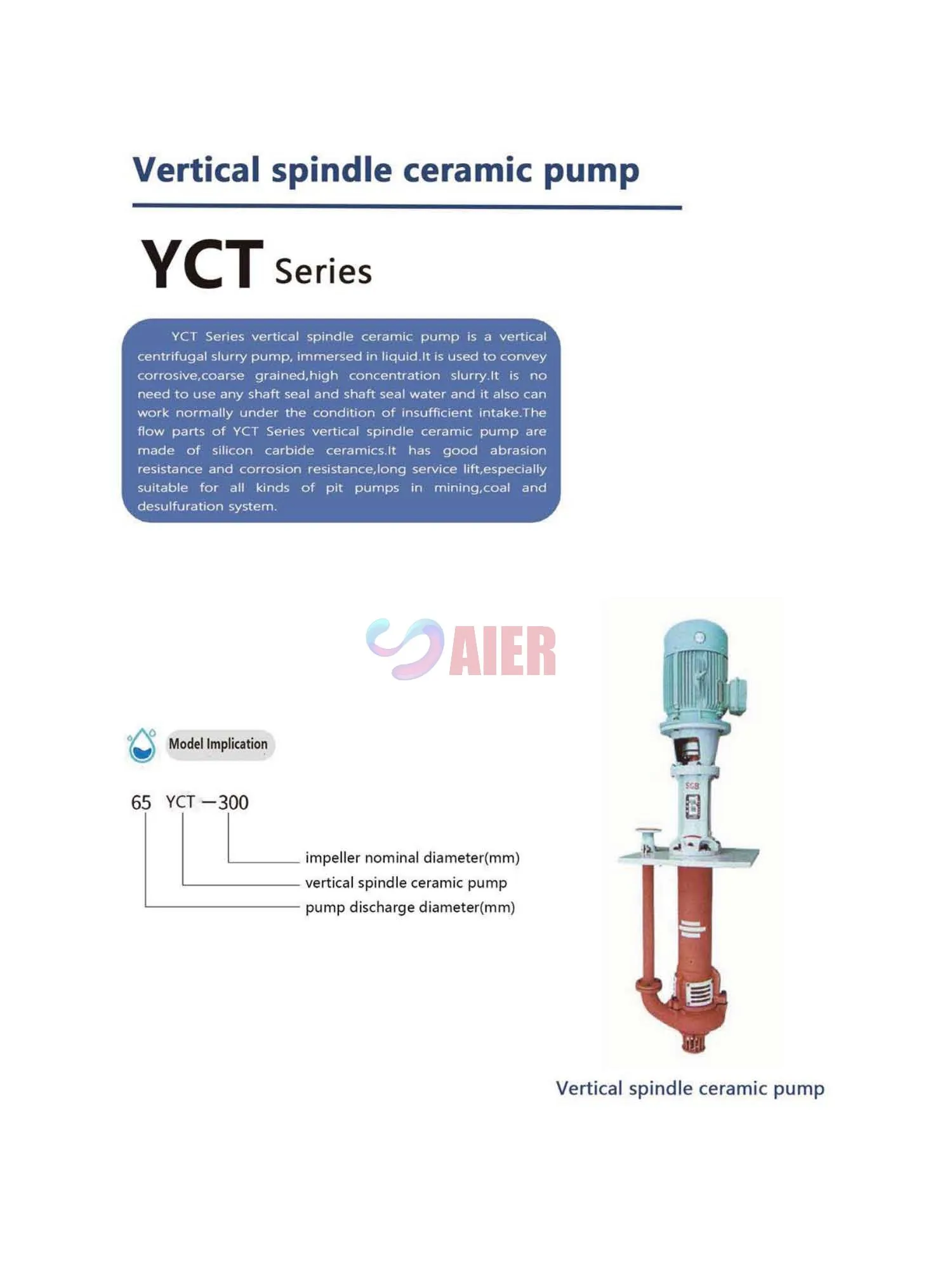

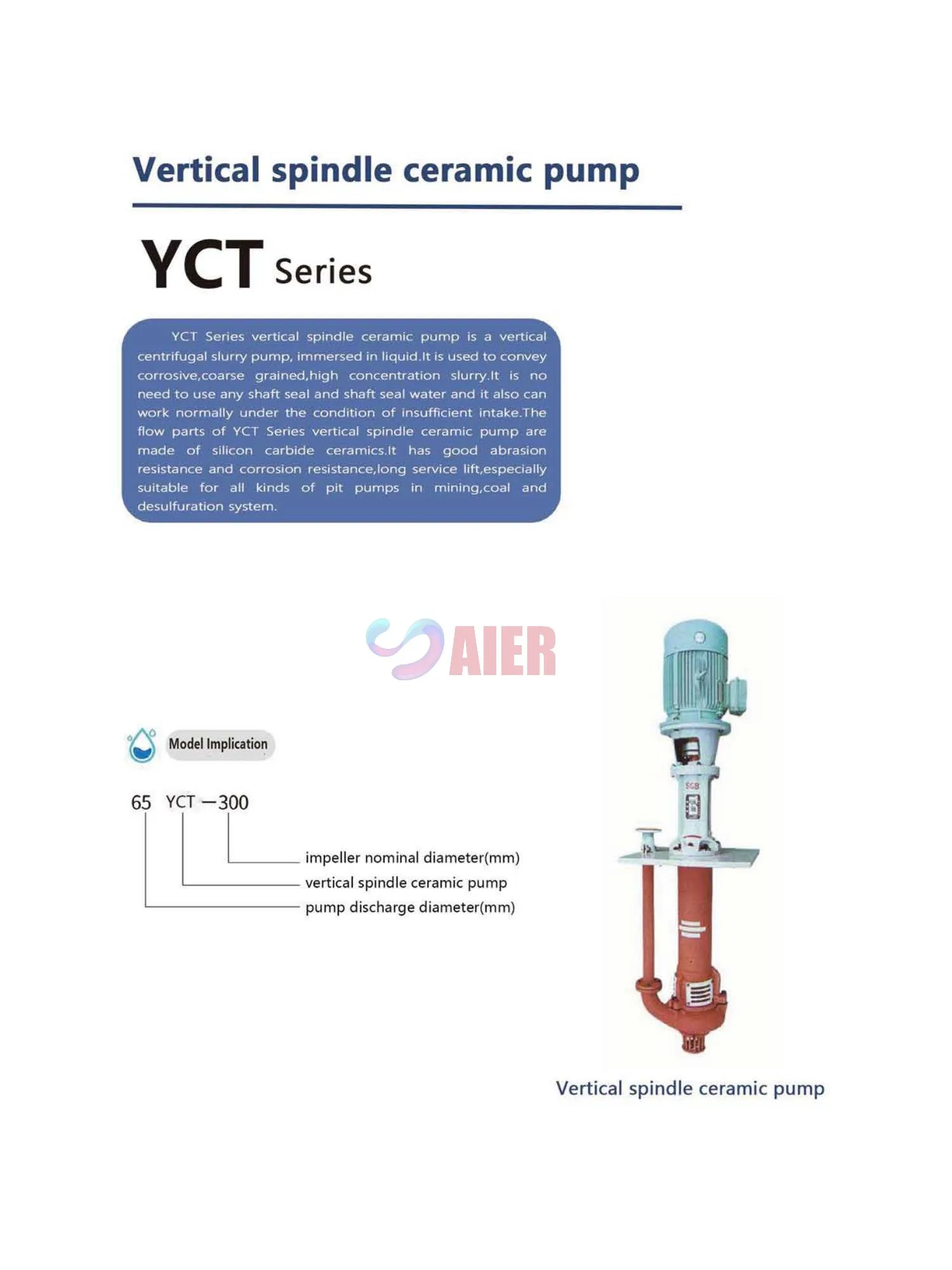

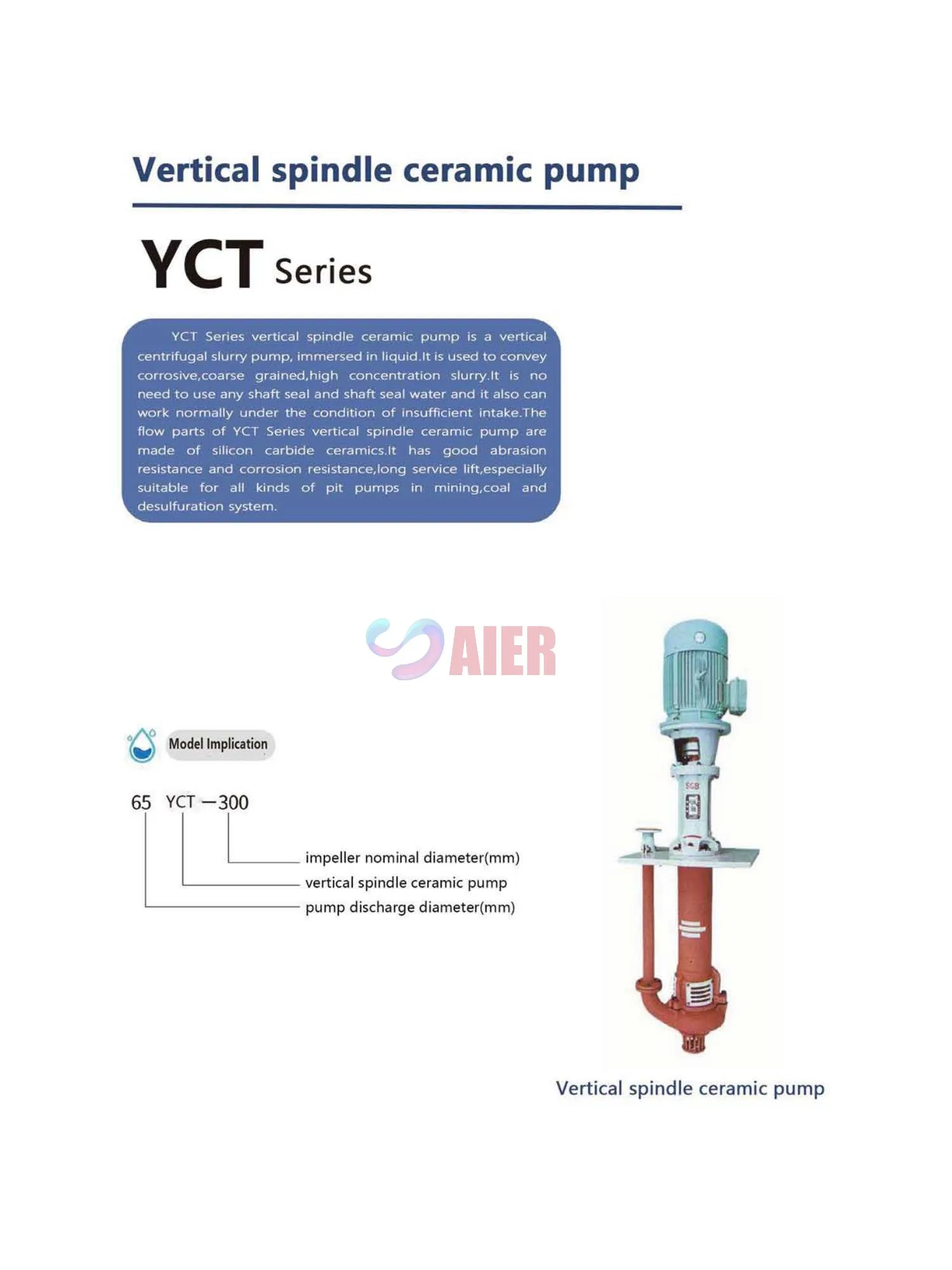

YCT Vertical Spindle Ceramic Pump

Advantages of Ceramic Pumps

SPECIFICATIONS:

Size: 1.5" to 12"

Capacity: 5-1089 m3/h

Head: 2-45 m

Handing solids: 0-70mm

Concentration: 0%-70%

Materials: Ceramic

AIER® YCT Vertical Spindle Ceramic Slurry Pump

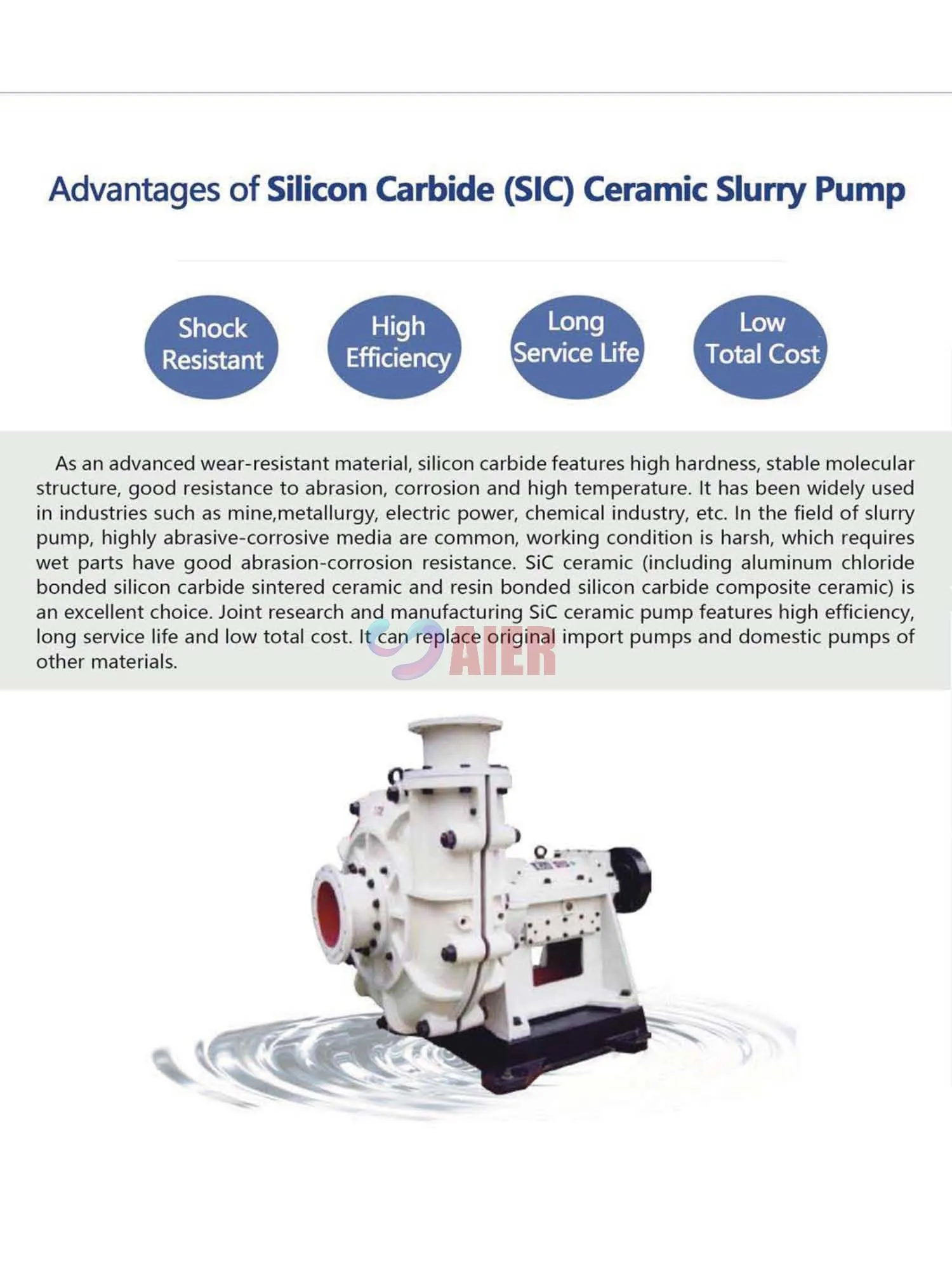

Advantages of Silicon Carbide (SIC) Ceramic Slurry Pump

Shock resistant

High efficiency

Long service time

Low total Cost

As an advanced wear-resistant material, silicon carbide features high hardness, stable molecular structure, good resistance to abrasion, corrosion, and high temperature. It has been widely used in industries such as mining, metallurgy, electric power, chemical industry, etc. In the field of slurry pump, highly abrasive-corrosive media are common, and working condition is adverse, which requires wet parts to have good abrasion-corrosion resistance. SiC ceramic (including aluminum chloride-bonded silicon carbide sintered ceramic and resin-bonded silicon carbide composite ceramic) is an excellent choice. Joint research and manufacturing of SiC ceramic pumps feature high efficiency, long service time and low total cost. It can replace original import pumps and domestic pumps of other materials.

Strong corrosion resistance of SiC

Good chemical stability. Silicon carbide resists most inorganic acids, organic acids, bases and oxidizing media.

Strong wear resistance. The abrasive resistance of silicon carbide is 3 ~ 5 times more than high chrome antiwear steel

Excellent corrosion resistance. Silicon carbide can stand various acids, bases, chemicals except hydrofluoric acid and hot concentrated caustic.

Good impact resistance. Silicon carbide can resist the impact of large particles and steel balls.

Wide range of temperature resistance. Silicon carbide can be used for a long time at -40°C ~ 90°C, up to 110°

Excellent wear resistance of SiC

The crystal structure of silicon carbide is close to the diamond tetrahedron. This compound is linked by strong covalent bonds. The hardness is second only to diamond. According to the contrast experiment conducted by Xi’an Jiaotong University, the wear resistance of silicon carbide is 3.51 times more than Cr30 antiwear steel.

Strong impact resistance of SiC

Application

|

Industry |

Station |

Product |

|

Mineral processing Tailings |

Mill pump, Cyclone feed pump, Tailing pump, Flotation/ concentration pump, Thickener underflow pump, Filer press feed pump |

ACT(ZCT) ceramic pump STP vertical pump |

|

Environment protection Coal power generation Steelmaking Metallurgy |

Desulfurizing slurry-circling pump, Mill slurry pump, Lime seriflux cycling pump, Gypsum discharge pump, Emergency pump, Hydrometallurgy slurry pump |

BCT ceramic pump SCT pump YCT vertical pump |

|

Chemical industry |

Salt chemical engineering, Process pump for highly corrosive chemical minerals |

BCT ceramic pump YCT vertical pump |

Product Description

Features

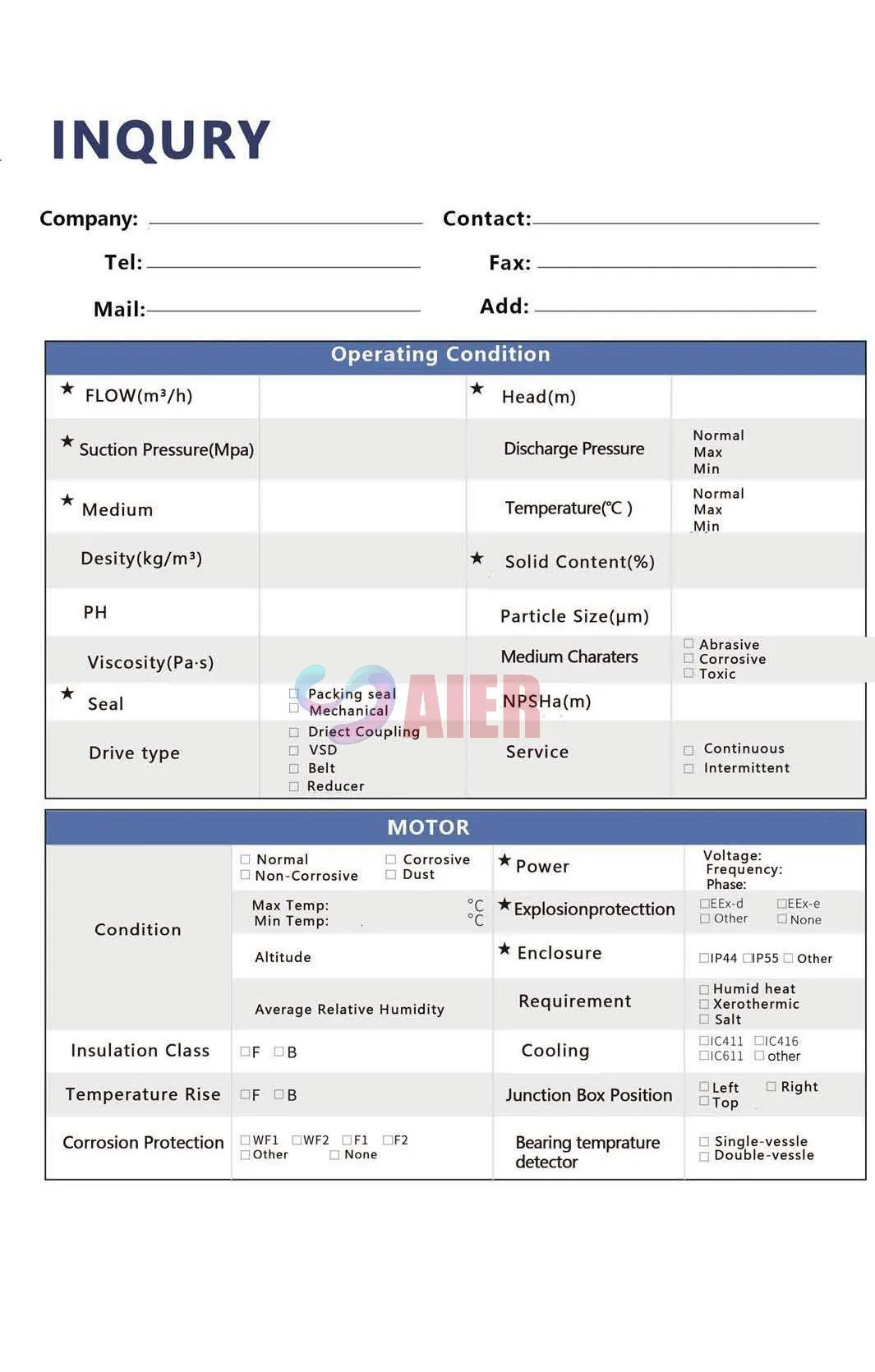

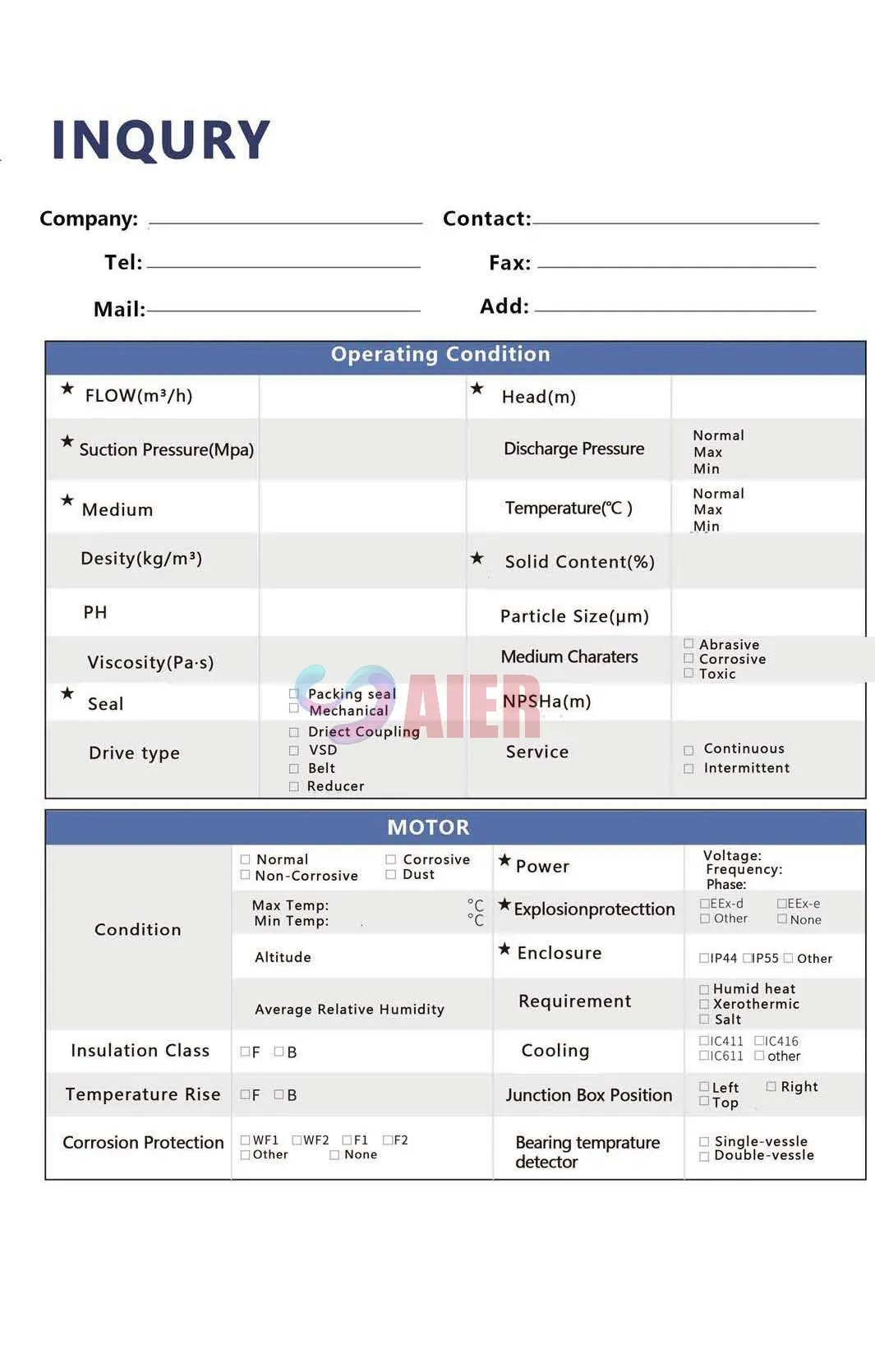

Inquiry Form

How to Choose the Right Ceramic Slurry Pump for Your Project

Selecting the right ceramic slurry pump is a critical step in ensuring efficient and reliable operation in industries that handle abrasive or corrosive slurries. Proper ceramic slurry pump selection involves evaluating several key factors, including slurry flow rate, pump head, particle size, concentration, temperature, and chemical composition. Each of these parameters directly affects the pump’s performance, durability, and energy efficiency.

First, the flow rate and head requirements must match the operational needs of your system. A pump that is too small may not provide sufficient pressure, causing operational inefficiencies, while an oversized pump can lead to energy waste and premature wear. Considering slurry properties is equally important: abrasive slurries with high solid content or sharp particles require thicker ceramic linings and wear-resistant impellers to extend service life. For corrosive fluids, selecting a ceramic lined slurry pump with materials like alumina or zirconia ensures long-term chemical resistance.

Next, pay attention to the ceramic slurry pump size and configuration. The size of the pump affects suction performance, discharge velocity, and the ability to handle large solid particles. Impeller design and material thickness also influence how well the pump resists erosion and maintains efficiency. Many manufacturers, including leading China ceramic slurry pump manufacturers, provide modular designs that allow customization of impellers, liners, and wear parts to suit specific industrial applications.

It is also important to consider operational conditions such as temperature, pH, and slurry viscosity. Pumps operating outside their design parameters may experience accelerated wear, vibration issues, or seal failures. To avoid common selection mistakes, consult technical datasheets and work with reputable ceramic slurry pump suppliers who can provide recommendations based on actual site conditions and slurry characteristics.

Finally, evaluating maintenance accessibility and spare parts availability is essential. Choosing a pump with easily replaceable components ensures minimal downtime and reduces long-term operating costs. The best ceramic slurry pump balances high wear resistance, chemical stability, energy efficiency, and maintainability. By carefully analyzing these factors, companies can select the ideal pump for mining, chemical, metallurgical, or wastewater applications, ensuring reliable and cost-effective performance.

Maintenance Tips to Extend the Life of Ceramic Slurry Pumps

Proper ceramic slurry pump maintenance is essential for prolonging service life and maintaining optimal performance in harsh industrial applications. Despite the exceptional wear resistance of ceramic materials, routine inspections and correct handling of ceramic pump spare parts are crucial to prevent unexpected downtime and costly repairs.

The first step in maintenance is regular visual inspection of critical components, including the impeller, liner, and throat bush. Look for signs of wear, cracking, or erosion, particularly in areas exposed to high-velocity slurry. Using genuine ceramic pump spare parts is critical, as aftermarket components may not match the original tolerances and can compromise the pump’s performance and lifespan.

Lubrication and bearing checks are also essential. Properly lubricated bearings reduce friction, prevent overheating, and minimize vibration. Regularly monitor bearing temperature and alignment to ensure smooth operation. Seal integrity is another key factor—check mechanical seals, gaskets, and packing to avoid leaks that could damage pump internals or cause environmental hazards.

It is also important to operate the pump within its designed performance curve. Running the pump under low flow, dry conditions, or excessive pressure can lead to premature wear or cracking of ceramic components. Slurry characteristics should be consistent with the pump’s design specifications, including particle size, density, and chemical composition. Adjustments to flow rate or slurry concentration may be necessary to optimize performance.

Cleaning and flushing the pump after prolonged operation or when handling corrosive slurries can further extend its service life. Removing sediment buildup prevents clogging and uneven wear. Many China ceramic slurry pump manufacturers provide detailed maintenance manuals and training to assist operators with best practices, ensuring that pumps continue to function efficiently over time.

By following these ceramic slurry pump maintenance practices—inspecting wear parts, using genuine ceramic pump spare parts, monitoring bearings and seals, and maintaining proper operating conditions—industrial operators can maximize ceramic slurry pump service life, reduce operational costs, and ensure safe, reliable slurry transfer in mining, chemical, and metallurgical applications.

Custom Ceramic Slurry Pump Solutions for Mining and Chemical Industries

In demanding industries like mining and chemical processing, standard pumps often fail to meet the specific needs of slurry transportation. This is where a custom ceramic slurry pump becomes essential. By working with a reliable ceramic slurry pump manufacturer, companies can obtain industrial slurry pump solutions tailored to their exact operational conditions, including flow rate, head, slurry density, particle size, and chemical composition. Customization ensures optimal performance, increased reliability, and extended service life, especially in harsh environments.

A key aspect of designing a custom ceramic slurry pump is selecting the appropriate ceramic material for wear parts. High-purity alumina or zirconia is commonly used to enhance abrasion resistance, while precise thickness of the ceramic lining ensures durability against highly abrasive slurries. Impeller design is another critical factor; depending on the flow rate and head, manufacturers can provide closed or semi-open impellers that optimize slurry handling efficiency and reduce turbulence.

In addition to material and design considerations, custom industrial slurry pump solutions often include modifications to suction and discharge diameters, casing shapes, and wear ring arrangements to match existing piping systems or pumping stations. Many china ceramic slurry pump manufacturers now offer modular designs, allowing clients to easily replace wear components without replacing the entire pump. This modularity reduces downtime and simplifies maintenance, which is particularly important in large-scale mining and chemical operations.

Moreover, customized pumps can be adapted for extreme temperatures, highly corrosive liquids, or variable slurry concentrations, providing a versatile solution for diverse industrial applications. Advanced engineering software is used to simulate hydraulic performance, ensuring that each custom ceramic slurry pump meets both efficiency and durability targets before manufacturing.

By leveraging custom ceramic slurry pump solutions, mining and chemical industries can achieve higher reliability, reduced maintenance costs, and longer pump life. These pumps not only handle abrasive and corrosive slurries effectively but also provide consistent operational efficiency, making them a critical component in modern industrial slurry handling systems. Choosing a reputable ceramic slurry pump manufacturer ensures that the customized solution aligns with specific operational requirements and provides long-term value.