WG High Kepala Slurry pompa

Pompa bubuka

spésifikasi:

Ukuran: 65-300mm

Kamampuh: 37-1919m3 / h

Sirah: 5-94m

Handing padet: 0-90mm

Konsentrasi: Max.70%

Max.tekanan: Max.4.5mpa

Bahan: Hyper chrome alloy jsb.

AIER® WG High Efficiency Slurry Pump

In order to meet the requirements on the development of the electric power, metallurgy and coal industries, our company has designed and developed WG(P) Series up-to-date general slurry pump with large capacity, high head, multi-stages in series to remove ash & sludge and to deliver liquid-solids mixture, based on the experience of slurry pump design and manufacture for many years, and abstracting the research results of advanced technology from home and abroad.

Fitur

Desain modern CAD, kinerja super hidrolik, efisiensi tinggi jeung laju abrasion handap;

petikan lega, non-clogging jeung kinerja alus NPSH;

segel Expeller digabungkeun jeung segel packing sarta segel mékanis geus diadopsi pikeun ngajamin slurry ti leakage;

Desain reliabiliti ensures lila MTBF (mean waktu antara acara);

The métrik bearing kalawan lubrication minyak, lubricating lumrah tur sistem cooling mastikeun bearing ka dioperasikeun dina suhu low;

Bahan bagian baseuh boga kinerja hade anti ngagem tur anti korosi;

Pompa bisa dipaké pikeun lebu seawater nyoplokkeun pikeun nyegah tina korosi seawater, uyah jeung halimun, sarta korosi éléktrokimia;

Pompa tiasa dioperasikeun sacara séri kalayan sababaraha tahap dina tekanan anu diidinan.

Pompa boga kaunggulan konstruksi lumrah, efisiensi tinggi, operasi dipercaya jeung pangropéa gampang. Ieu bisa loba dipaké pikeun nanganan campuran ngandung padet abrasive na corrosive dina kakuatan listrik, metallurgy, tambang, batubara, bahan constructional jeung departemén industri kimia, utamana pikeun nyoplokkeun lebu jeung sludge di stasiun kakuatan listrik.

Notasi Pompa

100WG(P):

100: Diaméter outlet (mm)

WG: Pompa slurry sirah tinggi

P: Pompa multi-tahap (1-2 tahap tanpa tanda)

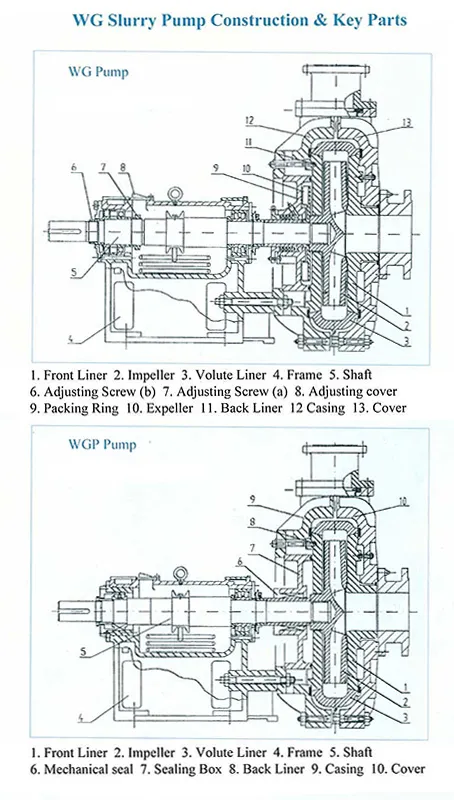

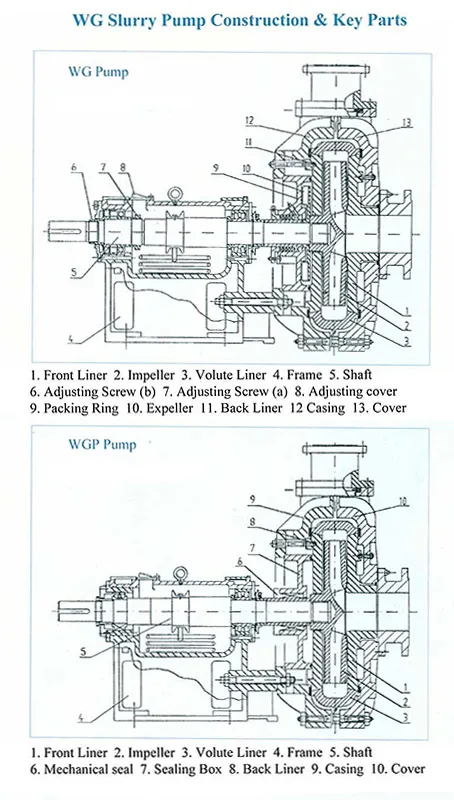

Pompa slurry WG nyaéta horizontal, tahap tunggal, nyeuseup tunggal, cantilevered, casing ganda, pompa slurry centrifugal. Pompa rotates dina jarum jam ditempo ti tungtung drive.

Bagian baseuh pompa WG sareng WGP dina diaméter outlet anu sami tiasa ditukeurkeun. Dimensi instalasi outline maranéhanana ogé sarua. Pikeun bagian drive pompa slurry WG (P), pigura pamisah horizontal kalayan pelumasan minyak sareng dua sét sistem penyejukan cai di jero sareng di luar parantos diadopsi. Upami diperlukeun, cai cooling bisa disadiakeun. Gabungan anu disiapkeun pikeun cai cooling sareng tekanan cai cooling tiasa ditingali dina tabel 1.

Two kinds of shaft seal – expeller seal combined with packing and mechanical seal.

The segel mékanis disadiakeun kalawan tekanan tinggi cai sealing dianjurkeun nalika pompa dioperasikeun dina runtuyan, sarta segel expeller digabungkeun jeung packing dipaké dina pompa single-tahap.

Tekanan cai sareng jumlah sadaya jinis segel aci nyaéta kieu:

1) tekanan cai Sealing

Pikeun pompa single-tahap kalawan segel expeller digabungkeun jeung packing, tekanan cai tina segel aci nyaeta 0.2-0.3 Mpa.

Pikeun multi-tahap dina operasi runtuyan jeung expeller segel digabungkeun jeung packing, tekanan cai sealing kudu: The panghandapna tekanan cai sealing tina n tahap = Hi + 0.7Hn Where: n ≥2.

Hi + 0.7Hn Where: n ≥2.

Pikeun segel mékanis, tekanan cai sealing unggal tahapan pompa leuwih luhur 0.1Mpa ti tekanan di outlet pompa.

2) Tekanan cai sealing (tingali tabél 1)

Méja 1: parameter cai sealing

| Jenis pompa | Pigura | Cai Sealing (l/s) |

Sealing Cai Joint | Cooling Cai Joint Dina pigura |

Tekanan Cai Cooling |

| 65WG | 320 | 0.5 | 1/4" | 1/2", 3/8" | 0.05 nepi ka 0.2Mpa |

| 80 wg | 406 | 0.7 | 1/2" | 3/4", 1/2" | |

| 100WG | |||||

| 80WGP | 406A | ||||

| 100WGP | |||||

| 150WG | 565 | 1.2 | 1/2" | 3/4", 3/4" | |

| 200WG | |||||

| 150WGP | 565A | ||||

| 200WGP | |||||

| 250WG | 743 | 1" | |||

| 300WG | |||||

| 250WGP | 743A |

Desain Pangwangunan

Bahan Bagian Pompa

| Ngaran Bagian | Bahan | Spésifikasi | HRC | Aplikasi | Kodeu OEM |

| Liners & Impeller | logam | AB27: 23% -30% beusi bodas krom | ≥56 | Dipaké pikeun kaayaan ngagem anu langkung luhur kalayan pH antara 5 sareng 12 | A05 |

| AB15: 14% -18% beusi bodas krom | ≥59 | Dipaké pikeun kaayaan maké luhur | A07 | ||

| AB29: 27% -29% beusi bodas krom | 43 | Dipaké pikeun kaayaan pH handap hususna keur FGD. Ogé bisa dipaké pikeun kaayaan low-haseum jeung instalasi desulfuration kalawan pH teu kurang ti 4 | A49 | ||

| AB33: 33% -37% beusi bodas krom | Bisa ngangkut slurry oxygenated kalawan pH teu kurang ti 1 kayaning phospor-plaster, asam nitrat, vitriol, fosfat jsb. | A33 | |||

| Expeller & cingcin expeller | logam | B27: 23% -30% beusi bodas Chrome | ≥56 | Dipaké pikeun kaayaan ngagem anu langkung luhur kalayan pH antara 5 sareng 12 | A05 |

| Beusi kulawu | G01 | ||||

| Kotak eusian | logam | AB27: 23% -30% beusi bodas krom | ≥56 | Dipaké pikeun kaayaan ngagem anu langkung luhur kalayan pH antara 5 sareng 12 | A05 |

| Beusi kulawu | G01 | ||||

| Pigura / Panutup piring, bearing imah & base | logam | Beusi kulawu | G01 | ||

| beusi ulet | D21 | ||||

| Aci | logam | Baja karbon | E05 | ||

| leungeun baju aci, ring lantera / restrictor, ring beuheung, kelenjar baud | Beusi sténless | 4Cr13 | C21 | ||

| 304 SS | C22 | ||||

| 316 SS | C23 | ||||

| cingcin gabungan & segel | karét | Butil | S21 | ||

| karét EPDM | S01 | ||||

| Nitrile | S10 | ||||

| Hypalon | S31 | ||||

| Neoprene | S44/S42 | ||||

| Viton | S50 |

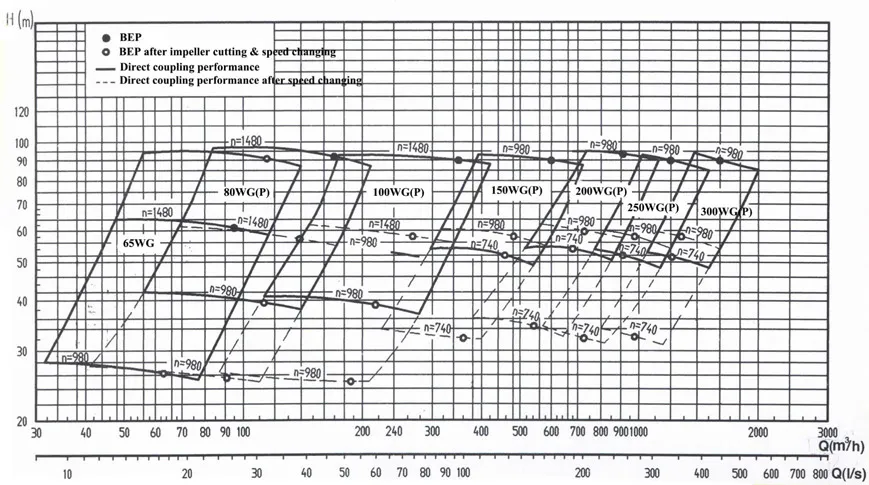

Kurva kinerja

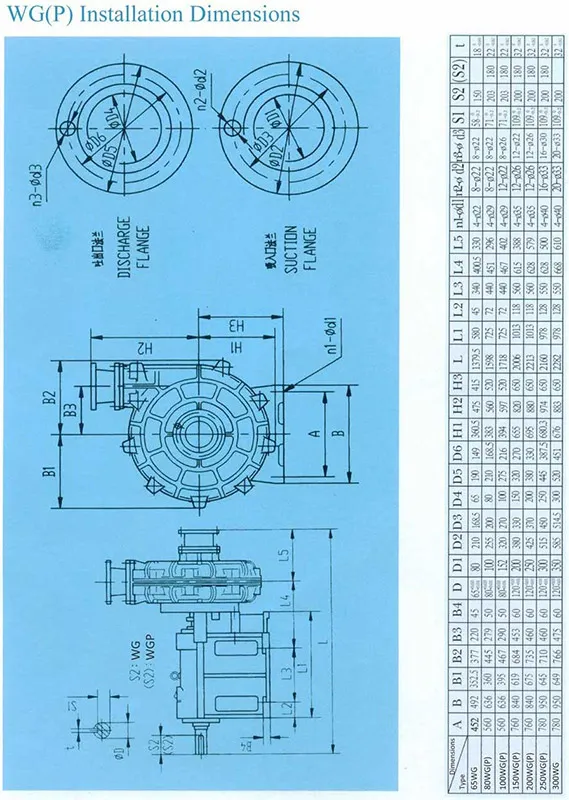

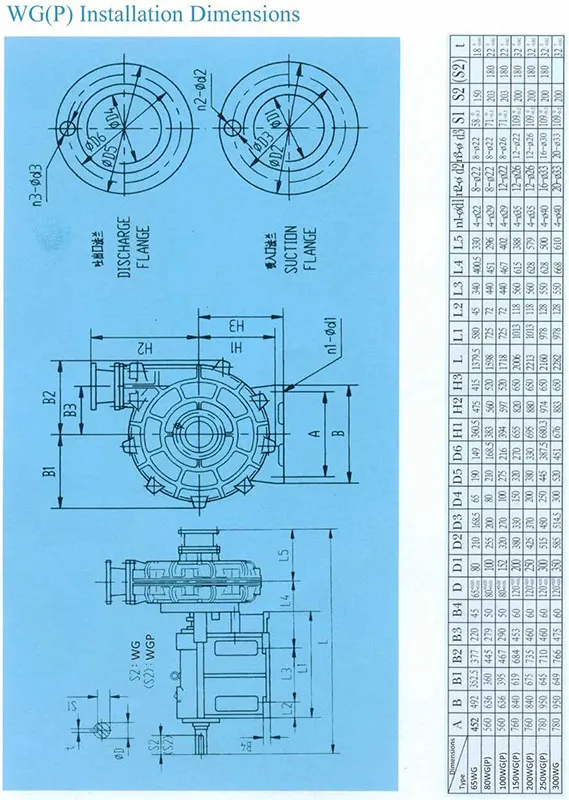

Dimensi instalasi