Aug. . 11, 2025 10:00 Back to list

Centrifugal Submersible Pump Manufacturer | Durable & Efficient

Navigating the Landscape of Submersible Pump Manufacturing

The industrial sector's relentless pursuit of efficiency and reliability in fluid management systems places significant emphasis on the performance of specialized pumping equipment. Among these, centrifugal submersible pump manufacturer plays a pivotal role, delivering solutions critical for diverse applications ranging from deep well dewatering to complex chemical processing. The market for these robust pumps is characterized by an escalating demand for energy-efficient designs, advanced material science integration, and smart monitoring capabilities. Current trends indicate a strong shift towards intelligent pumping systems equipped with IoT sensors for predictive maintenance, alongside a heightened focus on pumps capable of handling corrosive and abrasive media, which directly influences the material selection and manufacturing processes adopted by leading manufacturers. The global centrifugal submersible pump market is projected to grow at a CAGR of approximately 5-7% over the next five years, driven by urbanization, industrial expansion, and infrastructure development, particularly in emerging economies.

This growth trajectory is further fueled by increasing awareness of environmental regulations, pushing the adoption of more efficient and durable pumping solutions that minimize downtime and operational costs. For instance, the demand for `submersible sewage pump manufacturer` offerings has surged due to extensive wastewater treatment projects, while `submersible water pump manufacturer` innovation continues to underpin agricultural irrigation and municipal water supply initiatives. Companies are investing heavily in R&D to develop pumps with superior hydraulic performance and enhanced resistance to harsh operating conditions, often leveraging advanced computational fluid dynamics (CFD) for optimal impeller design. This evolution underscores the sophisticated engineering and manufacturing expertise required to remain competitive in this specialized segment, addressing challenges such as cavitation prevention and optimal motor-pump integration for extended service life.

The Precision Craft of Centrifugal Submersible Pump Manufacturing

The fabrication of high-performance centrifugal submersible pumps is a multi-stage process demanding meticulous attention to detail, from raw material selection to final assembly and testing. It typically begins with the careful sourcing of high-grade materials such as stainless steel (e.g., SS304, SS316, Duplex SS), cast iron, or specialized alloys like Hastelloy or Titanium, chosen based on the intended fluid's corrosivity and abrasiveness. Key components, including impellers, diffusers, and pump casings, are often produced through advanced casting or precision forging techniques, ensuring superior mechanical properties and structural integrity. For instance, the semi-open or closed impellers, vital for hydraulic efficiency, undergo precise CNC machining to achieve exact tolerances and optimal surface finishes, minimizing friction and maximizing flow.

Following initial shaping, components proceed to rigorous heat treatment processes to enhance their hardness and wear resistance, especially for critical elements like the `submersible pump shaft manufacturer` produces. Subsequent stages involve comprehensive quality control, including non-destructive testing (NDT) such as ultrasonic or radiographic inspections, material composition analysis (e.g., PMI), and dimensional verification using coordinate measuring machines (CMM). Adherence to international standards like ISO 9906 for hydraulic performance and ANSI/HI for general pump standards is paramount. This stringent quality assurance ensures that each `electrical submersible pump manufacturer` unit meets strict performance benchmarks, leading to an average operational lifespan of 5 to 10 years, often significantly longer with proper maintenance and component replacement facilitated by readily available `submersible pump part manufacturer` and `submersible pump spares manufacturer` products.

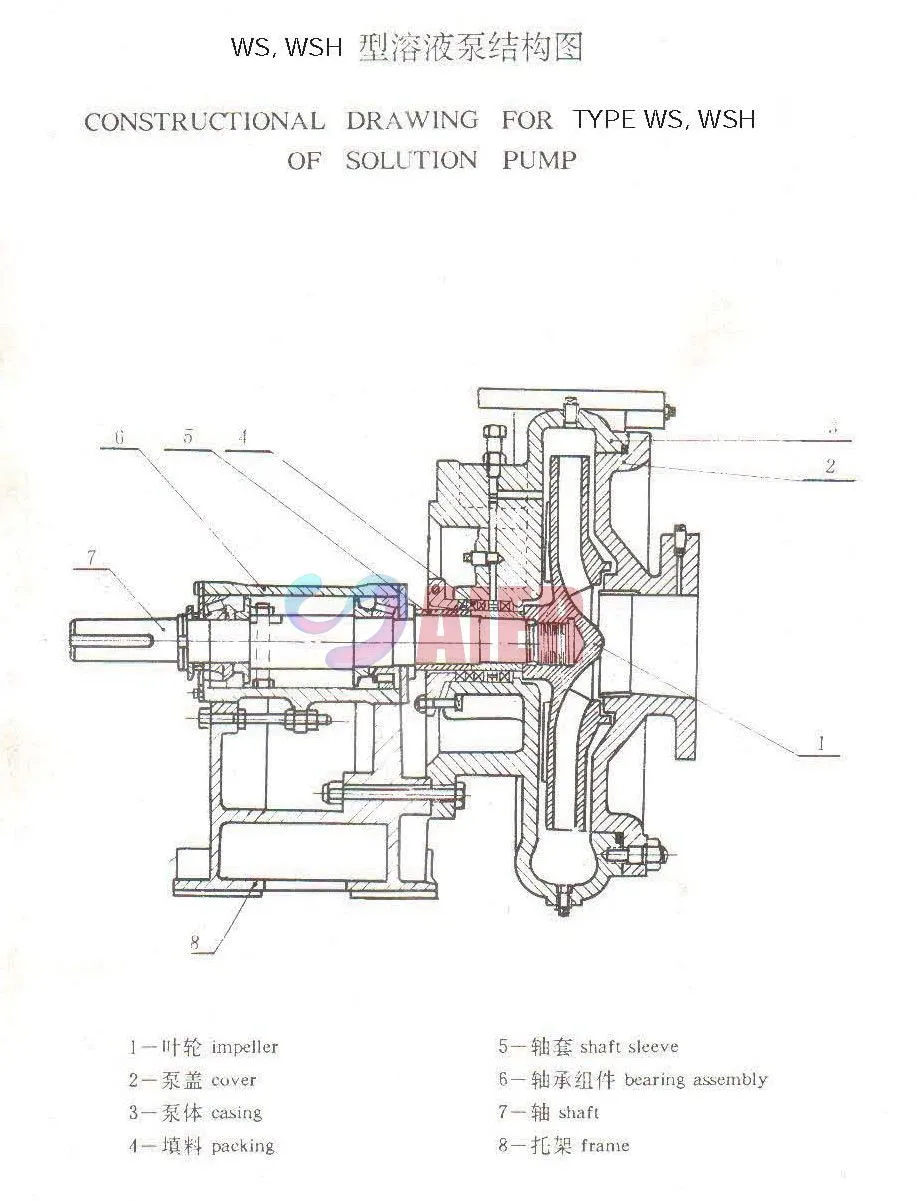

Technical Prowess: WS, WSH Solution Pumps Specifications

Our WS and WSH Solution Pumps exemplify advanced engineering designed for the most demanding fluid transfer applications. As a leading `manufacturer of submersible pump`, we understand the need for reliable performance in harsh industrial environments. These pumps are specifically engineered to handle corrosive, abrasive, and high-temperature liquids, making them ideal for the petrochemical, metallurgical, power generation, and chemical processing industries. Their robust design incorporates features that minimize energy consumption while maximizing output, aligning with the growing industry demand for sustainable and cost-effective pumping solutions. The pump’s motor is hermetically sealed and integrated within the unit, ensuring safe and efficient operation even when fully submerged, thus eliminating issues related to alignment and separate motor housing.

Key technical specifications highlight the versatility and capability of these units. For instance, their ability to operate within a wide pH range (2-13) and handle fluids with suspended solids up to 30% by weight makes them particularly suitable for diverse industrial effluents and slurries. The pumps are designed for continuous duty and are available with various power ratings and discharge sizes to match specific application requirements. Our commitment as a `china submersible pump manufacturer` is reflected in the detailed engineering and material selection that goes into every WS and WSH unit, ensuring long-term operational integrity and reduced maintenance frequency.

WS, WSH Solution Pump Key Specifications

| Parameter | Typical Range/Value | Notes |

|---|---|---|

| Flow Rate (Q) | Up to 2600 m³/h (11,440 US GPM) | Variable based on model and application. |

| Head (H) | Up to 80 m (262 ft) | Critical for discharge elevation and pressure. |

| Motor Power | 1.5 kW to 400 kW | High-efficiency, explosion-proof options available. |

| Fluid Temperature | -20°C to +120°C | Dependent on material selection and sealing. |

| Material Options | Cast Iron, SS304, SS316, Duplex SS, CD4MCU, Hastelloy, Titanium | Chosen for corrosion/abrasion resistance. |

| Solids Handling | Up to 30% by weight (depending on particle size) | Designed for slurries and wastewater. |

| Seal Type | Double Mechanical Seal (e.g., SiC/SiC) | Ensures long-term reliability against leaks. |

| Protection Class | IP68 | Fully submersible, dust-tight. |

Applications and Distinct Advantages in Diverse Industries

The robust design and versatile performance of WS, WSH Solution Pumps make them indispensable across a broad spectrum of industrial applications. In the petrochemical sector, they are crucial for handling corrosive effluents and process fluids, where their specialized material construction ensures longevity and prevents system contamination. Similarly, in metallurgy, these pumps are vital for managing abrasive slurries and cooling water in challenging environments, effectively resisting wear and tear from suspended solids. For municipal and industrial `submersible sewage pump manufacturer` applications, their ability to handle high concentrations of solids without clogging is a significant advantage, reducing maintenance interventions and operational costs. Furthermore, in mining and construction, particularly for `submersible well pump manufacturer` needs, these pumps are engineered to reliably dewater mines and construction sites, operating continuously in demanding, often remote, conditions.

Beyond these specific examples, our pumps offer distinct technical advantages that set them apart. Their highly efficient hydraulic design, often validated through rigorous CFD simulations, translates into significant energy savings, reducing overall operational expenditure by up to 15-20% compared to less optimized designs. The selection of advanced corrosion-resistant alloys ensures exceptional longevity even when exposed to highly aggressive chemicals, minimizing the need for frequent replacements. Moreover, the integrated motor and double mechanical seal system provide superior reliability and ingress protection (IP68), making them virtually maintenance-free under normal operating conditions. One notable application case involved a large-scale chemical plant where our WSH pump replaced conventional vertical pumps, resulting in a 25% reduction in energy consumption and extended Mean Time Between Failures (MTBF) by over 150%, demonstrating quantifiable benefits.

Choosing the Right Partner: Beyond Standard Offerings

Selecting the ideal centrifugal submersible pump manufacturer is not merely about product specifications; it's about partnering with a provider who offers comprehensive solutions, technical expertise, and unwavering support. While many `china submersible pump manufacturer` entities exist, differentiating factors lie in their R&D capabilities, adherence to international quality standards, and flexibility in providing customized solutions. A reputable `electrical submersible pump manufacturer` should demonstrate a profound understanding of diverse industry needs, offering not just off-the-shelf products but also engineering services to tailor pumps for unique application challenges. This includes precise material selection for specific fluid chemistry, hydraulic optimization for desired flow rates and heads, and integration with existing plant control systems.

Our company prides itself on decades of experience in the pump manufacturing sector, holding certifications such as ISO 9001:2015 for quality management and possessing numerous product-specific accreditations. We consistently invest in advanced manufacturing technologies and R&D to push the boundaries of pump performance and durability. Our collaborative approach ensures that client feedback is integrated into product development, leading to innovations like enhanced wear plates for abrasive slurries or specialized coatings for extreme corrosion resistance. Unlike providers focused solely on volume, we prioritize engineering excellence and long-term customer satisfaction, offering extensive pre-sales consultation and post-sales support that truly distinguishes a strategic partnership from a mere transactional purchase. Our long-standing partnerships with global engineering firms and Fortune 500 companies underscore our authoritative position as a reliable `manufacturer of submersible pump`.

Ensuring Trust: FAQs, Delivery, and Warranty Commitments

Building trust with B2B clients necessitates transparency in all aspects, from product performance to after-sales support. As a trusted centrifugal submersible pump manufacturer, we address common client concerns proactively to ensure a smooth acquisition and operational experience. Our standard delivery cycle for stock models is typically 4-6 weeks, with customized solutions requiring 8-12 weeks depending on complexity and material sourcing. We maintain a robust supply chain to minimize lead times and provide real-time updates on order status. Every pump undergoes a rigorous final performance test and a 48-hour continuous run test before shipment to guarantee immediate operational readiness upon delivery. Our commitment to quality is underscored by a comprehensive warranty program covering manufacturing defects and material failures for a minimum of 12 months from installation or 18 months from shipment, whichever comes first.

Frequently Asked Questions (FAQs)

A1: Material selection is crucial and depends primarily on the fluid's chemical composition, temperature, and abrasiveness. Our engineering team provides detailed consultation based on your specific media characteristics and operating conditions. Common choices include SS316 for general corrosion, Duplex SS for higher chloride resistance, and specialized alloys like Hastelloy for extreme chemical environments. For abrasive slurries, high-chromium cast iron or rubber-lined components are recommended.

A2: Due to their robust design and quality components, WS, WSH pumps require minimal routine maintenance. Key activities include periodic checks of the motor insulation resistance, oil changes in the seal chamber (if applicable), and inspection of mechanical seals. For abrasive applications, impeller and casing wear might necessitate occasional replacement, easily handled with our readily available `submersible pump part manufacturer` and `submersible pump spares manufacturer` offerings. Predictive maintenance through vibration monitoring and current analysis can further extend service intervals and prevent unexpected downtime.

A3: The WS, WSH series is designed to handle a range of fluids, including those with elevated viscosity and suspended solids. For highly viscous fluids, specific impeller designs (e.g., vortex impellers) and larger discharge openings are utilized. For large solids, specific `submersible sewage pump manufacturer` designs or cutter pumps can be integrated. We assess the fluid's rheological properties and particle size distribution during the design phase to recommend the optimal pump configuration to ensure efficient and clog-free operation.

Our dedicated customer support team is available 24/7 for technical assistance, troubleshooting, and spare parts inquiries, ensuring that our clients receive prompt and effective service throughout the pump’s lifecycle. We also offer comprehensive training programs for client personnel on proper installation, operation, and maintenance procedures.

Conclusion and Future Outlook

In conclusion, the selection of a centrifugal submersible pump manufacturer is a strategic decision that profoundly impacts operational efficiency, system reliability, and long-term cost of ownership. Our WS, WSH Solution Pumps, backed by extensive engineering expertise and stringent quality control, represent the pinnacle of performance in challenging industrial fluid transfer applications. As the industry continues to evolve, driven by demands for greater energy efficiency, sustainability, and intelligent monitoring capabilities, we remain at the forefront of innovation. Our commitment to continuous research and development ensures that our products not only meet current industry standards but also anticipate future needs, providing future-proof solutions. We are dedicated to forging lasting partnerships with our clients, empowering them with the most reliable and efficient pumping technology available.

The future of industrial pumping solutions will undoubtedly involve further integration of smart technologies, advanced materials, and modular designs that allow for easier maintenance and upgrades. As a forward-thinking `manufacturer of submersible pump`, we are actively exploring new composite materials for lighter yet stronger components, integrating AI-driven predictive maintenance algorithms, and developing pumps compatible with renewable energy sources. This proactive approach ensures that our clients benefit from cutting-edge technology, optimized performance, and a sustainable competitive advantage in their respective industries. Partnering with us means investing in a legacy of reliability and a future of innovation in fluid management.

References

- Hydraulic Institute. (2020). ANSI/HI 1.1-1.2-2020 Rotodynamic (Centrifugal) Pumps for Nomenclature, Definitions, Application, and Operation.

- ISO 9906:2012. (2012). Rotodynamic pumps — Hydraulic performance acceptance tests — Grades 1, 2 and 3. International Organization for Standardization.

- Gupta, R., & Singh, A. (2017). Advanced Materials for Enhanced Corrosion Resistance in Industrial Pumps. Journal of Industrial Engineering and Management.

- Market Research Future. (2023). Global Submersible Pumps Market Research Report, Forecast to 2030.

- Li, J., & Wang, Q. (2019). Energy Efficiency Optimization in Industrial Pumping Systems through CFD Analysis. International Journal of Fluid Mechanics Research.

-

Small Dredger and Marine Pontoon-Aier Machinery|Dredging Solutions&Marine Equipment

NewsAug.11,2025

-

Centrifugal Submersible Pump Manufacturer | Durable & Efficient

NewsAug.11,2025

-

Small Dredger and Marine Pontoon Solutions by Aier Machinery Hebei Co., Ltd

NewsAug.11,2025

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd | Industrial Dredges, Marine Pontoons

NewsAug.11,2025

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd. | Industrial Efficiency & Durable Solutions

NewsAug.11,2025

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd | Gold Mining Equipment, Durable Dredging Solutions

NewsAug.10,2025