KWP Non-clogging Sewage Pump

Product Description

SPECIFICATIONS:

Pump size: DN 40 to 500 mm

Flow rate: up to 5500m3/h

Discharge head: up to 100m

Fluid temperature: -40 to +120°C

Materials: Cast Iron, Ductile Iron, Cast Steel, Stainless Steel, Duplex Stainless Steel, High Chrome, etc.

AIER® KWP Non-clogging Sewage Pump

General

Series of KWP non-clogging centrifugal pump is a new type high-efficiency, energy-saving non-clogging pump with technology introduced from KSB Co.

KWP non-clogging pump is of no clog sewage pump with specially used for city water supply, sewage and effluent treatment, chemicals, iron & steel industries and paper, sugar & canned food industries.

Features

KWP sewage pump is characterized by high-efficiency, non clogging and back pull-out design which can allow the rotor to be removed from the pump casing without disturbing the piping or dismantling the casing. This not only simplifies maintenance but also allows fast inter change of the impellers and wear plate of suction side, thereby permitting the pump to be rapidly modified to suit different operating conditions.

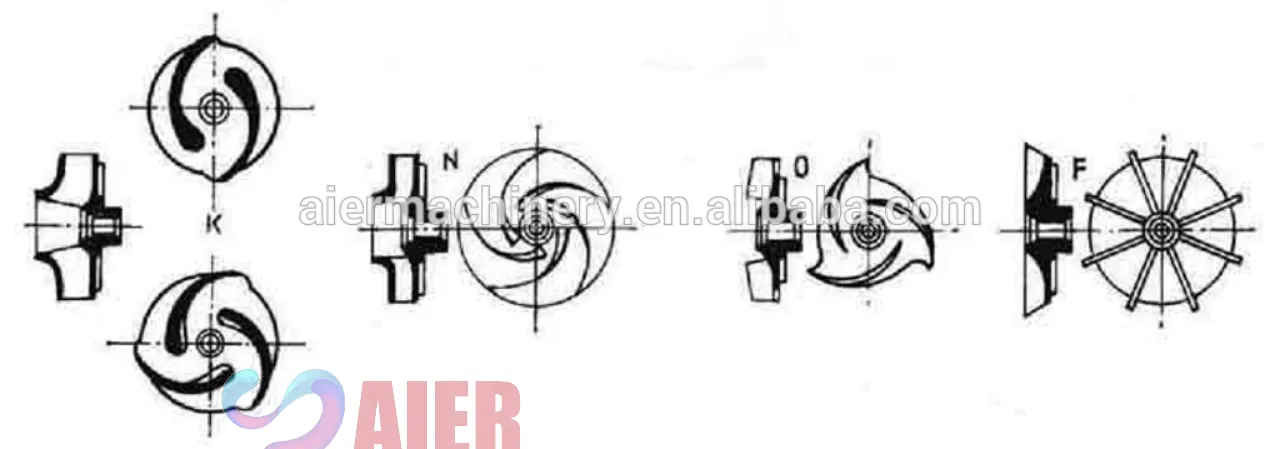

Impeller types of KWP no clog sewage pump

"K" impeller: Closed non-cloge impeller

For clear water, sewage, fluids containing solids and sludge which do not liberate gas.

"N" impeller: Closed multi-vane impeller

For clear water, fluids containing slight suspension such as treated sewage, screen water, pulp water, suger juices, etc.

"O" impeller: Open impeller

Same applications as "N" impeller, but also including fluids containing air.

"F" impeller: Free flow impeller

For fluids containing coarse solids liable to bunch or plait(such as long fiber admixtures, sticky particles, etc.) and fluids containing air.

Applications of KWP no clog sewage pump

They can be applied to city water supply, waterworks, breweries, chemical industry, construction, mining, metallurgy, paper making, sugar producing and canned food industry, particularly applicable to sewage treatment works; meanwhile, some of the impellers are suitable for conveying the object which contains solids or long-fiber non-abrasion solid-liquid mixtures.

They are widely used in the lossless transportations of fruits, potatoes, sugar beet, fish, grains and other food.

Type KWP pump normally is suitable for delivering the neutal media (PH value: about 6-8). For the application of corrosive fluid and other special requirements, corrosion resistant, abrasion resistant materials are available.

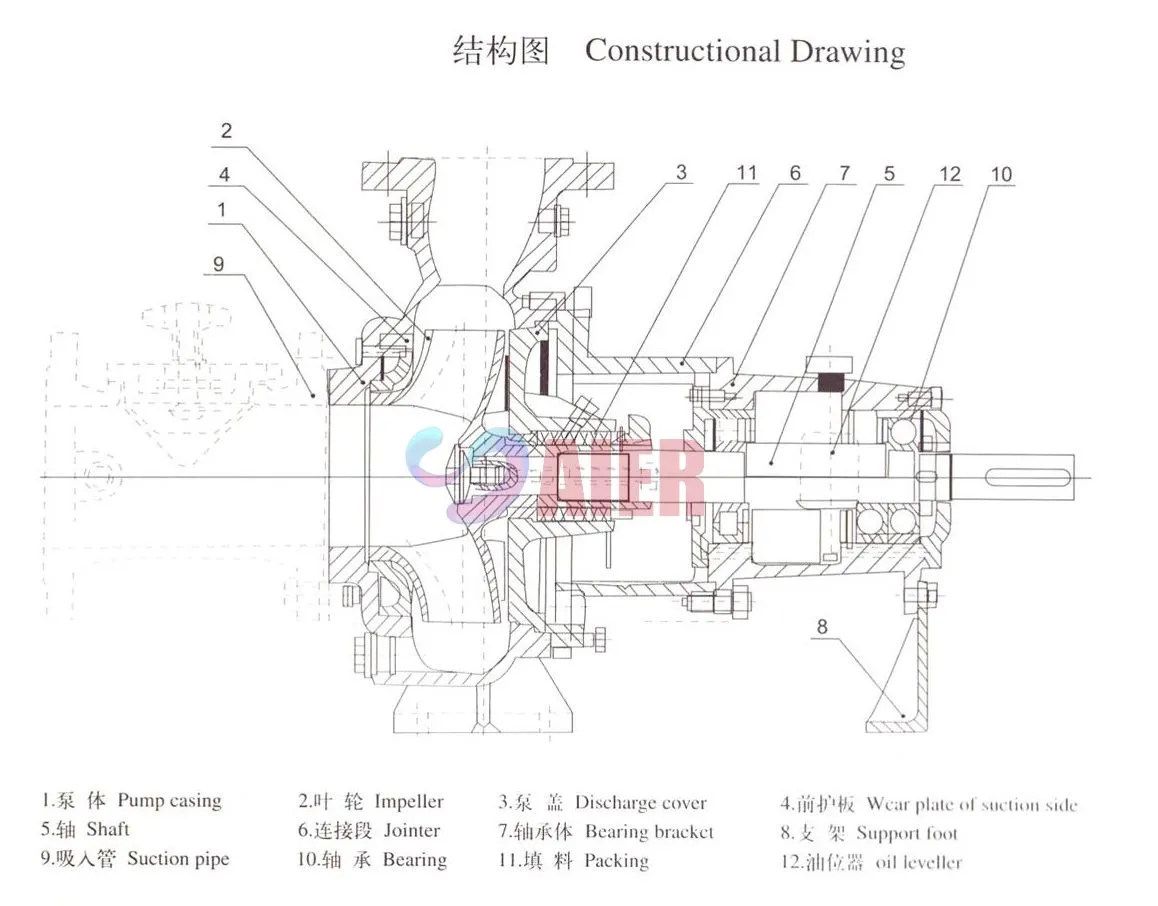

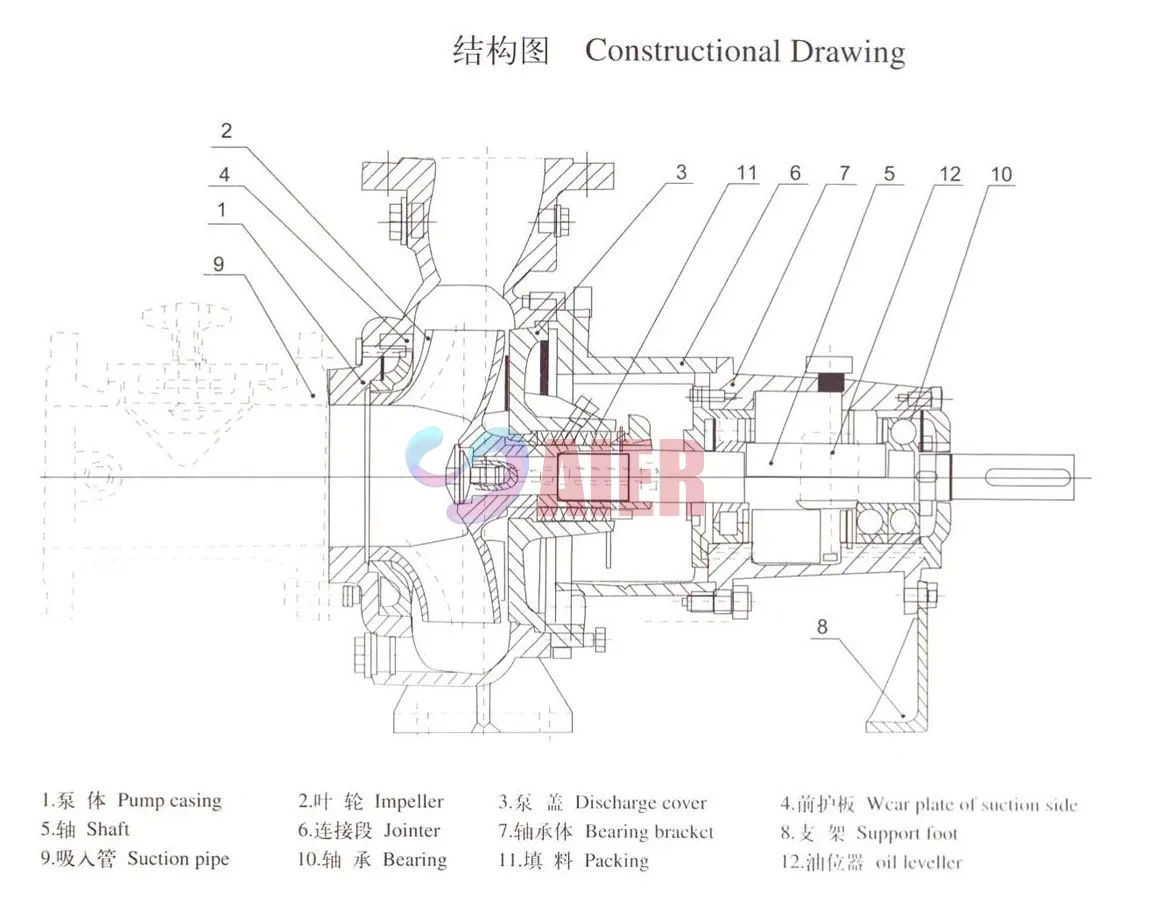

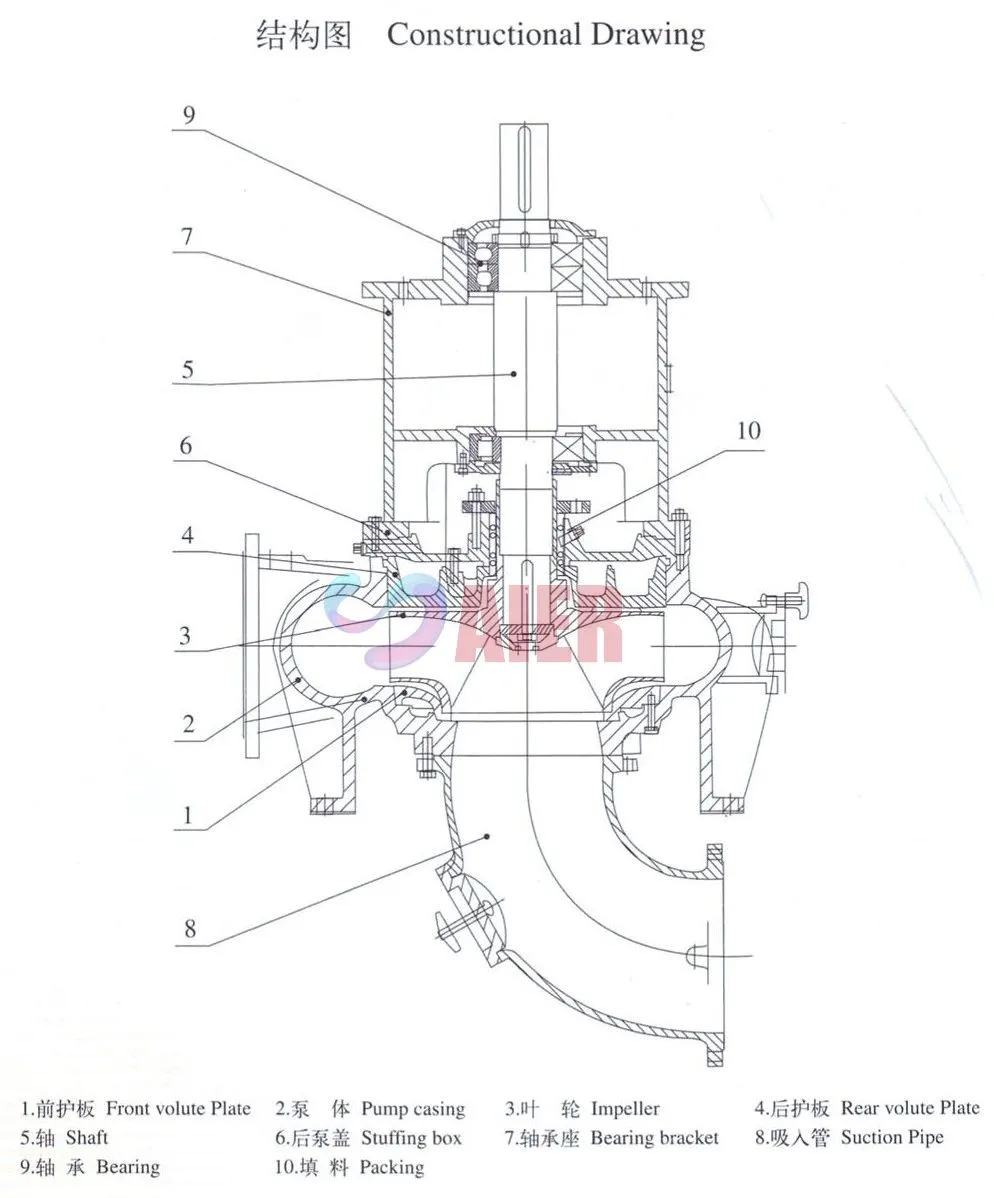

Construction Drawing

Construction Drawing of KWP Non-clogging Sewage Pump

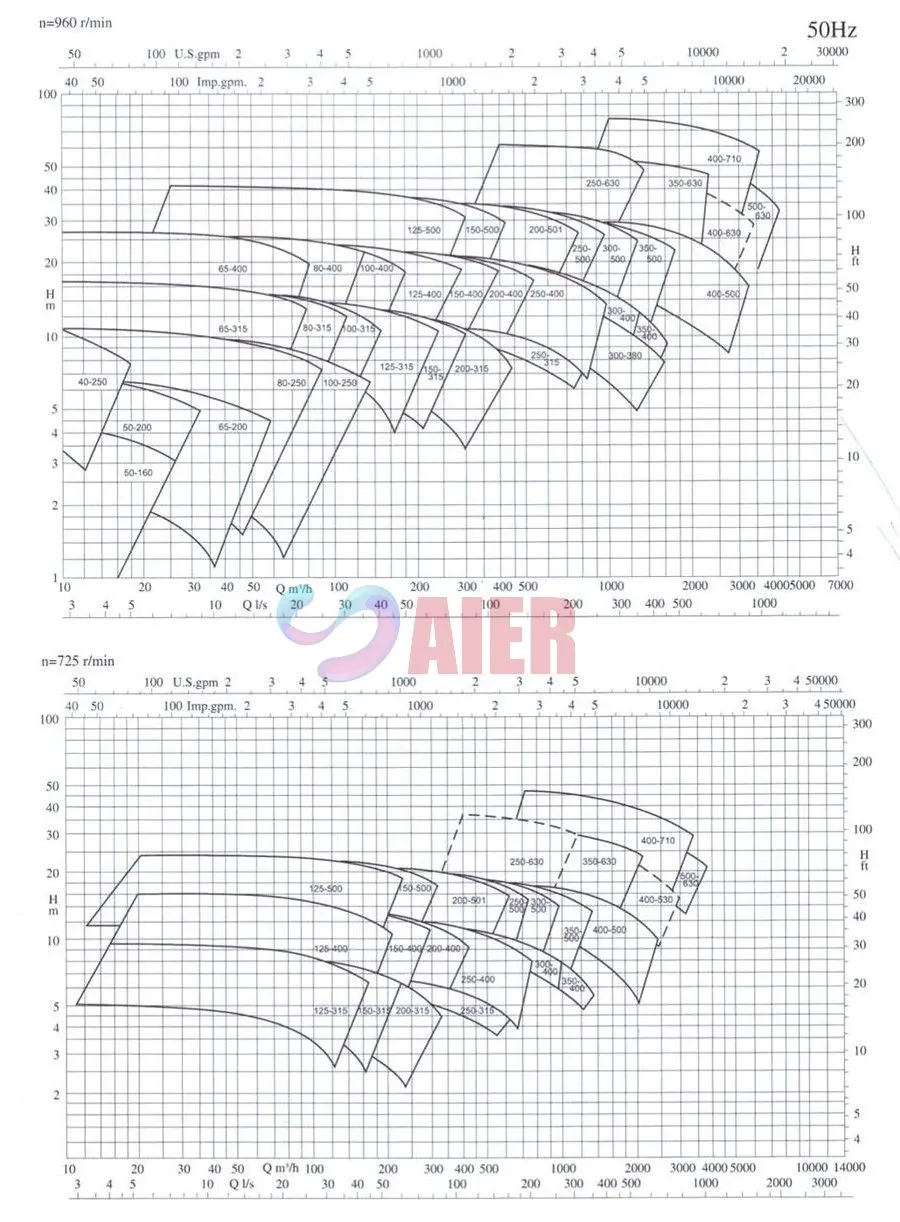

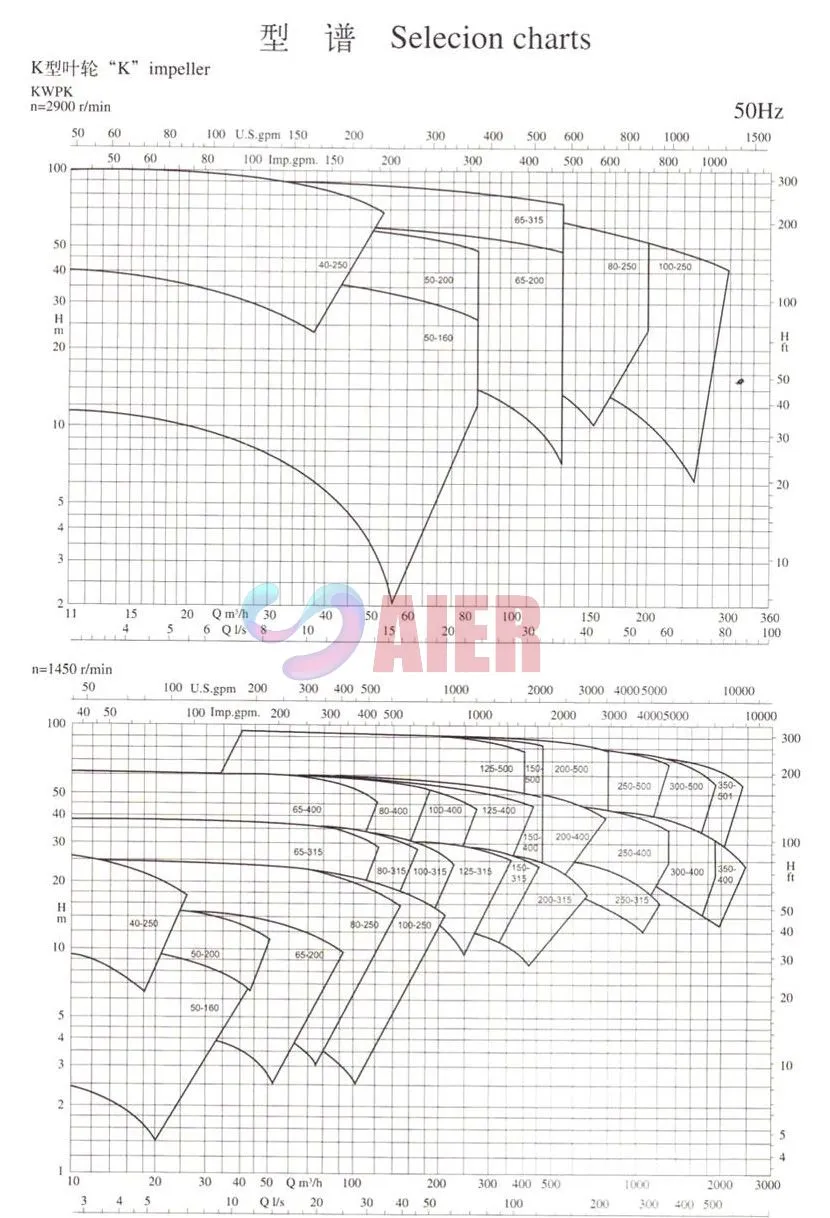

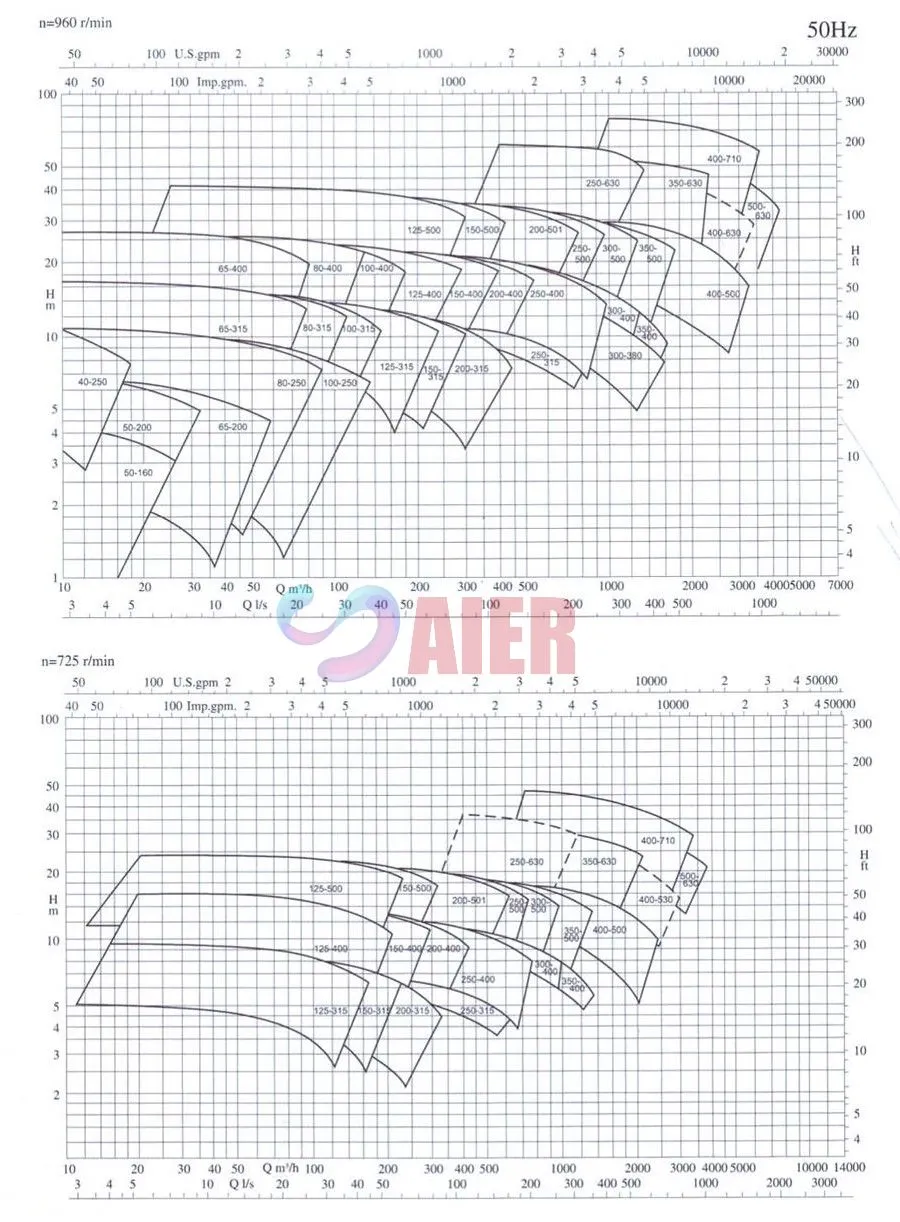

Selection Chart

Selection Chart of KWPk Non-clogging Pumps

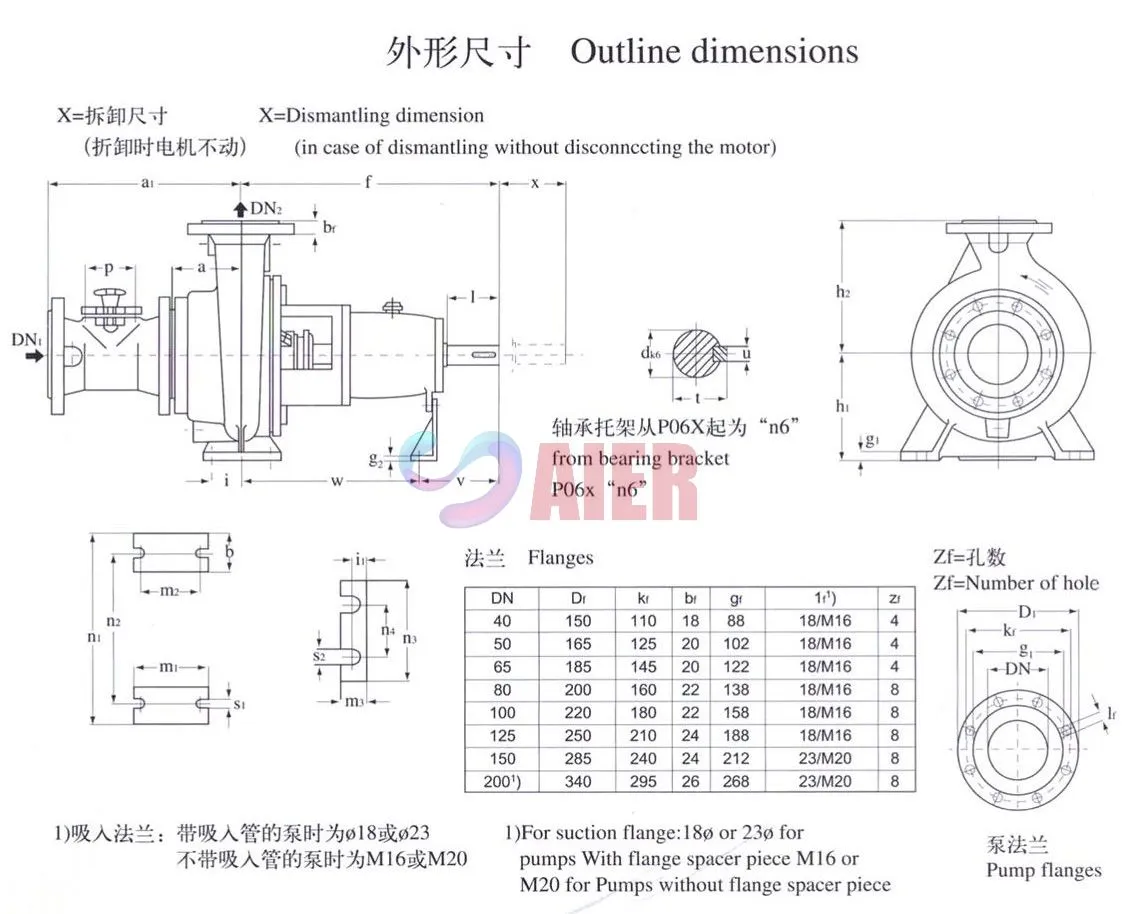

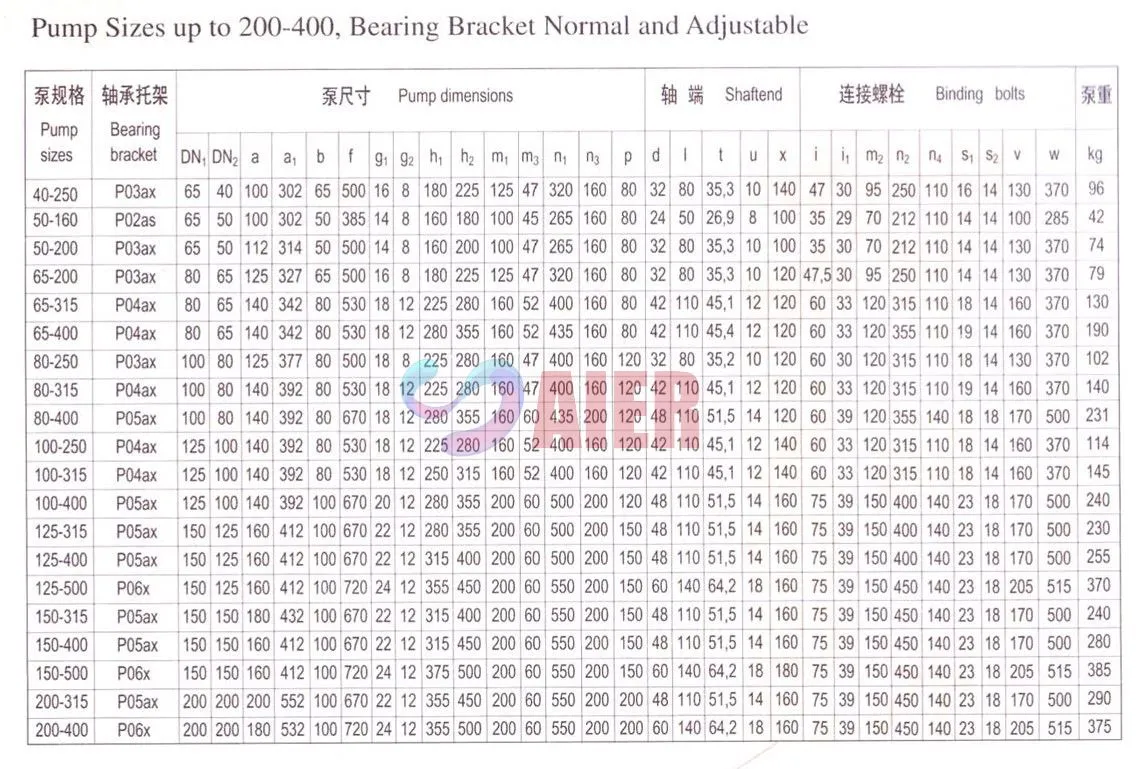

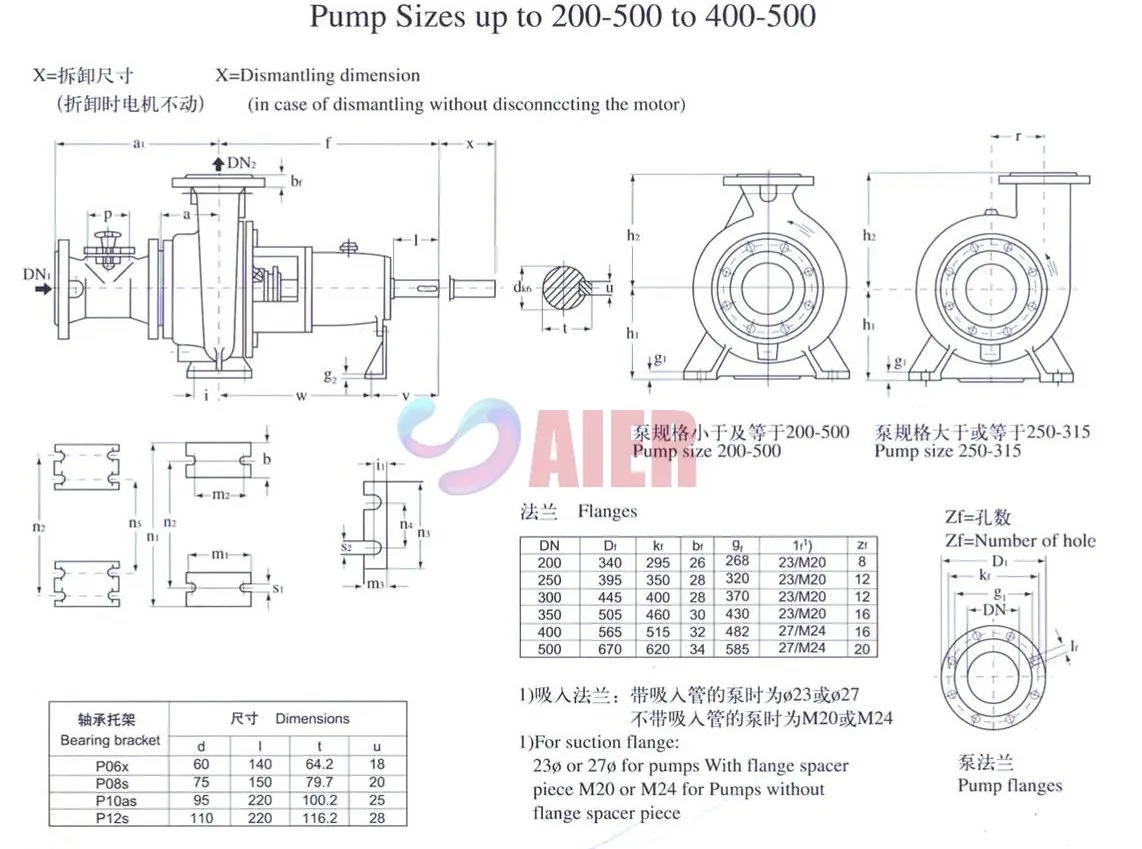

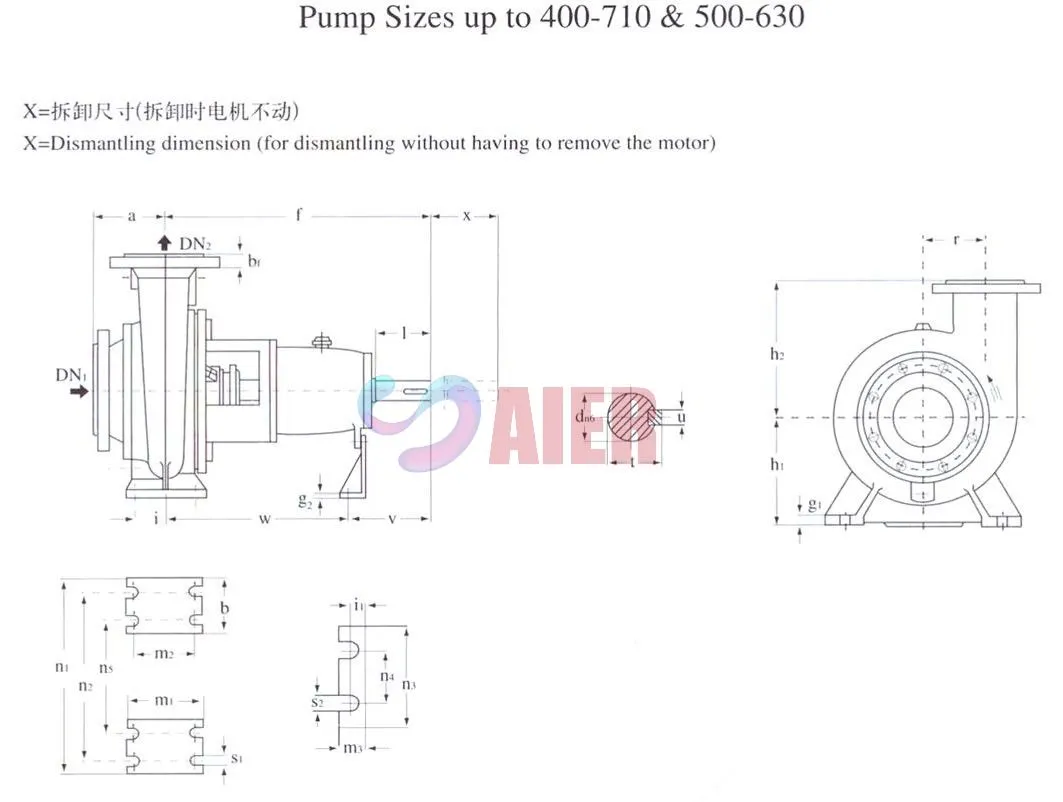

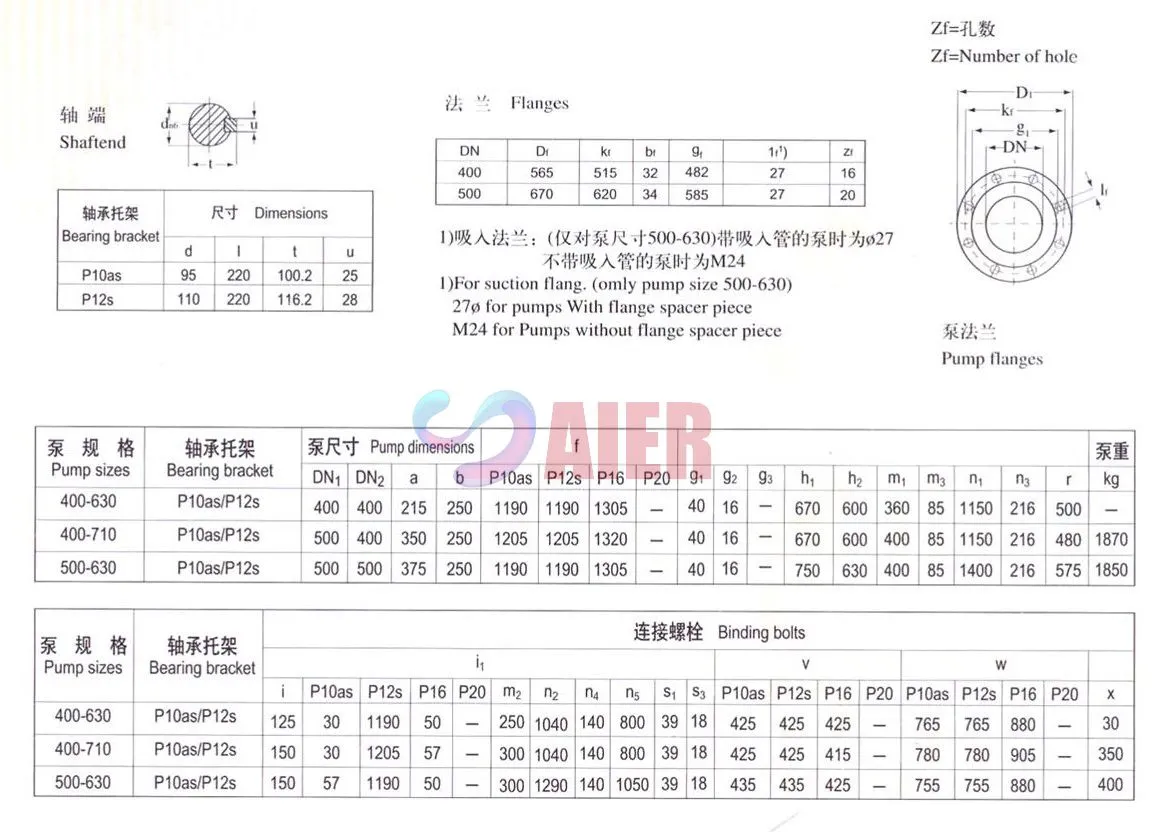

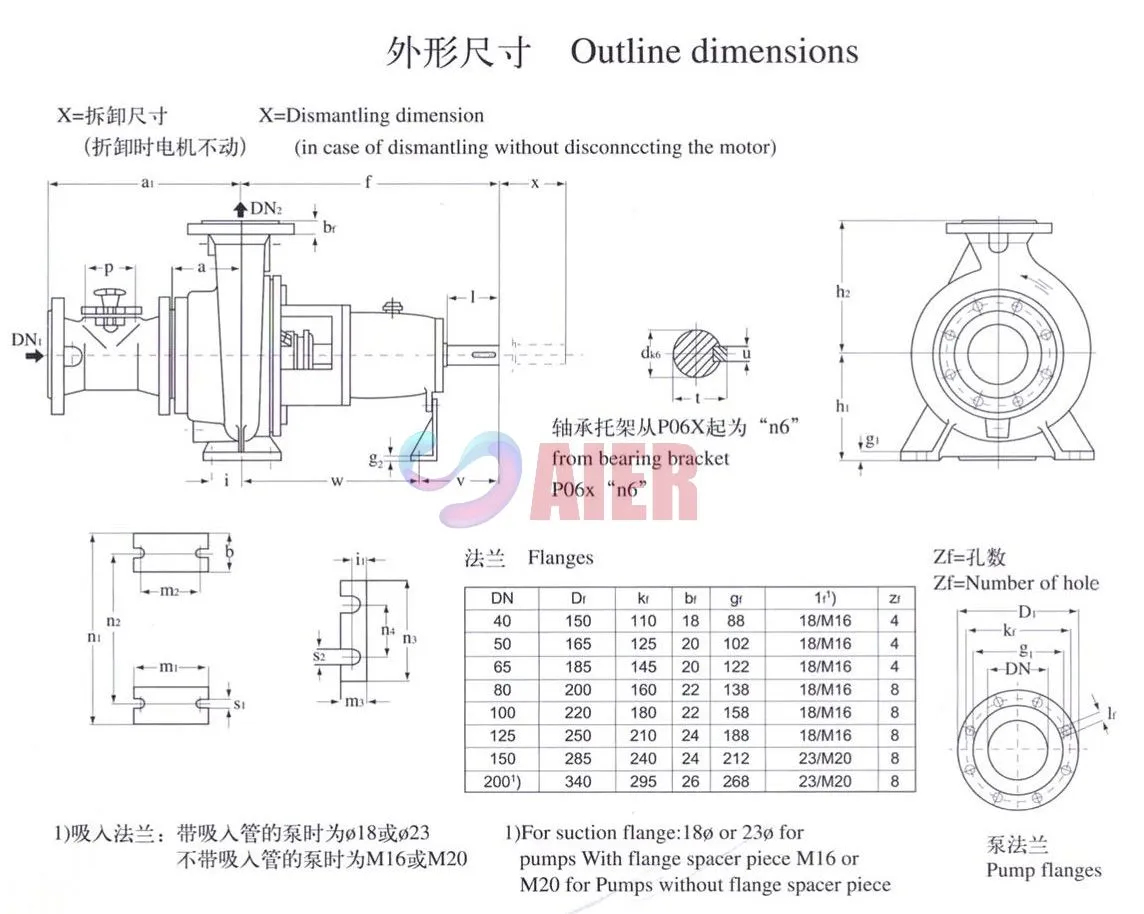

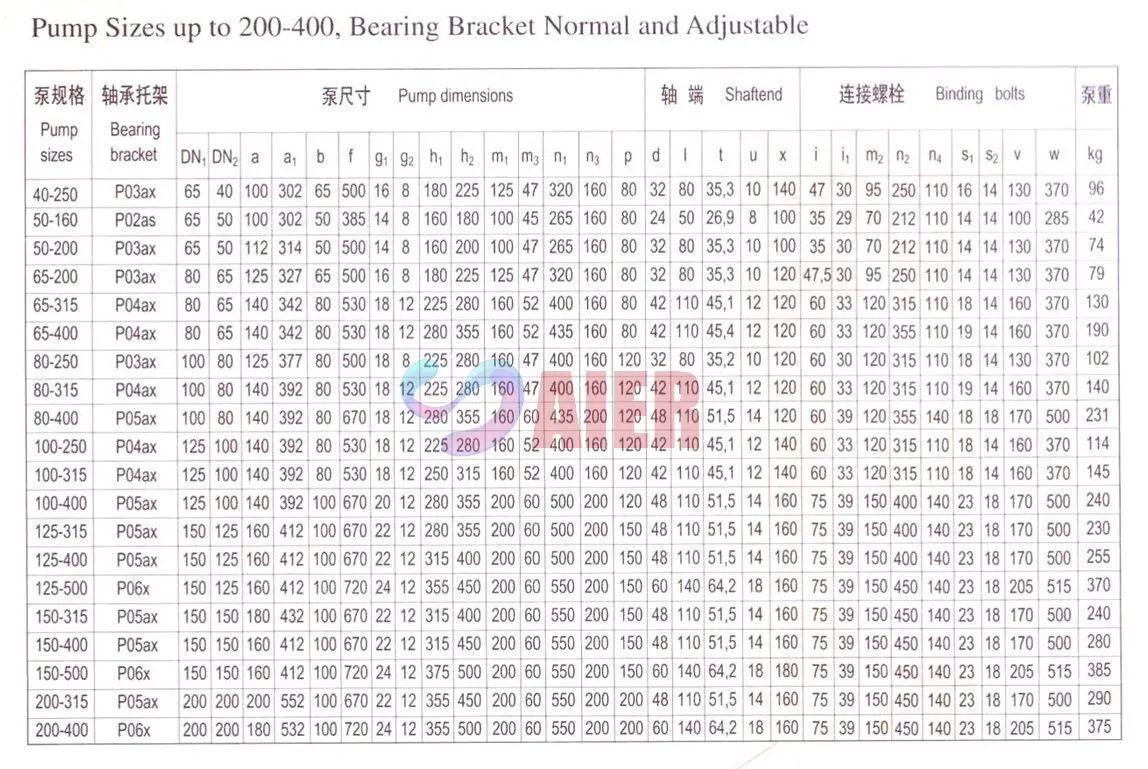

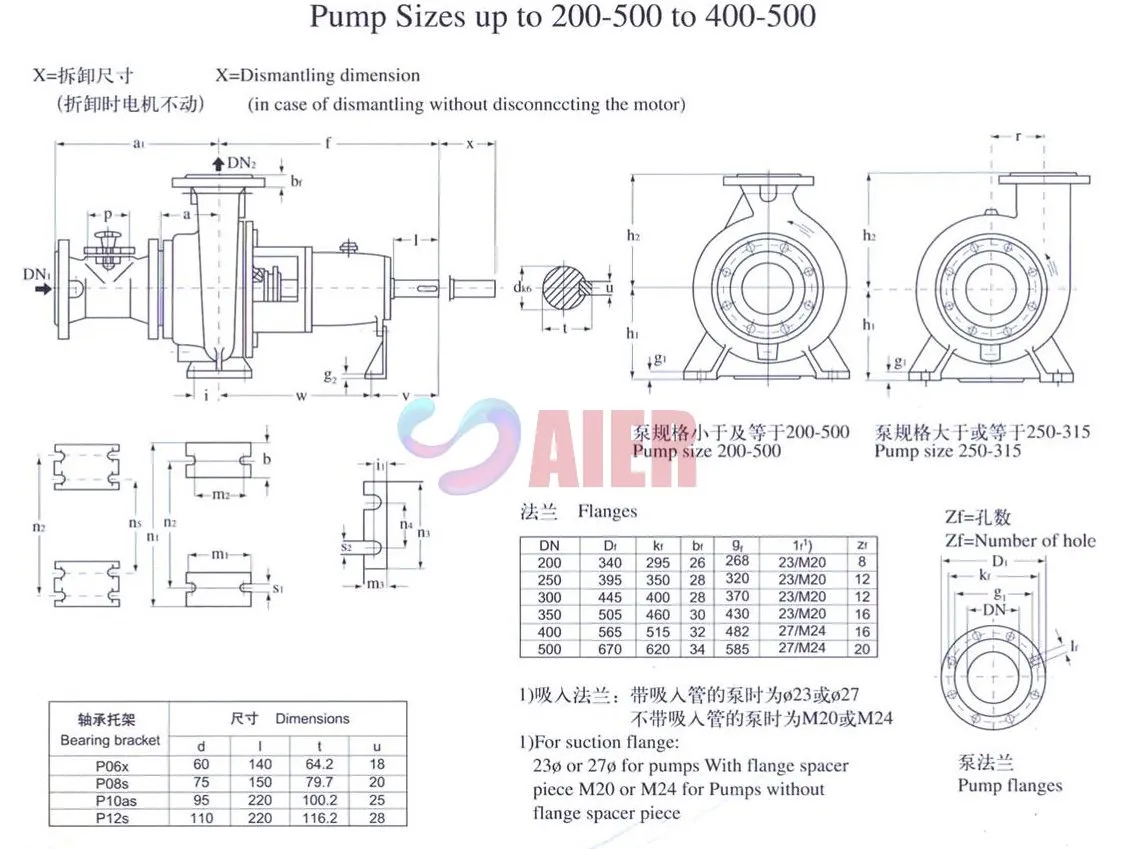

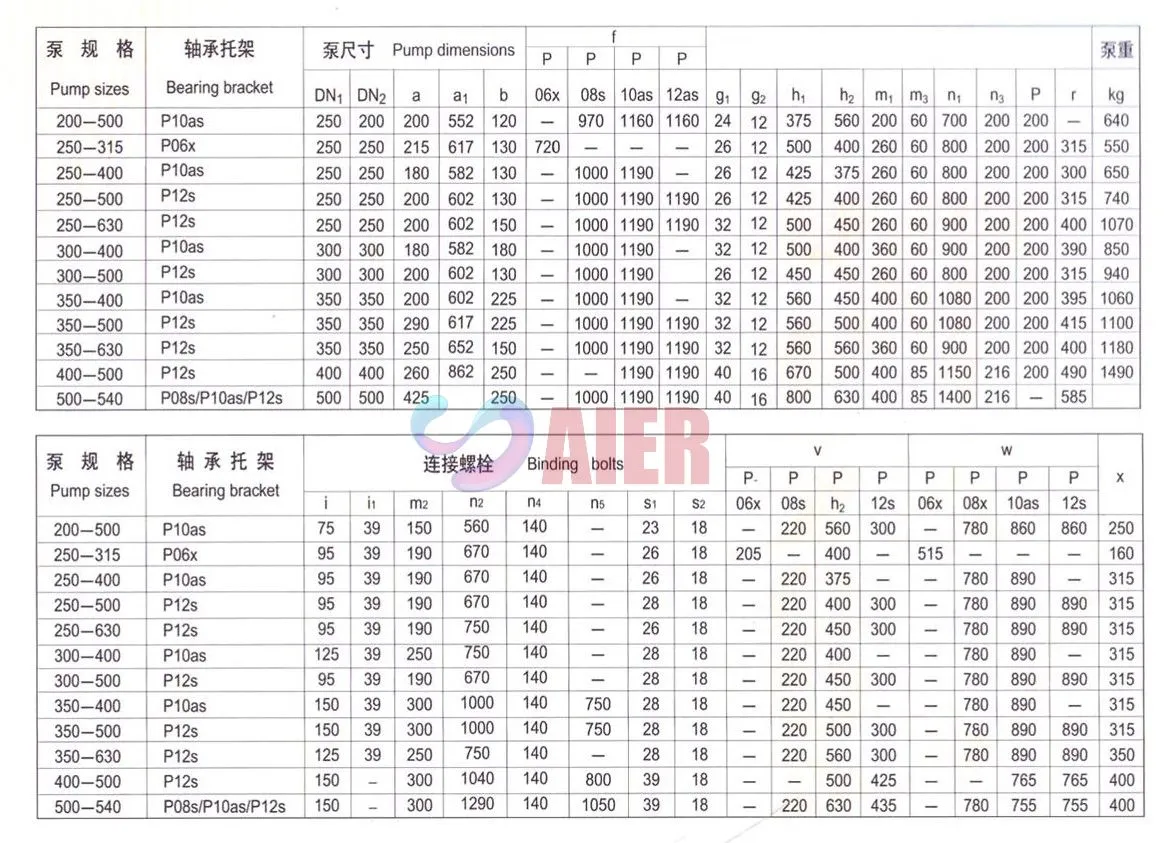

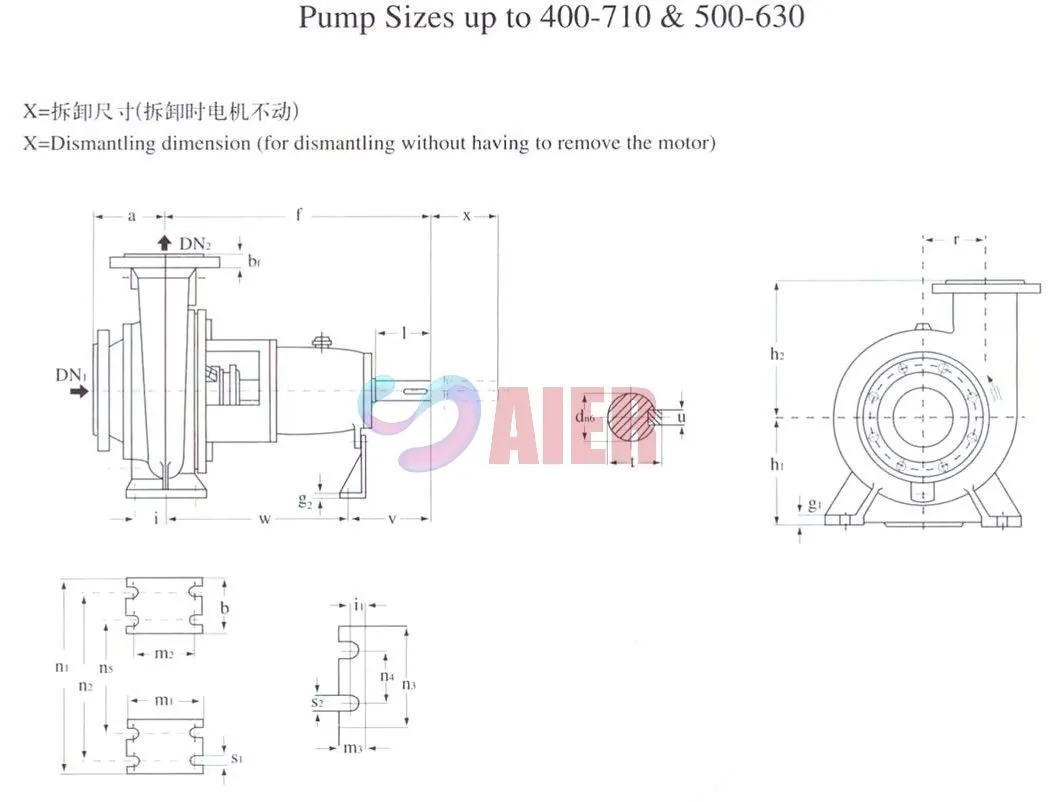

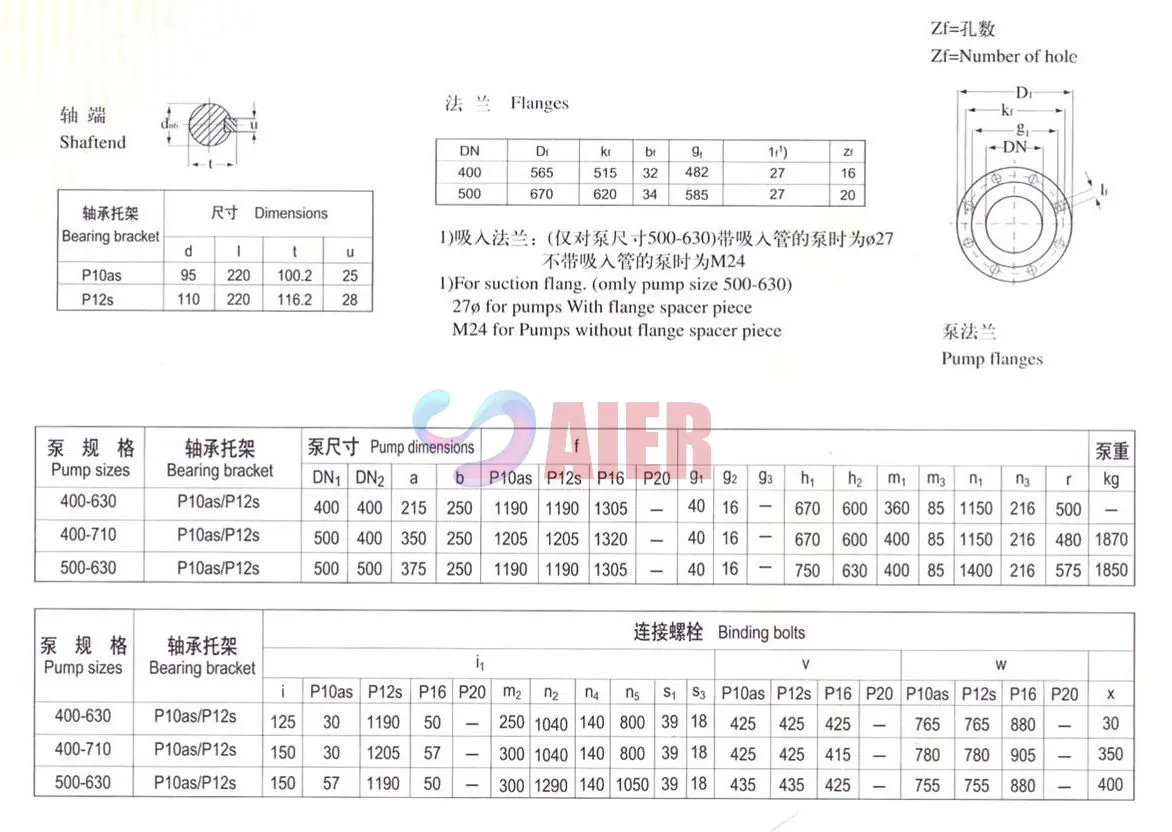

Outline Dimensions

Outline Dimensions of KWP Non-clogging Sewage Pumps

How Centrifugal Sewage Pump Factories Ensure Efficiency and Durability

A professional centrifugal sewage pump factory plays an essential role in delivering reliable and long-lasting wastewater transfer solutions. In both municipal and industrial sectors, a sewage pump manufacturer must focus on innovation, material excellence, and precision engineering to ensure every sewage pump meets global standards for efficiency and durability.

The manufacturing process begins with material selection—one of the most critical stages in ensuring performance. Premium factories typically use high-chromium cast iron, stainless steel, or duplex alloys for pump casings and impellers. These materials provide excellent wear and corrosion resistance, which is vital when the heavy duty sewage pump is exposed to slurry, sand, chemicals, or fibrous waste in treatment facilities. Each component is machined using CNC equipment for accuracy, ensuring perfect balance and alignment.

In terms of efficiency, centrifugal sewage pump factories often employ advanced fluid simulation technologies, such as Computational Fluid Dynamics (CFD), to design impeller and volute geometries that optimize flow while minimizing energy loss. This engineering precision improves hydraulic efficiency and reduces clogging risks, which is particularly important for large municipal drainage systems.

Durability is guaranteed through strict quality control at every stage. Every high quality sewage pump undergoes pressure, flow, and seal integrity tests before leaving the factory. Pumps are tested under simulated field conditions to verify performance stability. Anti-wear coatings, double mechanical seals, and reinforced bearings extend the pump’s operational lifespan even under demanding conditions.

Additionally, reliable sewage pump manufacturers provide modular designs for easier maintenance and part replacement. They may also incorporate smart monitoring systems to detect temperature, vibration, and leakage changes in real time—preventing costly breakdowns.

In summary, a reputable centrifugal sewage pump factory combines high-grade materials, fluid engineering, and intelligent quality management to produce heavy duty sewage pumps that ensure excellent hydraulic performance, low maintenance costs, and long-term reliability in wastewater and industrial applications.

Maintenance and Troubleshooting Tips for Sewage Pump Systems

To keep a high quality sewage pump operating at peak efficiency, regular maintenance and systematic troubleshooting are vital. Whether used in municipal wastewater plants, factories, or flood control systems, a well-maintained sewage pump can prevent costly downtime and significantly extend its lifespan.

Routine inspection starts with the external components. Operators should check for leaks, unusual vibrations, or noise. For heavy duty sewage pumps, frequent inspection of the pump casing and impeller is critical since abrasive particles can cause erosion or imbalance. Cleaning the suction and impeller areas regularly helps maintain smooth flow and prevents blockages.

Lubrication plays another important role. Bearings and seals in a sewage pump require periodic lubrication to reduce friction and wear. Over-lubrication can cause overheating, while lack of lubrication can result in bearing seizure. Always follow the sewage pump manufacturer’s lubrication schedule and recommended grease type.

Electrical systems also require attention. Loose connections, damaged insulation, or unstable voltage can lead to motor failure. For submersible types, ensuring cable sealing integrity prevents water ingress and short-circuiting.

When troubleshooting performance issues, start with flow rate and discharge pressure. If output drops, inspect for clogged impellers or suction lines. Excessive noise or vibration may indicate cavitation, misalignment, or worn bearings. Professional centrifugal sewage pump factories often recommend vibration analysis tools or temperature sensors to identify issues early before they escalate.

Preventive maintenance schedules, such as quarterly performance testing and yearly overhauls, can dramatically extend service life. Proper record-keeping of maintenance history helps operators predict wear patterns and replace parts before failure occurs.

By following these steps, users can ensure that their high quality sewage pump continues to operate efficiently, reducing energy costs and avoiding unexpected breakdowns in both municipal and industrial wastewater systems.

Comparing Submersible vs Centrifugal Sewage Pumps: Which is Better for You?

Choosing between a submersible sewage pump and a centrifugal sewage pump can greatly impact system efficiency, installation convenience, and maintenance requirements. Both pump types, designed by experienced sewage pump manufacturers, serve distinct operational needs and environments.

A submersible sewage pump is installed directly inside the wastewater, fully submerged during operation. Its sealed motor prevents water entry, making it ideal for applications with limited space such as residential basements, sewage pits, and municipal collection tanks. Because it operates underwater, it offers quiet operation and efficient priming without the need for external suction lines.

On the other hand, a centrifugal sewage pump factory typically produces dry-installed pumps, where the motor and impeller housing remain outside the fluid. This configuration allows for easy maintenance and access, which is highly beneficial in large-scale industrial applications such as chemical processing, paper mills, or mining operations. Heavy duty sewage pumps in this category can handle high flow rates, large solids, and corrosive fluids with minimal wear.

When comparing performance, high quality sewage pumps in submersible form tend to excel in space-saving installations and automatic operation. However, they can be harder to service since removal from the sump is necessary for inspection. Centrifugal pumps, in contrast, offer easier maintenance, durability, and flexibility in handling different fluid viscosities and temperatures.

For facilities that require continuous, high-volume wastewater transfer with easy access for inspection, the centrifugal sewage pump from a trusted sewage pump manufacturer is typically the better choice. Meanwhile, for underground or remote drainage systems where noise and space are concerns, submersible sewage pumps provide the ideal balance of efficiency and compactness.

Ultimately, the best pump depends on your system design, installation space, and maintenance resources. Consulting a reputable centrifugal sewage pump factory ensures you select a pump that provides long-term reliability, minimal energy consumption, and maximum performance tailored to your specific wastewater handling requirements.