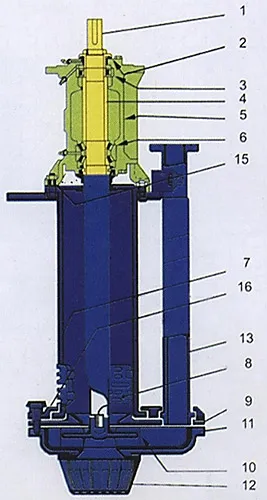

WY Sump Pump

Product Description

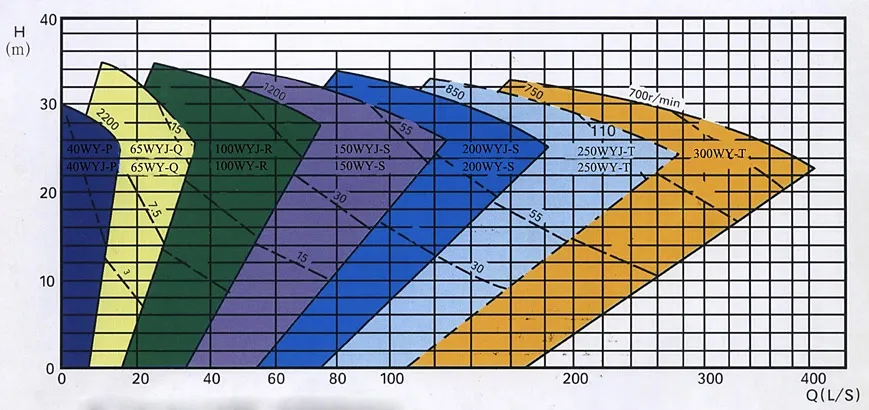

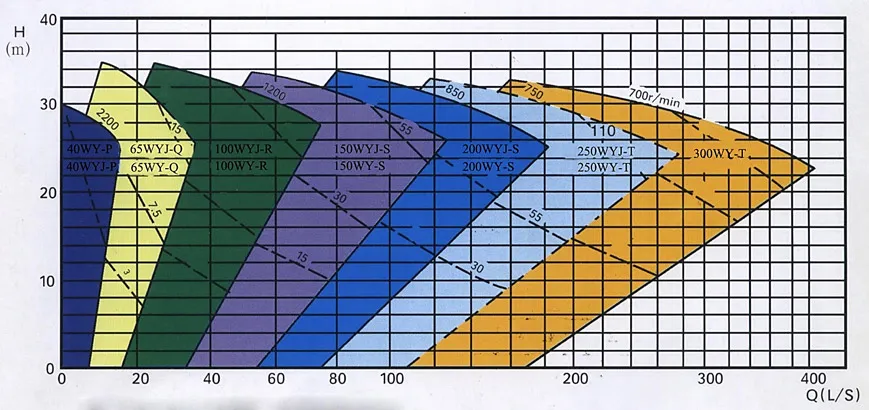

SPECIFICATIONS:

Qhov Loj (tso tawm): 40mm txog 300mm

Peev xwm: 7.28-1300 m3 / h

Lub taub hau: 3m-45m

Muab cov khoom siv: 0-79mm

Cov ntsiab lus: 0% -70%

Khoom siv: High chrome alloy, Roj Hmab,

Polyurethane, Ceramic, Stainless hlau thiab lwm yam.

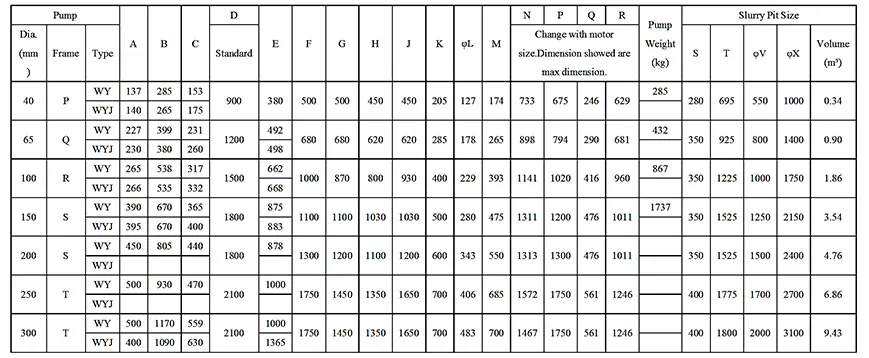

AIER® WY Sump Pump

WY & WYJ sump twj tso kua mis yog ntsug centrifugal slurry twj tso kua mis, submerged rau hloov abrasive, coarse hais thiab siab ceev slurry. Thaum ua haujlwm, nws xav tau tsis muaj dej foob lossis lwm yam foob. Nws tuaj yeem ua haujlwm tau zoo thiab thaum nqus ntim tsis txaus.

Tej kev siv

Sump tso dej los yog ntxuav

Cov dej hauv pem teb

Mill sump

Kev hloov pauv carbon

Saib xyuas

Magnetite sib tov

Nta

WY hom twj tso kua mis yog ua los ntawm cov hlau tsis muaj zog, cov khoom siv impeller tuaj yeem ua rau cov hlau lossis roj hmab.

Lub submerged qhov chaw ntawm WYJ yog tag nrho cov kab nrog roj hmab, rau kev hloov corrosive slurry.

Pump Notation

150 WY-S:

150: Qhov hluav taws xob txoj kab uas hla: mm

WY: Pump hom: High chrome alloy lined sump twj

S: Ncej phaj hom

150 WYJ-S:

150: Qhov hluav taws xob txoj kab uas hla: mm

WYJ: Pump type: Rubber lined sump pump

S: Ncej phaj hom

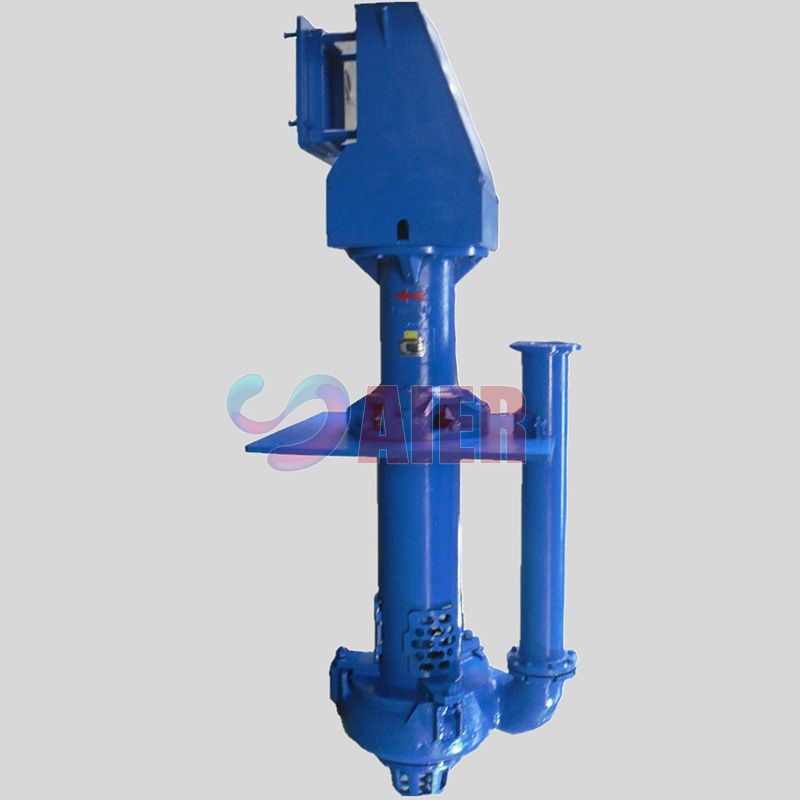

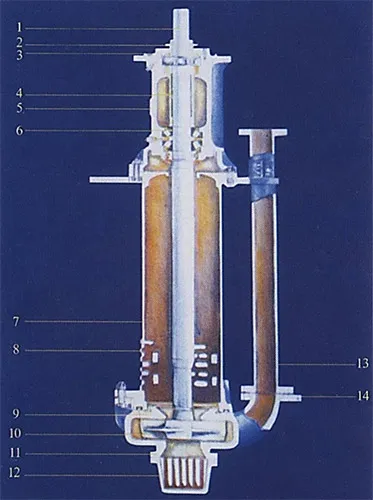

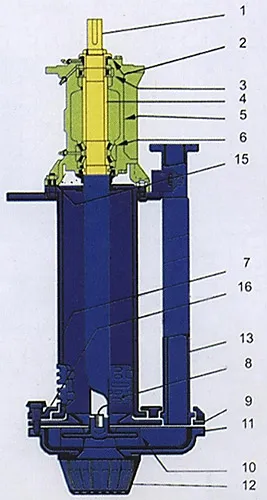

Tsim Tsim

WY High Chrome Alloy Lined

|

1. Ncej 2. Labyrinth 3. Cov kabmob 4. Bearing Spacer 5. Cov vaj tse nyob 6. Cov kabmob 7. Kem 8. Strainer 9. Rov qab Liner 10. Lub impeller 11. Pump casing 12. Qis Strainer 13. Cov yeeb nkab tawm 14. Split Discharge Flange |

|

1. Ncej 2. Labyrinth 3. Cov kabmob 4. Bearing Spacer 5. Cov vaj tse nyob 6. Cov kabmob 7. Kem 8. Strainer 9. Rov qab Liner 10. Lub impeller 11. Pump casing 12. Qis Strainer 13. Cov yeeb nkab tawm 15. Kem Bolt & Txiv Ntseej 16. Kem Bolt |

|

Pump Part Material

| Lub Npe | Khoom siv | Specification | HRC | Daim ntawv thov | OEM Code |

| Casing, Back Liner & Impeller | Hard Hlau | AB 8: KmTBCr8 | ≥55 | Siv rau av nkos twj tso kua mis | A01 |

| AM: KmTBMnMo | 38-42 | Siv rau lub teeb hnav zoo nrog cov nplej zoo | A11 | ||

| AB27: 23% -30% chrome dawb hlau | ≥56 | Siv rau kev hnav khaub ncaws siab dua nrog pH ntawm 5 txog 12 | A05 | ||

| AB15: 14% -18% chrome dawb hlau | ≥59 | Siv rau kev hnav zoo dua | A07 | ||

| AB29: 27% -29% chrome dawb hlau | 43 | Siv rau qis pH mob tshwj xeeb tshaj yog rau FGD. Nws kuj tuaj yeem siv rau cov mob qis thiab desulfurization installation nrog pH tsawg dua 4 | A49 | ||

| AB33: 33% -37% chrome dawb hlau | Nws tuaj yeem thauj cov pa oxygenated slurry nrog pH tsis tsawg dua 1 xws li phospor-plaster, nitric acid, vitriol, phosphate thiab lwm yam. | A33 | |||

| Roj hmab | R08 ua | ||||

| R26 | |||||

| R33 | |||||

| R55 | |||||

| Ncej | Hlau | Cov pa roj carbon steel | E05 | ||

| Joint rings & seals | Roj hmab | Butyl | S21 | ||

| EPDM roj hmab | S01 | ||||

| Nitrile | S10 | ||||

| Hypalon | S31 | ||||

| Neoprene | S44/S42 | ||||

| Viton | S50 |

Cov dej ntshiab huv

1

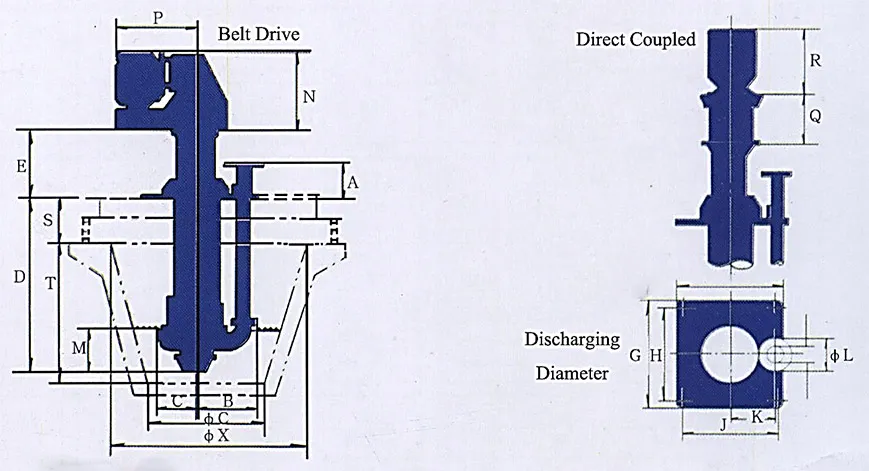

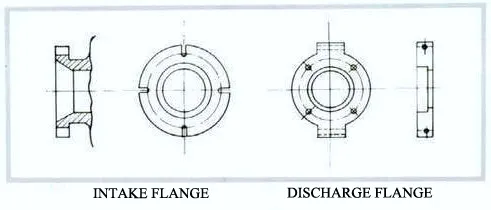

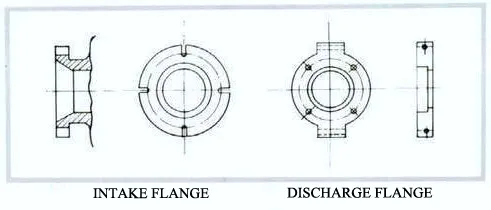

Installation Dimensions

| Hom | Intake Flange | Tshem tawm Flange | ||||||

| OD | ID | C/C Rau Qhov |

Qhov | OD | ID | C/C Rau Qhov |

Qhov | |

| 40 WY-P | φ170 | φ81 | φ140 | 4-φ14 | φ127 | φ40 | φ98 | 4-φ16 |

| 40 WYJ-P | ||||||||

| 65 WY-Q | φ240 | φ104 | φ215 | 4-φ14 | φ178 | φ65 | φ140 | 4-φ19 |

| 65 WYJ-Q | ||||||||

| 100 WY-R | φ380 | φ175 | φ325 | 4-φ24 | φ229 | φ100 | φ191 | 8-φ19 |

| 100 WYJ-R | ||||||||

| 150 WY-S | φ280 | φ150 | φ241 | 8-φ22 | ||||

| 150 WYJ-S | ||||||||

| 200 WY-S | φ343 | φ200 | φ298 | 8-φ22 | ||||

| 200 WYJ-S | ||||||||

| 250 WY-S | φ406 | φ250 | φ362 | 12-φ25 | ||||

| 250 WYJ-S | ||||||||

| 300 WY-S | φ483 | φ300 | φ432 | 12-φ25 | ||||

| 300 WYJ-S | ||||||||