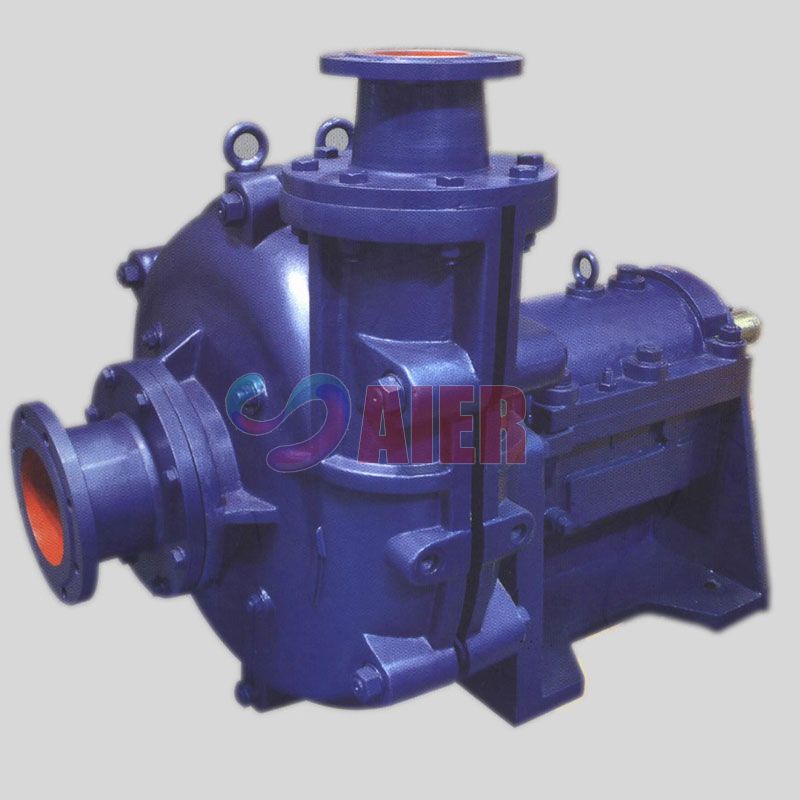

WZ High Efficiency Slurry Pump

Pump Yntroduksje

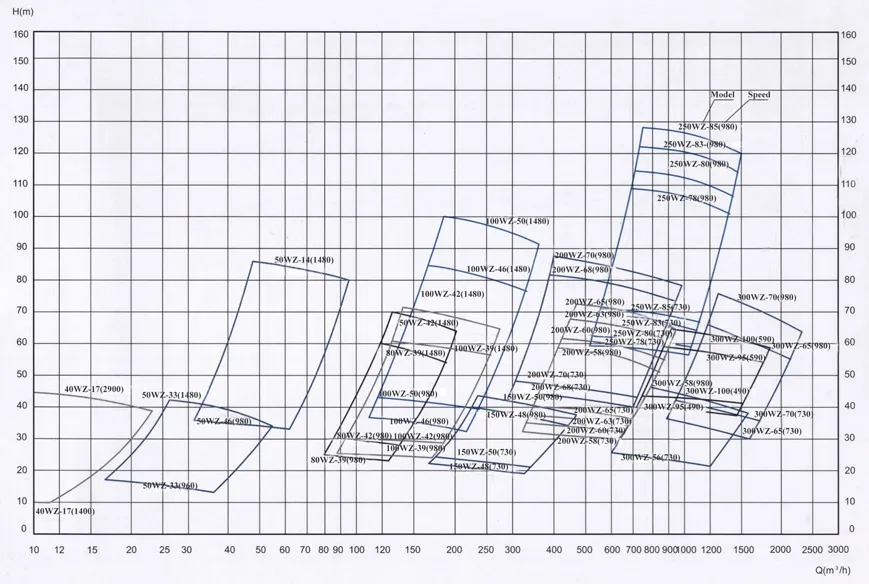

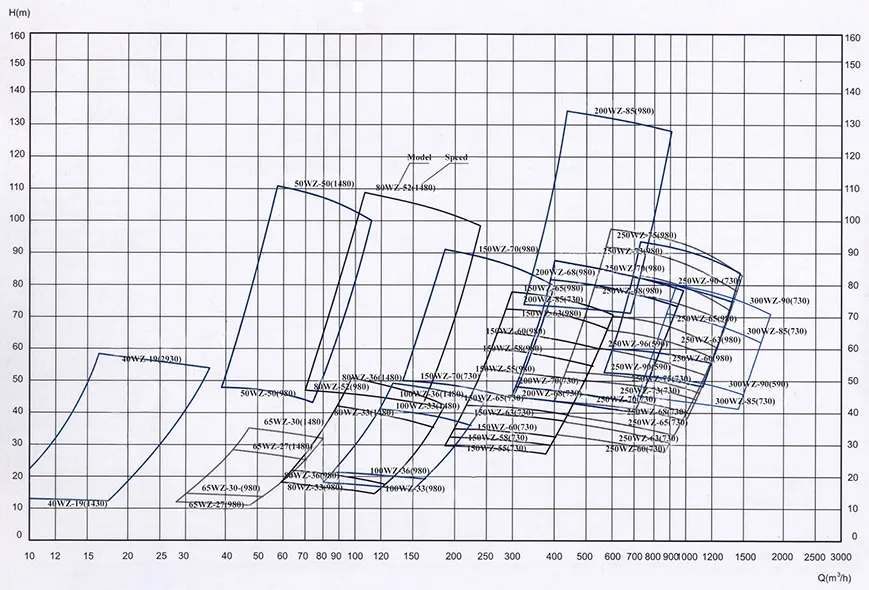

SPESIFIKASJES:

Grutte (ûntslach): 40 mm oant 300 mm

Capacity: 4-1826 m3/h

Head: 9m-133.7 m

Handing fêste stoffen: 11-92mm

Konsintraasje: 0% -70%

Materials:High chrome alloy etc

AIER® WZ Slurry Pump

WZ-searje slurrypompen binne nij type slijtbestindich en korrosjebestindich slurrypomp foar de kompleksiteit en spesifisiteit fan stienkoal, enerzjysintrale, metallurgy, gemyske, boumaterialen en oare yndustry.

WZ rige slurry pompen wurde ûntwikkele op de brede oanpassing fan sawol binnen- en bûtenlân advance technology en in protte jierren fan slurry pump design en fjild operaasje ûnderfinings.

Features: hege effisjinsje, enerzjybesparring, lege trilling, stabile operaasje, lege libbensdoer, maklik ûnderhâld, ensfh.

Wurkomstannichheden

Faasje: Direkte keppele: 2900/1480/980/730/590 r/min; Oare type: as per klant eask

Medium temperature: commonly ≤ 80 ˚C; specially: 110 ˚C

Weight density of slurry: Grout: ≤ 45%, Mining slurry: ≤ 60%

Kapasiteit: 30 oan 2000m3 / h

Head: 15-30m

Features

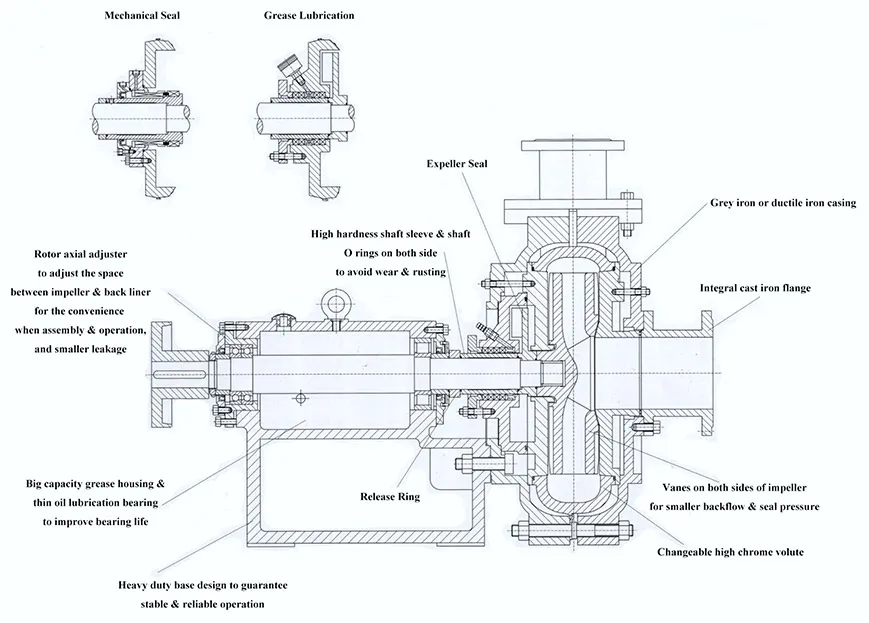

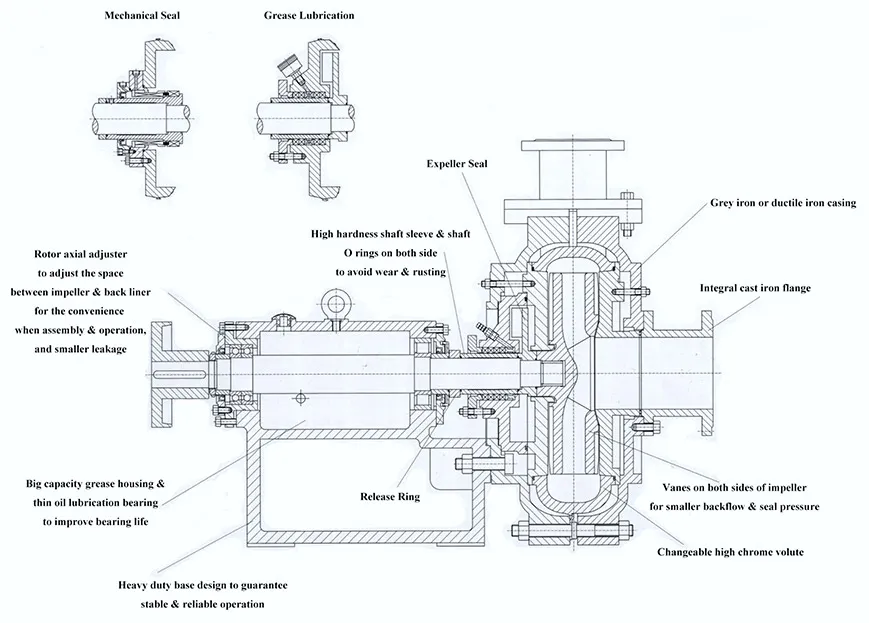

De frameplaat foar pompen fan 'e WA-searje hat útwikselbere hurdmetaal as drukfoarmige elastomere liners. De waaiers binne makke fan hurdmetaal as drukfoarmige elastomere liners.

De skaftdichtingen foar WA-searje kinne pakkingsegel, sintrifugale seal of meganyske seal wêze.

De ûntslachtûke kin wurde pleatst yn yntervallen fan 45 graden op oanfraach en oriïntearre op elke acht posysjes om te passen by ynstallaasjes en tapassingen. D'r binne in protte oandriuwmodi foar opsje, lykas V-riem, fleksibele koppeling, gearbox, hydraulyske koppeling fariabele frekwinsje, silisium kontroleare snelheid, ensfh Under harren, de fleksibele shaft coupling drive en V-riem funksje fan lege kosten en maklike ynstallaasje.

As Seal Type

Packing Seal: hege druk seal wetter nedich. Foar discharge druk < suction parse ien poadium ynstallaasje of multi stage rige ynstallaasje.

Expeller- en ferpakkingskombinaasje: Foar ûntlaaddruk> suction parse ynstallaasje fan ien poadium as ynstallaasje fan meartalige searjes.

Mechanyske seal: Foar brûkers fan strikte fraach nei lekkage.

Pomp notaasje

100WZ-42

100: ôflaat diameter (mm)

WZ: slurrypomp

42: waaier diameter (cm)

Konstruksje Design

Pump Part Materiaal

| Part Namme | Materiaal | Spesifikaasje | HRC | Oanfraach | OEM Code |

| Liners & Impeller | Metaal | AB27: 23% -30% chrome wyt izer | ≥56 | Brûkt foar hegere wearbetingsten mei pH tusken 5 en 12 | A05 |

| AB15: 14% -18% chrome wyt izer | ≥59 | Wurdt brûkt foar hegere wearbetingsten | A07 | ||

| AB29: 27% -29% chrome wyt izer | 43 | Wurdt brûkt foar legere pH-tastân foaral foar FGD. It kin ek brûkt wurde foar lege-soere tastân en desulfuration ynstallaasje mei pH net minder dan 4 | A49 | ||

| AB33: 33% -37% chrome wyt izer | It kin oxygenated slurry transportearje mei pH net minder dan 1 lykas phospor-pleister, salpetersûr, vitriol, fosfaat ensfh. | A33 | |||

| Expeller & Expeller ring | Metaal | B27: 23% -30% chrome wyt izer | ≥56 | Brûkt foar hegere wearbetingsten mei pH tusken 5 en 12 | A05 |

| Griis izer | G01 | ||||

| Stuffing Box | Metaal | AB27: 23% -30% chrome wyt izer | ≥56 | Brûkt foar hegere wearbetingsten mei pH tusken 5 en 12 | A05 |

| Griis izer | G01 | ||||

| Frame/dekplaat, lagerhuis en basis | Metaal | Griis izer | G01 | ||

| Duktiel izer | D21 | ||||

| Shaft | Metaal | Koalstof stiel | E05 | ||

| Shaft sleeve, lantearnring / rescstrictor, hals ring, gland bout | Rustfrij stiel | 4 kr13 | C21 | ||

| 304 SS | C22 | ||||

| 316 SS | C23 | ||||

| Joint ringen en sealen | Rubber | Butyl | S21 | ||

| EPDM rubber | S01 | ||||

| Nitril | S10 | ||||

| Hypalon | S31 | ||||

| Neoprene | S44/S42 | ||||

| Viton | S50 |

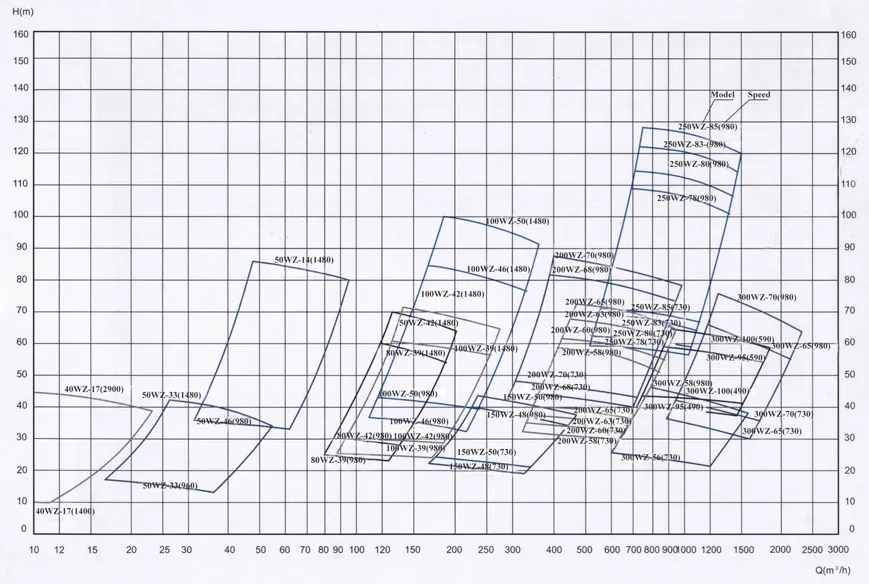

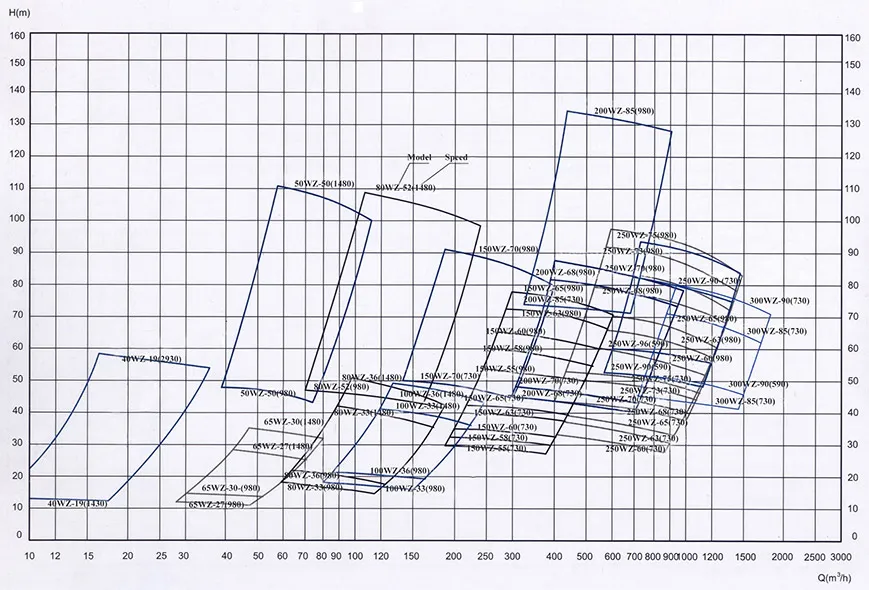

Performance Data

| Model | Max Mating Power (kw) | Clear Water Performance | Max Solid Hoewol mm |

Pomp Gewicht kg |

||||

| Capcity m3/h |

Holle m |

Faasje rpm |

De heechste wearde fan EFF. % |

NPSHr m |

||||

| 40WZ-14 | 7.5 | 4-23 | 9.0-44.5 | 1400-2900 | 52.4 | 2.5 | 11 | 100 |

| 40WZ-19 | 15 | 8-35 | 12.8-57.1 | 1430-2930 | 58.8 | 1.3 | 11 | 160 |

| 50WZ-33 | 18.5 | 12-54 | 7.7-42.5 | 700-1480 | 41.4 | 2.9 | 13 | 450 |

| 50WZ-46 | 55 | 23-94 | 17.9-85.8 | 700-1480 | 44.7 | 1.4 | 13 | 690 |

| 50WZ-50 | 90 | 27-111 | 22.3-110.7 | 700-1480 | 45.1 | 3.0 | 13 | 1050 |

| 65WZ-27 | 11 | 20-72 | 6.0-29.0 | 700-1460 | 62.5 | 1.8 | 19 | 400 |

| 65WZ-30 | 15 | 23-80 | 7.4-35.8 | 700-1460 | 63.5 | 2.0 | 19 | 420 |

| 80WZ-33 | 37 | 43-174 | 8.8-43.3 | 700-1460 | 67.7 | 2.3 | 24 | 580 |

| 80WZ-36 | 45 | 46-190 | 9.6-51.5 | 700-1480 | 68.2 | 2.5 | 24 | 600 |

| 80WZ-39 | 55 | 57-189 | 12.4-60.9 | 700-1480 | 66.0 | 2.5 | 24 | 660 |

| 80WZ-42 | 75 | 61-204 | 14.4-70.6 | 700-1480 | 67.8 | 2.5 | 24 | 680 |

| 80WZ-52 | 160 | 51-242 | 22.1-109.8 | 700-1480 | 56.3 | 2.1 | 21 | 1100 |

| 100WZ-33 | 45 | 56-225 | 8.2-41.6 | 700-1480 | 69.6 | 1.8 | 32 | 700 |

| 100WZ-36 | 55 | 61-245 | 9.7-48.6 | 700-1480 | 72.6 | 2.0 | 32 | 710 |

| 100WZ-39 | 75 | 61-255 | 12.6-61.2 | 700-1480 | 71.0 | 2.4 | 35 | 760 |

| 100WZ-42 | 90 | 66-275 | 14.7-71.0 | 700-1480 | 71.0 | 2.5 | 35 | 780 |

| 100WZ-46 | 132 | 79-311 | 17.3-86.0 | 700-1480 | 68.9 | 2.6 | 34 | 1100 |

| 100WZ-50 | 160 | 85-360 | 20.5-101.6 | 700-1480 | 71.3 | 2.5 | 34 | 1120 |

| 150WZ-42 | 132 | 142-550 | 12.1-64.0 | 700-1480 | 76.4 | 2.2 | 69 | 1550 |

| 150WZ-48 | 75 | 111-442 | 8.7-39.7 | 490-980 | 78.0 | 2.5 | 48 | 1610 |

| 150WZ-50 | 75 | 115-460 | 9.5-43.1 | 490-980 | 78.0 | 2.5 | 48 | 1630 |

| 150WZ-55 | 110 | 124-504 | 12.3-54.2 | 490-980 | 74.5 | 2.3 | 48 | 1660 |

| 150WZ-58 | 132 | 131-532 | 13.7-60.3 | 490-980 | 77.5 | 2.5 | 48 | 1680 |

| 150WZ-60 | 160 | 135-550 | 14.7-64.5 | 490-980 | 77.5 | 2.5 | 48 | 1700 |

| 150WZ-63 | 185 | 146-582 | 16.3-73.7 | 490-980 | 75.0 | 2.5 | 48 | 1900 |

| 150WZ-65 | 200 | 150-600 | 17.4-78.5 | 490-980 | 72.0 | 2.5 | 48 | 1930 |

| 150WZ-70 | 185 | 93-400 | 20.0-91.2 | 490-980 | 62.3 | 2.0 | 37 | 1950 |

| Model | Max Mating Power (kw) | Clear Water Performance | Max Solid Hoewol mm |

Pomp Gewicht kg |

||||

| Capcity m3/h |

Holle m |

Faasje rpm |

De heechste wearde fan EFF. % |

NPSHr m |

||||

| 200WZ-58 | 185 | 211-841 | 13.0-59.8 | 490-980 | 81.7 | 2.5 | 62 | 1940 |

| 200WZ-60 | 200 | 218-870 | 13.9-64.0 | 490-980 | 82.7 | 2.5 | 62 | 1970 |

| 200WZ-63 | 250 | 228-921 | 15.4-67.6 | 490-980 | 79.3 | 2.5 | 62 | 2030 |

| 200WZ-65 | 250 | 235-950 | 16.4-72.0 | 490-980 | 80.0 | 2.5 | 62 | 2050 |

| 200WZ-68 | 315 | 199-948 | 18.3-81.5 | 490-980 | 74.6 | 2.8 | 56 | 2130 |

| 200WZ-70 | 315 | 205-976 | 19.4-86.4 | 490-980 | 75.6 | 2.8 | 56 | 2150 |

| 200WZ-73 | 355 | 219-876 | 21.6-98.2 | 490-980 | 74.5 | 3.0 | 56 | 2660 |

| 200WZ-75 | 355 | 225-900 | 22.8-103.0 | 490-980 | 74.5 | 3.0 | 56 | 2700 |

| 200WZ-85 | 560 | 221-907 | 32.0-133.7 | 490-980 | 70.5 | 2.8 | 54 | 3610 |

| 250WZ-60 | 280 | 276-1152 | 13.1-58.4 | 490-980 | 73.9 | 2.8 | 72 | 2800 |

| 250WZ-63 | 315 | 290-1211 | 14.4-64.3 | 490-980 | 76.5 | 3.0 | 72 | 2820 |

| 250WZ-65 | 315 | 299-1249 | 15.4-69.0 | 490-980 | 77.5 | 3.0 | 72 | 2840 |

| 250WZ-68 | 450 | 272-1341 | 17.1-80.9 | 490-980 | 72.5 | 2.7 | 72 | 3120 |

| 250WZ-70 | 450 | 280-1380 | 18.1-85.7 | 490-980 | 74.0 | 2.9 | 72 | 3150 |

| 250WZ-73 | 500 | 292-1441 | 19.7-93.2 | 490-980 | 76.0 | 3.0 | 72 | 3190 |

| 250WZ-75 | 560 | 300-1480 | 20.8-98.4 | 490-980 | 96.0 | 3.0 | 72 | 3230 |

| 250WZ-78 | 630 | 345-1380 | 25.4-109.3 | 490-980 | 70.8 | 3.2 | 76 | 4530 |

| 250WZ-80 | 710 | 354-1415 | 26.7-115.0 | 490-980 | 72.6 | 3.4 | 76 | 4540 |

| 250WZ-83 | 800 | 367-1468 | 28.7-123.8 | 490-980 | 74.6 | 3.5 | 76 | 4550 |

| 250WZ-85 | 800 | 376-1504 | 30.1-129.8 | 490-980 | 75.6 | 3.5 | 76 | 4560 |

| 250WZ-90 | 450 | 378-1374 | 22.3-82.4 | 400-730 | 73.8 | 3.4 | 69 | 4600 |

| 250WZ-96 | 560 | 403-1466 | 25.4-93.7 | 400-730 | 77.8 | 3.5 | 69 | 4650 |

| 300WZ-56 | 250 | 395-1568 | 9.7-46.0 | 490-980 | 81.3 | 3.5 | 96 | 2900 |

| 300WZ-65 | 500 | 589-2166 | 13.8-66.2 | 490-980 | 78.4 | 3.7 | 92 | 2920 |

| 300WZ-70 | 630 | 635-2333 | 16.0-76.8 | 490-980 | 80.4 | 3.9 | 92 | 2940 |

| 300WZ-85 | 450 | 477-1742 | 18.9-69.6 | 400-730 | 78.7 | 3.8 | 85 | 4900 |

| 300WZ-90 | 560 | 505-1844 | 21.2-80.0 | 400-730 | 81.5 | 3.8 | 85 | 4950 |

| 300WZ-95 | 400 | 441-1735 | 13.8-58.8 | 300-590 | 77.8 | 3.0 | 88 | 5010 |

| 300WZ-100 | 450 | 464-1826 | 15.3-65.2 | 300-590 | 80.8 | 3.0 | 88 | 5060 |

Primêr seleksjediagram