ZJQ dompelpompe

Produk Beskrywing

Aier® Submersible Slurry Pumps

The submersible slurry pump is a pump designed for pumping liquids containing solid particles. Aier® ZJQ series submersible slurry pump is a kind of hydraulic machinery, the motor and the pump of which are coaxially submerged in medium to work. The wet parts of the pump are made from high alloy wear-resistant material, so the pump has good wear resistance and large flowing passage. It is applicable for conveying medium such as sand, sludge, ore slurry, coal slurry, sand, stones containing big solid particles. It with wide range of applications in the industrial fields.

As one of the manufacturers of robust submersible pumps, Aier® is a market leader in terms of product quality. We have a full range of high quality submersible slurry pumps for dewatering, de-friction, abrasive media with high solids content (e.g. sand) in quarries and mining. The user-friendly design and ease of use of heavy submersible mortar pumps make them the first choice for submersible pumps.

Spesifikasies vir swaardiens dompel-slibpomp

1. Grootte: 50-400mm

2. Kapasiteit: 10-2000m3/h

3. Kop: 8-80m

4. Maks.deeltjies: 60mm

5. Temperature Range: ≤80°C

6. Materiale: Hoë chroom legering, Gietyster, SS304, SS316L ens.

Kenmerke van ZJQ-dompelpompe

1. Vertikale, sentrifugale, dompelpompontwerp.

2. Benewens die hoofwaaier, is daar die roerwaaier wat die slyk wat op die waterbodem neergelê is in turbulente vloei kan laat roer en die slyk uitpomp.

3. The wet parts such as the impeller and the agitation impeller are made from high-hardness high chromium cast steel, have dra weerstand, weerstand teen korrosie en sterk dreineringsvermoë, en laat groot vaste deeltjies deur.

4. Die motor is ondergedompel in water, word nie deur suigslag beperk nie, en het 'n hoë slyksuigtempo en deeglike ontsuiling.

5. Die integrale toestel is vereenvoudig, het geen hulproertoestel of uitwerptoestel nodig nie, en het 'n eenvoudige en gerieflike werking en 'n lae totale belegging van die eenheid.

6. Die roerwaaier nader die afsettingsoppervlak direk en beheer die konsentrasie deur onderwater diepte. Onder die toestand van 'n groot medium proporsie, kan 'n hulptoestel gereël word om die konsentrasie van die medium te verhoog.

7. Verskeie parameterkonfigurasies van mispompe kan aangepas word.

8. Reliable and long-lasting, the highest quality construction and materials ensure long service life.

Hoe om 'n geskikte mispomp te kies?

The following can help you understand the pump specifications so that you need to take into account the size, strength, volume, and routine of the submersible pump. If you don't understand anything, you can target="_blank">contact us, we will have a professionals to solve it.

1. Grootte

2. Krag

3. Volume

4. Kop ens.

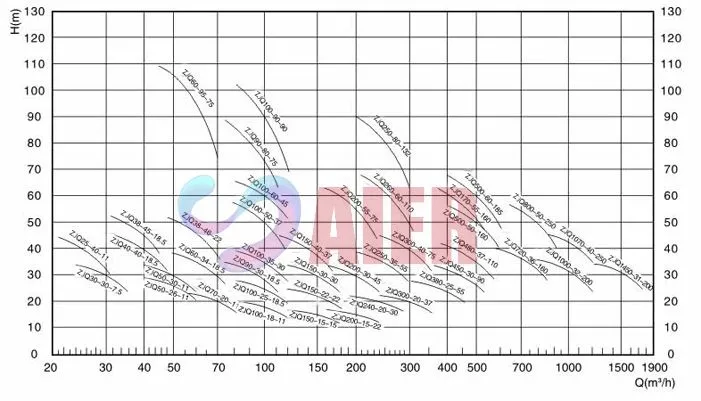

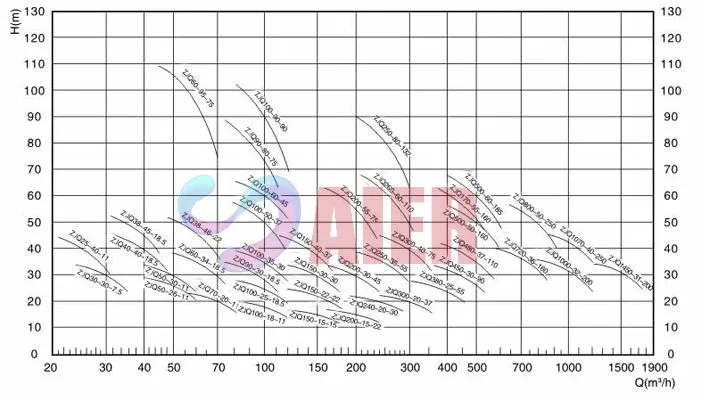

Prestasie grafiek

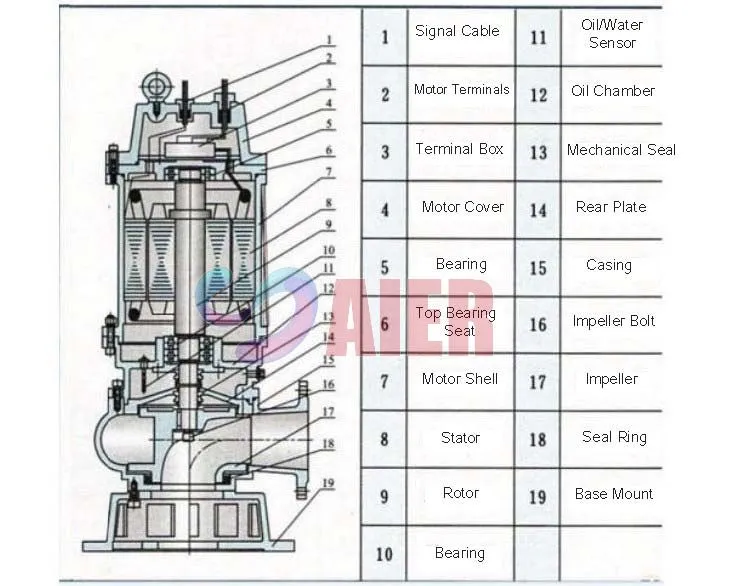

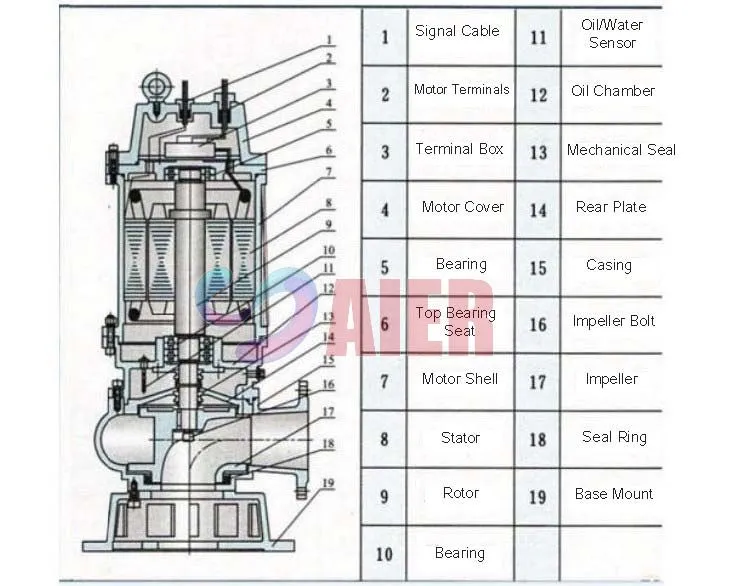

Konstruksiediagram

Prestasieparameters

| Aier® ZJQ Submersible Slurry Pumps Performance Parameters: | |||||||||

| Geen. | Model | Grootte (mm) | Kapasiteit Q (m3/h) | Kop H (m) | Drywing P (kw) | Eff. η (%) | Spoed n (r/min) | Maks. deeltjies (mm) | Gewig (kg) |

| 1 | 50ZJQ10-20-3 | 50 | 10 | 20 | 3 | 37 | 1460 | 8 | 110 |

| 2 | 50ZJQ15-18-3 | 50 | 15 | 18 | 3 | 46 | 1460 | 8 | 110 |

| 3 | 50ZJQ20-15-3 | 50 | 20 | 15 | 3 | 52 | 1460 | 8 | 110 |

| 4 | 50ZJQ25-12-3 | 50 | 25 | 12 | 3 | 58 | 1460 | 8 | 110 |

| 5 | 65ZJQ30-12-3 | 65 | 30 | 12 | 3 | 60 | 1460 | 8 | 110 |

| 6 | 65ZJQ35-10-3 | 65 | 35 | 10 | 3 | 64 | 1460 | 8 | 110 |

| 7 | 65ZJQ40-8-3 | 65 | 40 | 8 | 3 | 66 | 1460 | 8 | 110 |

| 8 | 50ZJQ15-22-4 | 50 | 15 | 22 | 4 | 43 | 1460 | 10 | 113 |

| 9 | 50ZJQ18-20-4 | 50 | 18 | 20 | 4 | 46 | 1460 | 10 | 113 |

| 10 | 50ZJQ20-18-4 | 50 | 20 | 18 | 4 | 50 | 1460 | 10 | 113 |

| 11 | 50ZJQ25-20-4 | 50 | 25 | 20 | 4 | 52 | 1460 | 10 | 113 |

| 12 | 65ZJQ30-16-4 | 65 | 30 | 16 | 4 | 52 | 1460 | 10 | 113 |

| 13 | 65ZJQ35-15-4 | 65 | 35 | 15 | 4 | 60 | 1460 | 10 | 113 |

| 14 | 65ZJQ40-12-4 | 65 | 40 | 12 | 4 | 63 | 1460 | 10 | 113 |

| 15 | 65ZJQ45-10-4 | 65 | 45 | 10 | 4 | 66 | 1460 | 10 | 113 |

| 16 | 80ZJQ20-30-5.5 | 80 | 20 | 30 | 5.5 | 42 | 1460 | 13 | 205 |

| 17 | 80ZJQ30-20-5.5 | 80 | 30 | 20 | 5.5 | 54 | 1460 | 13 | 205 |

| 18 | 80ZJQ45-15-5.5 | 80 | 45 | 15 | 5.5 | 41 | 1460 | 13 | 205 |

| 19 | 80ZJQ15-20-5.5 | 80 | 15 | 20 | 5.5 | 33 | 1460 | 13 | 205 |

| 20 | 80ZJQ50-10-5.5 | 80 | 50 | 10 | 5.5 | 44 | 1460 | 13 | 205 |

| 21 | 80ZJQ15-20-7.5 | 80 | 15 | 20 | 7.5 | 34 | 1460 | 13 | 210 |

| 22 | 80ZJQ20-25-7.5 | 80 | 20 | 25 | 7.5 | 35 | 1460 | 13 | 210 |

| 23 | 80ZJQ25-20-7.5 | 80 | 25 | 20 | 7.5 | 36 | 1460 | 13 | 210 |

| 24 | 80ZJQ25-30-7.5 | 80 | 25 | 30 | 7.5 | 36 | 1460 | 13 | 210 |

| 25 | 80ZJQ30-30-7.5 | 80 | 30 | 30 | 7.5 | 37 | 1460 | 13 | 210 |

| 26 | 80ZJQ32-20-7.5 | 80 | 32 | 20 | 7.5 | 37 | 1460 | 13 | 210 |

| 27 | 80ZJQ45-15-7.5 | 80 | 45 | 15 | 7.5 | 41 | 1460 | 13 | 210 |

| 28 | 100ZJQ100-10-7.5 | 100 | 100 | 10 | 7.5 | 48 | 1460 | 21 | 220 |

| 29 | 80ZJQ25-40-11 | 80 | 25 | 40 | 11 | 36 | 1460 | 13 | 300 |

| 30 | 80ZJQ40-25-11 | 80 | 40 | 25 | 11 | 38 | 1460 | 13 | 240 |

| 31 | 80ZJQ50-21-11 | 80 | 50 | 21 | 11 | 40 | 1460 | 13 | 240 |

| 32 | 80ZJQ50-26-11 | 80 | 50 | 26 | 11 | 40 | 1460 | 13 | 240 |

| 33 | 80ZJQ70-20-11 | 80 | 70 | 20 | 11 | 43 | 1460 | 13 | 240 |

| 34 | 100ZJQ100-18-11 | 100 | 100 | 18 | 11 | 48 | 1460 | 21 | 240 |

| 35 | 80ZJQ25-40-15 | 80 | 25 | 40 | 15 | 37 | 1460 | 13 | 330 |

| 36 | 80ZJQ50-26-15 | 80 | 50 | 26 | 15 | 40 | 1460 | 13 | 260 |

| 37 | 80ZJQ50-28-15 | 80 | 50 | 28 | 15 | 40 | 1460 | 13 | 260 |

| 38 | 100ZJQ60-30-15 | 100 | 60 | 30 | 15 | 41 | 1460 | 13 | 265 |

| 39 | 80ZJQ70-24-15 | 80 | 70 | 24 | 15 | 42 | 1460 | 13 | 260 |

| 40 | 100ZJQ75-25-15 | 100 | 75 | 25 | 15 | 43 | 1460 | 13 | 260 |

| 41 | 100ZJQ100-18-15 | 100 | 100 | 18 | 15 | 49 | 1460 | 21 | 270 |

| 42 | 100ZJQ150-15-15 | 100 | 150 | 15 | 15 | 51 | 1460 | 21 | 270 |

| 43 | 150ZJQ150-18-18.5 | 150 | 150 | 18 | 18.5 | 49 | 980 | 32 | 550 |

| 44 | 150ZJQ200-12-18.5 | 150 | 200 | 12 | 18.5 | 53 | 980 | 45 | 550 |

| 45 | 150ZJQ150-22-22 | 150 | 150 | 22 | 22 | 47 | 980 | 32 | 600 |

| 46 | 150ZJQ200-15-22 | 150 | 200 | 15 | 22 | 50 | 980 | 45 | 600 |

| 47 | 150ZJQ60-46-30 | 150 | 60 | 46 | 30 | 41 | 980 | 14 | 550 |

| 48 | 150ZJQ70-38-30 | 150 | 70 | 38 | 30 | 42 | 980 | 21 | 710 |

| 49 | 150ZJQ100-35-30 | 150 | 100 | 35 | 30 | 44 | 980 | 21 | 710 |

| 50 | 150ZJQ108-30-30 | 150 | 108 | 30 | 30 | 44 | 980 | 21 | 710 |

| 51 | 150ZJQ150-30-30 | 150 | 150 | 30 | 30 | 46 | 980 | 21 | 710 |

| 52 | 150ZJQ150-35-30 | 150 | 150 | 35 | 30 | 46 | 980 | 21 | 710 |

| 53 | 150ZJQ200-20-30 | 150 | 200 | 20 | 30 | 52 | 980 | 21 | 710 |

| 54 | 150ZJQ240-20-30 | 150 | 240 | 20 | 30 | 55 | 980 | 21 | 710 |

| 55 | 200ZJQ300-15-30 | 200 | 300 | 15 | 30 | 56 | 980 | 28 | 700 |

| 56 | 150ZJQ100-50-37 | 150 | 100 | 50 | 37 | 44 | 980 | 21 | 850 |

| 57 | 200ZJQ300-20-37 | 200 | 300 | 20 | 37 | 56 | 980 | 28 | 775 |

| 58 | 200ZJQ400-15-37 | 200 | 400 | 15 | 37 | 58 | 980 | 28 | 775 |

| 59 | 150ZJQ150-35-45 | 150 | 150 | 35 | 45 | 47 | 980 | 36 | 1000 |

| 60 | 150ZJQ200-30-45 | 150 | 200 | 30 | 45 | 49 | 980 | 36 | 1110 |

| 61 | 200ZJQ500-15-45 | 200 | 500 | 15 | 45 | 59 | 980 | 46 | 1100 |

| 62 | 150ZJQ150-45-55 | 150 | 150 | 45 | 55 | 46 | 980 | 21 | 1140 |

| 63 | 150ZJQ250-35-55 | 150 | 250 | 35 | 55 | 51 | 980 | 36 | 1140 |

| 64 | 250ZJQ600-15-55 | 250 | 600 | 15 | 55 | 60 | 980 | 46 | 1220 |

| 65 | 150ZJQ200-45-75 | 150 | 200 | 45 | 75 | 49 | 980 | 21 | 1540 |

| 66 | 150ZJQ200-50-75 | 150 | 200 | 50 | 75 | 48 | 980 | 14 | 1550 |

| 67 | 200ZJQ350-35-75 | 200 | 350 | 35 | 75 | 53 | 980 | 28 | 1550 |

| 68 | 200ZJQ400-25-75 | 200 | 400 | 25 | 75 | 58 | 980 | 25 | 1550 |

| 69 | 200ZJQ500-20-75 | 200 | 500 | 20 | 75 | 59 | 980 | 25 | 1550 |

| 70 | 150ZJQ200-60-90 | 150 | 200 | 60 | 90 | 48 | 980 | 14 | 1550 |

| 71 | 200ZJQ400-40-90 | 200 | 400 | 40 | 90 | 54 | 980 | 28 | 1550 |

| 72 | 200ZJQ500-25-90 | 200 | 500 | 25 | 90 | 60 | 980 | 25 | 1550 |

| 73 | 200ZJQ400-50-110 | 200 | 400 | 50 | 110 | 53 | 980 | 28 | 1970 |

| 74 | 250ZJQ600-30-110 | 250 | 600 | 30 | 110 | 61 | 980 | 28 | 1970 |

| 75 | 300ZJQ780-26-110 | 300 | 780 | 26 | 110 | 62 | 980 | 50 | 1970 |

| 76 | 300ZJQ1000-18-110 | 300 | 1000 | 18 | 110 | 64 | 980 | 50 | 1970 |

| 77 | 200ZJQ400-60-132 | 200 | 400 | 60 | 132 | 53 | 980 | 28 | 2000 |

| 78 | 200ZJQ500-45-132 | 200 | 500 | 45 | 132 | 56 | 980 | 28 | 2000 |

| 79 | 200ZJQ500-55-132 | 200 | 500 | 55 | 132 | 55 | 980 | 28 | 2000 |

| 80 | 300ZJQ800-35-132 | 300 | 800 | 35 | 132 | 63 | 980 | 42 | 2000 |

| 81 | 300ZJQ1000-22-132 | 300 | 1000 | 22 | 132 | 64 | 980 | 50 | 2000 |

| 82 | 200ZJQ650-52-160 | 200 | 650 | 52 | 160 | 58 | 980 | 28 | 2650 |

| 83 | 300ZJQ780-50-185 | 300 | 780 | 50 | 185 | 60 | 980 | 38 | 3330 |

| 84 | 250ZJQ600-55-200 | 250 | 600 | 55 | 200 | 62 | 980 | 28 | 4080 |

| 85 | 300ZJQ800-55-220 | 300 | 800 | 55 | 220 | 60 | 980 | 38 | 3400 |

| 86 | 350ZJQ1250-35-220 | 350 | 1250 | 35 | 220 | 65 | 980 | 45 | 3400 |

| 87 | 350ZJQ1750-30-250 | 350 | 1750 | 30 | 250 | 70 | 980 | 55 | 3750 |

| 88 | 350ZJQ1500-35-250 | 350 | 1500 | 35 | 250 | 70 | 980 | 50 | 3750 |

| 89 | 350ZJQ1750-40-315 | 350 | 1750 | 40 | 315 | 70 | 980 | 55 | 4200 |

| 90 | 400ZJQ2000-35-315 | 400 | 2000 | 35 | 315 | 72 | 980 | 60 | 3800 |

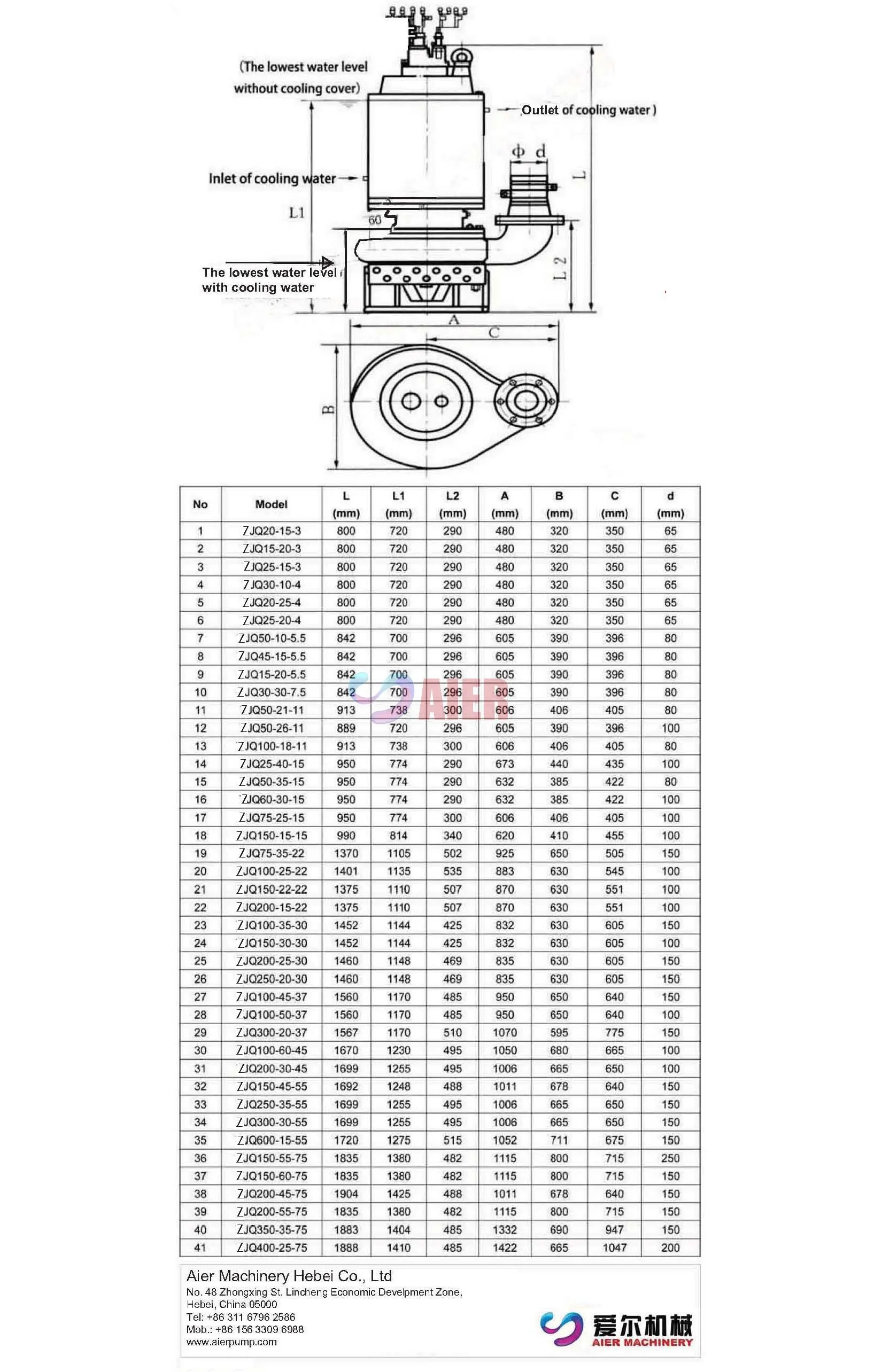

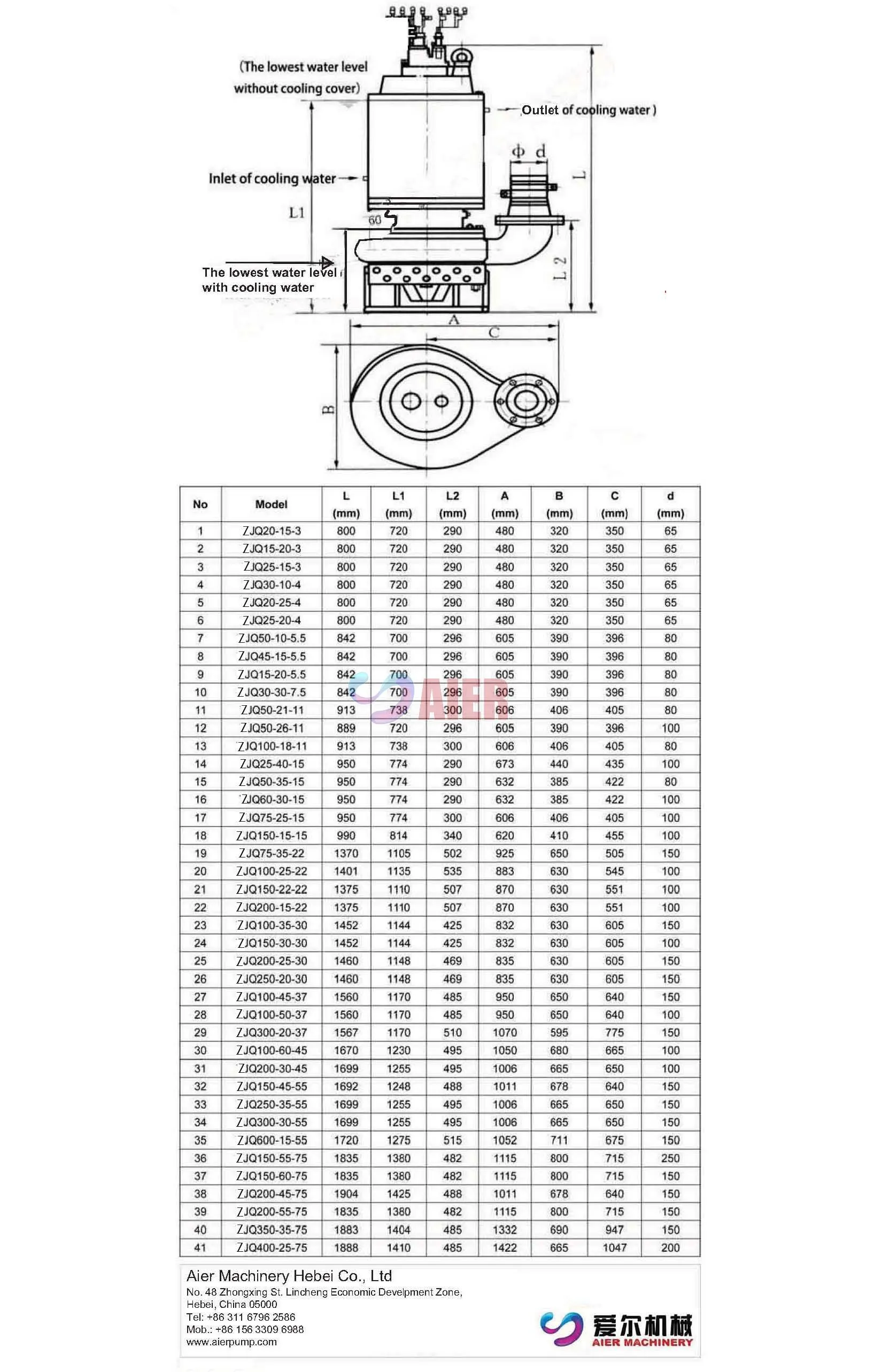

Omlyn afmetings