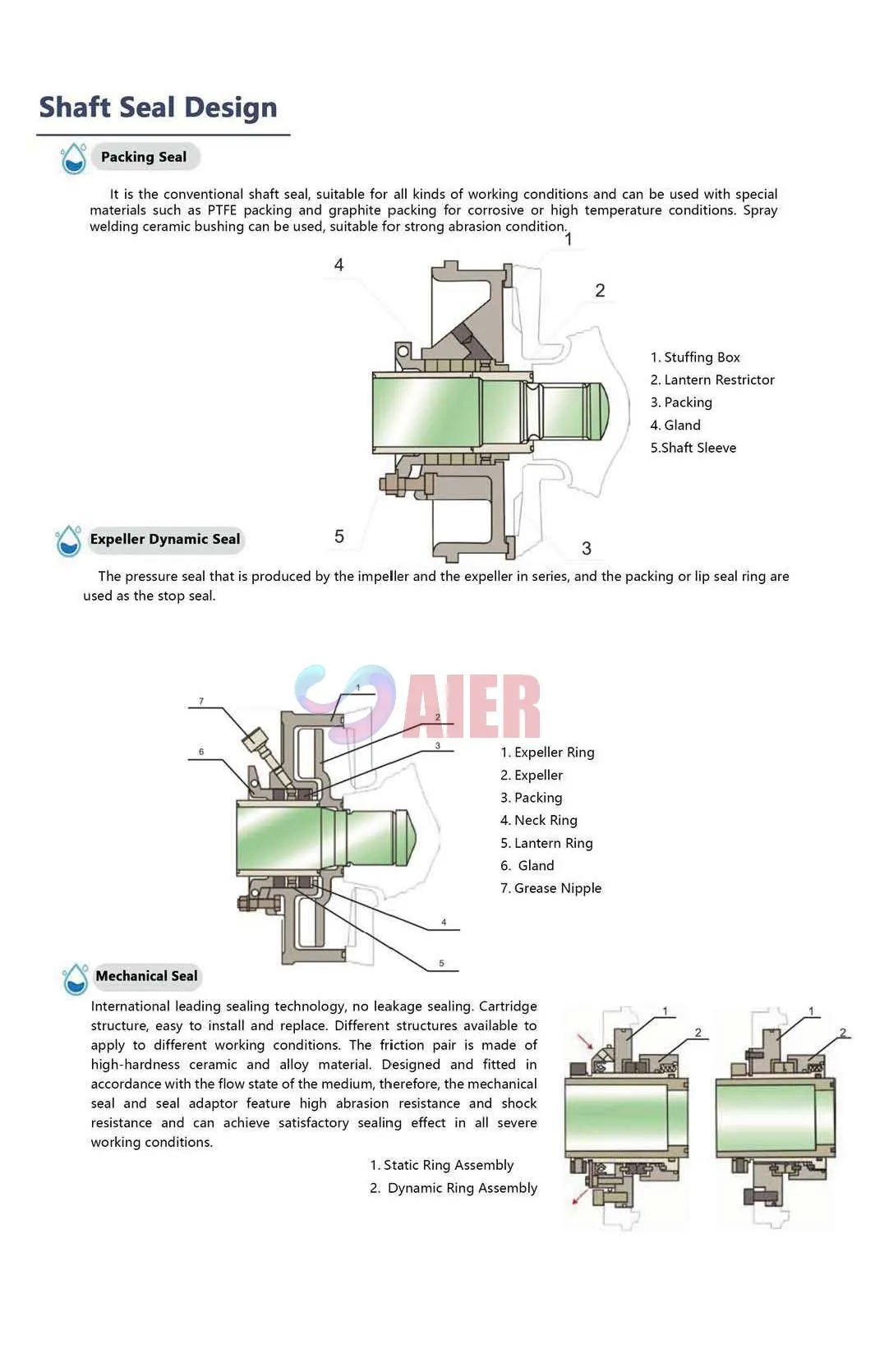

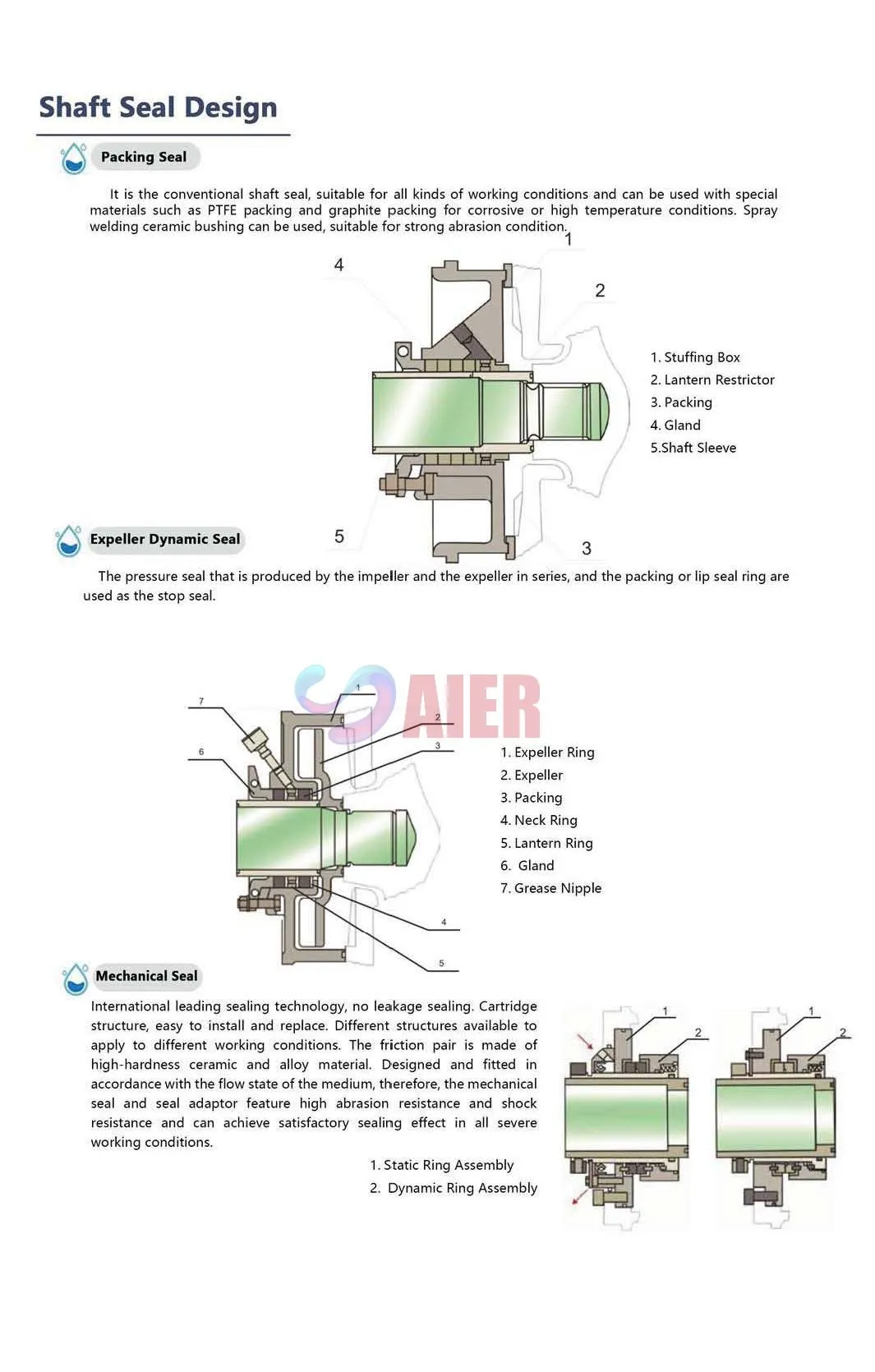

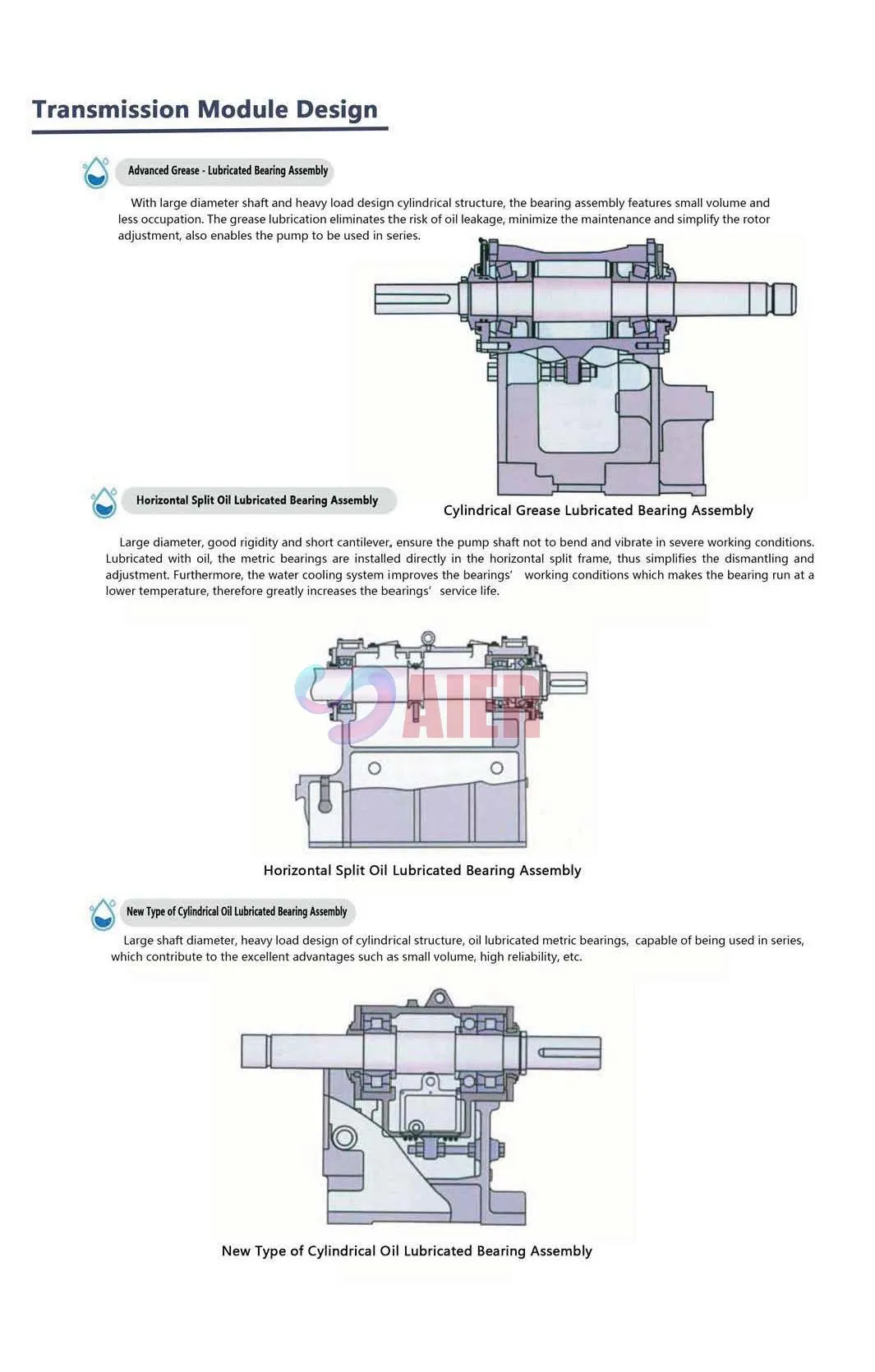

Diagram Drawing

Design Features

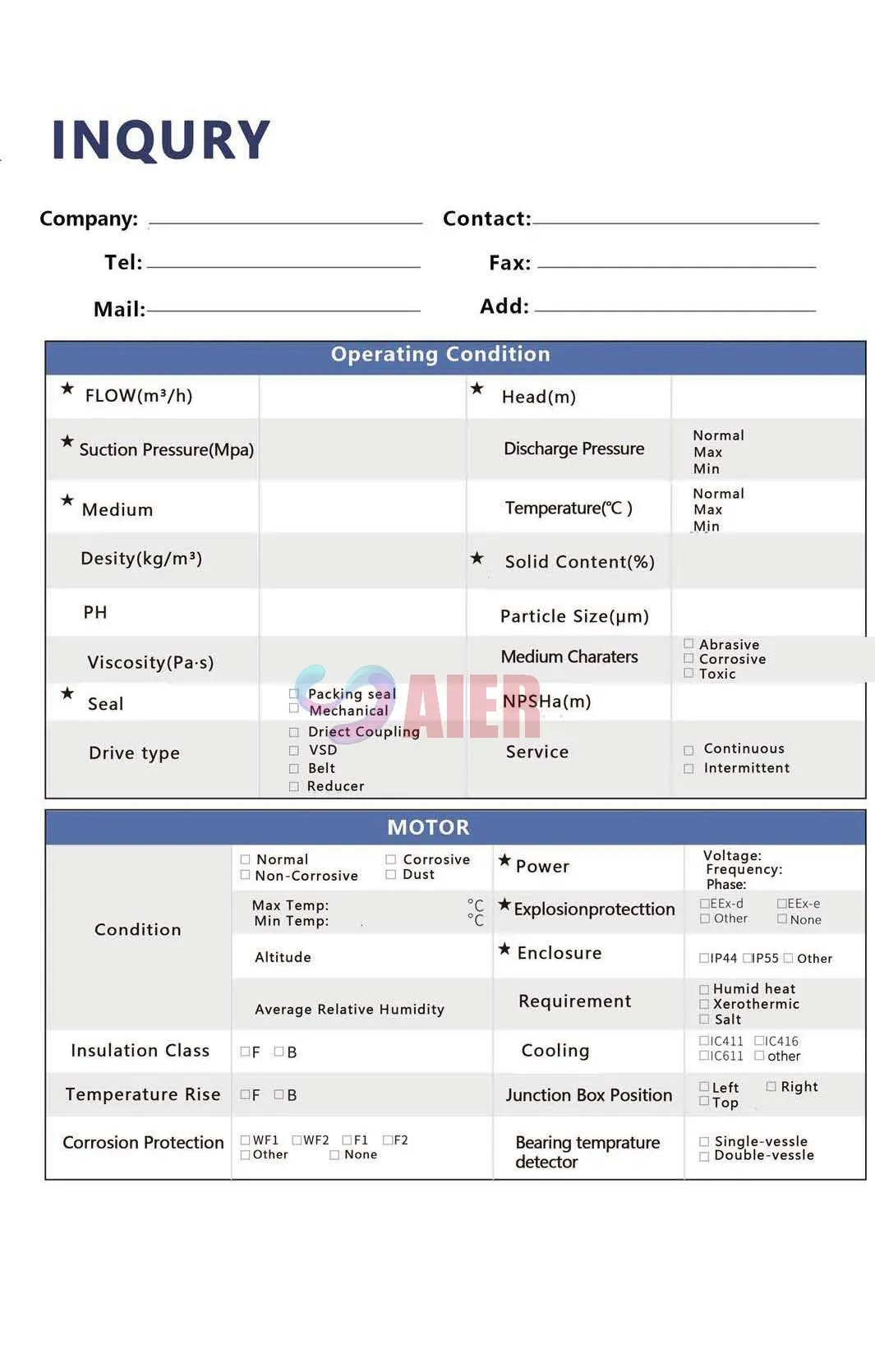

Inquiry Form

Comparing Ceramic Slurry Pumps with Rubber and Metal Lined Pumps

Selecting the right type of slurry pump is crucial for optimizing efficiency and reducing operational costs. Understanding the differences between a ceramic slurry pump vs rubber pump and metal lined slurry pump can help industries make informed decisions. Each type has its own advantages, limitations, and suitable applications depending on the slurry’s abrasiveness, chemical properties, and operational conditions.

A ceramic slurry pump is ideal for highly abrasive and corrosive slurries. Its ceramic components, such as alumina or zirconia liners and impellers, provide exceptional wear resistance and chemical stability. These pumps excel in mining, metallurgy, chemical processing, and power plant desulfurization, where slurries often contain sharp or dense particles. The smooth ceramic surface reduces friction and energy loss, maintaining pump efficiency over long periods, and extending service life compared with traditional pumps.

In contrast, a rubber lined slurry pump is more suitable for moderately abrasive slurries with lower chemical aggressiveness. Rubber liners provide good corrosion resistance and absorb impact from larger particles, which helps reduce damage to the pump structure. Rubber pumps are generally more flexible and lighter than ceramic models, but they wear faster when handling highly abrasive slurries, leading to more frequent maintenance.

A metal lined slurry pump, typically made from high-chrome alloys or stainless steel, combines strength with moderate wear resistance. Metal pumps are suitable for slurries that are less abrasive but may contain corrosive chemicals. They can handle higher pressures and flow rates than rubber pumps but tend to wear faster than ceramic pumps under extreme abrasion. Industrial slurry pump comparison often highlights that metal pumps offer a balance between cost and durability but may not perform as well as ceramics in very harsh conditions.

When deciding among these options, factors such as slurry composition, operating temperature, flow rate, head, and maintenance requirements must be considered. While ceramic slurry pumps deliver maximum wear and corrosion resistance, rubber pumps offer flexibility and impact resistance, and metal lined slurry pumps provide strength and moderate durability. Choosing the correct type ensures optimal performance, lower total cost of ownership, and longer service life in industrial applications.

Ceramic Slurry Pumps in Mining: Tailings and Ore Slurry Transportation

In the mining industry, handling abrasive slurries is a major challenge that requires robust and reliable equipment. A ceramic slurry pump for mining provides an ideal solution for transporting highly abrasive ore slurries and tailings efficiently. Unlike conventional metal or rubber-lined pumps, ore slurry pumps equipped with ceramic components such as impellers, liners, and throat bushes exhibit exceptional wear resistance and durability. These properties allow mining operations to handle slurries containing coarse particles or high concentrations of solids with minimal maintenance.

Tailings transportation is one of the most demanding tasks in a mining operation. A tailings pump must withstand constant exposure to sharp and dense mineral particles, which can quickly erode traditional pump materials. Ceramic linings, made from high-purity alumina or zirconia, maintain structural integrity under these conditions, reducing downtime and replacement costs. The smooth surface of ceramic components also minimizes friction losses, maintaining high hydraulic efficiency and ensuring consistent flow rates even under heavy loads.

In addition to wear resistance, ceramic slurry pumps for mining are highly adaptable to different flow and head requirements. Manufacturers can customize impeller design, casing configuration, and ceramic thickness to match site-specific slurry conditions. For example, high-volume tailings pipelines may require pumps with larger impellers and reinforced liners, while ore concentration circuits benefit from optimized impeller geometry for improved solids handling. These customized solutions ensure maximum efficiency, reduced energy consumption, and longer service life.

Another advantage of ore slurry pumps in mining is their ability to operate under variable pH and chemical environments. Some slurries contain acidic or alkaline components due to ore processing chemicals, and ceramic linings provide superior corrosion resistance compared to metal or rubber alternatives. This combination of wear and corrosion resistance makes ceramic slurry pumps a cost-effective and reliable choice for continuous mining operations.

Overall, the use of ceramic slurry pumps in mining enhances operational reliability, reduces maintenance costs, and ensures efficient handling of abrasive ore slurries and tailings. With proper selection, installation, and routine maintenance, these pumps can deliver years of consistent performance, making them a critical component in modern mining infrastructure.

Ceramic Slurry Pumps in Chemical Industry: Handling Corrosive Liquids

In the chemical industry, pumping corrosive and abrasive slurries requires equipment that combines durability, chemical resistance, and high efficiency. A ceramic slurry pump for chemical industry meets these requirements by using advanced ceramic materials such as alumina, zirconia, or silicon carbide for critical components like impellers, liners, and wear rings. These materials ensure that the pump can handle acidic, alkaline, or chemically aggressive fluids without suffering premature wear or corrosion.

An acid slurry pump is particularly valuable in processes where strong acids or highly corrosive slurries must be transported continuously. Metal pumps often degrade quickly under these conditions, resulting in downtime and costly replacements. Ceramic linings, however, are chemically inert and maintain structural integrity, providing long-term reliability and protecting the pump casing and shaft from chemical attack. This significantly extends the service life of the pump and reduces maintenance costs for chemical plants.

In addition to chemical resistance, corrosion resistant slurry pumps offer excellent wear resistance against abrasive particles often found in industrial chemical processes. Slurries containing catalysts, precipitates, or suspended solids can erode traditional pump components, but ceramic-lined pumps retain their performance due to the high hardness and smooth surface of the ceramic material. This combination of abrasion and corrosion resistance ensures stable hydraulic efficiency over long operational periods.

Customization is another important feature of ceramic slurry pumps for the chemical industry. Manufacturers can adjust impeller design, lining thickness, and casing configuration to match specific flow rates, slurry densities, and operating temperatures. Modular designs allow easy replacement of wear parts, minimizing downtime and simplifying maintenance. By selecting the right acid slurry pump, chemical plants can optimize process efficiency while ensuring safe and reliable transport of corrosive fluids.

Overall, the use of ceramic slurry pumps in chemical industry applications enhances operational reliability, reduces maintenance costs, and improves overall process efficiency. These pumps provide a durable, high-performance solution for transporting corrosive and abrasive liquids, making them an essential component in modern chemical manufacturing and processing facilities.