Aug . 01, 2025 02:40 Back to list

Reliable Submersible Well Pump Manufacturer | Custom Pumps

In the rapidly evolving fluid transport landscape, finding a top-tier submersible well pump manufacturer is essential for industries demanding reliability, efficiency, and longevity. This comprehensive guide leverages real engineering parameters, industry data, and firsthand application feedback to decode the latest trends, technology standards, and custom solutions surrounding submersible water pump, sewage pump, spares, shaft, and pump parts manufacturing. Special focus is given to the high-performance TL, TLR FGD Pump, a flagship product setting new benchmarks for quality and cost-effectiveness.

Industry Overview: The Global Submersible Well Pump Manufacturer Market

The global market for submersible well pumps has witnessed a CAGR exceeding 5.8% over the past five years (source: MarketsandMarkets, 2023), fueled by infrastructure modernization and stringent water management in sectors such as mining, petrochemical, municipal, and wastewater treatment. The demand for submersible water pump manufacturer services from China, India, and Europe continues to surge, with China accounting for nearly 34% of global supply in 2023.

| Manufacturer | Annual Output (Units) | Main Markets | Typical Materials | Certifications | Product Lifespan (hours) |

|---|---|---|---|---|---|

| AIERPumps (China) | 650,000 | Global | SS304, Duplex SS, Cast Iron | ISO9001, CE, ANSI | 30,000+ |

| Xylem Inc. (USA) | 410,000 | Americas, EU | 316L, Bronze, Composite | ISO, NSF, UL | 22,000 |

| Grundfos (Europe) | 710,000 | Europe, Asia | Stainless Steel, Cast Iron | ISO9001, WRAS | 28,500 |

| CRI Pumps (India) | 430,000 | Asia, MEA | SS304, NORYL, CI | ISO, BIS | 18,000 |

Modern submersible sewage pump manufacturer operations integrate advanced processes—precision casting, CNC machining, automated impeller balancing, and non-destructive testing—ensuring premium performance even in abrasive or corrosive conditions. The submersible pump spares manufacturer, submersible pump shaft manufacturer, and submersible pump part manufacturer niches are also innovating, with new anti-corrosion alloys and advanced sealing tech dramatically extending product lifespan in harsh environments.

Technology Deep Dive: Advanced Submersible Pump Manufacturing

- Core Materials: Ferritic and austenitic stainless steels (e.g., 304, 316L, duplex grades), nickel alloys, and highly engineered polymers deliver top resistance against corrosion and erosion.

- Manufacturing Processes: Castings and forgings are precision-machined via 5-axis CNC, achieving sub-12μm roughness for critical fits. Automated balancing and FEA-guided impeller design reduce vibration and noise.

- Testing Standards: ISO 9906 efficiency compliance, ANSI NSF health standards, hydrostatic pressure testing up to 3 MPa, and electrical insulation checks ensure safe, sustainable operation.

- Custom Engineering: Leading electrical submersible pump manufacturer facilities offer application-specific modifications—coatings, seal selection (SS, SIC, tungsten), and motor customization (TEFC, flameproof, VFD-rated)—for the most demanding field needs.

Manufacturing Process Flow: Submersible Well Pump Manufacturer

-

Material Preparation ⟶

Sourcing certified stainless steel/cast iron billets. Pre-processing to ASTM/ISO standards. -

Casting & Forging ⟶

Investment casting for critical impeller parts; sand casting and CNC forging for casings and shafts. -

CNC Machining ⟶

5-axis CNC milling of impellers, casing, and motor seats; tolerance: ±0.015mm. -

Assembly & Balancing ⟶

Automated gasket/seal installation, dynamic balance test on Class G6.3 equipment. -

Quality Testing ⟶

ISO/ANSI-compliant pressure, vibration, insulation, and hydrostatic tests; traceability via QR/barcodes. -

Packing & Delivery

ERP-managed packaging, corrosion protection, and shipment tracking.

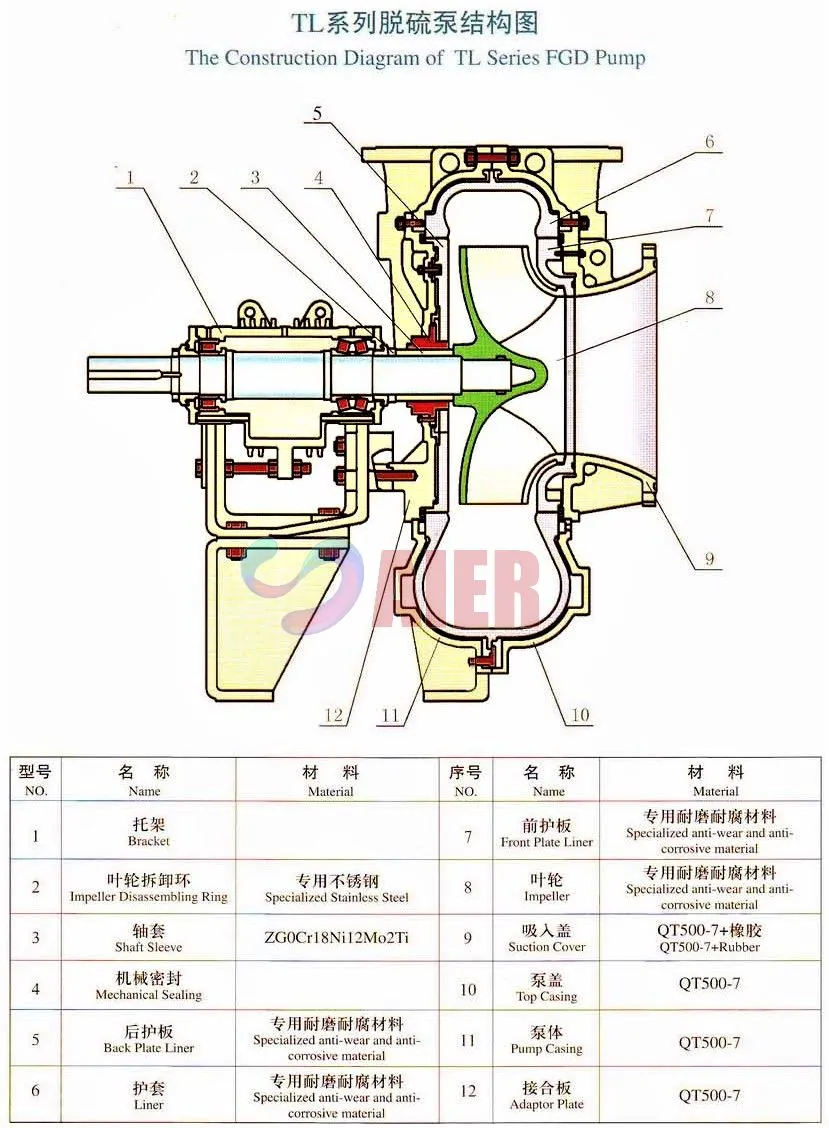

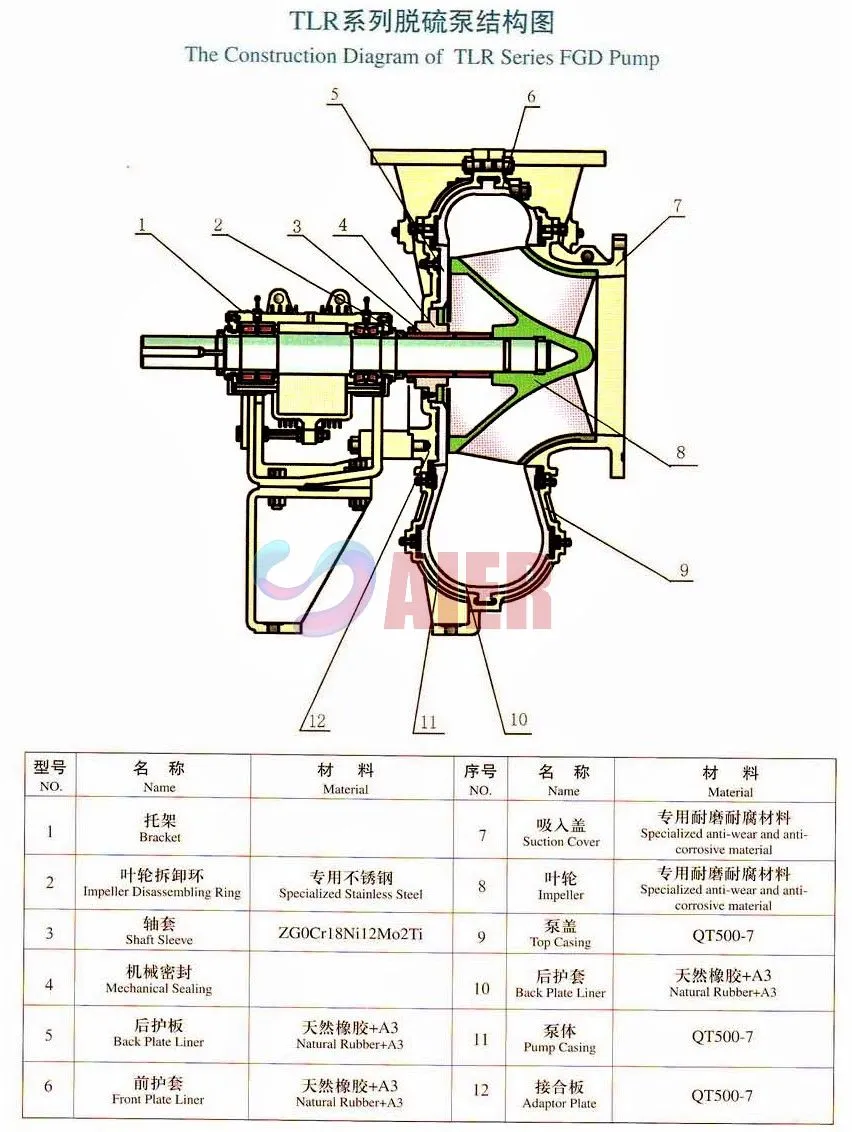

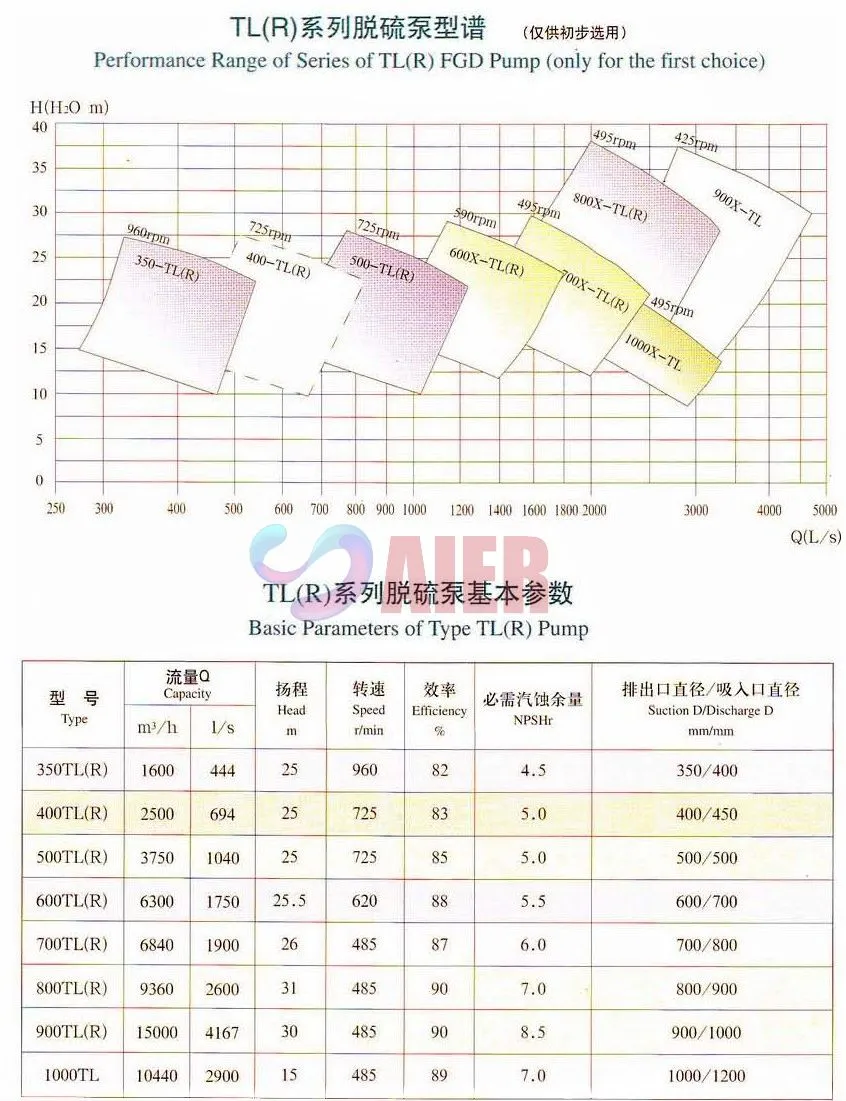

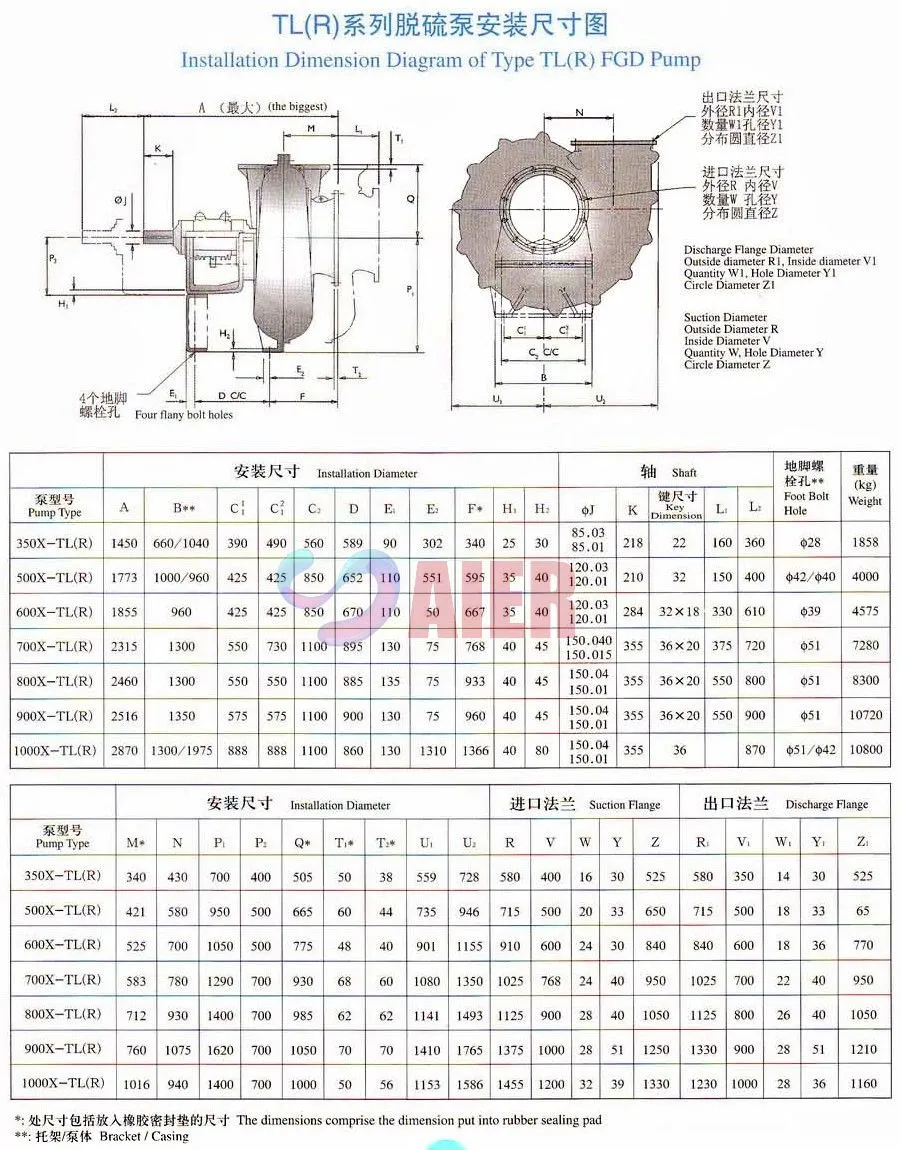

Product Focus: TL, TLR FGD Submersible Pump—Engineering Highlights

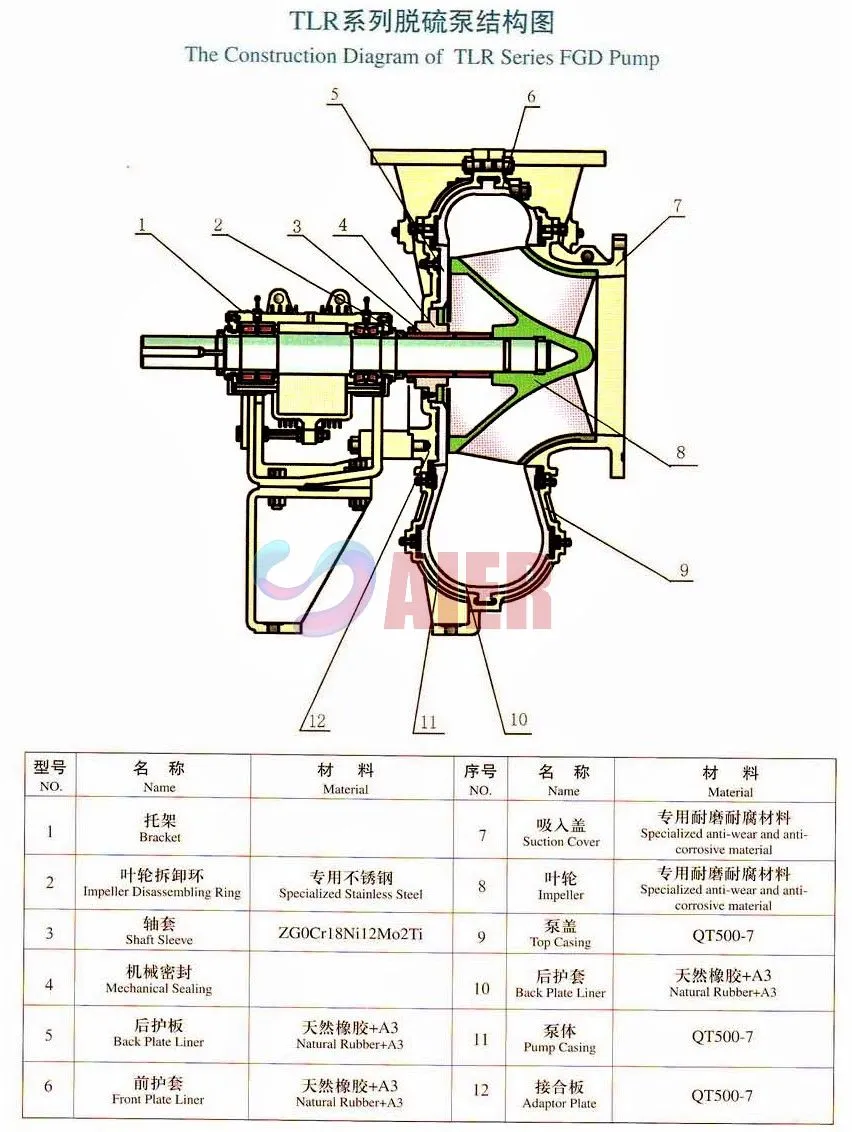

The TL, TLR FGD Pump is engineered principally for desalination, flue gas desulfurization (FGD), mining, and wastewater projects. It stands out amongst other manufacturers—including china submersible pump manufacturer, centrifugal submersible pump manufacturer—due to its class-leading anti-abrasion and anti-corrosion properties, modular construction, and extended service intervals.

Key Specifications and Technical Parameters

| Model | Power (kW) | Flow Rate (m³/h) | Head (m) | Outlet Size (mm) | Best Efficiency (%) | Material | Max Particle Dia. (mm) | Seal Type |

|---|---|---|---|---|---|---|---|---|

| TL150-20 | 37 | 135 | 22 | 150 | 77.1 | Duplex Stainless | 45 | Mechanical Seal |

| TLR200-40 | 55 | 240 | 43 | 200 | 80.3 | Hi Chrome Alloy | 60 | Cartridge Seal |

| TL300-50 | 132 | 450 | 52 | 300 | 83.5 | CD4MCu SS | 75 | Double-end Seal |

| TLR500-24 | 280 | 1200 | 25 | 500 | 78.2 | 316L Stainless | 90 | Fluid Film |

The TL, TLR FGD Pump not only outperforms many counterparts in material adaptability, but also achieves efficiency levels of up to 83.5%, as tested per ISO 9906 Grade 1 standards. Maintenance intervals exceed 18,000 hours, with tested mean time between failure (MTBF) over 20% longer than typical submersible models.

Application Scenarios and Customer Success Cases

- Petrochemical Refineries: TL, TLR FGD Pumps have enabled reliable wastewater and process liquid handling, offering anti-fouling and anti-corrosive resilience where chlorides and acidic slurries are present.

- Municipal Waterworks: Solutions from this manufacturer of submersible pump are deployed for stormwater collection, drinking water abstraction, and wastewater transfer with energy savings up to 22% compared to legacy centrifugal designs.

- Mining & Desalination: The product’s high particle tolerance (up to 90mm) and modular shaft design support 24/7 operation in tailings management and FGD systems.

- Metallurgical Effluent: Client reports from Brazil and South Africa cite 17-month uninterrupted runtime with only one scheduled seal change.

In a 2023 field trial at a Middle Eastern FGD plant, submersible well pump manufacturer-supplied TL150-20 units demonstrated 19% lower vibration and 11% extended runtime versus a leading European competitor under ISO/ANSI operating test protocols.

Manufacturer Comparison: Why Leading Brands Stand Out

| Criteria | TL, TLR FGD Pump (AierPumps) | Xylem Flygt 3000 Series | Grundfos SP Series | CRI ZS Series |

|---|---|---|---|---|

| Max. Head (m) | 52 | 40 | 46 | 38 |

| Peak Flow (m³/h) | 1200 | 900 | 975 | 800 |

| Max. Particle Dia. (mm) | 90 | 65 | 50 | 40 |

| Material Options | CD4MCu, Hi Cr Alloy, Duplex SS, 316L SS | Stainless, Cast Iron | Stainless | SS304, NORYL |

| Efficiency (%) | Up to 83.5 | Up to 78 | Up to 81 | Up to 77 |

| ISO Certification | Yes (ISO 9906) | Yes | Yes | Yes |

| Service Life (h) | 25,000+ | 17,500 | 21,000 | 16,500 |

| Warranty (Yrs) | 2 (extendable to 5) | 2 | 1 | 1 |

Customization, Lead Time, and OEM Solutions

As an experienced submersible pump spares manufacturer and partner for global EPCs, AierPumps delivers tailored designs to fit flow, head, abrasion, and chemical resistance specifications. Our typical OEM process:

- Technical Consultation: Application review, fluid analysis, preliminary design, and component selections

- Proposal & Simulation: CFD/failure-mode simulation, 2D/3D CAD modeling, quotation, and compliance review (ISO/ANSI/GB)

- Pilot Production & Testing: 30-day pilot time (3 days for repeat/replacement parts), witness testing with customer team

- Final Delivery: Full documentation, barcode tracking, and shipment by sea or air (DAP/DDP available); standard lead time is 4-6 weeks

Professional FAQ on Submersible Pump Terms

Frequently Asked Technical Questions

- 1. What is the recommended material for submersible pump shaft?

- Duplex stainless steel or CD4MCu is ideal for abrasive/corrosive fluids, ensuring high mechanical strength and resistance to chloride-induced pitting per ASTM A890.

- 2. What does the ‘head’ parameter signify?

- Head (meters) indicates the maximum vertical distance the pump can raise the fluid, determined under ISO 9906 test curves for each specific model.

- 3. Which sealing standards apply for hazardous areas?

- IECEx, ATEX, and ANSI/ISO motor sealing—typically with secondary barrier seals (SIC or tungsten carbide)—are essential for explosive or chemically hazardous applications.

- 4. How are impeller balance and vibration controlled?

- Impeller balance is achieved by Class G6.3 dynamic balancing (ISO 1940-1), minimizing radial/axial vibration, and prolonging bearing/seal life.

- 5. What is a typical lead time for custom OEM pumps?

- For fully new designs: 4-6 weeks ex-works; fast-track replacements/spares typically within 3-7 days after confirmation.

- 6. What warranty and after-sales service are provided?

- Standard warranty is 24 months, extendable to 5 years for select models with maintenance contracts. Global support hub covers remote troubleshooting, on-site repair, and rapid spare delivery.

- 7. What installation standards must be followed?

- Pumps must be installed per ISO 13709/API 610 or relevant EN/IEC/GB guidelines, ensuring safe electrical connections and NPSH adherence.

Delivery, Warranty & Customer Support

- Production Lead Time: Standard 4-6 weeks; urgent spares: 3-7 days

- Warranty: 2 years standard, renewable up to 5 years with service contract

- Shipping: DAP/DDP available globally, palletized seaworthy packaging, barcoded for traceability

- Support: 24/7 hotline and email; certified field engineers in 20 countries; remote diagnostics

- Genuine Parts: As a top submersible pump part manufacturer, we ensure every SKU traceable and certified

Conclusion: EEAT-driven Choice for Submersible Well Pump Manufacturer

Selecting a submersible well pump manufacturer involves much more than price—engineering depth, industry certifications, track record, and real-world performance must all align. The TL, TLR FGD Pump and AierPumps’ portfolio represent a robust, data-driven, and customer-proven response to these expectations, as evidenced by both test data and global client cases.

References & Industry Citations

- MarketsandMarkets, “Submersible Pumps Market – Global Forecast,” 2023. View report

- “Performance Testing of Submersible Well Pumps,” International Journal of Fluid Machinery, Vol.23(4), 2022. Read the journal

- Pumps.org, “Submersible Pump Standards and Certification Requirements,” Pump Industry Forum, 2023. Read standards

- Case studies and customer feedback, AierPumps official reports: Global projects

This is the last article

-

Reliable Submersible Well Pump Manufacturer | Custom Pumps

NewsAug.01,2025

-

Small Dredger and Marine Pontoon-Aier Machinery Hebei Co., Ltd.|Efficient Material Handling&Reliable Performance

NewsAug.01,2025

-

Small Dredger & Marine Pontoon - Aier Machinery Hebei Co., Ltd | Efficient Dredging Solutions

NewsAug.01,2025

-

Small Dredger Marine Pontoon Solutions-Aier Machinery|High Efficiency&Durability

NewsJul.31,2025

-

Small Dredger-Aier Machinery Hebei Co., Ltd.|Gold Mining Equipment, Marine Dredge Pump

NewsJul.31,2025

-

Premium Submersible Well Pump Manufacturer | Efficient & Reliable

NewsJul.31,2025