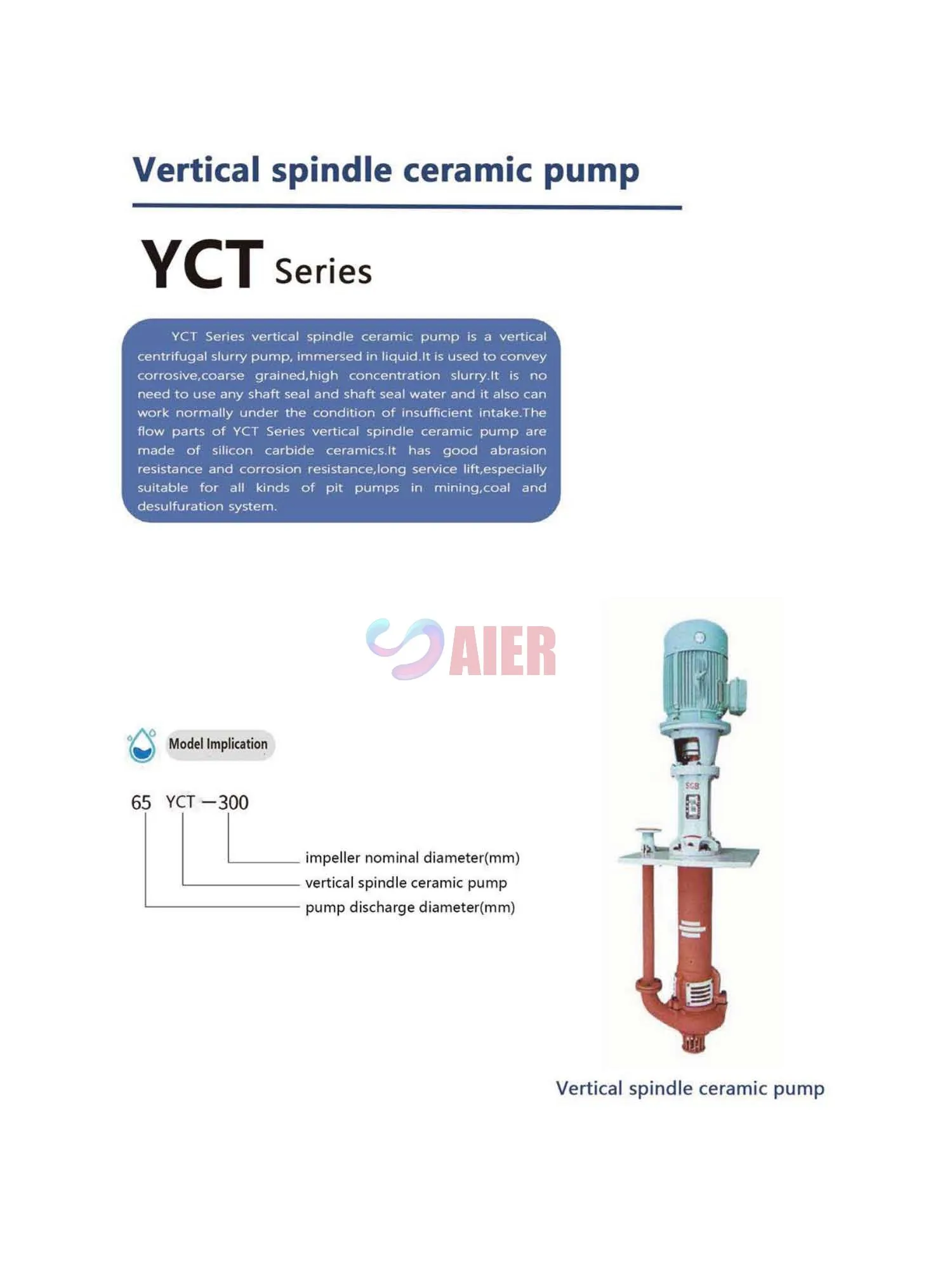

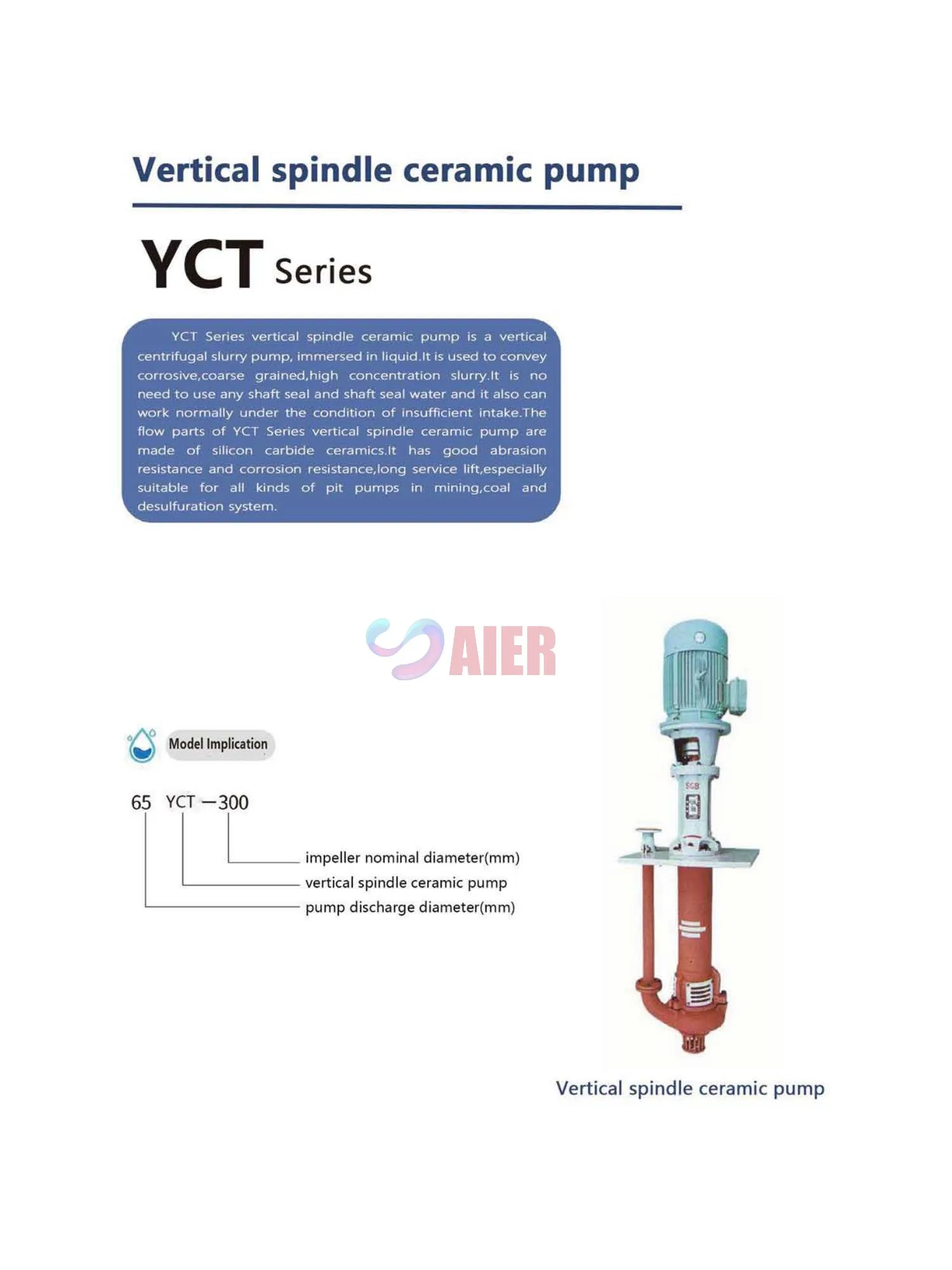

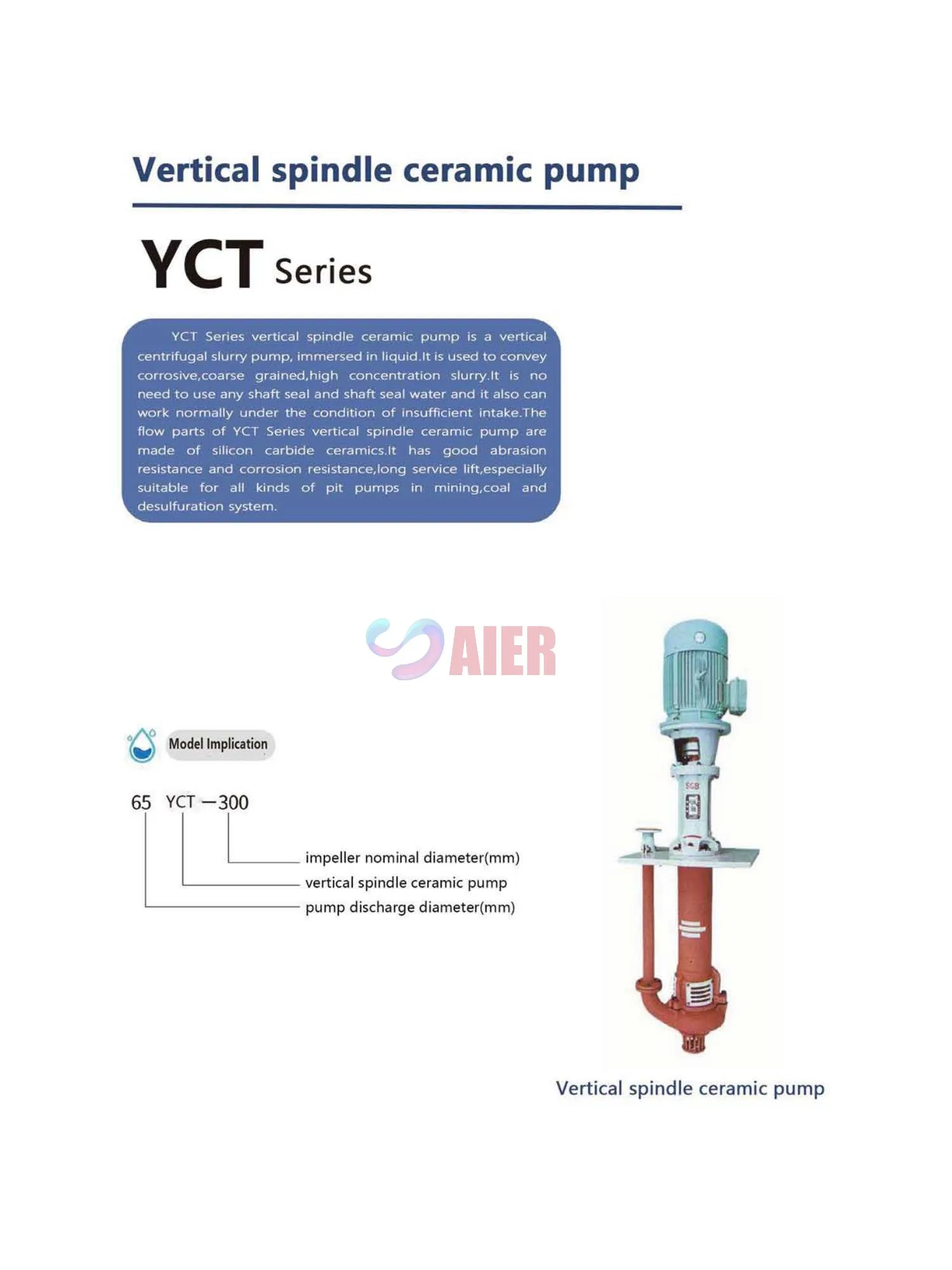

YCT Vertical Spindle Ceramic Pump

Melemo ea lipompo tsa Ceramic

TLHALOSO:

Boholo: 1.5" ho isa ho 12"

Matla: 5-1089 m3 / h

Hlooho: 2-45 m

Lintho tse tiileng tsa letsoho: 0-70mm

Tsepamiso ea maikutlo: 0%-70%

Lintho tse bonahalang: Ceramic

AIRER® YCT Vertical Spindle Ceramic Slurry Pump

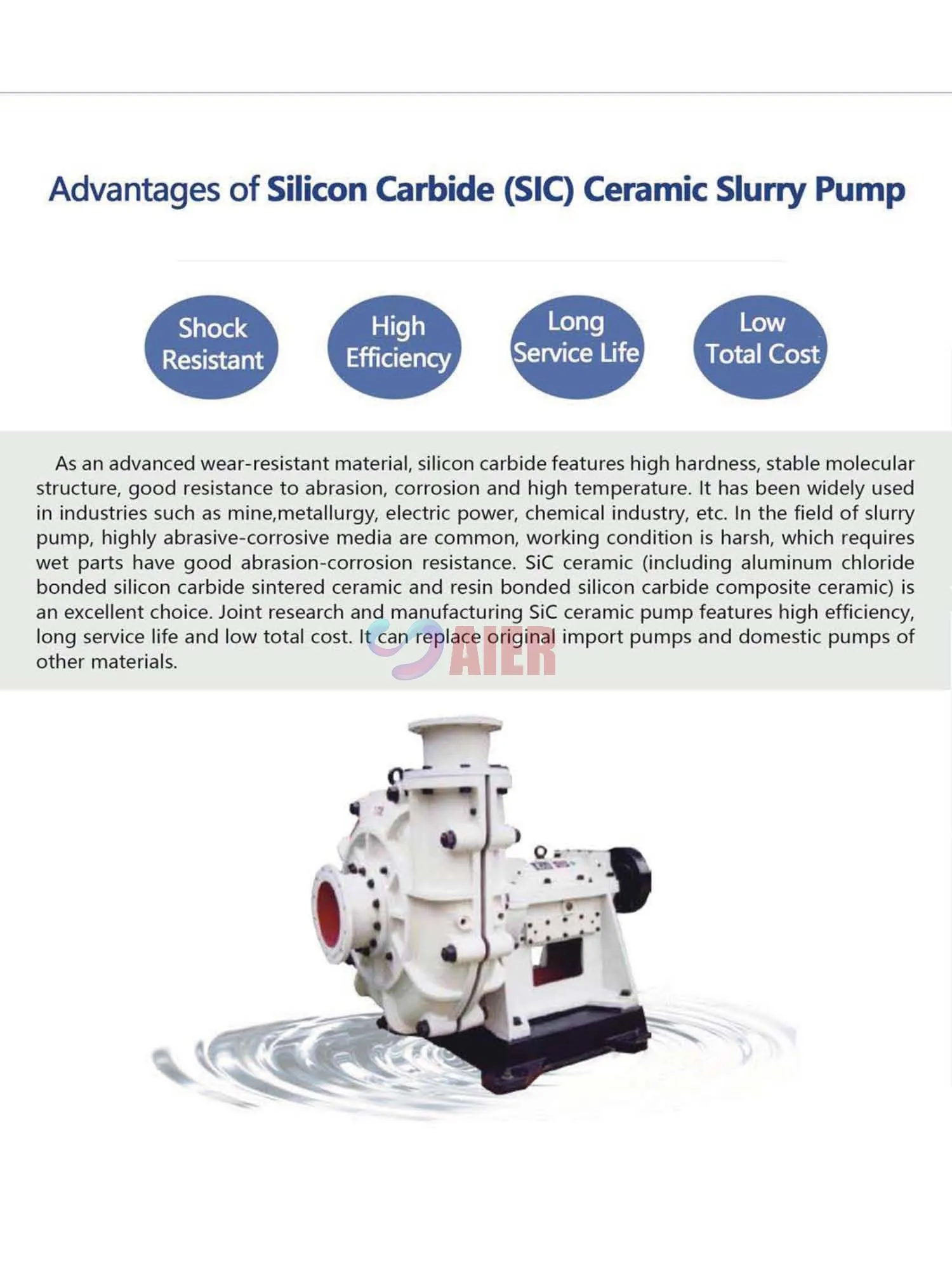

Melemo ea Silicon Carbide (SIC) Ceramic Slurry Pump

E hanana le ho tshoha

Bokgoni bo phahameng

Nako e telele ea tšebeletso

Litšenyehelo tse tlase

E le thepa e tsoetseng pele e sa keneng, silicon carbide e na le boima bo phahameng, sebopeho se tsitsitseng sa limolek'hule, ho hanyetsa ho hoholo, ho senya le mocheso o phahameng. E 'nile ea sebelisoa haholo liindastering tse kang tsa merafo, metallurgy, matla a motlakase, indasteri ea lik'hemik'hale, joalo-joalo Lefapheng la pompo ea slurry, mecha ea litaba e senyang haholo e tloaelehile,' me boemo ba ho sebetsa bo bobe, bo hlokang hore likarolo tse metsi li be le abrasion e ntle. -ho hanyetsa ho bola. SiC ceramic (ho kenyeletsoa aluminium chloride-bonded silicon carbide sintered ceramic le resin-bonded silicon carbide composite ceramic) ke khetho e ntle haholo. Patlisiso e kopaneng le tlhahiso ea lipompo tsa ceramic tsa SiC li na le ts'ebetso e phahameng, nako e telele ea ts'ebeletso le litšenyehelo tse tlase. E ka nka sebaka sa lipompo tsa mantlha tsa kantle ho naha le lipompo tsa lapeng tsa lisebelisoa tse ling.

Khanyetso e matla ea kutu ea SiC

Botsitso bo botle ba lik'hemik'hale. Silicon carbide e hanela boholo ba li-inorganic acid, organic acid, metheo le mecha ea litaba ea oxidizing.

Khanyetso e matla ea ho apara. Khanyetso e matla ea silicon carbide ke makhetlo a 3 ~ 5 ho feta tšepe e phahameng ea antiwear ea chrome

E babatsehang khanyetso ea corrosion. Silicon carbide e ka ema li-acids tse fapaneng, metheo, lik'hemik'hale ntle le hydrofluoric acid le caustic e chesang haholo.

Tšusumetso e ntle ea ho hanyetsa. Silicon carbide e ka hanela tšusumetso ea likaroloana tse kholo le libolo tsa tšepe.

Wide range of temperature resistance. Silicon carbide can be used for a long time at -40°C ~ 90°C, up to 110°

Khahlano e ntle ka ho fetisisa ea SiC

The crystal structure of silicon carbide is close to the diamond tetrahedron. This compound is linked by strong covalent bonds. The hardness is second only to diamond. According to the contrast experiment conducted by Xi’an Jiaotong University, the wear resistance of silicon carbide is 3.51 times more than Cr30 antiwear steel.

Tšusumetso e matla ea ho hanyetsa SiC

Kopo

|

Indasteri |

Seteishene |

Sehlahisoa |

|

Liminerale sebetsa Tailings |

Mill pump, Cyclone feed pump, Tailing pump, Flotation/ concentration pump, Thickener underflow pump, Filer press feed pump |

ACT (ZCT) pompo ea ceramic pompo e emeng ea STP |

|

Tšireletso ea tikoloho Ho fehla matla a mashala Ho etsa tšepe Metallurgy |

Pompe e thibang seretse se pota-potileng, Mill slurry pump, Lime seriflux cycling pump, Gypsum discharge pump, Emergency pump, Hydrometallurgy slurry pump |

Pompo ea ceramic ea BCT pompo ea SCT Pompo e emeng ea YCT |

|

Indasteri ea lik'hemik'hale |

Boenjiniere ba lik'hemik'hale tsa letsoai, Pompo ea ho sebetsa bakeng sa liminerale tsa lik'hemik'hale tse senyang haholo |

Pompo ea ceramic ea BCT Pompo e emeng ea YCT |

Tlhaloso ea Sehlahisoa

Likaroloana

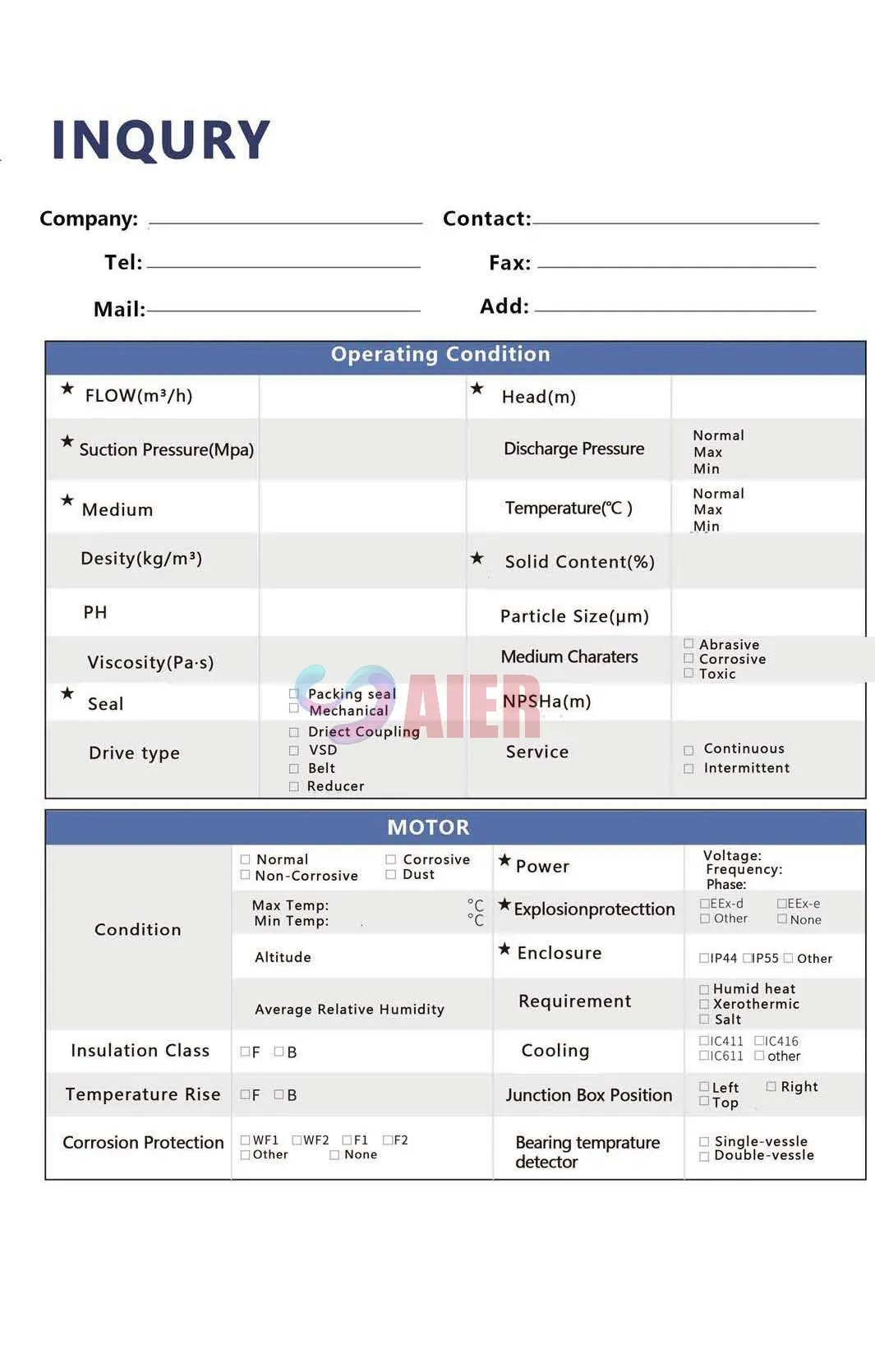

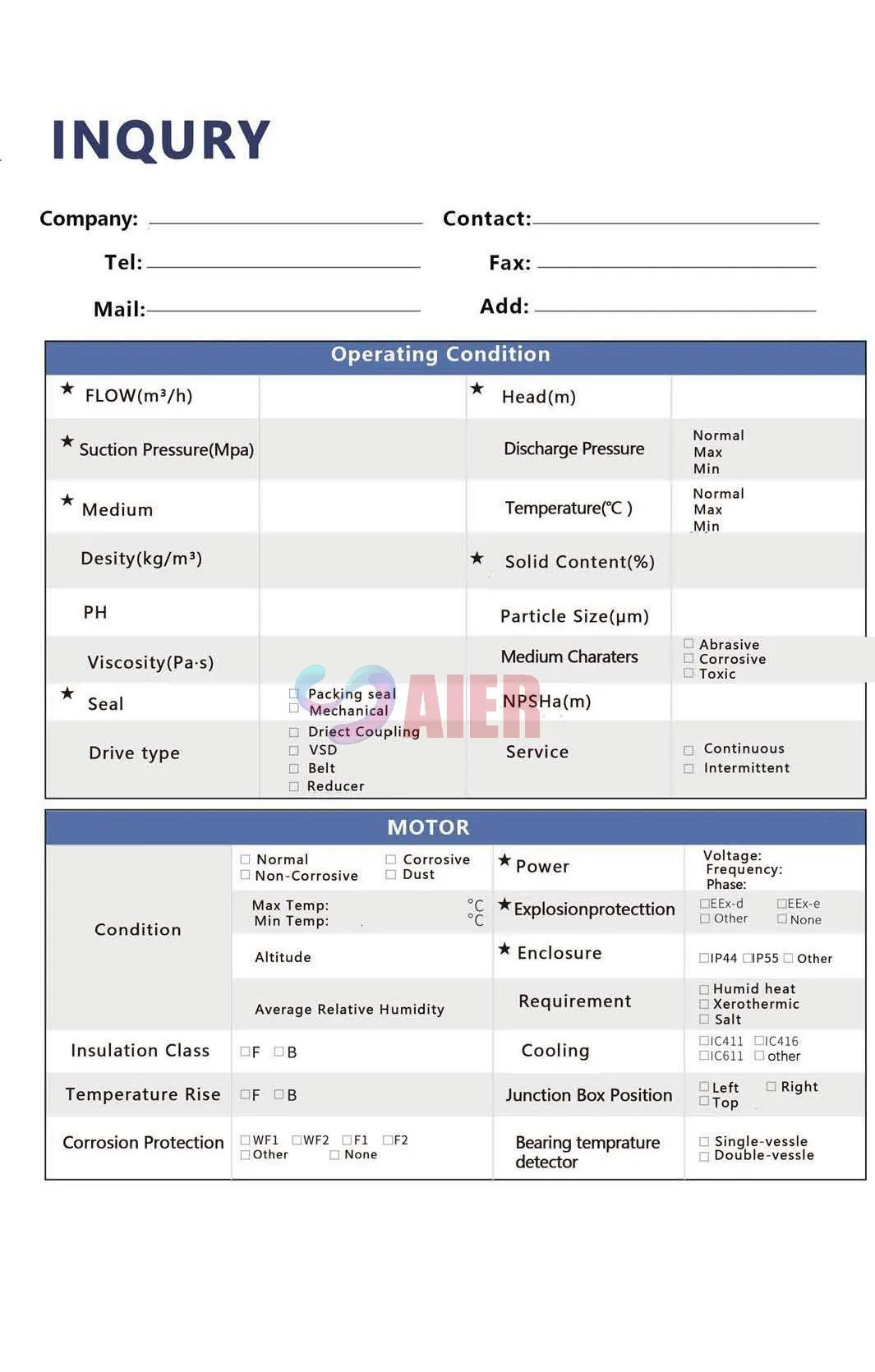

Foromo ea Lipatlisiso