ZJQ Submersible Slurry Pumps

Product Description

Aier® Submersible Slurry Pumps

The submersible slurry pump is a pump designed for pumping liquids containing solid particles. Aier® ZJQ series submersible slurry pump is a kind of hydraulic machinery, the motor and the pump of which are coaxially submerged in medium to work. The wet parts of the pump are made from high alloy wear-resistant material, so the pump has good wear resistance and large flowing passage. It is applicable for conveying medium such as sand, sludge, ore slurry, coal slurry, sand, stones containing big solid particles. It with wide range of applications in the industrial fields.

As one of the manufacturers of robust submersible pumps, Aier® is a market leader in terms of product quality. We have a full range of high quality submersible slurry pumps for dewatering, de-friction, abrasive media with high solids content (e.g. sand) in quarries and mining. The user-friendly design and ease of use of heavy submersible mortar pumps make them the first choice for submersible pumps.

Heavy-duty submersible slurry pombi zvirevo

1. Kukura: 50-400mm

2. Kukwanisa: 10-2000m3 / h

3. Musoro: 8-80m

4. Max.particles: 60mm

5. Temperature Range: ≤80°C

6. Zvishandiso: High chrome alloy, Cast iron, SS304, SS316L nezvimwe.

ZJQ submersible slurry pombi maficha

1. Vertical, centrifugal, submersible pombi design.

2. Kunze kwechinhu chikuru chinopenesa, pane chinokonzeresa chinozunguza icho chinogona kubvongodza matope akaiswa pasi pemvura mukuyerera kune nyonganyonga uye kupomba matope kunze.

3. The wet parts such as the impeller and the agitation impeller are made from high-hardness high chromium cast steel, have kupfeka kuramba, corrosion resistance uye simba remvura rakasimba, uye bvumira zvidimbu zvakakura zvakasimba kuti zvipfuure.

4. Motokari inonyudzwa mumvura, haigumiri nekusvetwa sitiroko, uye ine high sludge kusveta rate uye kunyatsobvisa.

5. Chishandiso chakabatanidzwa chinorerutswa, hachidi chigadziriso chekubatsira kana ejector mudziyo, uye chine nyore uye chiri nyore kushanda uye kuderera kwekudyara kweyuniti.

6. Ipeller yenyonganiso inoswedera pedyo nedepositional surface, uye inodzora kusungirira kuburikidza nekudzika kwakadzika. Pasi pemamiriro ehukuru hwepakati chikamu, mudziyo wekubatsira unogona kurongeka kuti uwedzere kuwanda kwepakati.

7. Yakasiyana-siyana parameter configurations slurry pombi anogona customized.

8. Reliable and long-lasting, the highest quality construction and materials ensure long service life.

Nzira yekusarudza pombi yakakodzera slurry?

The following can help you understand the pump specifications so that you need to take into account the size, strength, volume, and routine of the submersible pump. If you don't understand anything, you can target="_blank">contact us, we will have a professionals to solve it.

1. Saizi

2. Simba

3. Inzwi

4. Musoro nezvimwe.

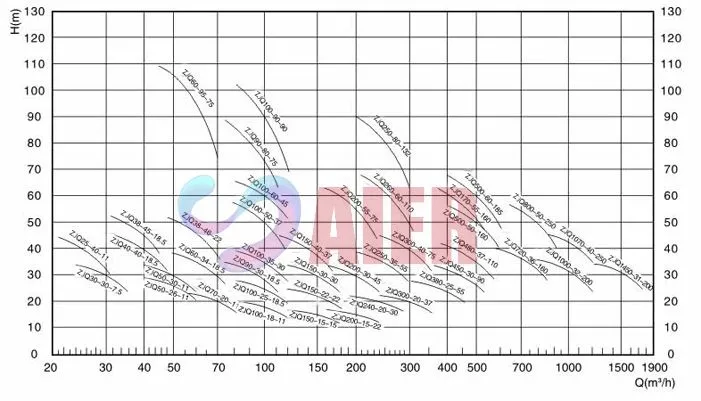

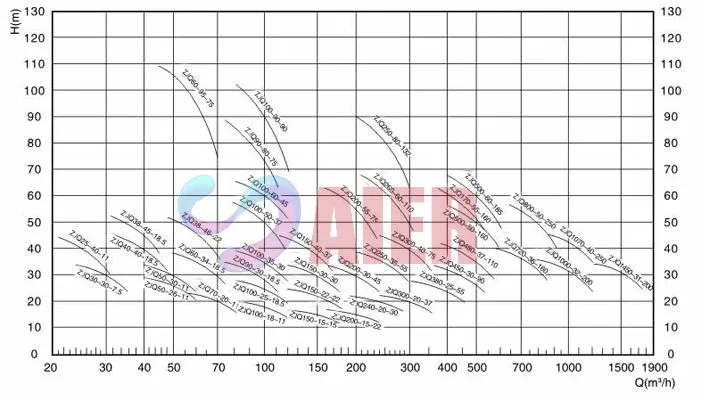

Performance Chart

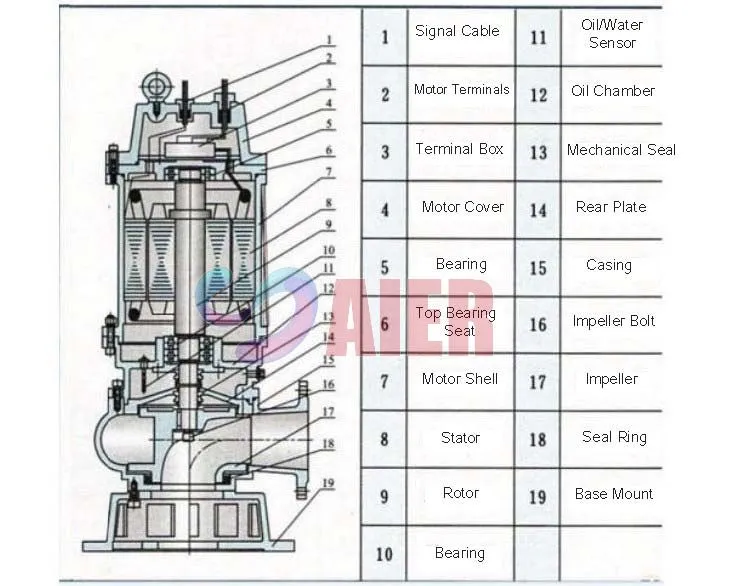

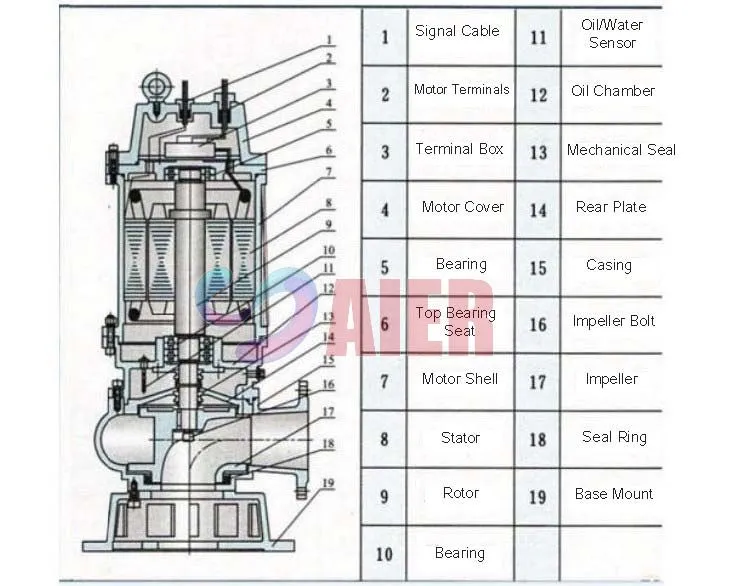

Dhiagiramu yekuvaka

Performance Parameters

| Aier® ZJQ Submersible Slurry Pumps Performance Parameters: | |||||||||

| Aihwa. | Model | Saizi (mm) | Kukwanisa Q (m3/h) | Musoro H (m) | Simba P (kw) | Eff. η (%) | Speed n (r/min) | Max. zvidimbu (mm) | Huremu (kg) |

| 1 | 50ZJQ10-20-3 | 50 | 10 | 20 | 3 | 37 | 1460 | 8 | 110 |

| 2 | 50ZJQ15-18-3 | 50 | 15 | 18 | 3 | 46 | 1460 | 8 | 110 |

| 3 | 50ZJQ20-15-3 | 50 | 20 | 15 | 3 | 52 | 1460 | 8 | 110 |

| 4 | 50ZJQ25-12-3 | 50 | 25 | 12 | 3 | 58 | 1460 | 8 | 110 |

| 5 | 65ZJQ30-12-3 | 65 | 30 | 12 | 3 | 60 | 1460 | 8 | 110 |

| 6 | 65ZJQ35-10-3 | 65 | 35 | 10 | 3 | 64 | 1460 | 8 | 110 |

| 7 | 65ZJQ40-8-3 | 65 | 40 | 8 | 3 | 66 | 1460 | 8 | 110 |

| 8 | 50ZJQ15-22-4 | 50 | 15 | 22 | 4 | 43 | 1460 | 10 | 113 |

| 9 | 50ZJQ18-20-4 | 50 | 18 | 20 | 4 | 46 | 1460 | 10 | 113 |

| 10 | 50ZJQ20-18-4 | 50 | 20 | 18 | 4 | 50 | 1460 | 10 | 113 |

| 11 | 50ZJQ25-20-4 | 50 | 25 | 20 | 4 | 52 | 1460 | 10 | 113 |

| 12 | 65ZJQ30-16-4 | 65 | 30 | 16 | 4 | 52 | 1460 | 10 | 113 |

| 13 | 65ZJQ35-15-4 | 65 | 35 | 15 | 4 | 60 | 1460 | 10 | 113 |

| 14 | 65ZJQ40-12-4 | 65 | 40 | 12 | 4 | 63 | 1460 | 10 | 113 |

| 15 | 65ZJQ45-10-4 | 65 | 45 | 10 | 4 | 66 | 1460 | 10 | 113 |

| 16 | 80ZJQ20-30-5.5 | 80 | 20 | 30 | 5.5 | 42 | 1460 | 13 | 205 |

| 17 | 80ZJQ30-20-5.5 | 80 | 30 | 20 | 5.5 | 54 | 1460 | 13 | 205 |

| 18 | 80ZJQ45-15-5.5 | 80 | 45 | 15 | 5.5 | 41 | 1460 | 13 | 205 |

| 19 | 80ZJQ15-20-5.5 | 80 | 15 | 20 | 5.5 | 33 | 1460 | 13 | 205 |

| 20 | 80ZJQ50-10-5.5 | 80 | 50 | 10 | 5.5 | 44 | 1460 | 13 | 205 |

| 21 | 80ZJQ15-20-7.5 | 80 | 15 | 20 | 7.5 | 34 | 1460 | 13 | 210 |

| 22 | 80ZJQ20-25-7.5 | 80 | 20 | 25 | 7.5 | 35 | 1460 | 13 | 210 |

| 23 | 80ZJQ25-20-7.5 | 80 | 25 | 20 | 7.5 | 36 | 1460 | 13 | 210 |

| 24 | 80ZJQ25-30-7.5 | 80 | 25 | 30 | 7.5 | 36 | 1460 | 13 | 210 |

| 25 | 80ZJQ30-30-7.5 | 80 | 30 | 30 | 7.5 | 37 | 1460 | 13 | 210 |

| 26 | 80ZJQ32-20-7.5 | 80 | 32 | 20 | 7.5 | 37 | 1460 | 13 | 210 |

| 27 | 80ZJQ45-15-7.5 | 80 | 45 | 15 | 7.5 | 41 | 1460 | 13 | 210 |

| 28 | 100ZJQ100-10-7.5 | 100 | 100 | 10 | 7.5 | 48 | 1460 | 21 | 220 |

| 29 | 80ZJQ25-40-11 | 80 | 25 | 40 | 11 | 36 | 1460 | 13 | 300 |

| 30 | 80ZJQ40-25-11 | 80 | 40 | 25 | 11 | 38 | 1460 | 13 | 240 |

| 31 | 80ZJQ50-21-11 | 80 | 50 | 21 | 11 | 40 | 1460 | 13 | 240 |

| 32 | 80ZJQ50-26-11 | 80 | 50 | 26 | 11 | 40 | 1460 | 13 | 240 |

| 33 | 80ZJQ70-20-11 | 80 | 70 | 20 | 11 | 43 | 1460 | 13 | 240 |

| 34 | 100ZJQ100-18-11 | 100 | 100 | 18 | 11 | 48 | 1460 | 21 | 240 |

| 35 | 80ZJQ25-40-15 | 80 | 25 | 40 | 15 | 37 | 1460 | 13 | 330 |

| 36 | 80ZJQ50-26-15 | 80 | 50 | 26 | 15 | 40 | 1460 | 13 | 260 |

| 37 | 80ZJQ50-28-15 | 80 | 50 | 28 | 15 | 40 | 1460 | 13 | 260 |

| 38 | 100ZJQ60-30-15 | 100 | 60 | 30 | 15 | 41 | 1460 | 13 | 265 |

| 39 | 80ZJQ70-24-15 | 80 | 70 | 24 | 15 | 42 | 1460 | 13 | 260 |

| 40 | 100ZJQ75-25-15 | 100 | 75 | 25 | 15 | 43 | 1460 | 13 | 260 |

| 41 | 100ZJQ100-18-15 | 100 | 100 | 18 | 15 | 49 | 1460 | 21 | 270 |

| 42 | 100ZJQ150-15-15 | 100 | 150 | 15 | 15 | 51 | 1460 | 21 | 270 |

| 43 | 150ZJQ150-18-18.5 | 150 | 150 | 18 | 18.5 | 49 | 980 | 32 | 550 |

| 44 | 150ZJQ200-12-18.5 | 150 | 200 | 12 | 18.5 | 53 | 980 | 45 | 550 |

| 45 | 150ZJQ150-22-22 | 150 | 150 | 22 | 22 | 47 | 980 | 32 | 600 |

| 46 | 150ZJQ200-15-22 | 150 | 200 | 15 | 22 | 50 | 980 | 45 | 600 |

| 47 | 150ZJQ60-46-30 | 150 | 60 | 46 | 30 | 41 | 980 | 14 | 550 |

| 48 | 150ZJQ70-38-30 | 150 | 70 | 38 | 30 | 42 | 980 | 21 | 710 |

| 49 | 150ZJQ100-35-30 | 150 | 100 | 35 | 30 | 44 | 980 | 21 | 710 |

| 50 | 150ZJQ108-30-30 | 150 | 108 | 30 | 30 | 44 | 980 | 21 | 710 |

| 51 | 150ZJQ150-30-30 | 150 | 150 | 30 | 30 | 46 | 980 | 21 | 710 |

| 52 | 150ZJQ150-35-30 | 150 | 150 | 35 | 30 | 46 | 980 | 21 | 710 |

| 53 | 150ZJQ200-20-30 | 150 | 200 | 20 | 30 | 52 | 980 | 21 | 710 |

| 54 | 150ZJQ240-20-30 | 150 | 240 | 20 | 30 | 55 | 980 | 21 | 710 |

| 55 | 200ZJQ300-15-30 | 200 | 300 | 15 | 30 | 56 | 980 | 28 | 700 |

| 56 | 150ZJQ100-50-37 | 150 | 100 | 50 | 37 | 44 | 980 | 21 | 850 |

| 57 | 200ZJQ300-20-37 | 200 | 300 | 20 | 37 | 56 | 980 | 28 | 775 |

| 58 | 200ZJQ400-15-37 | 200 | 400 | 15 | 37 | 58 | 980 | 28 | 775 |

| 59 | 150ZJQ150-35-45 | 150 | 150 | 35 | 45 | 47 | 980 | 36 | 1000 |

| 60 | 150ZJQ200-30-45 | 150 | 200 | 30 | 45 | 49 | 980 | 36 | 1110 |

| 61 | 200ZJQ500-15-45 | 200 | 500 | 15 | 45 | 59 | 980 | 46 | 1100 |

| 62 | 150ZJQ150-45-55 | 150 | 150 | 45 | 55 | 46 | 980 | 21 | 1140 |

| 63 | 150ZJQ250-35-55 | 150 | 250 | 35 | 55 | 51 | 980 | 36 | 1140 |

| 64 | 250ZJQ600-15-55 | 250 | 600 | 15 | 55 | 60 | 980 | 46 | 1220 |

| 65 | 150ZJQ200-45-75 | 150 | 200 | 45 | 75 | 49 | 980 | 21 | 1540 |

| 66 | 150ZJQ200-50-75 | 150 | 200 | 50 | 75 | 48 | 980 | 14 | 1550 |

| 67 | 200ZJQ350-35-75 | 200 | 350 | 35 | 75 | 53 | 980 | 28 | 1550 |

| 68 | 200ZJQ400-25-75 | 200 | 400 | 25 | 75 | 58 | 980 | 25 | 1550 |

| 69 | 200ZJQ500-20-75 | 200 | 500 | 20 | 75 | 59 | 980 | 25 | 1550 |

| 70 | 150ZJQ200-60-90 | 150 | 200 | 60 | 90 | 48 | 980 | 14 | 1550 |

| 71 | 200ZJQ400-40-90 | 200 | 400 | 40 | 90 | 54 | 980 | 28 | 1550 |

| 72 | 200ZJQ500-25-90 | 200 | 500 | 25 | 90 | 60 | 980 | 25 | 1550 |

| 73 | 200ZJQ400-50-110 | 200 | 400 | 50 | 110 | 53 | 980 | 28 | 1970 |

| 74 | 250ZJQ600-30-110 | 250 | 600 | 30 | 110 | 61 | 980 | 28 | 1970 |

| 75 | 300ZJQ780-26-110 | 300 | 780 | 26 | 110 | 62 | 980 | 50 | 1970 |

| 76 | 300ZJQ1000-18-110 | 300 | 1000 | 18 | 110 | 64 | 980 | 50 | 1970 |

| 77 | 200ZJQ400-60-132 | 200 | 400 | 60 | 132 | 53 | 980 | 28 | 2000 |

| 78 | 200ZJQ500-45-132 | 200 | 500 | 45 | 132 | 56 | 980 | 28 | 2000 |

| 79 | 200ZJQ500-55-132 | 200 | 500 | 55 | 132 | 55 | 980 | 28 | 2000 |

| 80 | 300ZJQ800-35-132 | 300 | 800 | 35 | 132 | 63 | 980 | 42 | 2000 |

| 81 | 300ZJQ1000-22-132 | 300 | 1000 | 22 | 132 | 64 | 980 | 50 | 2000 |

| 82 | 200ZJQ650-52-160 | 200 | 650 | 52 | 160 | 58 | 980 | 28 | 2650 |

| 83 | 300ZJQ780-50-185 | 300 | 780 | 50 | 185 | 60 | 980 | 38 | 3330 |

| 84 | 250ZJQ600-55-200 | 250 | 600 | 55 | 200 | 62 | 980 | 28 | 4080 |

| 85 | 300ZJQ800-55-220 | 300 | 800 | 55 | 220 | 60 | 980 | 38 | 3400 |

| 86 | 350ZJQ1250-35-220 | 350 | 1250 | 35 | 220 | 65 | 980 | 45 | 3400 |

| 87 | 350ZJQ1750-30-250 | 350 | 1750 | 30 | 250 | 70 | 980 | 55 | 3750 |

| 88 | 350ZJQ1500-35-250 | 350 | 1500 | 35 | 250 | 70 | 980 | 50 | 3750 |

| 89 | 350ZJQ1750-40-315 | 350 | 1750 | 40 | 315 | 70 | 980 | 55 | 4200 |

| 90 | 400ZJQ2000-35-315 | 400 | 2000 | 35 | 315 | 72 | 980 | 60 | 3800 |

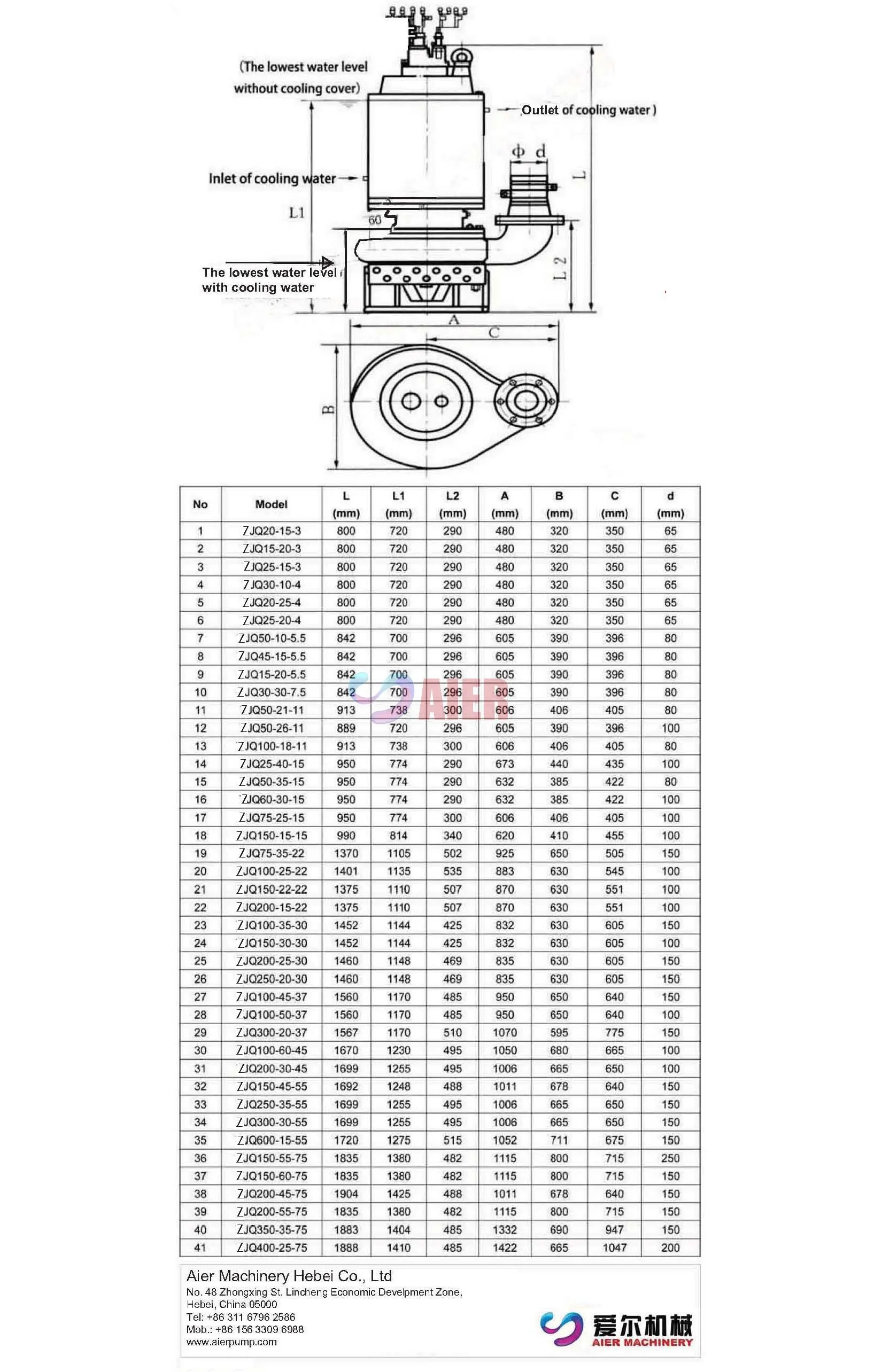

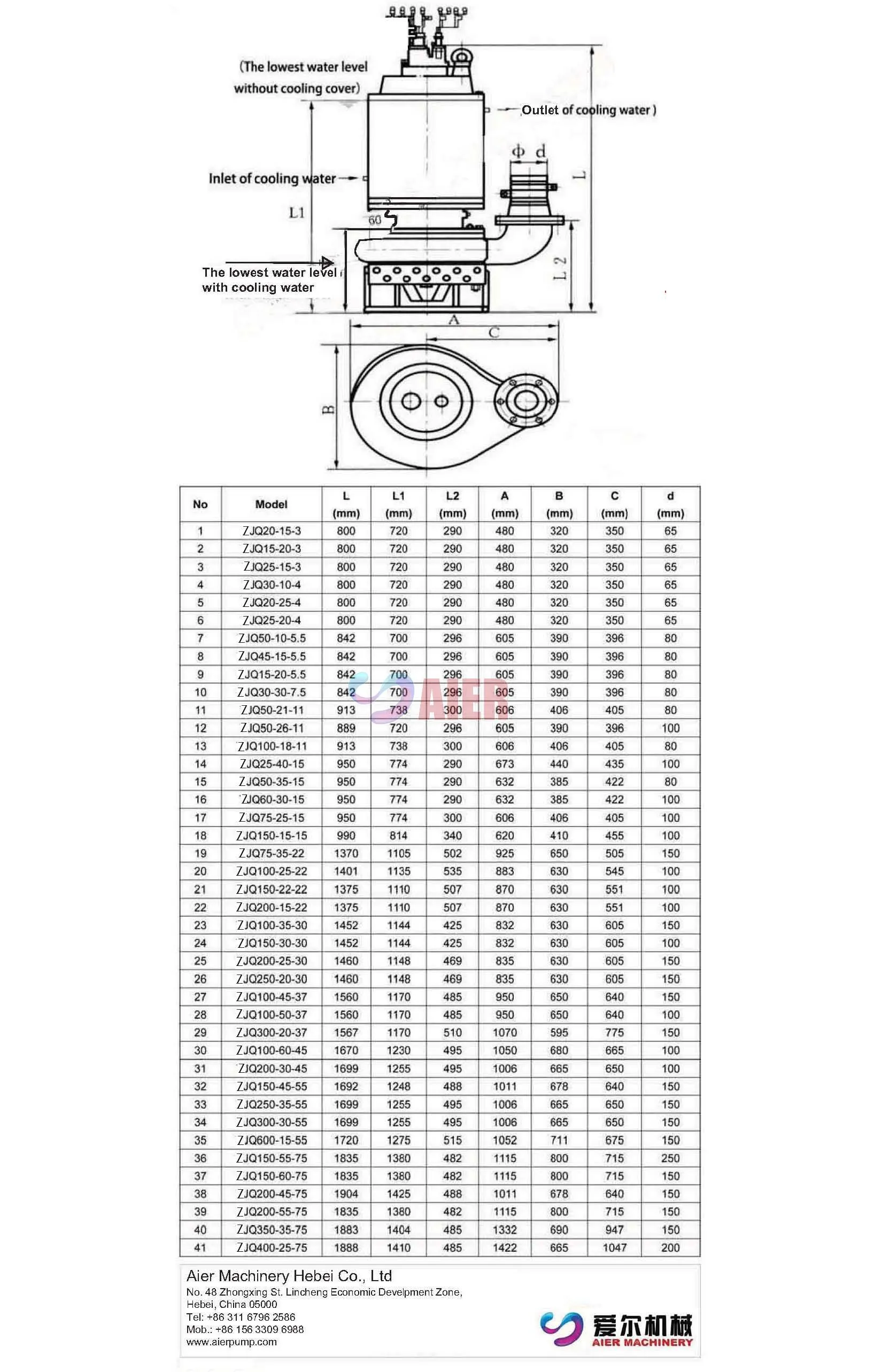

Rondedzera Dimensions