WL Light-tugas Slurry Pump

Deskripsi Produk

SPESIFIKASI:

Ukuran: 20-650 mm

Kapasitas: 2,34-9108m3 / h

Kepala: 4-60m

Tekanan: Max.250psi

Bahan: paduan Hyper chrome, Karet, Poliuretan dll.

AIER® WL Light Dudy Slurry Pump

Pompa WL Series yaiku pompa slurry sentrifugal horisontal, cantilevered. Padha cocok kanggo ngirim slurries Kapadhetan kurang kanggo metalurgi, pertambangan, batu bara lan departemen bahan bangunan. Segel batang nganggo segel kelenjar lan segel sentrifugal.

Pompa seri WL beroperasi kanthi kacepetan kanthi volume cilik kanggo ngirit area lantai. Piring pigura wis diganti, nyandhang liner logam tahan lan impeller digawe saka logam tahan nyandhang.

Aplikasi Khas

Pelepasan pabrik SAG, pelepasan ball mill, pelepasan Rod mil, slurry asam Ni, pasir kasar, tailing kasar, matriks fosfat, konsentrat mineral, media berat, bit gula, bottom/fly ash, pasir minyak, pasir mineral, tailing halus, granulasi terak , asam fosfat, batu bara, flotasi, proses kimia, pulp lan kertas, FGD, feed siklon, banyu sampah, sumber banyu tanduran, etc.

Fitur

Piring pigura digawe saka liner logam keras sing tahan nganggo.

Impeller digawe saka logam atos.

Segel poros bisa dadi segel pengepakan, segel sentrifugal utawa segel mekanik.

Cabang discharge bisa dipanggonke kanthi interval 45 derajat kanthi panyuwunan lan orientasi menyang wolung posisi sing cocog karo instalasi lan aplikasi. Ana akeh mode drive kanggo pilihan, kayata V-belt, kopling fleksibel, gearbox, hydraulic coupler frekuensi variabel, kacepetan kontrol silikon, etc. Antarane wong-wong mau, fleksibel poros kopling drive lan fitur V-sabuk biaya murah lan instalasi gampang.

Notasi Pompa

200WL-S:

200: diameteripun Outlet: mm

WL: Pompa slurry tugas entheng

S: jinis pigura piring

Desain Konstruksi

|

|

Casing Setengah casing pamisah saka wesi cor utawa ductile ngemot liner nyandhang lan nyedhiyakake kemampuan tekanan operasi sing dhuwur.

Diijolake hard logam lan nyetak elastomer liners |

|

Impeller Impeller bisa uga digawe elastomer utawa logam keras. Vanes sealing sisih jero nyuda tekanan segel lan nyuda recirculation. Utas impeller cast-in luwih cocog kanggo slurries. |

Mating faces in hard metal liners are tapered to allow positive alignment during assembly and allow components to be easily removed for replacement.

Bahan Bagian Pompa

| Jeneng Part | Bahan | Spesifikasi | HRC | Aplikasi | Kode OEM |

| Liners & Impeller | logam | AB27: 23%-30% wesi putih krom | ≥56 | Digunakake kanggo kondisi nyandhang sing luwih dhuwur kanthi pH antarane 5 lan 12 | A05 |

| AB15: 14% -18% wesi putih krom | ≥59 | Digunakake kanggo kondisi nyandhang sing luwih dhuwur | A07 | ||

| AB29: 27% -29% wesi putih krom | 43 | Digunakake kanggo kondisi pH sing luwih murah utamane kanggo FGD. Uga bisa digunakake kanggo kahanan kurang asam lan instalasi desulfuration karo pH ora kurang saka 4 | A49 | ||

| AB33: 33% -37% wesi putih krom | Bisa ngeterake slurry oksigen kanthi pH ora kurang saka 1 kayata phospor-plaster, asam nitrat, vitriol, fosfat lsp. | A33 | |||

| karet | R08 | ||||

| R26 | |||||

| R33 | |||||

| R55 | |||||

| Expeller & expeller ring | logam | B27: 23% -30% wesi putih krom | ≥56 | Digunakake kanggo kondisi nyandhang sing luwih dhuwur kanthi pH antarane 5 lan 12 | A05 |

| wesi abu-abu | G01 | ||||

| Kothak Isi | logam | AB27: 23%-30% wesi putih krom | ≥56 | Digunakake kanggo kondisi nyandhang sing luwih dhuwur kanthi pH antarane 5 lan 12 | A05 |

| wesi abu-abu | G01 | ||||

| Bingkai/Plat tutup, omah bantalan & alas | logam | wesi abu-abu | G01 | ||

| wesi ulet | D21 | ||||

| poros | logam | Baja karbon | E05 | ||

| Lengan poros, cincin lentera/restriktor, cincin leher, baut kelenjar | baja tahan karat | 4Cr13 | C21 | ||

| 304 SS | C22 | ||||

| 316 SS | C23 | ||||

| Dering gabungan & segel | karet | Butil | S21 | ||

| karet EPDM | S01 | ||||

| Nitrile | S10 | ||||

| Hypalon | S31 | ||||

| Neoprene | S44/S42 | ||||

| Viton | S50 |

Desain Modul Transmisi

Desain Modul Transmisi

|

Poros pompa diameter gedhe, silinder Konstruksi beban abot, bantalan metrik nggunakake pelumasan lenga utawa pelumas pelumas; dibukak ing serial, fitur construction saka volume cilik lan linuwih dhuwur. |

|

|

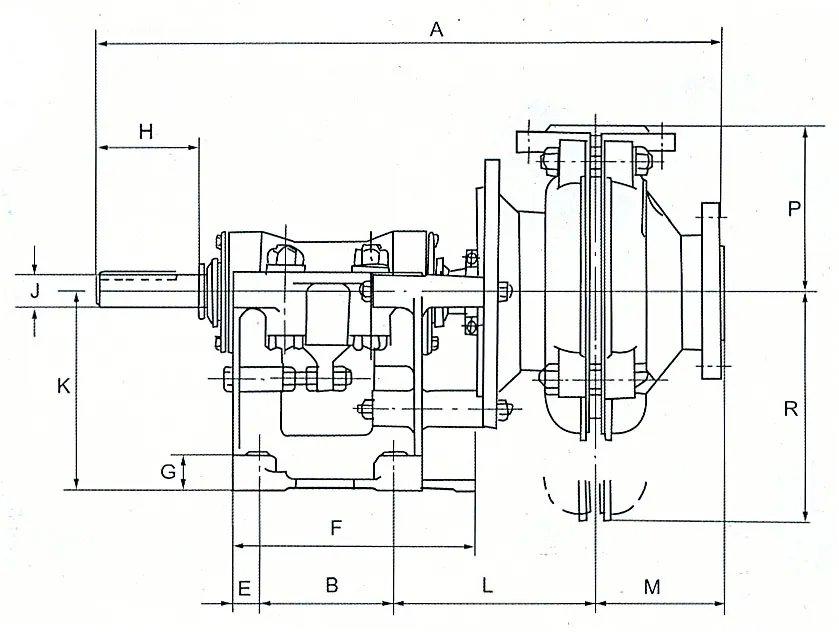

Majelis Bantalan Poros Poros diameter gedhe kanthi overhang cendhak nyuda defleksi lan geter. Bantalan rol tugas abot disimpen ing kartrid bantalan sing bisa dicopot. Pangkalan Pompa Nyepetake pompa ing pangkalan kanthi jumlah bolt minimal lan atur impeller ing posisi sing trep ing ngisor omah bantalan. Tutup anti banyu nyegah banyu bocor saka mabur. Tutup perlindungan nyegah banyu bocor saka braket bantalan.

|

Desain Modul Shaft Seal

|

1. Packing Box 2. Ring Lentera ngarep 3. Packing 4. Packing Gland 5. Lengan Poros |

|

1. Release Gland 2. Expeller 3. Packing 4. Packing Gasket 5. Ring Lantern 6. Packing Gland 7. Cangkir Minyak |

|

|

Seal Mekanik GRJ Jinis GRG digunakake kanggo cairan sing ora diidini diencerake. Seal Mekanik HRJ jinis HRJ digunakake kanggo Cairan diijini dilute. Keramik kekerasan dhuwur lan sekutu diadopsi kanggo bahan bagean gesekan. Nduwe resistensi abrasif & bukti goyang sing dhuwur kanggo njamin efek sealing bisa ditindakake dening pelanggan ing macem-macem kahanan.

|

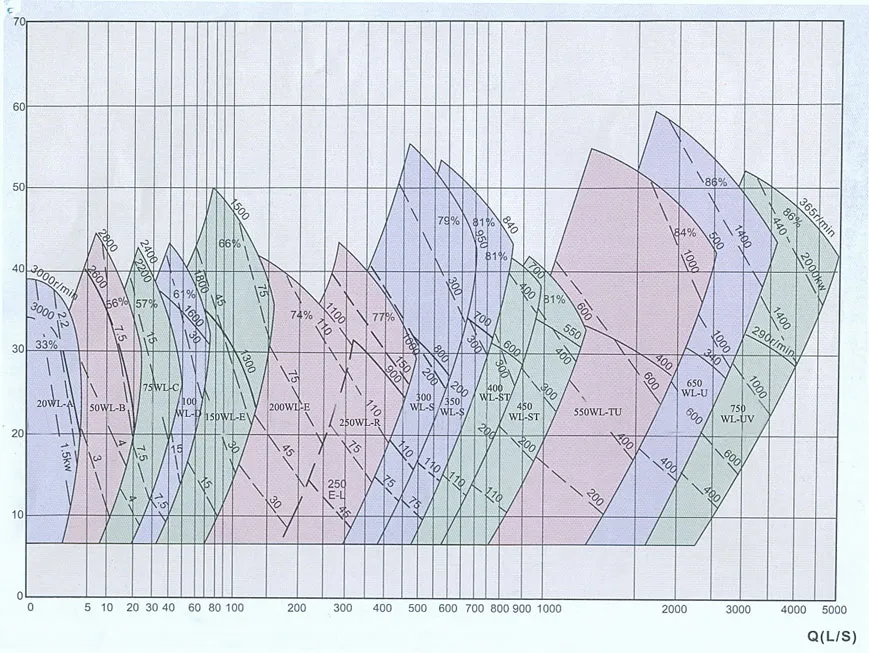

Kurva Kinerja

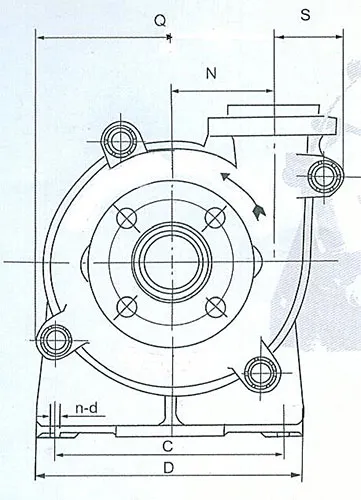

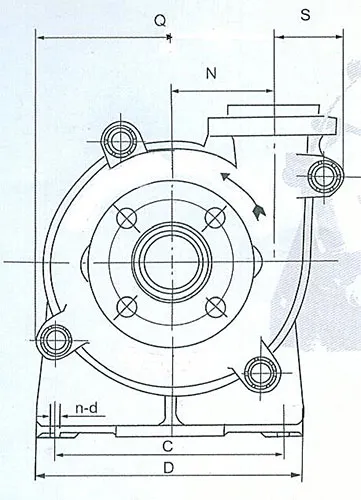

Dimensi Instalasi

| Jinis | A | B | C | D | E | F | G | nd | H | J | K | L | M |

| 20WL-A | 461 | 159 | 241 | 286 | 25 | 210 | 28 | 4-Φ18 | 57 | 20 | 145 | 89 | 90 |

| 50WL-B | 624 | 143 | 254 | 295 | 24 | 248 | 38 | 4-Φ14 | 80 | 28 | 197 | 191 | 136 |

| 75WL-C | 813 | 175 | 356 | 406 | 32 | 311 | 48 | 4-Φ19 | 120 | 42 | 254 | 253 | 163 |

| 100WL-D | 950 | 213 | 432 | 492 | 38 | 364 | 64 | 4-Φ22 | 163 | 65 | 330 | 280 | 187 |

| 150WL-E | 1218 | 257 | 546 | 622 | 54 | 448 | 76 | 4-Φ29 | 220 | 80 | 457 | 376 | 237 |

| 200WL-E | 1334 | 257 | 546 | 622 | 54 | 448 | 76 | 4-Φ29 | 220 | 80 | 457 | 413 | 306 |

| 250WL-E | 1348 | 257 | 546 | 622 | 54 | 448 | 76 | 4-Φ29 | 220 | 80 | 457 | 411 | 324 |

| 250WL-R | 1406 | 490 | 560 | 680 | 50 | 590 | 70 | 4-Φ28 | 216 | 85 | 350 | 322 | 324 |

| 300WL-S | 1720 | 640 | 760 | 920 | 70 | 780 | 90 | 4-Φ35 | 280 | 120 | 450 | 415 | 300 |

| 350WL-S | 1776 | 640 | 760 | 920 | 70 | 780 | 90 | 4-Φ35 | 280 | 120 | 450 | 425 | 340 |

| 400WL-ST | 1840 | 620 | 900 | 1150 | 80 | 780 | 125 | 4-Φ48 | 280 | 120 | 650 | 480 | 375 |

| 450WL-ST | 1875 | 620 | 900 | 1150 | 80 | 780 | 125 | 4-Φ48 | 280 | 120 | 650 | 500 | 400 |

| 550WL-TU | 2400 | 860 | 1200 | 1460 | 95 | 1050 | 150 | 4-Φ79 | 350 | 150 | 900 | 625 | 500 |

|

|

| Jinis | Ukuran Kepala Pompa | Suction Flange | Discharge Flange Kab | ||||||||||

| N | S | Q | R | P | OD | ID | CC Nanging. bolongan |

bolongan | OD | ID | CC Nanging. bolongan |

bolongan | |

| 20WL-A | 86 | 144 | 128 | 114 | 25 | 83 | 4-Φ14 | 102 | 20 | 73 | 4-Φ14 | ||

| 50WL-B | 114 | 155 | 163 | 184 | 75 | 146 | 4-Φ19 | 165 | 50 | 127 | 4-Φ19 | ||

| 75WL-C | 146 | 102 | 204 | 229 | 100 | 191 | 4-Φ19 | 203 | 75 | 165 | 4-Φ19 | ||

| 100WL-D | 190 | 118 | 262 | 305 | 150 | 260 | 4-Φ22 | 229 | 100 | 191 | 4-Φ22 | ||

| 150WL-E | 248 | 155 | 324 | 368 | 200 | 324 | 8-Φ19 | 305 | 150 | 260 | 8-Φ19 | ||

| 200WL-E | 292 | 199 | 401 | 445 | 250 | 394 | 8-Φ22 | 382 | 200 | 337 | 8-Φ22 | ||

| 250WL-E | 438 | 257 | 476 | 603 | 470 | 552 | 305 | 495 | 8-Φ32 | 483 | 254 | 425 | 8-Φ32 |

| 250WL-R | 438 | 257 | 476 | 603 | 470 | 552 | 305 | 495 | 8-Φ32 | 483 | 254 | 425 | 8-Φ32 |

| 300WL-S | 475 | 265 | 599 | 634 | 570 | 560 | 350 | 500 | 12-Φ26 | 530 | 300 | 470 | 12-Φ26 |

| 350WL-S | 530 | 295 | 643 | 691 | 620 | 640 | 400 | 580 | 12-Φ26 | 590 | 350 | 530 | 12-Φ26 |

| 400WL-ST | 600 | 343 | 747 | 809 | 740 | 720 | 450 | 650 | 12-Φ33 | 685 | 400 | 615 | 12-Φ33 |

| 450WL-ST | 660 | 375 | 814 | 872 | 800 | 770 | 500 | 700 | 12-Φ33 | 740 | 450 | 670 | 12-Φ33 |

| 550WL-TU | 860 | 453 | 1055 | 1142 | 975 | 975 | 650 | 880 | 12-Φ39 | 900 | 550 | 800 | 12-Φ39 |