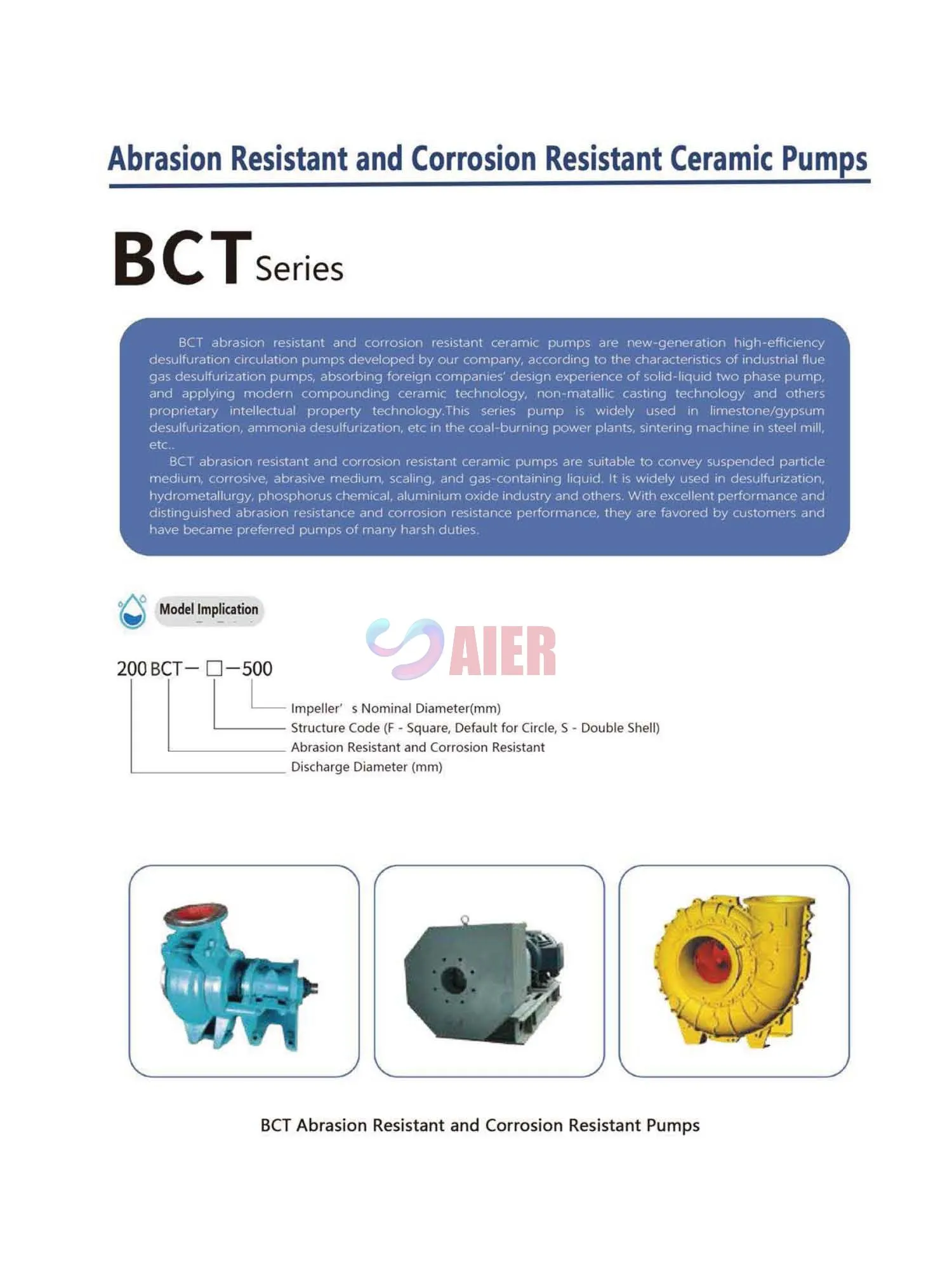

Nā Pump Slurry Ceramic BCT

ʻO nā pono o nā Pump Ceramic

NĀ KULA:

Nui: 4" a 24"

Kaha: 50-6000 m3/h

Poʻo: 5-45 m

Nā mea paʻa lima: 0-130mm

Hoʻonui: 0%-70%

Mea Hana: Ceramic

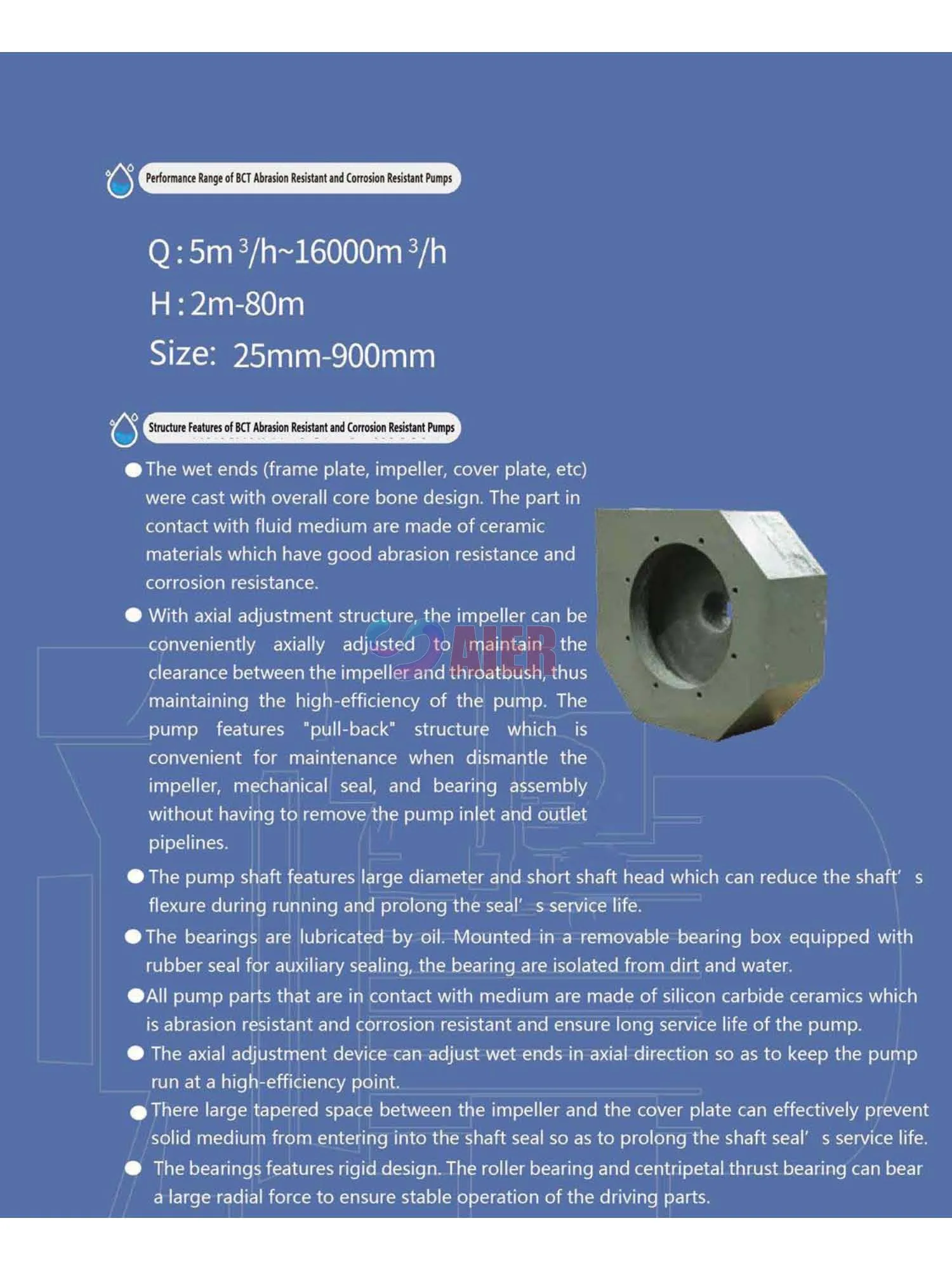

AIER® BCT Abrasion Resistant, Corrosion Reistant Ceramic Slurry Pump

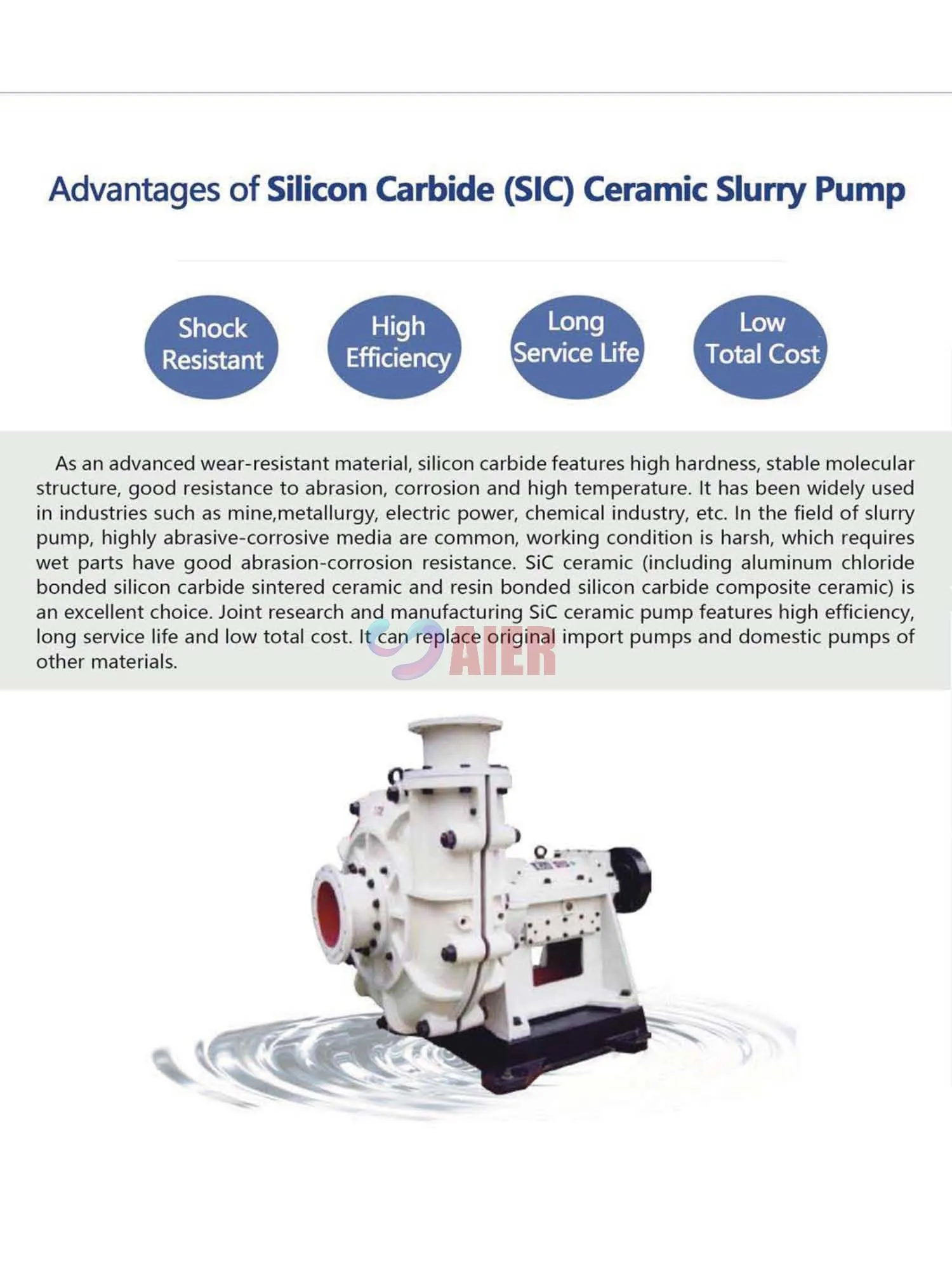

ʻO nā pono o ka Silicon Carbide (SIC) Ceramic Slurry Pump

Paʻa haʻalulu

ʻO ka hana kiʻekiʻe

Ka manawa lawelawe lōʻihi

Haahaa huina kumukuai

Ma ke ʻano he mea paʻa paʻa kiʻekiʻe, ʻike ʻia ka silicon carbide i ka paʻakikī kiʻekiʻe, ke ʻano molekala paʻa, ke kūpaʻa maikaʻi i ka abrasion, corrosion, a me ka wela kiʻekiʻe. Ua hoʻohana nui ʻia i nā ʻoihana e like me ka mining, metallurgy, mana uila, ʻoihana kemika, a me nā mea ʻē aʻe. - pale ʻana i ka corrosion. He koho maikaʻi loa ka SiC ceramic (me ka alumini chloride-bonded silicon carbide sintered ceramic a me ka resin-bonded silicon carbide composite ceramic. ʻO ka noiʻi hui ʻana a me ka hana ʻana i nā pāpaʻi seramika SiC e hōʻike ana i ka hana kiʻekiʻe, ka manawa lawelawe lōʻihi a me ka uku haʻahaʻa haʻahaʻa. Hiki iā ia ke hoʻololi i nā pump import kumu a me nā pump home o nā mea ʻē aʻe.

ʻO ka pale ʻana i ka corrosion ikaika o SiC

Paʻa kemika maikaʻi. Kū'ē ka Silicon carbide i ka hapa nui o nā waikawa inorganic, nā ʻakika organik, nā kumu a me ka media oxidizing.

ʻO ke kūpaʻa ʻaʻahu ikaika. ʻO ke kūpaʻa abrasive o ka silicon carbide he 3 ~ 5 mau manawa ʻoi aku ma mua o ke kila chrome antiwear kiʻekiʻe

ʻOi loa ka pale ʻana i ka corrosion. Hiki i ka Silicon carbide ke kū i nā ʻakika like ʻole, nā kumu, nā kemika koe wale nō ka waika hydrofluoric a me ka caustic concentrated.

Kūleʻa hopena maikaʻi. Hiki i ka Silicon carbide ke pale aku i ka hopena o nā mea nui a me nā pōpō kila.

Wide range of temperature resistance. Silicon carbide can be used for a long time at -40°C ~ 90°C, up to 110°

Kūleʻa maikaʻi loa o SiC

The crystal structure of silicon carbide is close to the diamond tetrahedron. This compound is linked by strong covalent bonds. The hardness is second only to diamond. According to the contrast experiment conducted by Xi’an Jiaotong University, the wear resistance of silicon carbide is 3.51 times more than Cr30 antiwear steel.

Paʻa ikaika o ka hopena o SiC

Palapala noi

|

ʻOihana |

Kūlana |

Huahana |

|

ʻO ka hana ʻana i ka minerala ʻO nā huelo |

Mill pump, Cyclone feed pump, Tailing pump, Flotation/ concentration pump, Thickener underflow pump, Filer press feed pump |

ACT(ZCT) pāpaʻa seramika ʻO ka pāpaʻi kūpaʻa STP |

|

Palekana kaiapuni Hana mana lanahu Ka hana kila Metallurgy |

ʻO ka pauma slurry-circling desulfurizing, Mill slurry pump, Lime seriflux cycling pump, Gypsum discharge pump, Emergency pump, Hydrometallurgy slurry pump |

ʻO ka pauma seramika BCT SCT pump ʻO ka pāpaʻi kūpaʻa YCT |

|

ʻOihana kemika |

ʻEnekinia kemika paʻakai, ʻO ka pauma kaʻina no nā minela kemika ʻino loa |

ʻO ka pauma seramika BCT ʻO ka pāpaʻi kūpaʻa YCT |

Hōʻike huahana

Nā hiʻohiʻona

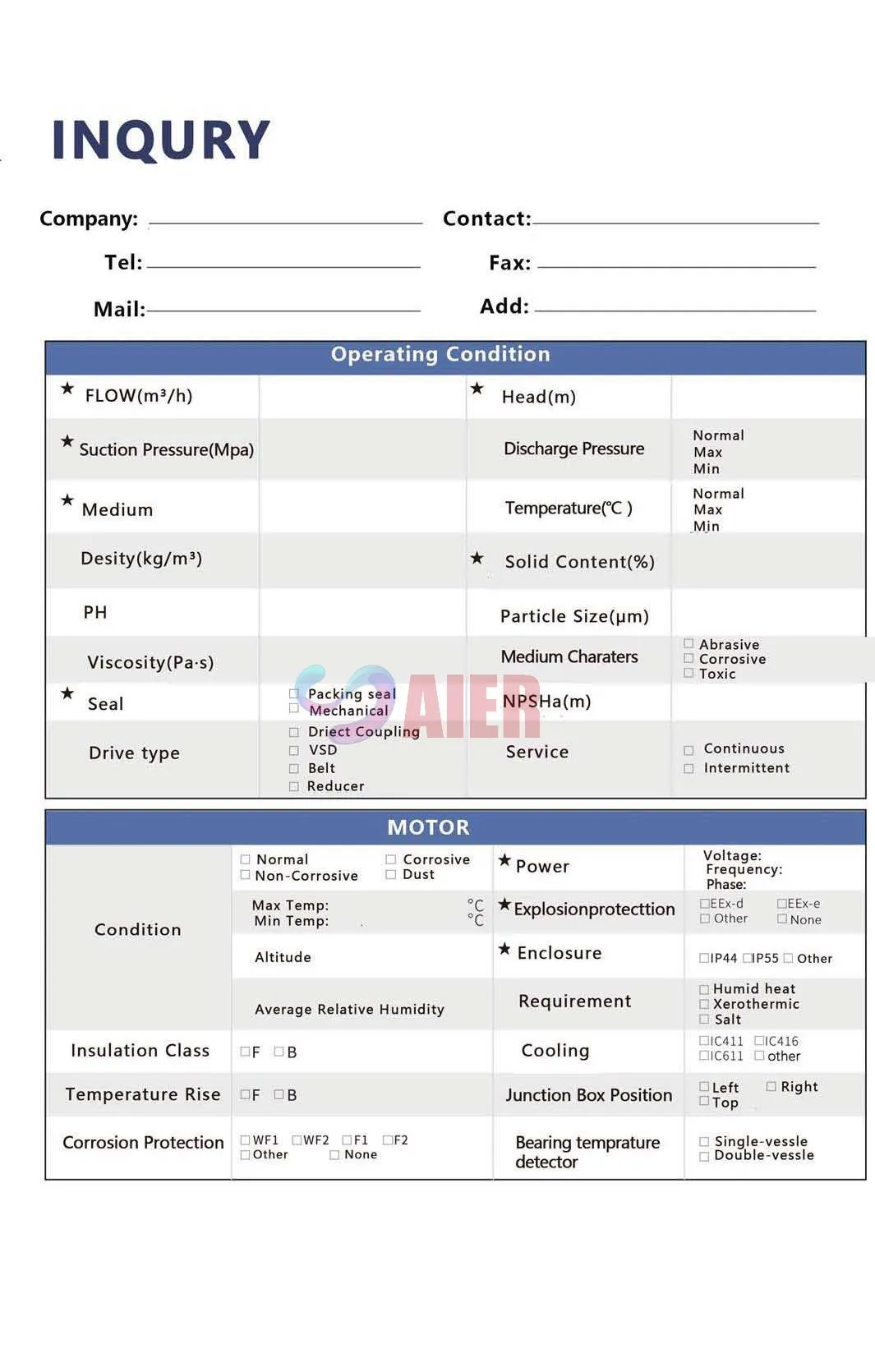

Pepa Ninau