WZ High Efficiency Slurry Pump

Pambuka Pump

SPESIFIKASI:

Ukuran (discharge): 40mm nganti 300mm

Capacity: 4-1826 m3/h

Head: 9m-133.7 m

Handing ngalangi: 11-92mm

Konsentrasi: 0%-70%

Materials:High chrome alloy etc

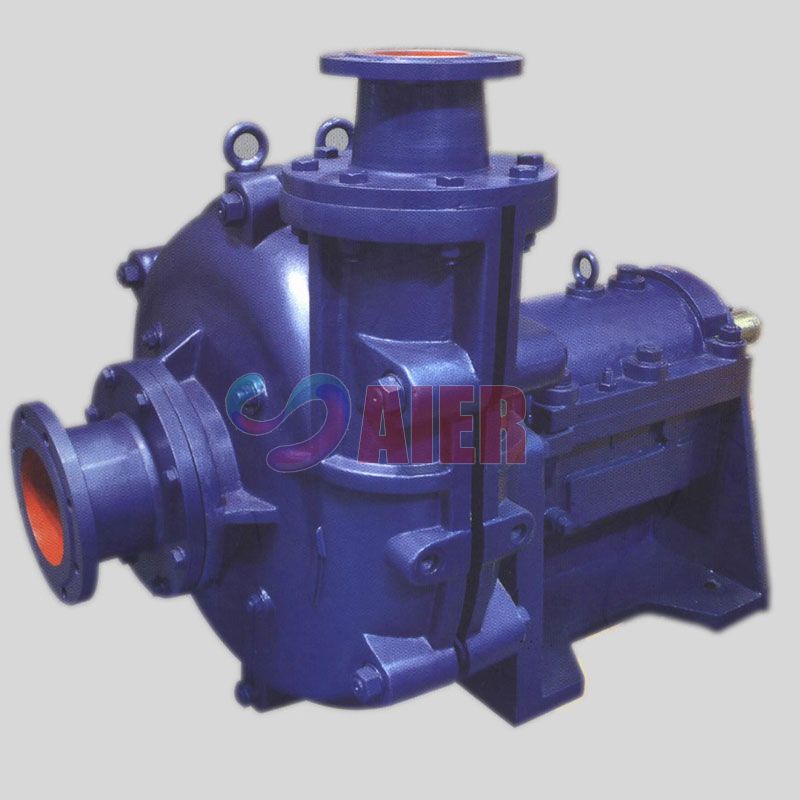

AIER® WZ Slurry Pump

Pumps slurry seri WZ minangka pompa lumpur tahan lan tahan korosi anyar kanggo kerumitan lan kekhususan batu bara, pembangkit listrik, metalurgi, kimia, bahan bangunan lan industri liyane.

Pumps slurry seri WZ dikembangake kanthi adaptasi saka teknologi maju ing omah lan ing luar negeri lan pengalaman desain pompa slurry lan pengalaman operasi lapangan sajrone pirang-pirang taun.

Fitur: efisiensi dhuwur, hemat energi, geter kurang, operasi stabil, umur layanan kurang, pangopènan gampang, lsp.

Kondisi Kerja

Kacepetan: Langsung gandheng: 2900/1480/980/730/590 r / min; Tipe liyane: miturut kabutuhan pelanggan

Medium temperature: commonly ≤ 80 ˚C; specially: 110 ˚C

Weight density of slurry: Grout: ≤ 45%, Mining slurry: ≤ 60%

Kapasitas: 30 nganti 2000m3 / h

Sirah: 15-30m

Fitur

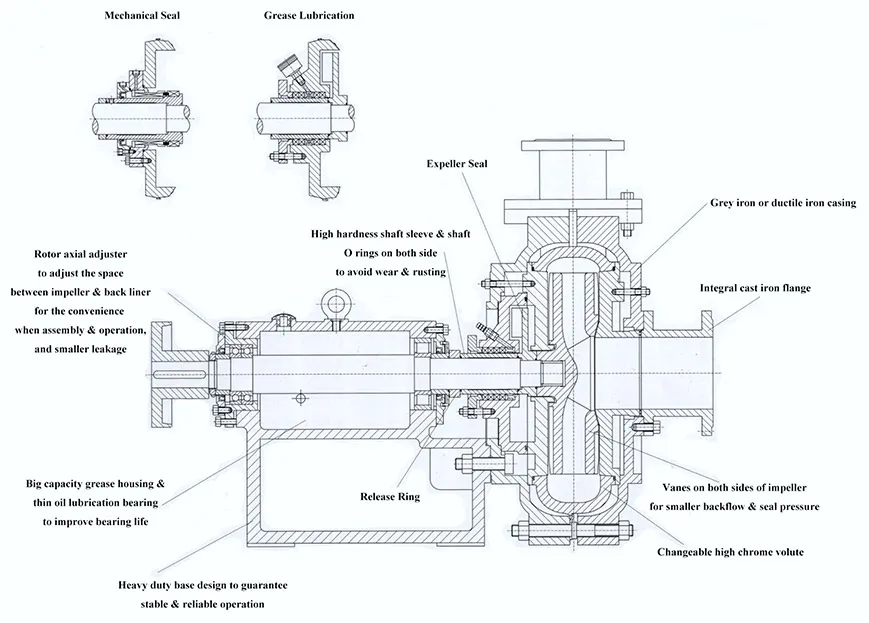

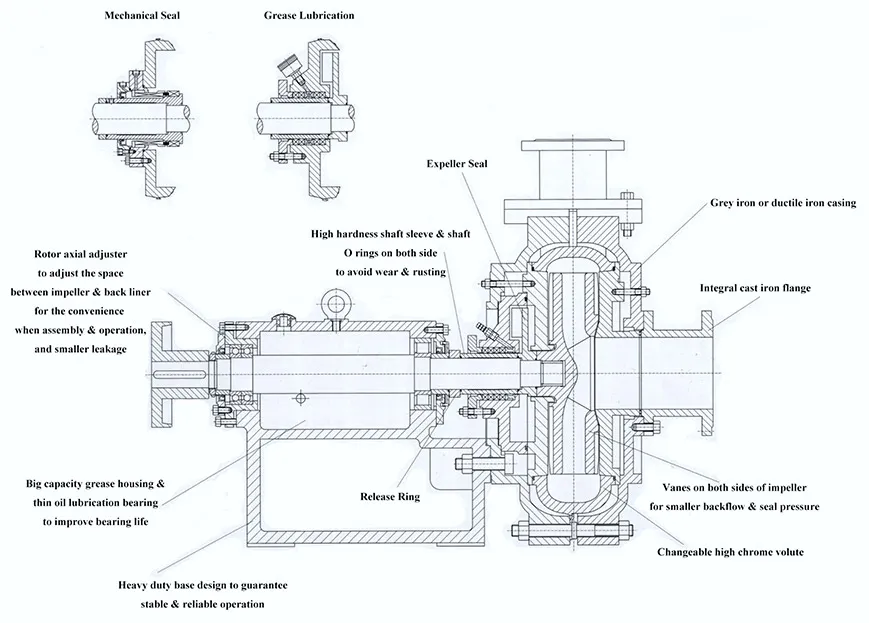

Piring pigura kanggo pompa seri WA nduweni lapisan elastomer logam sing bisa diganti utawa dicetak tekanan. Impeller digawe saka logam keras utawa liner elastomer cetakan tekanan.

Segel poros kanggo seri WA bisa dadi segel pengepakan, segel sentrifugal utawa segel mekanik.

Cabang discharge bisa dipanggonke kanthi interval 45 derajat kanthi panyuwunan lan orientasi menyang wolung posisi sing cocog karo instalasi lan aplikasi. Ana akeh mode drive kanggo pilihan, kayata V-belt, kopling fleksibel, gearbox, hydraulic coupler frekuensi variabel, kacepetan kontrol silikon, etc. Antarane wong-wong mau, fleksibel poros kopling drive lan fitur V-sabuk biaya murah lan instalasi gampang.

Tipe Seal Shaft

Packing Seal: tekanan dhuwur segel banyu dibutuhake. Kanggo tekanan discharge < nyedhot tekan instalasi siji tahap utawa instalasi seri multi tahap.

Expeller & packing kombinasi: Kanggo meksa discharge > nyedhot pencet instalasi siji tahap utawa multi tahap instalasi seri.

Segel mekanik: Kanggo pangguna sing mbutuhake bocor sing ketat.

Notasi Pompa

100WZ-42

100: discharge diameteripun (mm)

WZ: pompa lumpur

42: diameteripun impeller (cm)

Desain Konstruksi

Bahan Bagian Pompa

| Jeneng Part | Bahan | Spesifikasi | HRC | Aplikasi | Kode OEM |

| Liners & Impeller | logam | AB27: 23%-30% wesi putih krom | ≥56 | Digunakake kanggo kondisi nyandhang sing luwih dhuwur kanthi pH antarane 5 lan 12 | A05 |

| AB15: 14% -18% wesi putih krom | ≥59 | Digunakake kanggo kondisi nyandhang sing luwih dhuwur | A07 | ||

| AB29: 27% -29% wesi putih krom | 43 | Digunakake kanggo kondisi pH sing luwih murah utamane kanggo FGD. Uga bisa digunakake kanggo kahanan kurang asam lan instalasi desulfuration karo pH ora kurang saka 4 | A49 | ||

| AB33: 33% -37% wesi putih krom | Bisa ngeterake slurry oksigen kanthi pH ora kurang saka 1 kayata phospor-plaster, asam nitrat, vitriol, fosfat lsp. | A33 | |||

| Expeller & expeller ring | logam | B27: 23% -30% wesi putih krom | ≥56 | Digunakake kanggo kondisi nyandhang sing luwih dhuwur kanthi pH antarane 5 lan 12 | A05 |

| wesi abu-abu | G01 | ||||

| Kothak Isi | logam | AB27: 23%-30% wesi putih krom | ≥56 | Digunakake kanggo kondisi nyandhang sing luwih dhuwur kanthi pH antarane 5 lan 12 | A05 |

| wesi abu-abu | G01 | ||||

| Bingkai/Plat tutup, omah bantalan & alas | logam | wesi abu-abu | G01 | ||

| wesi ulet | D21 | ||||

| poros | logam | Baja karbon | E05 | ||

| Lengan poros, cincin lentera/restriktor, cincin leher, baut kelenjar | baja tahan karat | 4Cr13 | C21 | ||

| 304 SS | C22 | ||||

| 316 SS | C23 | ||||

| Dering gabungan & segel | karet | Butil | S21 | ||

| karet EPDM | S01 | ||||

| Nitrile | S10 | ||||

| Hypalon | S31 | ||||

| Neoprene | S44/S42 | ||||

| Viton | S50 |

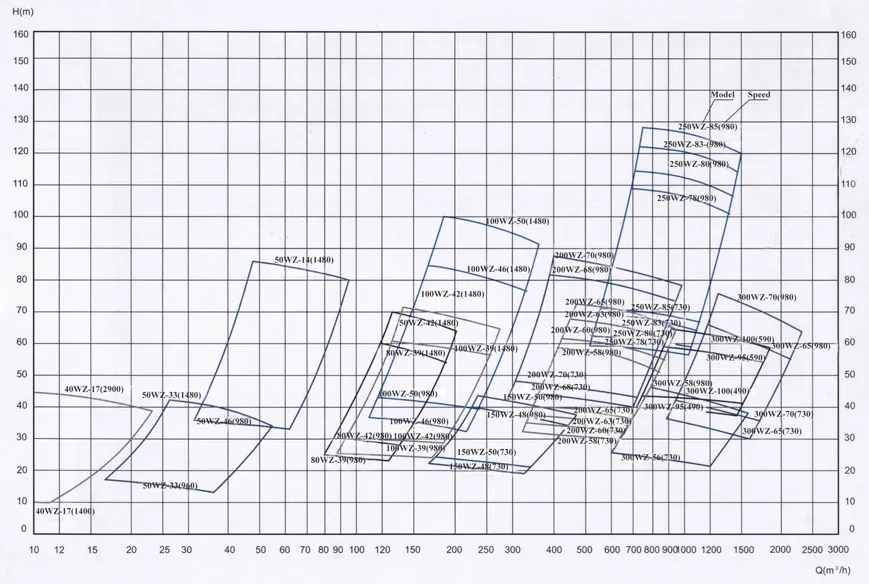

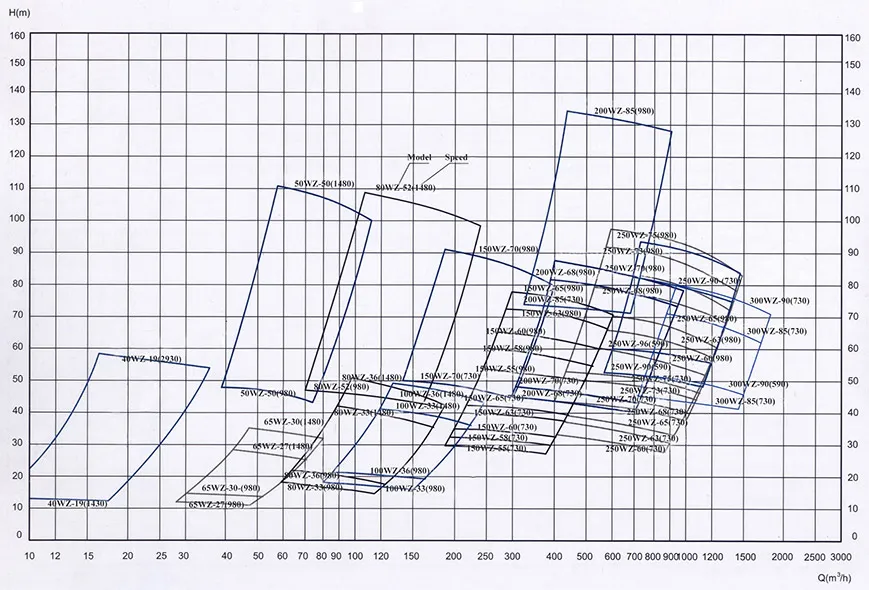

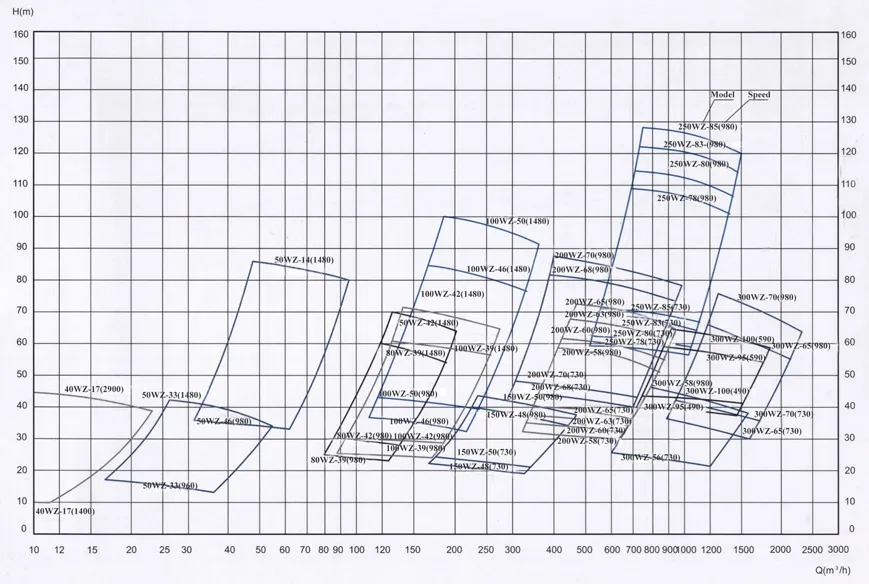

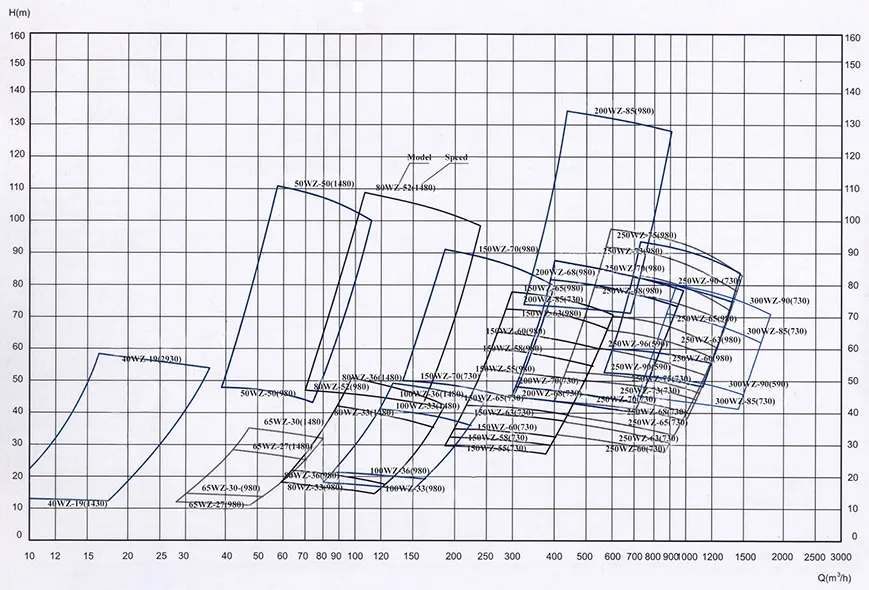

Data Kinerja

| Model | Daya Kawin Maks (kw) | Kinerja Banyu Bening | Max Solid Sanadyan mm |

Bobot Pompa kg |

||||

| Kapasitas m3/jam |

sirah m |

Kacepetan rpm |

Nilai paling dhuwur saham Effi. % |

NPSHr m |

||||

| 40WZ-14 | 7.5 | 4-23 | 9.0-44.5 | 1400-2900 | 52.4 | 2.5 | 11 | 100 |

| 40WZ-19 | 15 | 8-35 | 12.8-57.1 | 1430-2930 | 58.8 | 1.3 | 11 | 160 |

| 50WZ-33 | 18.5 | 12-54 | 7.7-42.5 | 700-1480 | 41.4 | 2.9 | 13 | 450 |

| 50WZ-46 | 55 | 23-94 | 17.9-85.8 | 700-1480 | 44.7 | 1.4 | 13 | 690 |

| 50WZ-50 | 90 | 27-111 | 22.3-110.7 | 700-1480 | 45.1 | 3.0 | 13 | 1050 |

| 65WZ-27 | 11 | 20-72 | 6.0-29.0 | 700-1460 | 62.5 | 1.8 | 19 | 400 |

| 65WZ-30 | 15 | 23-80 | 7.4-35.8 | 700-1460 | 63.5 | 2.0 | 19 | 420 |

| 80WZ-33 | 37 | 43-174 | 8.8-43.3 | 700-1460 | 67.7 | 2.3 | 24 | 580 |

| 80WZ-36 | 45 | 46-190 | 9.6-51.5 | 700-1480 | 68.2 | 2.5 | 24 | 600 |

| 80WZ-39 | 55 | 57-189 | 12.4-60.9 | 700-1480 | 66.0 | 2.5 | 24 | 660 |

| 80WZ-42 | 75 | 61-204 | 14.4-70.6 | 700-1480 | 67.8 | 2.5 | 24 | 680 |

| 80WZ-52 | 160 | 51-242 | 22.1-109.8 | 700-1480 | 56.3 | 2.1 | 21 | 1100 |

| 100WZ-33 | 45 | 56-225 | 8.2-41.6 | 700-1480 | 69.6 | 1.8 | 32 | 700 |

| 100WZ-36 | 55 | 61-245 | 9.7-48.6 | 700-1480 | 72.6 | 2.0 | 32 | 710 |

| 100WZ-39 | 75 | 61-255 | 12.6-61.2 | 700-1480 | 71.0 | 2.4 | 35 | 760 |

| 100WZ-42 | 90 | 66-275 | 14.7-71.0 | 700-1480 | 71.0 | 2.5 | 35 | 780 |

| 100WZ-46 | 132 | 79-311 | 17.3-86.0 | 700-1480 | 68.9 | 2.6 | 34 | 1100 |

| 100WZ-50 | 160 | 85-360 | 20.5-101.6 | 700-1480 | 71.3 | 2.5 | 34 | 1120 |

| 150WZ-42 | 132 | 142-550 | 12.1-64.0 | 700-1480 | 76.4 | 2.2 | 69 | 1550 |

| 150WZ-48 | 75 | 111-442 | 8.7-39.7 | 490-980 | 78.0 | 2.5 | 48 | 1610 |

| 150WZ-50 | 75 | 115-460 | 9.5-43.1 | 490-980 | 78.0 | 2.5 | 48 | 1630 |

| 150WZ-55 | 110 | 124-504 | 12.3-54.2 | 490-980 | 74.5 | 2.3 | 48 | 1660 |

| 150WZ-58 | 132 | 131-532 | 13.7-60.3 | 490-980 | 77.5 | 2.5 | 48 | 1680 |

| 150WZ-60 | 160 | 135-550 | 14.7-64.5 | 490-980 | 77.5 | 2.5 | 48 | 1700 |

| 150WZ-63 | 185 | 146-582 | 16.3-73.7 | 490-980 | 75.0 | 2.5 | 48 | 1900 |

| 150WZ-65 | 200 | 150-600 | 17.4-78.5 | 490-980 | 72.0 | 2.5 | 48 | 1930 |

| 150WZ-70 | 185 | 93-400 | 20.0-91.2 | 490-980 | 62.3 | 2.0 | 37 | 1950 |

| Model | Daya Kawin Maks (kw) | Kinerja Banyu Bening | Max Solid Sanadyan mm |

Bobot Pompa kg |

||||

| Kapasitas m3/jam |

sirah m |

Kacepetan rpm |

Nilai paling dhuwur saham Effi. % |

NPSHr m |

||||

| 200WZ-58 | 185 | 211-841 | 13.0-59.8 | 490-980 | 81.7 | 2.5 | 62 | 1940 |

| 200WZ-60 | 200 | 218-870 | 13.9-64.0 | 490-980 | 82.7 | 2.5 | 62 | 1970 |

| 200WZ-63 | 250 | 228-921 | 15.4-67.6 | 490-980 | 79.3 | 2.5 | 62 | 2030 |

| 200WZ-65 | 250 | 235-950 | 16.4-72.0 | 490-980 | 80.0 | 2.5 | 62 | 2050 |

| 200WZ-68 | 315 | 199-948 | 18.3-81.5 | 490-980 | 74.6 | 2.8 | 56 | 2130 |

| 200WZ-70 | 315 | 205-976 | 19.4-86.4 | 490-980 | 75.6 | 2.8 | 56 | 2150 |

| 200WZ-73 | 355 | 219-876 | 21.6-98.2 | 490-980 | 74.5 | 3.0 | 56 | 2660 |

| 200WZ-75 | 355 | 225-900 | 22.8-103.0 | 490-980 | 74.5 | 3.0 | 56 | 2700 |

| 200WZ-85 | 560 | 221-907 | 32.0-133.7 | 490-980 | 70.5 | 2.8 | 54 | 3610 |

| 250WZ-60 | 280 | 276-1152 | 13.1-58.4 | 490-980 | 73.9 | 2.8 | 72 | 2800 |

| 250WZ-63 | 315 | 290-1211 | 14.4-64.3 | 490-980 | 76.5 | 3.0 | 72 | 2820 |

| 250WZ-65 | 315 | 299-1249 | 15.4-69.0 | 490-980 | 77.5 | 3.0 | 72 | 2840 |

| 250WZ-68 | 450 | 272-1341 | 17.1-80.9 | 490-980 | 72.5 | 2.7 | 72 | 3120 |

| 250WZ-70 | 450 | 280-1380 | 18.1-85.7 | 490-980 | 74.0 | 2.9 | 72 | 3150 |

| 250WZ-73 | 500 | 292-1441 | 19.7-93.2 | 490-980 | 76.0 | 3.0 | 72 | 3190 |

| 250WZ-75 | 560 | 300-1480 | 20.8-98.4 | 490-980 | 96.0 | 3.0 | 72 | 3230 |

| 250WZ-78 | 630 | 345-1380 | 25.4-109.3 | 490-980 | 70.8 | 3.2 | 76 | 4530 |

| 250WZ-80 | 710 | 354-1415 | 26.7-115.0 | 490-980 | 72.6 | 3.4 | 76 | 4540 |

| 250WZ-83 | 800 | 367-1468 | 28.7-123.8 | 490-980 | 74.6 | 3.5 | 76 | 4550 |

| 250WZ-85 | 800 | 376-1504 | 30.1-129.8 | 490-980 | 75.6 | 3.5 | 76 | 4560 |

| 250WZ-90 | 450 | 378-1374 | 22.3-82.4 | 400-730 | 73.8 | 3.4 | 69 | 4600 |

| 250WZ-96 | 560 | 403-1466 | 25.4-93.7 | 400-730 | 77.8 | 3.5 | 69 | 4650 |

| 300WZ-56 | 250 | 395-1568 | 9.7-46.0 | 490-980 | 81.3 | 3.5 | 96 | 2900 |

| 300WZ-65 | 500 | 589-2166 | 13.8-66.2 | 490-980 | 78.4 | 3.7 | 92 | 2920 |

| 300WZ-70 | 630 | 635-2333 | 16.0-76.8 | 490-980 | 80.4 | 3.9 | 92 | 2940 |

| 300WZ-85 | 450 | 477-1742 | 18.9-69.6 | 400-730 | 78.7 | 3.8 | 85 | 4900 |

| 300WZ-90 | 560 | 505-1844 | 21.2-80.0 | 400-730 | 81.5 | 3.8 | 85 | 4950 |

| 300WZ-95 | 400 | 441-1735 | 13.8-58.8 | 300-590 | 77.8 | 3.0 | 88 | 5010 |

| 300WZ-100 | 450 | 464-1826 | 15.3-65.2 | 300-590 | 80.8 | 3.0 | 88 | 5060 |

Bagan Pilihan Utama