- Moafrika

- Sealbania

- Seamharic

- Searabia

- Searmenia

- Se-Azerbaijani

- Sebasque

- Sebelarusia

- Benghali

- Sebosnia

- Se-Bulgaria

- Secatalan

- Sebuano

- China

- China (Taiwan)

- Corsican

- Secroatia

- Czech

- Sedanishe

- Se-Dutch

- Senyesemane

- Esperanto

- Seestonia

- Sefinnishe

- Sefora

- Sefrisia

- Segalician

- Segeorgia

- Sejeremane

- Segerike

- Segujarati

- Secreole sa Haiti

- hausa

- siwaiian

- Seheberu

- Che

- Miao

- Se-Hungary

- Seiceland

- igbo

- Seindonesia

- irish

- Setaliana

- Sejapane

- Se-Javanese

- Kannada

- kazakh

- Khmer

- Rwanda

- Sekorea

- Sekurdish

- Sekyrgyz

- Lefuba

- Selatine

- Selatvia

- Selithuania

- Se-Luxembourgish

- Semacedonia

- Malgashi

- Semalay

- Semalayalam

- Semalta

- Semaori

- Marathi

- Mongolian

- Myanmar

- tsa Nepali

- Norwegian

- Norwegian

- Occitan

- Sepashto

- Sepersia

- Sepolishe

- Sepotoketsi

- Sepunjabi

- Seromania

- Serussia

- Sesamoa

- Segaeli sa Scotland

- Seserbia

- Senyesemane

- Seshona

- Sindhi

- Sesinhala

- Seslovak

- Seslovenia

- Somalia

- Sepanish

- Sesundanese

- Seswahili

- Seswedishe

- Setagalog

- Se-Tajik

- Setamil

- Setatare

- Setelugu

- Sethai

- Se-Turkey

- Turkmen

- Seukraine

- Seurdu

- Uighur

- Seuzbek

- Sevietnam

- Welsh

- Thusa

- Yiddish

- Yoruba

- Sezulu

Khutlela lethathamong

Ho Khetha Pompo e Ntle ea Slurry Bakeng sa Kopo ea Hao

Choosing the right target="_blank" title="Slurry Pump">pompo ea seretse for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the target="_blank" title="Slurry Pump Supplier">mofani oa pompo ea slurry o tla li arolelana le uena.

Moralo oa pompo ea seretse

Moralo oa pompo ea slurry o bohlokoa ho netefatsa hore likarolo tse senyang le tse senyang hangata tsa seretse ha li senye impeller. Ho phaella moo, li-slurries le li-sludges li ka 'na tsa e-ba le lintho tse ngata tse sa lebelloang, tse tla koala mefuta e mengata ea lipompo. Kaha li-impellers tse ngata tsa centrifugal li na le mamello e thata haholo holim'a lisebelisoa tsa liboko, tlhaho ea abrasive ('me ka linako tse ling e senya) ea slurry e tla senya ka potlako lisebelisoa tsa liboko ebe e senya mamello. Ka lehlakoreng le leng, sena se etsa hore pompo e lahleheloe ke ho hula. Sena se ka lebisa ho fokotseha ho hoholo ha pompo ea slurry, hammoho le tlhokomelo e theko e boima le likarolo tse ling.

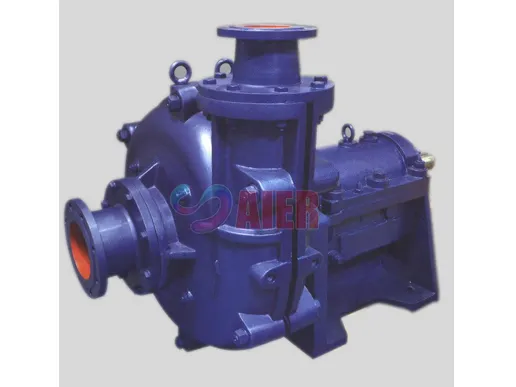

Pompo ea Seretse

Lipompompe tsa slurry tsa WZ ke mofuta o mocha oa ho sesa & corrosion resistant slurry pump bakeng sa ho rarahana le ho hlaka ha mashala, setsi sa motlakase, metallurgy, lik'hemik'hale, thepa ea mohaho le liindasteri tse ling.

Lipompompe tsa slurry tsa WZ li ntlafatsoa ka mokhoa o pharaletseng oa theknoloji ea lapeng le kantle ho naha le lilemo tse ngata tsa moralo oa pompo ea slurry le liphihlelo tsa ts'ebetso ea masimong.

If you want to get more information about the slurry pump for sale, welcome to target="_blank" title="Contact Us">iteanye le rona.

Lisebelisoa tsa kaho ea pompo ea seretse

Ho khetha thepa e nepahetseng bakeng sa pompo ea slurry ke ts'ebetso e 'ngoe ea bohlokoa ea ho khetholla pompo e nepahetseng bakeng sa ho sebetsana le slurry. Haeba slurry e senya haholo ka pH e sa jeleng paate, joale thepa e ntle ka ho fetisisa ea kaho ke Hi-Chrome. metallurgy ena na le phahameng ka ho fetisisa Brinell thatafala le ka mamella abrasiveness ea slurry.

Ka lehlakoreng le leng, haeba slurry e sa qhekelle feela empa hape e na le pH e tlaase, joale kaho ea tšepe e sa hloekang ea duplex e molemo. Boitsebiso bona bo loketse ka ho fetisisa bakeng sa lipompo tsa slurry ho mamella lisebelisoa tse thata (tse kang li-acids) ha li ntse li e-na le boima bo phahameng ba Brinell.

Litiiso tsa pompo ea slurry

Ho itšetlehile ka mofuta oa abrasive ea slurry, ke habohlokoa ho khetha tiiso e loketseng. Litiiso tsa pompo ea slurry li lokela ho ba le bokaholimo bo thata bo entsoeng ka silicon carbide kapa tungsten carbide. Lipompompo tsa Vortex li sebelisa theknoloji ea tiiso e nang le tokelo ea molao e sebelisang setaele sa mochini o habeli le sistimi e arohaneng ea litiiso. Sena se lumella sebaka sa ho tiisa hore se lule se pholile ka linako tsohle ntle le ho etsa hore slurry e chese tiiso le ho senya bokaholimo.

Phetoho ea matla a pompo ea slurry

Ho bohlokoa ho tseba boholo bo nepahetseng ba pompo ea slurry le litlhoko tsa matla bakeng sa ts'ebeliso ea hau. Ho itšetlehile ka tlhaho ea abrasive ea slurry, ke habohlokoa ho khetha boholo ba pompo bo tla e lumella ho matha ka lebelo le lekaneng ho lelefatsa bophelo ba pompo ea slurry. RPM e loketseng ea ho tsamaisa pompo ea seretse e pakeng tsa 900 le 1200 RPM. Hang ha lebelo leo le qala ho fetisoa, bophelo ba pompo bo fokotsehile haholo hobane lintlha tsa ho roala tsa pompo ea slurry li hlile li le lehlabathe.

-

Small Dredge Pump Applications in Aquaculture and Ponds

LitabaAug.28,2025

-

Portable Sump Pumps for Emergency Flood Situations

LitabaAug.28,2025

-

Metal Slurry Pump Applications in Mining Industry

LitabaAug.28,2025

-

Hydraulic Performance Testing for Centrifugal Vertical Slurry Pumps

LitabaAug.28,2025

-

Froth Pump Automation Trends in Modern Industry

LitabaAug.28,2025

-

Common Applications for Rubber Slurry Pumps

LitabaAug.28,2025