WY Sump Pump

Product Description

ZVINOTAURWA:

Kukura (kubuda): 40mm kusvika 300mm

Kukwanisa: 7.28-1300 m3 / h

Musoro: 3m-45 m

Kutakura zvinhu zvakasimba: 0-79mm

Kuwedzera: 0% -70%

zvinhu: High chrome alloy, Rubber,

Polyurethane, Ceramic, Stainless simbi nezvimwe.

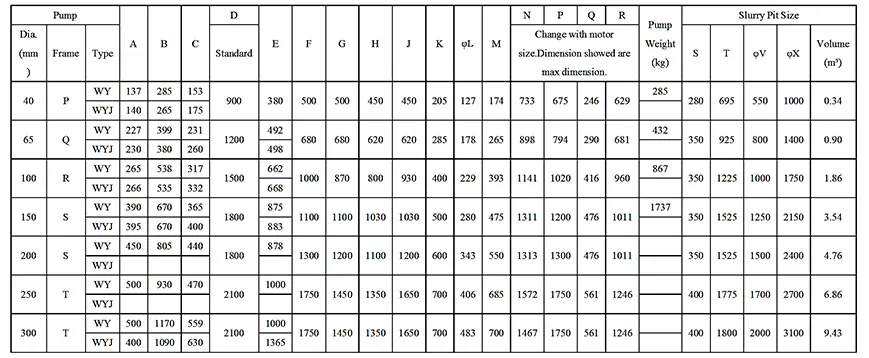

AIER® WY Sump Pump

WY & WYJ sump pombi yakatwasuka centrifugal slurry pombi, yakanyudzwa kuitira kutamisa abrasive, zvidimbu zvakakora uye high density slurry. Pakushanda, haidi mvura yechidhindo kana chero rudzi rwechisimbiso. Inogona kushanda zvakanaka zvakare kana vhoriyamu yekusveta isina kukwana.

Typical Applications

Sump drainage kana washdown

Floor drainage

Mill sump

Carbon transfer

Monitoring

Magnetite kusanganisa

Features

WY mhando yepombi casing inogadzirwa neabrasion inodzivirira simbi, impeller zvinhu zvinogona kuve abrasion inodzivirira simbi kana rabha.

Iwo akanyudzwa zvikamu zveWYJ zvese zvakamisikidzwa nerabha, kuitira kutamisa corrosive slurry.

Pombi Notation

150WY-S:

150: Kubuda kwedhayamita: mm

WY: Mhando yepombi: Yakakwira chrome alloy yakamisikidzwa sump pombi

S: Frame ndiro mhando

150WYJ-S:

150: Kubuda kwedhayamita: mm

WYJ: Mhando yepombi: Rubber yakarongedzwa sump pombi

S: Frame ndiro mhando

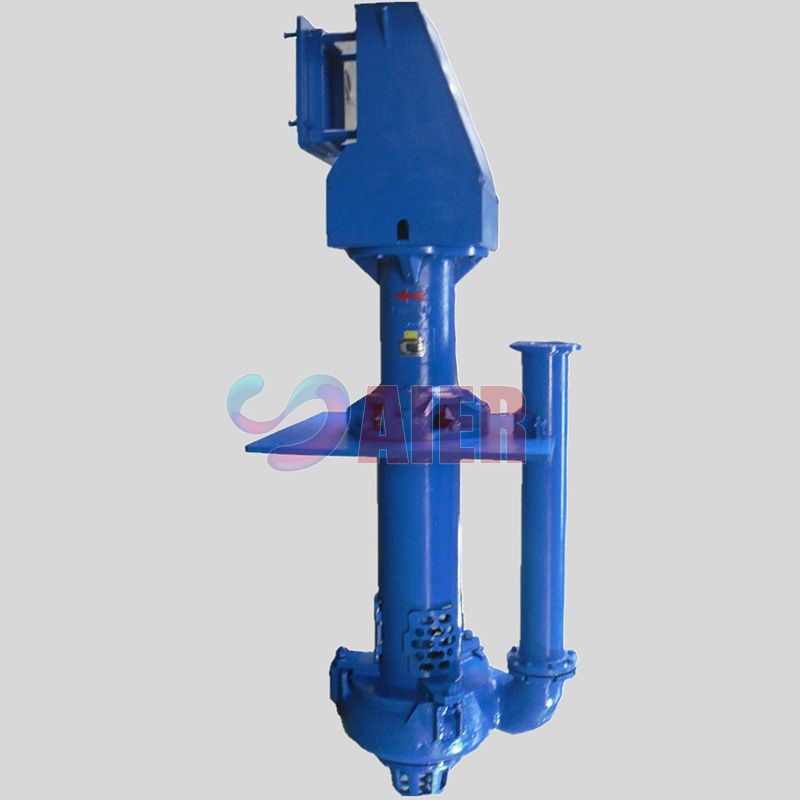

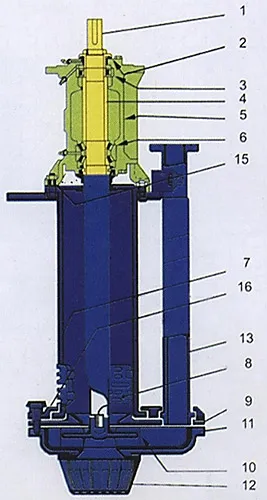

Kuvaka Dhizaini

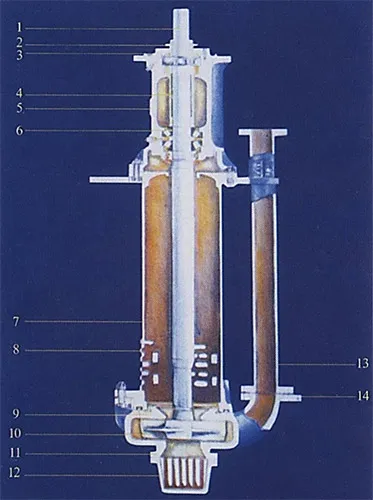

WY Yakakwira Chrome Alloy Yakaiswa Mitsetse

|

1. Shaft 2. Labyrinth 3. Kubereka 4. Kubereka Spacer 5. Bearing Housing 6. Kubereka 7. Column 8. Strainer 9. Back Liner 10. Impeller 11. Pombi Casing 12. Lower Strainer 13. Kuburitsa Pipe 14. Split Discharge Flange |

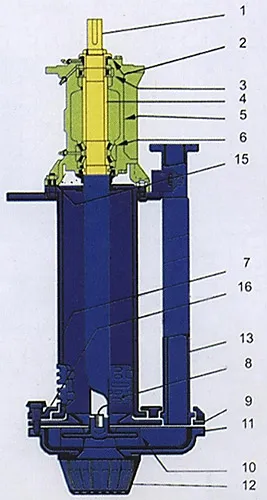

|

1. Shaft 2. Labyrinth 3. Kubereka 4. Kubereka Spacer 5. Bearing Housing 6. Kubereka 7. Column 8. Strainer 9. Back Liner 10. Impeller 11. Pombi Casing 12. Lower Strainer 13. Kuburitsa Pipe 15. Column Bolt & Nut 16. Column Bolt |

|

Pombi Chikamu Material

| Chikamu Zita | Material | Tsanangudzo | HRC | Application | OEM Code |

| Casing, Back Liner & Impeller | Hard Metal | AB8: KmTBCr8 | ≥55 | Inoshandiswa pombi yedhaka | A01 |

| AM: KmTBMnMo | 38-42 | Inoshandiswa kune chiedza kupfeka mamiriro ane zviyo zvakanaka | A11 | ||

| AB27: 23% -30% chrome chena iron | ≥56 | Inoshandiswa kune yakakwirira kupfeka mamiriro ane pH iri pakati pe5 ne12 | A05 | ||

| AB15: 14% -18% chrome chena iron | ≥59 | Inoshandiswa kune yakakwirira kupfeka mamiriro | A07 | ||

| AB29: 27% -29% chrome chena iron | 43 | Inoshandiswa kune yakaderera pH mamiriro kunyanya kune FGD. Iyo zvakare inogona kushandiswa kune yakaderera-yakavava mamiriro uye desulfurization yekumisikidza ine pH isingasviki 4 | A49 | ||

| AB33: 33% -37% chrome chena iron | Inogona kutakura oxygenated slurry ine pH isiri pasi pe1 senge phospor-plaster, nitric acid, vitriol, phosphate nezvimwe. | A33 | |||

| Rubber | R08 | ||||

| R26 | |||||

| R33 | |||||

| R55 | |||||

| Shaft | Metal | Carbon steel | E05 | ||

| Joint zvindori & zvisimbiso | Rubber | Butyl | S21 | ||

| EPDM rabha | S01 | ||||

| Nitrile | S10 | ||||

| Hypalon | S31 | ||||

| Neoprene | S44/S42 | ||||

| Viton | S50 |

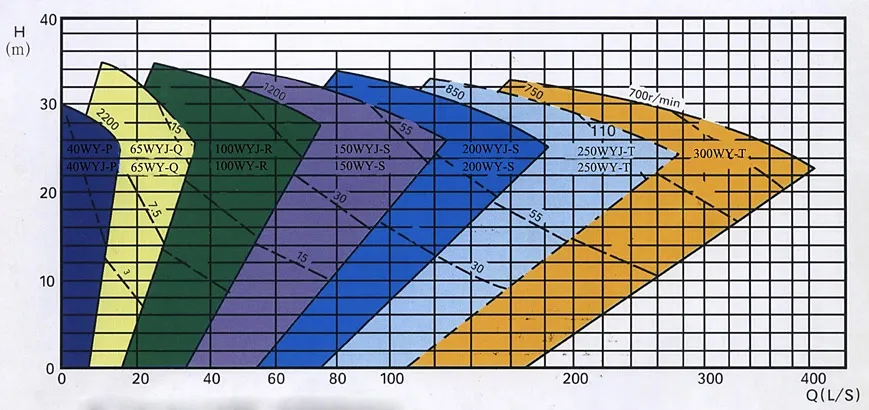

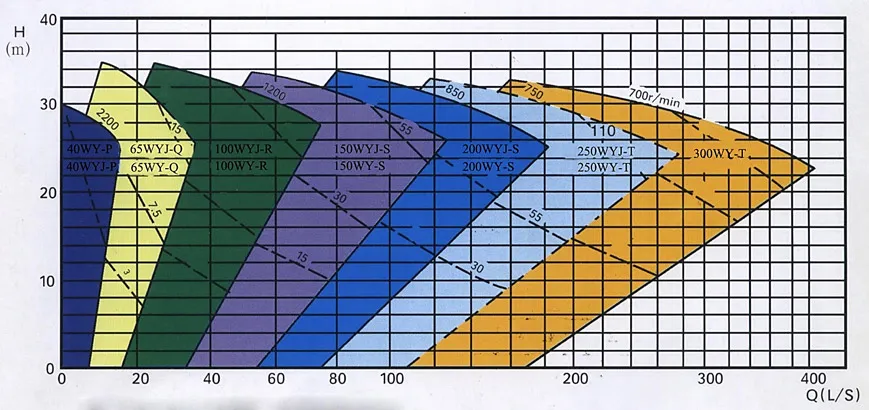

Clear Water Performance

1

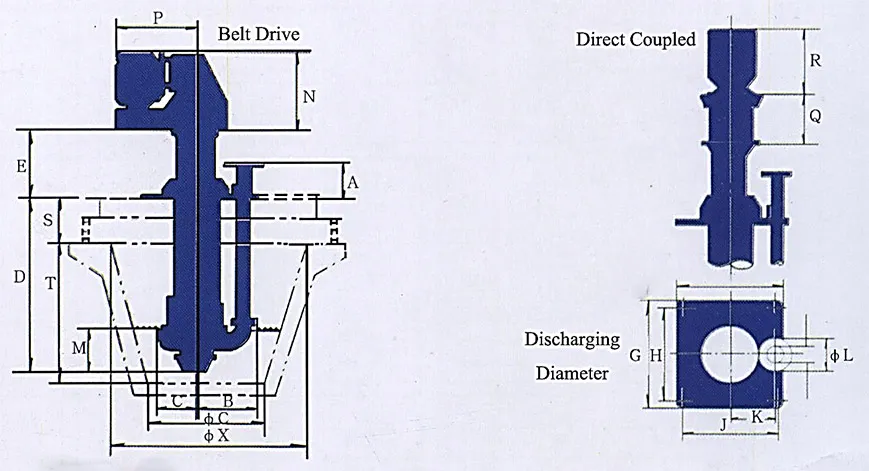

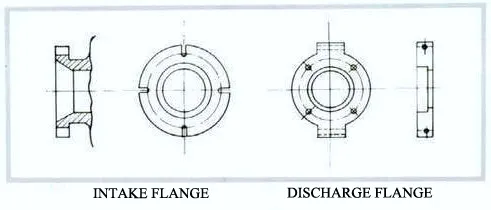

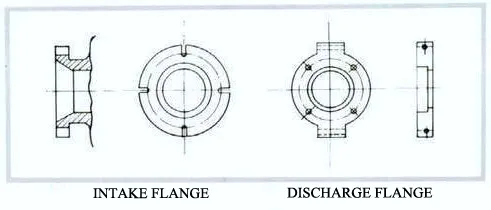

Installation Dimensions

| Type | Kutora Flange | Discharge Flange | ||||||

| OD | ID | C/C For Makomba |

Hole | OD | ID | C/C For Makomba |

Hole | |

| 40WY-P | φ170 | φ81 | φ140 | 4-φ14 | φ127 | φ40 | φ98 | 4-φ16 |

| 40WYJ-P | ||||||||

| 65WY-Q | φ240 | φ104 | φ215 | 4-φ14 | φ178 | φ65 | φ140 | 4-φ19 |

| 65WYJ-Q | ||||||||

| 100WY-R | φ380 | φ175 | φ325 | 4-φ24 | φ229 | φ100 | φ191 | 8-φ19 |

| 100WYJ-R | ||||||||

| 150WY-S | φ280 | φ150 | φ241 | 8-φ22 | ||||

| 150WYJ-S | ||||||||

| 200WY-S | φ343 | φ200 | φ298 | 8-φ22 | ||||

| 200WYJ-S | ||||||||

| 250WY-S | φ406 | φ250 | φ362 | 12-φ25 | ||||

| 250WYJ-S | ||||||||

| 300WY-S | φ483 | φ300 | φ432 | 12-φ25 | ||||

| 300WYJ-S | ||||||||