Aug . 26, 2025 01:20 Back to list

Submersible Well Pump Manufacturer: Quality Water & Sewage Pumps

Introduction to Advanced Submersible Well Pump Manufacturing

In the demanding landscape of industrial fluid management, the reliability and efficiency of pumping equipment are paramount. Submersible well pumps, designed to operate fully submerged in the fluid, offer unparalleled advantages in terms of prime retention, noise reduction, and space efficiency. As a leading submersible well pump manufacturer, we understand the critical role these engineered solutions play across a spectrum of vital industries, from municipal water supply to complex mining operations and severe slurry handling.

This comprehensive guide delves into the intricate world of submersible pump manufacturing, highlighting the technical expertise, robust processes, and innovative solutions that define a premier provider in this specialized field. We explore industry trends, crucial technical specifications, diverse application scenarios, and the profound advantages offered by advanced manufacturing techniques.

Current Industry Trends and Market Dynamics for Submersible Pumping Solutions

The global market for submersible pumps is experiencing dynamic growth, driven by increasing infrastructure development, urbanization, and the escalating demand for efficient water and wastewater management. Key trends include a strong emphasis on energy efficiency, the adoption of smart pumping technologies, and a growing demand for robust solutions capable of handling abrasive and corrosive media.

Manufacturers are increasingly focusing on developing pumps with advanced materials and hydraulic designs to improve Mean Time Between Failures (MTBF) and reduce operational costs. The integration of IoT for predictive maintenance and remote monitoring is transforming the sector, allowing for optimized performance and proactive issue resolution. Furthermore, the push for sustainability is leading to the development of pumps that consume less energy and are made from recyclable materials. A forward-thinking submersible well pump manufacturer, therefore, must constantly innovate to meet these evolving demands, focusing on both performance and environmental responsibility.

Demand for specialized pumps is also rising, with significant growth in segments requiring a dedicated submersible water pump manufacturer for clean water applications and a specialized submersible sewage pump manufacturer for wastewater and drainage challenges. The need for high-head, heavy-duty pumps, such as our WG High Head Slurry Pump, is particularly acute in mining, construction, and power generation sectors, where abrasive slurries and high flow rates are common.

The Meticulous Manufacturing Process of Submersible Well Pumps

Producing high-performance submersible pumps is a multi-stage process that combines precision engineering with stringent quality control. Each step is critical to ensuring the final product's reliability, efficiency, and longevity in harsh operating environments.

Process Flow Overview:

- Design and Engineering (CAD/CAE): Utilizing advanced Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) to optimize hydraulic performance and structural integrity, ensuring peak efficiency and durability under specific load conditions.

- Material Selection and Sourcing: Critical selection of wear-resistant and corrosion-resistant alloys such as high-chrome white iron, stainless steel (SS304, SS316, Duplex SS), and specialized rubber or polyurethane for impellers and liners, tailored to the fluid's properties.

- Casting and Forging: Precision casting of pump casings, impellers, and other hydraulic components to achieve exact geometric tolerances. Forging for high-stress components like shafts ensures superior strength and fatigue resistance.

- CNC Machining: Advanced Computer Numerical Control (CNC) machining centers meticulously finish components, ensuring tight tolerances for critical fits and clearances, which are essential for hydraulic efficiency and sealing integrity.

- Motor Manufacturing: Production of high-efficiency, hermetically sealed submersible motors, often oil-filled or water-filled, designed for continuous operation and thermal management under submerged conditions. This is a core competency for any electrical submersible pump manufacturer.

- Assembly: Skilled technicians meticulously assemble all components, including impellers, diffusers, shafts (often from a specialized submersible pump shaft manufacturer), bearings, seals, and motors within the pump housing.

- Testing and Quality Assurance:

- Hydrostatic Testing: Ensures casing integrity and leak-proof seals under extreme pressure.

- Performance Curve Testing: Validates hydraulic parameters such as head, flow, efficiency, and power consumption against design specifications, often adhering to ISO 9906 or ANSI/HI standards.

- Vibration Analysis and Noise Testing: Detects potential mechanical imbalances or cavitation issues.

- Electrical Testing: Verifies motor insulation, resistance, and operational stability.

- Non-Destructive Testing (NDT): Ultrasonic or radiographic inspection for critical components to detect internal flaws.

- Coating and Finishing: Application of protective coatings (e.g., epoxy, ceramic) for enhanced corrosion and abrasion resistance, extending the service life, especially in aggressive media like those encountered in the petrochemical and metallurgy industries.

- Packaging and Dispatch: Secure packaging for safe transportation, often tailored for international shipping requirements.

The service life of a well-engineered submersible pump can exceed 10-15 years with proper maintenance, significantly outperforming less robust alternatives. This extended lifespan directly translates to lower total cost of ownership (TCO) for target industries such as petrochemical processing, metallurgy, mining, municipal water supply & drainage, and power generation.

A key advantage in typical application scenarios, like dewatering coal mines or handling abrasive tailings in mineral processing, is energy saving through optimized hydraulics and corrosion resistance achieved through advanced material selection. This commitment to quality and performance underscores the capabilities of a dedicated submersible well pump manufacturer.

Technical Specifications and Engineering Excellence

The performance of a submersible pump is defined by its technical specifications, which dictate its suitability for specific applications. Understanding these parameters is crucial for engineers and procurement specialists.

Key Parameters for Submersible Well Pumps:

- Flow Rate (Q): The volume of fluid pumped per unit time, typically measured in m³/h or GPM.

- Head (H): The vertical distance the pump can lift the fluid, or the pressure generated, measured in meters or feet. High head capabilities are critical for deep wells or systems with significant pressure drops.

- Power (P): The motor's electrical power input (kW or HP).

- Efficiency (η): The ratio of hydraulic power output to electrical power input, indicating energy conversion effectiveness. Modern pumps boast efficiencies often exceeding 75-80%.

- Solids Handling Capability: The maximum size of solid particles the pump can pass without clogging, essential for a submersible sewage pump manufacturer or slurry pump applications.

- Material of Construction: Selection based on fluid corrosivity, abrasiveness, and temperature. Common materials include Cast Iron, Ductile Iron, Chrome Alloy (27% Cr), various Stainless Steels (304, 316, Duplex), and specialized elastomeric linings.

- Operating Temperature Range: Critical for high-temperature fluid applications in industrial processes.

- Immersion Depth: The maximum depth at which the pump can operate effectively.

- Seal Arrangement: Double mechanical seals with oil barriers are standard for robust submersible pumps, protecting the motor from fluid ingress.

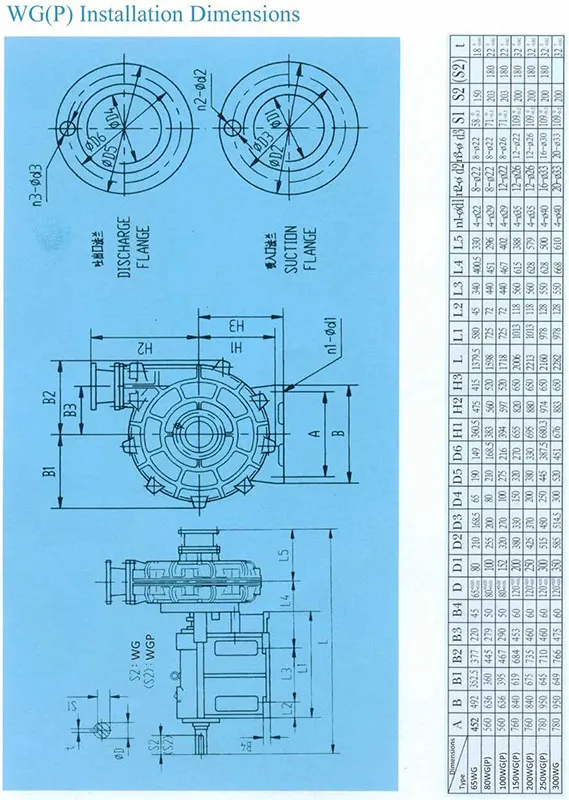

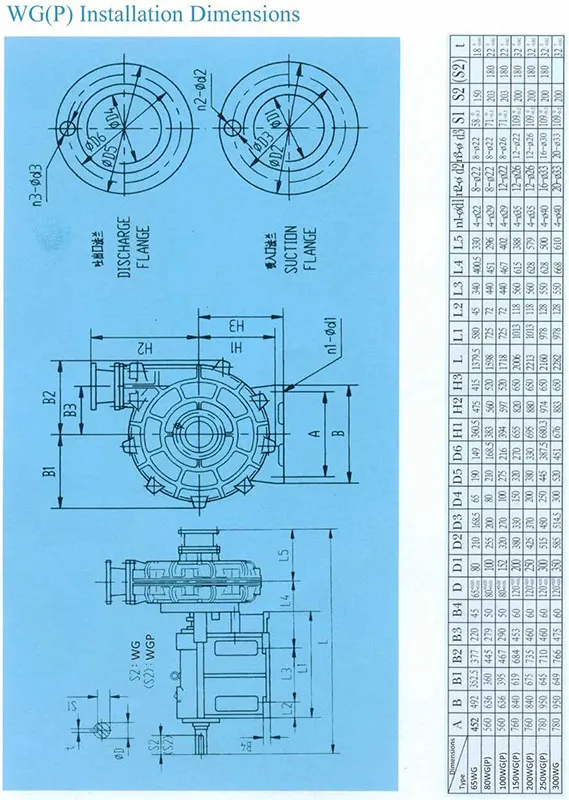

Representative Product Specification: WG High Head Slurry Pump

| Parameter | Specification | Notes |

|---|---|---|

| Model | WG Series (High Head) | Designed for abrasive slurry with high lifting requirements |

| Flow Rate (Q) | Up to 1200 m³/h | Variable based on model and impeller size |

| Head (H) | Up to 150 m | Exceptional high-head capability for deep applications |

| Motor Power | Up to 400 kW | High-efficiency submersible motor (IE3/IE4 options) |

| Solids Handling | Up to 80 mm | Large passage for abrasive solids without clogging |

| Materials | High Chrome Alloy (27% Cr), Rubber Lined, Polyurethane | Specific to slurry type and abrasion severity |

| Sealing | Dual Mechanical Seal with Oil Barrier | Robust protection against fluid ingress |

| Max. Temp. | Up to 80°C | Suitable for moderately high-temperature slurries |

| Protection Class | IP68 | Full protection against dust and continuous submersion |

These specifications are crucial for engineering accurate system designs and predicting operational costs and maintenance requirements. Only a well-versed submersible well pump manufacturer can provide such detailed and reliable data.

Versatile Application Scenarios for Submersible Pumps

Submersible pumps are indispensable in numerous industrial applications due to their inherent design advantages. Their ability to operate directly within the fluid streamlines operations and minimizes maintenance.

- Mining and Mineral Processing: Dewatering of open-pit and underground mines, tailings ponds, and slurry transfer. The WG High Head Slurry Pump is specifically designed for these abrasive and high-head environments.

- Construction Sites: Dewatering excavations, managing storm water, and transferring concrete slurry.

- Water Supply and Drainage: Deep well water extraction for municipal and agricultural use (a prime area for a dedicated submersible water pump manufacturer), flood control, and general wastewater transfer.

- Wastewater Treatment: Pumping raw sewage, activated sludge, and effluent. Here, the expertise of a submersible sewage pump manufacturer focusing on solids handling and anti-clogging features is paramount.

- Power Generation: Ash pond management, cooling water systems, and general plant dewatering.

- Oil & Gas (Petrochemical): Though often specialized for this industry, certain submersible pumps can handle process fluids or dewatering around facilities. Electrical submersible pumps (ESPs) are a cornerstone of artificial lift in oil wells, making the electrical submersible pump manufacturer a critical player.

- Industrial Processes: Transferring industrial slurries, chemicals (with appropriate materials), and cooling liquids.

The selection of the correct submersible pump for any of these applications requires a thorough understanding of fluid properties, required head and flow, and environmental conditions. This expertise is a hallmark of a reputable submersible well pump manufacturer.

Technical Advantages Offered by a Leading Submersible Well Pump Manufacturer

The advantages of partnering with an experienced submersible well pump manufacturer extend beyond just providing a product. It encompasses advanced design, superior materials, and a commitment to operational excellence.

- Enhanced Energy Efficiency: Optimized hydraulic designs (often from a specialized centrifugal submersible pump manufacturer perspective) and high-efficiency motors significantly reduce power consumption, leading to substantial operational cost savings over the pump's lifecycle.

- Superior Abrasion & Corrosion Resistance: Strategic use of high-chrome alloys, specially treated steels, and elastomeric liners combats the effects of abrasive slurries and corrosive chemicals, ensuring extended service life and reduced downtime.

- Robust Sealing Technology: Dual mechanical seals with independent oil barriers provide multi-layered protection against fluid ingress into the motor, a common failure point for lesser-quality pumps.

- Thermal Management: Efficient heat dissipation from the motor, either through direct fluid contact or integrated cooling systems, prevents overheating and extends motor life in continuous duty applications.

- Compact and Integrated Design: Being fully submerged, these pumps require no additional priming, saving space and simplifying installation. The motor and pump are a single, compact unit.

- Reduced Noise and Vibration: Submerged operation naturally dampens noise and vibration, making them ideal for sensitive environments and contributing to a safer workplace.

- Easy Maintenance & Spares Availability: Modular designs allow for easier access to wear parts, and a reliable submersible pump spares manufacturer ensures quick replacement of components like impellers, casings, and seals, minimizing maintenance-related downtime.

Vendor Comparison: Selecting the Right Submersible Pump Manufacturer

Choosing the optimal manufacturer of submersible pump requires careful evaluation beyond just initial purchase price. Key factors include product quality, technical support, customization capabilities, and after-sales service.

Comparative Factors for Submersible Pump Manufacturers:

| Feature/Service | Premium Manufacturer (e.g., Aier Pumps) | Standard Manufacturer |

|---|---|---|

| Hydraulic Design | Proprietary, CFD-optimized for max efficiency & wear life | Standard, off-the-shelf designs, less optimized |

| Material Quality | High-grade alloys (e.g., 27% Cr white iron), certified materials | Basic alloys, less strict material certification |

| Sealing System | Advanced dual mechanical seals with monitoring options | Single mechanical seal or simpler arrangements |

| Testing & QA | Full performance curve testing (ISO 9906), NDT, vibration analysis | Basic functional testing, limited performance verification |

| Customization | Extensive, tailor-made solutions for specific applications | Limited, standard product modifications only |

| Lead Time | Optimized production, typically 4-8 weeks for standard models | Variable, often longer or less predictable |

| After-Sales Support | Global network, technical support, comprehensive spare parts | Limited regional support, fewer spare parts options |

| Certifications | ISO 9001, CE, specific industry compliance (e.g., ATEX) | Basic or no international quality certifications |

For critical industrial applications, investing in a premium manufacturer minimizes lifecycle costs and maximizes operational reliability.

Customized Solutions and Engineering Adaptability

Recognizing that no two industrial applications are identical, a leading submersible well pump manufacturer offers extensive customization options. This involves tailoring pump specifications to unique operational parameters, fluid characteristics, and environmental conditions.

Customization can include:

- Material Adaptation: Specifying exotic alloys or specialized linings (e.g., rubber, polyurethane) for extreme pH levels, high temperatures, or highly abrasive slurries.

- Hydraulic Modifications: Custom impeller designs (e.g., open, closed, vortex) or trimming for specific head/flow requirements to ensure operation at peak efficiency.

- Motor & Electrical Variants: Different voltage requirements, hazardous area certifications (e.g., ATEX), or integration with variable frequency drives (VFDs) for dynamic control.

- Sensor and Monitoring Integration: Embedding temperature, vibration, or leakage sensors for advanced predictive maintenance and remote monitoring capabilities.

- Mounting and Installation Adaptations: Custom frames, guide rail systems, or discharge connections to seamlessly integrate with existing infrastructure.

Our strong collaboration with specialized entities like a submersible pump part manufacturer and a submersible pump spares manufacturer ensures that even custom parts are produced with the same high quality and are readily available for maintenance, guaranteeing the long-term viability of tailored solutions.

Real-World Application Case Studies

Demonstrating capability through real-world examples is key. Here are illustrative case studies highlighting the impact of high-quality submersible pumps.

Case Study 1: Hard Rock Mining Dewatering

- Client: Major international gold mining corporation.

- Challenge: Managing high volumes of abrasive, acidic mine water from deep underground shafts (100m+ head) containing significant suspended solids. Previous pumps experienced frequent failures due to wear and corrosion.

- Solution: Deployment of a customized WG High Head Slurry Pump, featuring a high-chrome alloy wet-end, a robust dual mechanical seal system, and a 300 kW high-efficiency motor. The pump's design focused on extended wear life and consistent high-head performance.

- Result: Reduced pump failures by 70%, extending MTBF from 3 months to over 10 months. Energy consumption was cut by 15% due to optimized hydraulics, leading to significant operational cost savings and increased productivity.

Case Study 2: Municipal Wastewater Treatment Plant

- Client: Large urban municipal wastewater authority.

- Challenge: Clogging and frequent maintenance of existing pumps handling raw sewage containing fibrous materials and non-biodegradable debris, leading to emergency call-outs and high operational costs.

- Solution: Installation of several custom-designed submersible sewage pumps from a specialized submersible sewage pump manufacturer. These pumps featured a large free passage vortex impeller and cutter mechanism, specifically engineered to handle high solids content without clogging.

- Result: Elimination of clogging incidents over a 24-month period, reducing maintenance frequency by 85%. The plant achieved uninterrupted operation, improving overall efficiency and public health compliance.

Ensuring Quality: Certifications, Authoritativeness, and Years of Service

Authoritativeness in the manufacturing sector is built on a foundation of consistent quality, adherence to international standards, and a proven track record.

- ISO 9001:2015 Certification: Demonstrates a robust quality management system covering design, manufacturing, testing, and after-sales service. This certification is fundamental for any credible submersible well pump manufacturer.

- Compliance with ANSI/HI Standards: Adherence to Hydraulic Institute standards ensures pumps are tested and rated according to globally recognized performance benchmarks.

- CE Marking: Essential for products marketed in the European Economic Area, signifying compliance with health, safety, and environmental protection standards.

- Years of Industry Experience: With over two decades in the pump manufacturing industry, our expertise is proven through countless successful installations and a loyal client base across various demanding sectors.

- Strategic Partnerships: Collaborations with research institutions and material suppliers further enhance our innovative capacity and access to cutting-edge technologies.

These certifications and extensive experience not only underpin our reputation but also provide tangible assurance of product quality and reliability to our clients.

Trustworthiness and Comprehensive Customer Support

Frequently Asked Questions (FAQ)

A1: Standard models typically have a lead time of 4-8 weeks. For highly customized solutions, lead times can range from 8-16 weeks, depending on material sourcing and complexity. We provide accurate timelines upon project specification.

A2: We offer a standard 12-month warranty from installation or 18 months from shipment, whichever comes first, covering defects in materials and workmanship. Extended warranties are available upon request for specific projects.

A3: Our dedicated after-sales team provides comprehensive technical support, troubleshooting, and field service. We maintain a large inventory of submersible pump spares manufacturer-certified parts and can dispatch them globally to minimize downtime. Long-term service contracts are also available.

A4: Yes, we offer specific models and motor configurations designed and certified for ATEX-compliant hazardous locations. Please specify your zone requirements during inquiry.

A5: Absolutely. We offer optional on-site supervision for installation and commissioning, as well as comprehensive training for your operational and maintenance staff.

Lead Time and Fulfillment

Our streamlined production facilities, combined with efficient supply chain management, enable us to offer competitive lead times. For complex bespoke projects, detailed project plans with milestone tracking are provided to ensure transparency and timely delivery. As a prominent china submersible pump manufacturer, we leverage robust manufacturing capabilities to balance cost-effectiveness with global supply chain reliability.

Warranty Commitments

Our warranty reflects our confidence in the quality and durability of our pumps. Each unit undergoes rigorous testing before leaving our facility, ensuring it meets the highest performance and reliability standards.

After-Sales Support

Our commitment extends well beyond the sale. We provide comprehensive after-sales support, including remote diagnostics, readily available spare parts, and expert field service engineers to ensure the continued optimal performance of your submersible pumping solutions. Our goal is to forge long-term partnerships built on trust and consistent support.

Conclusion: Partnering for Pumping Excellence

The selection of a reliable submersible well pump manufacturer is a strategic decision that directly impacts operational efficiency, uptime, and long-term cost-effectiveness. Our dedication to engineering excellence, advanced manufacturing processes, rigorous quality control, and unparalleled customer support positions us as a trusted partner for demanding industrial applications worldwide.

From initial design consultation to after-sales service, we are committed to delivering submersible pumping solutions that not only meet but exceed performance expectations, ensuring robust, efficient, and sustainable fluid management for your operations.

References

- Hydraulic Institute. (2018). ANSI/HI 9.6.3 Rotodynamic (Centrifugal and Vertical) Pump Guideline for Design and Application.

- ISO 9906:2012. (2012). Rotodynamic pumps - Hydraulic performance acceptance tests - Grades 1, 2 and 3. International Organization for Standardization.

- Pumps & Systems Magazine. (Various Issues). Industry trends and technological advancements in industrial pumping.

- International Energy Agency (IEA). (2020). Energy Efficiency 2020. Analysis and key findings.

- Mining Technology. (Various articles). Mine dewatering and slurry management solutions.

- Water & Wastewater Treatment Journal. (Various articles). Submersible pump applications in municipal infrastructure.

-

Wholesale Slurry Pump Spare Part Impeller - Rubber & Metal

NewsAug.27,2025

-

Submersible Well Pump Manufacturer: Quality Water & Sewage Pumps

NewsAug.26,2025

-

Manufacturer of Submersible Pumps & Slurry Impellers - Factory Direct

NewsAug.25,2025

-

Submersible Well Pump Manufacturer | Quality Water, Sewage & ESP

NewsAug.24,2025

-

Wholesale Slurry Pump Spare Part Impeller | Durable & High-Performance

NewsAug.23,2025

-

China Wear-Resistant Slurry Pump | Durable, Efficient Industrial Solutions

NewsAug.22,2025