WL Lub Teeb Ua Haujlwm Slurry Pump

Product Description

SPECIFICATIONS:

Loj: 20-650mm

Peev xwm: 2.34-9108m3 / h

Lub taub hau: 4-60m

Siab: Max.250psi

Khoom siv: Hyper chrome alloy, Roj Hmab, Polyurethane thiab lwm yam.

AIER® WL Light Dudy Slurry Pump

WL Series twj yog cantilevered, kab rov tav centrifugal slurry twj. Lawv tsim nyog rau kev xa cov slurries tsawg ntom ntom rau metallurgical, mining, thee thiab cov khoom siv hauv tsev. Lub foob foob siv ob lub qog foob thiab centrifugal foob.

WL series twj tso kua mis ua haujlwm hauv kev kub ceev nrog cov ntim me me kom txuag tau hauv pem teb. Cov phaj thav duab muaj qhov hloov pauv tau, hnav cov hlau tsis muaj zog thiab cov impellers yog ua los ntawm cov hlau tsis muaj zog.

Tej kev siv

SAG zeb tawm, pob zeb tawm, qws mil tawm, Ni acid slurry, coarse xuab zeb, ntxhib tailings, phosphate matrix, minerals concentrate, hnyav xov xwm, qab zib beet, hauv qab / ya tshauv, roj xuab zeb, ntxhia xuab zeb, nplua tailings, slag granulation , phosphoric acid, thee, flotation, process chemical, pulp and paper, FGD, cyclone feed, waste water, plant water supply, etc.

Nta

Lub thav duab phaj yog ua los ntawm hnav resistant hard hlau liners.

Cov impellers yog ua los ntawm cov hlau tawv.

Cov ntsaws ruaj ruaj tuaj yeem yog ntim cov foob, centrifugal foob lossis cov khoom siv foob.

Lub chaw tso tawm tuaj yeem muab tso rau ntawm lub sijhawm ntawm 45 degrees los ntawm kev thov thiab taw qhia rau yim txoj haujlwm kom haum rau kev teeb tsa thiab kev siv. Muaj ntau hom tsav rau kev xaiv, xws li V-siv, hloov tau yooj yim coupling, gearbox, hydraulic coupler kuj tsis paub meej zaus, silicon tswj ceev, thiab lwm yam. Ntawm lawv, lub saj zawg zog ncej coupling tsav thiab V-siv feature ntawm tus nqi qis thiab yooj yim installation.

Pump Notation

200 WL-S:

200: Qhov hluav taws xob txoj kab uas hla: mm

WL: Lub teeb lub luag haujlwm slurry twj tso kua mis

S: Ncej phaj hom

Tsim Tsim

|

|

Casing Split casing halves ntawm cam khwb cia los yog cov hlau ductile muaj cov ris tsho hnav thiab muab lub peev xwm ua haujlwm siab.

Hloov pauv tau tawv hlau thiab molded elastomer liner |

|

Impeller Lub impeller tej zaum yuav yog molded elastomer los yog tawv hlau. Sib sib zog nqus sab sealing vanes txo lub foob siab thiab txo qis recirculation. Cast-in impeller threads zoo dua rau slurries. |

Mating faces in hard metal liners are tapered to allow positive alignment during assembly and allow components to be easily removed for replacement.

Pump Part Material

| Lub Npe | Khoom siv | Specification | HRC | Daim ntawv thov | OEM Code |

| Liners & Impeller | Hlau | AB27: 23% -30% chrome dawb hlau | ≥56 | Siv rau kev hnav khaub ncaws siab dua nrog pH ntawm 5 txog 12 | A05 |

| AB15: 14% -18% chrome dawb hlau | ≥59 | Siv rau kev hnav zoo dua | A07 | ||

| AB29: 27% -29% chrome dawb hlau | 43 | Siv rau qis pH mob tshwj xeeb tshaj yog rau FGD. Nws kuj tseem tuaj yeem siv rau qhov qis qis thiab desulfuration installation nrog pH tsawg dua 4 | A49 | ||

| AB33: 33% -37% chrome dawb hlau | Nws tuaj yeem thauj cov pa oxygenated slurry nrog pH tsis tsawg dua 1 xws li phospor-plaster, nitric acid, vitriol, phosphate thiab lwm yam. | A33 | |||

| Roj hmab | R08 ua | ||||

| R26 | |||||

| R33 | |||||

| R55 | |||||

| Expeller & expeller nplhaib | Hlau | B27: 23% -30% chrome dawb hlau | ≥56 | Siv rau kev hnav khaub ncaws siab dua nrog pH ntawm 5 txog 12 | A05 |

| Grey hlau | G01 | ||||

| Khoom Box | Hlau | AB27: 23% -30% chrome dawb hlau | ≥56 | Siv rau kev hnav khaub ncaws siab dua nrog pH ntawm 5 txog 12 | A05 |

| Grey hlau | G01 | ||||

| Ncej / npog phaj, bearing tsev & puag | Hlau | Grey hlau | G01 | ||

| Hlau hlau | D21 | ||||

| Ncej | Hlau | Cov pa roj carbon steel | E05 | ||

| Lub tes tsho ncej, teeb lub nplhaib / lub teeb tsa, lub caj dab nplhaib, caj dab bolt | Stainless hlau | 4 cr13 | C21 | ||

| SIB 304 | C22 | ||||

| 316 SIB | C23 | ||||

| Joint rings & seals | Roj hmab | Butyl | S21 | ||

| EPDM roj hmab | S01 | ||||

| Nitrile | S10 | ||||

| Hypalon | S31 | ||||

| Neoprene | S44/S42 | ||||

| Viton | S50 |

Transmission Module Tsim

Transmission Module Tsim

|

Loj txoj kab uas hla twj tso kua mis ncej, cylindrical Kev tsim cov khoom hnyav, metric bearing siv roj lubrication lossis roj lubrication; qhib nyob rau hauv serial, kev tsim kho nta ntawm me me ntim thiab kev ntseeg siab. |

|

|

Ncej Bearing Assembly Ib txoj kab uas hla loj nrog lub luv overhang minimizes deflection thiab vibration. Heavy luag hauj lwm rau cov menyuam bearings yog nyob rau hauv ib tug tshem tau bearing cartridge. Pump Base Fasten lub twj tso kua mis nyob rau hauv lub hauv paus nrog ib tug tsawg kawg nkaus tus naj npawb ntawm bolts thiab kho impeller nyob rau hauv ib tug yooj yim txoj hauj lwm hauv qab no bearing vaj tse. Dej pov thawj npog tiv thaiv cov dej ntws los ntawm ya. Kev tiv thaiv npog tiv thaiv cov dej ntws los ntawm cov kabmob bracket.

|

Ncej Foob Module Tsim

|

1. Ntim Box 2. Pem hauv ntej teeb lub nplhaib 3. Ntim 4. Ntim Gland 5. Lub tes tsho ncej |

|

1. Tso Gland 2. Expeller 3. Ntim 4. Ntim Gasket 5. Lub nplhaib nplhaib 6. Ntim Gland 7. Roj khob |

|

|

GRJ Mechanical Foob GRG hom yog siv rau cov kua uas tsis tso cai rau diluted. HRJ Mechanical Foob HRJ hom yog siv rau cov kua tso cai dilute. High hardness ceramic thiab ally yog saws rau cov khoom ntawm kev sib txhuam qhov chaw. Nws muaj siab abrasive tsis kam & co pov thawj los lav tias cov nyhuv sealing tuaj yeem txaus siab los ntawm cov neeg siv khoom hauv ntau yam mob.

|

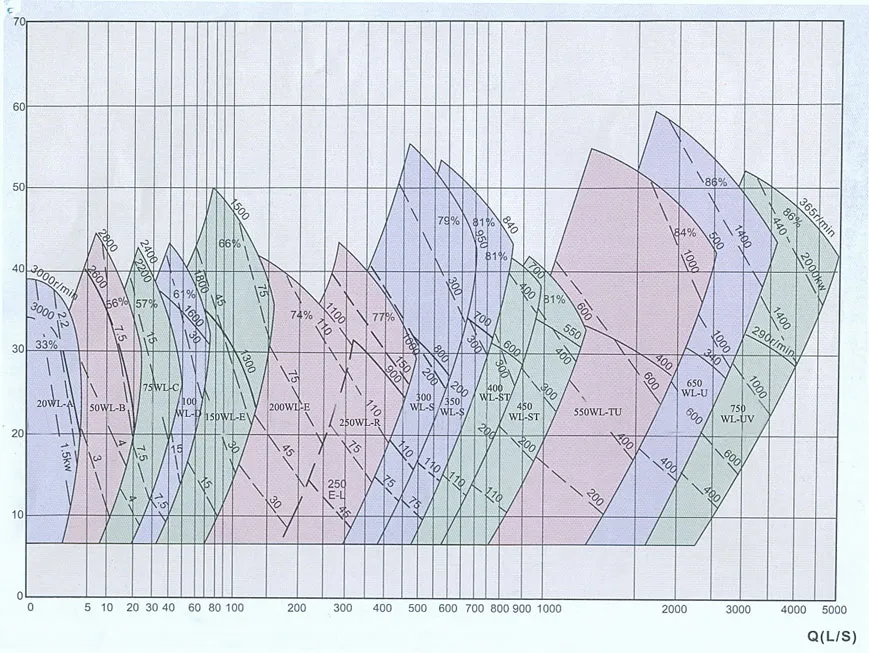

Performance Curve

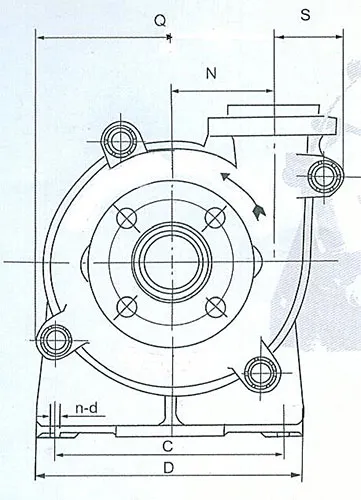

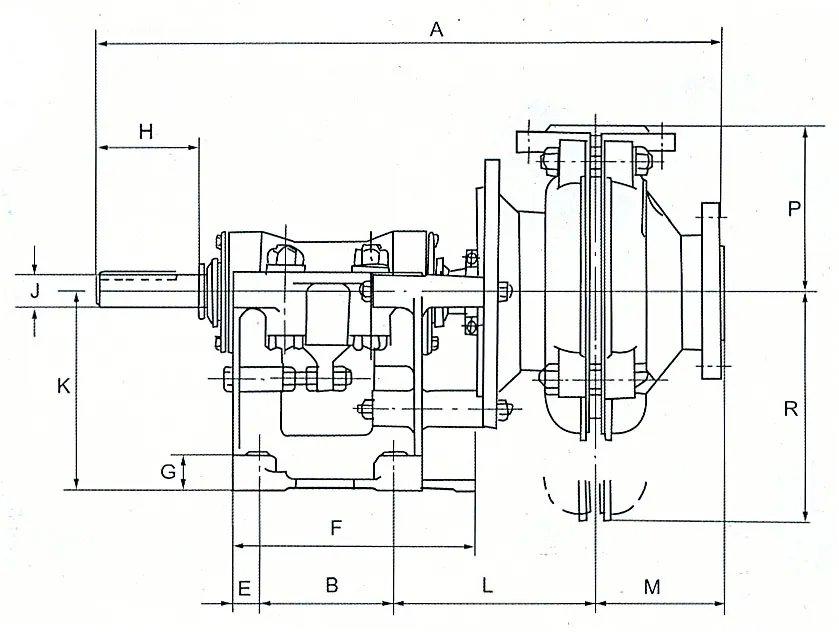

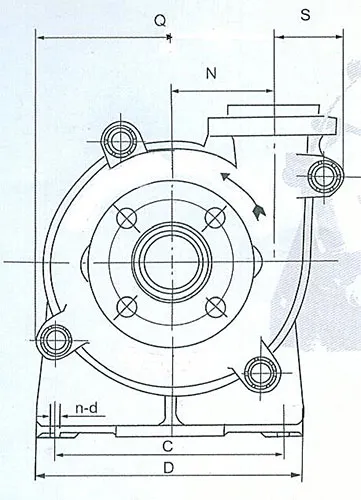

Installation Dimensions

| Hom | A | B | C | D | E | F | G | nd | H | J | K | L | M |

| 20 AW-A | 461 | 159 | 241 | 286 | 25 | 210 | 28 | 4-Φ18 | 57 | 20 | 145 | 89 | 90 |

| 50 WL-B | 624 | 143 | 254 | 295 | 24 | 248 | 38 | 4-Φ14 | 80 | 28 | 197 | 191 | 136 |

| 75 WM-C | 813 | 175 | 356 | 406 | 32 | 311 | 48 | 4-Φ19 | 120 | 42 | 254 | 253 | 163 |

| 100 WL-D | 950 | 213 | 432 | 492 | 38 | 364 | 64 | 4-Φ22 | 163 | 65 | 330 | 280 | 187 |

| 150 AW-E | 1218 | 257 | 546 | 622 | 54 | 448 | 76 | 4-Φ29 | 220 | 80 | 457 | 376 | 237 |

| 200 AW-E | 1334 | 257 | 546 | 622 | 54 | 448 | 76 | 4-Φ29 | 220 | 80 | 457 | 413 | 306 |

| 250 AW-E | 1348 | 257 | 546 | 622 | 54 | 448 | 76 | 4-Φ29 | 220 | 80 | 457 | 411 | 324 |

| 250 AW-R | 1406 | 490 | 560 | 680 | 50 | 590 | 70 | 4-Φ28 | 216 | 85 | 350 | 322 | 324 |

| 300 AW-S | 1720 | 640 | 760 | 920 | 70 | 780 | 90 | 4-Φ35 | 280 | 120 | 450 | 415 | 300 |

| 350 AWV-S | 1776 | 640 | 760 | 920 | 70 | 780 | 90 | 4-Φ35 | 280 | 120 | 450 | 425 | 340 |

| 400 WL-ST | 1840 | 620 | 900 | 1150 | 80 | 780 | 125 | 4-Φ48 | 280 | 120 | 650 | 480 | 375 |

| 450 WL-ST | 1875 | 620 | 900 | 1150 | 80 | 780 | 125 | 4-Φ48 | 280 | 120 | 650 | 500 | 400 |

| 550 WL-TU | 2400 | 860 | 1200 | 1460 | 95 | 1050 | 150 | 4-Φ79 | 350 | 150 | 900 | 625 | 500 |

|

|

| Hom | Lub taub hau loj | Suction Flange | Tshem tawm Flange | ||||||||||

| N | S | Q | R | P | OD | ID | CC Tab sis. Qhov |

Qhov | OD | ID | CC Tab sis. Qhov |

Qhov | |

| 20 AW-A | 86 | 144 | 128 | 114 | 25 | 83 | 4-Φ14 | 102 | 20 | 73 | 4-Φ14 | ||

| 50 WL-B | 114 | 155 | 163 | 184 | 75 | 146 | 4-Φ19 | 165 | 50 | 127 | 4-Φ19 | ||

| 75 WM-C | 146 | 102 | 204 | 229 | 100 | 191 | 4-Φ19 | 203 | 75 | 165 | 4-Φ19 | ||

| 100 WL-D | 190 | 118 | 262 | 305 | 150 | 260 | 4-Φ22 | 229 | 100 | 191 | 4-Φ22 | ||

| 150 AW-E | 248 | 155 | 324 | 368 | 200 | 324 | 8-Φ19 | 305 | 150 | 260 | 8-Φ19 | ||

| 200 AW-E | 292 | 199 | 401 | 445 | 250 | 394 | 8-Φ22 | 382 | 200 | 337 | 8-Φ22 | ||

| 250 AW-E | 438 | 257 | 476 | 603 | 470 | 552 | 305 | 495 | 8-Φ32 | 483 | 254 | 425 | 8-Φ32 |

| 250 AW-R | 438 | 257 | 476 | 603 | 470 | 552 | 305 | 495 | 8-Φ32 | 483 | 254 | 425 | 8-Φ32 |

| 300 AW-S | 475 | 265 | 599 | 634 | 570 | 560 | 350 | 500 | 12-Φ26 | 530 | 300 | 470 | 12-Φ26 |

| 350 AWV-S | 530 | 295 | 643 | 691 | 620 | 640 | 400 | 580 | 12-Φ26 | 590 | 350 | 530 | 12-Φ26 |

| 400 WL-ST | 600 | 343 | 747 | 809 | 740 | 720 | 450 | 650 | 12-Φ33 | 685 | 400 | 615 | 12-Φ33 |

| 450 WL-ST | 660 | 375 | 814 | 872 | 800 | 770 | 500 | 700 | 12-Φ33 | 740 | 450 | 670 | 12-Φ33 |

| 550 WL-TU | 860 | 453 | 1055 | 1142 | 975 | 975 | 650 | 880 | 12-Φ39 | 900 | 550 | 800 | 12-Φ39 |