BCT Ceramic Slurry Pumps

Qhov zoo ntawm Ceramic Pumps

SPECIFICATIONS:

Loj: 4 "- 24"

Muaj peev xwm: 50-6000 m3 / h

Qhov siab: 5-45 m

Cov khoom siv: 0-130mm

Cov ntsiab lus: 0% -70%

Khoom siv: Ceramic

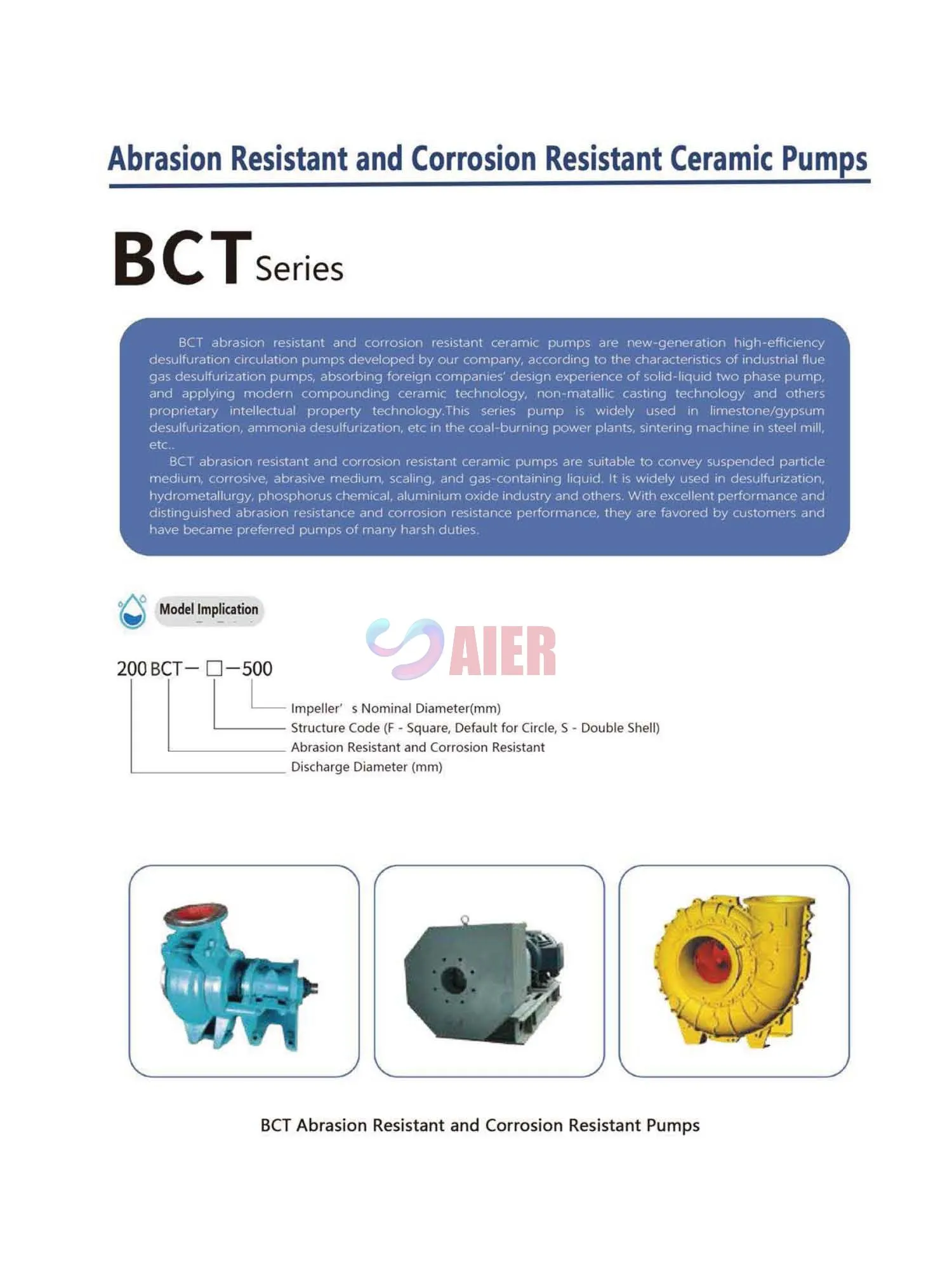

AIER® BCT Abrasion Resistant, Corrosion Reistant Ceramic Slurry Pump

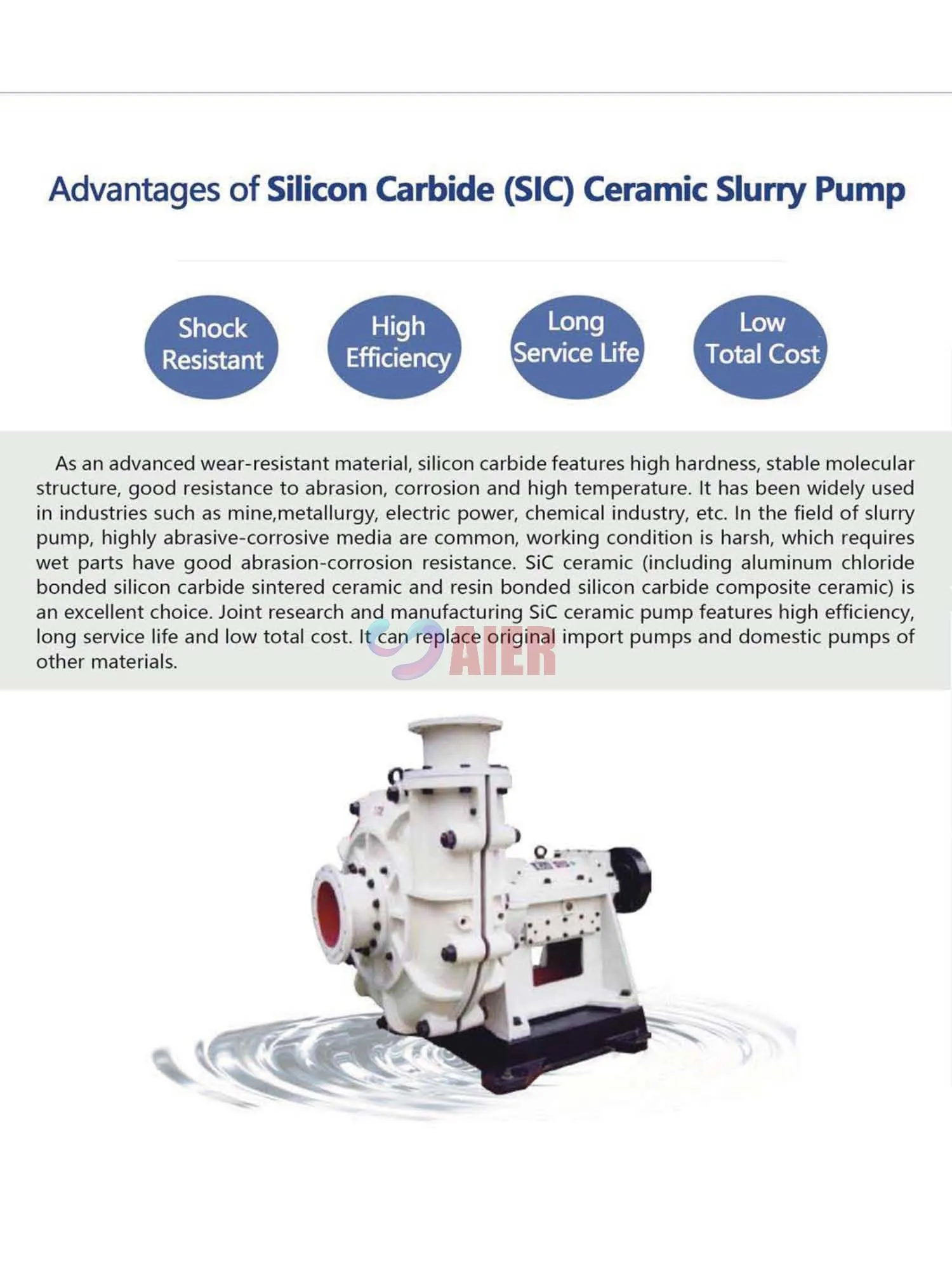

Qhov zoo ntawm Silicon Carbide (SIC) Ceramic Slurry Twj

Shock resistant

Kev ua haujlwm siab

Lub sijhawm ua haujlwm ntev

Tus nqi qis

Raws li cov khoom siv hnav-tiv taus siab heev, silicon carbide nta siab hardness, ruaj khov molecular qauv, zoo tiv thaiv abrasion, corrosion, thiab kub kub. Nws tau dav siv nyob rau hauv kev lag luam xws li mining, metallurgy, hluav taws xob fais fab, tshuaj lom neeg kev lag luam, thiab lwm yam. Nyob rau hauv lub teb ntawm slurry twj tso kua mis, heev abrasive-corrosive xov xwm yog heev, thiab ua hauj lwm mob yog tsis zoo, uas yuav tsum tau ntub qhov chaw kom muaj zoo abrasion. - corrosion kuj. SiC ceramic (xws li txhuas chloride-bonded silicon carbide sintered ceramic thiab resin-bonded silicon carbide puas ceramic) yog ib qho kev xaiv zoo heev. Kev tshawb fawb thiab kev tsim khoom ntawm SiC ceramic twj tso kua mis muaj kev ua haujlwm siab, lub sijhawm ua haujlwm ntev thiab tus nqi qis. Nws tuaj yeem hloov cov twj tso kua mis thawj thiab cov twj hauv tsev ntawm lwm cov ntaub ntawv.

Muaj zog corrosion kuj ntawm SiC

Zoo tshuaj stability. Silicon carbide resists feem ntau inorganic acids, organic acids, bases thiab oxidizing media.

Muaj zog hnav tsis kam. Lub abrasive tsis kam ntawm silicon carbide yog 3 ~ 5 npaug ntau dua li siab chrome antiwear hlau

Zoo heev corrosion kuj. Silicon carbide tuaj yeem sawv ntsug ntau yam kua qaub, hauv paus, tshuaj tshwj tsis yog hydrofluoric acid thiab kub concentrated caustic.

Kev cuam tshuam zoo. Silicon carbide tuaj yeem tiv taus qhov cuam tshuam ntawm cov khoom loj thiab cov pob hlau.

Wide range of temperature resistance. Silicon carbide can be used for a long time at -40°C ~ 90°C, up to 110°

Zoo hnav tsis kam ntawm SiC

The crystal structure of silicon carbide is close to the diamond tetrahedron. This compound is linked by strong covalent bonds. The hardness is second only to diamond. According to the contrast experiment conducted by Xi’an Jiaotong University, the wear resistance of silicon carbide is 3.51 times more than Cr30 antiwear steel.

Muaj zog tiv thaiv ntawm SiC

Daim ntawv thov

|

Kev lag luam |

Chaw nres tsheb |

Khoom |

|

Mineral ua Tailings |

Mill pump, Cyclone feed pump, Tailing pump, Flotation/ concentration pump, Thickener underflow pump, Filer press feed pump |

ACT (ZCT) ceramic twj tso kua mis STP ntsug twj tso kua mis |

|

Kev tiv thaiv ib puag ncig Coal fais fab tuag Steelmaking metallurgy |

Desulfurizing slurry-circling twj tso kua mis, zeb slurry twj tso kua mis, Txiv qaub seriflux cycling twj tso kua mis, Gypsum tso twj tso kua mis, Thaum muaj xwm ceev twj tso kua mis, Hydrometallurgy slurry twj tso kua mis |

BCT ceramic twj tso kua mis SCT twj YCT ntsug twj tso kua mis |

|

Kev lag luam tshuaj |

Ntsev chemical engineering, Cov txheej txheem twj tso kua mis rau cov tshuaj lom neeg muaj zog heev |

BCT ceramic twj tso kua mis YCT ntsug twj tso kua mis |

Product Description

Nta

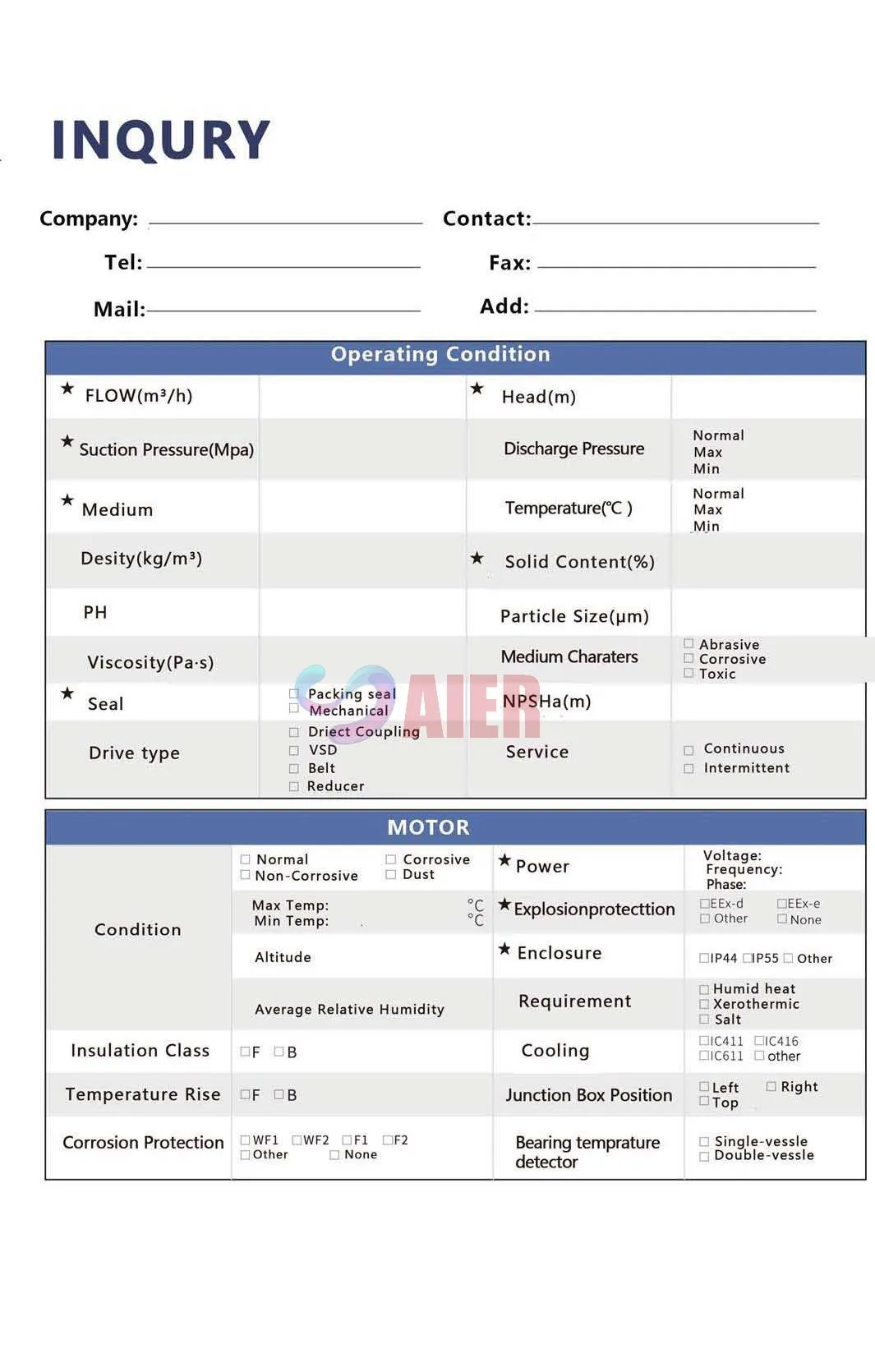

Daim ntawv nug