Aug . 18, 2025 00:40 Back to list

Submersible Well Pump Manufacturer | Durable Water & Sewage Pumps

Navigating the Landscape of Submersible Well Pump Manufacturing

The global demand for efficient and reliable water extraction solutions continues to drive innovation within the pump industry. At the forefront of this evolution is the submersible well pump manufacturer, a pivotal entity in delivering critical infrastructure for various sectors. These manufacturers specialize in designing and producing pumps that operate fully submerged in the fluid, a configuration that offers significant advantages in terms of efficiency, reduced noise, and resistance to cavitation, particularly in deep well applications. The market for these specialized pumps is characterized by stringent performance requirements, diverse application environments—ranging from municipal water supply to agricultural irrigation and industrial processes—and a growing emphasis on energy efficiency and sustainability. Understanding the intricate details of manufacturing processes, material science, and hydraulic engineering is paramount for any leading submersible well pump manufacturer aiming to meet the exacting standards of modern industrial and residential demands. The continuous advancements in motor technology, impeller design, and sealing mechanisms further enhance the reliability and longevity of these essential pumping solutions, solidifying their role in global water management.

In recent years, the industry has witnessed a pronounced shift towards pumps that not only deliver high performance but also integrate smart technologies for monitoring and predictive maintenance. This trend is shaping how a top-tier submersible well pump manufacturer approaches product development, incorporating sensors and IoT capabilities to provide real-time operational data, optimize energy consumption, and anticipate potential failures before they occur. Furthermore, the increasing global focus on water scarcity and sustainable resource management has spurred innovation in pump efficiency and durability. Manufacturers are investing heavily in research and development to create pumps that can operate reliably in harsh conditions, including those with corrosive fluids or abrasive solids, while minimizing energy footprint. This comprehensive approach, encompassing advanced engineering, robust material selection, and smart integration, defines the cutting edge for any reputable submersible water pump manufacturer, ensuring that their products contribute positively to environmental goals and operational cost savings for end-users across diverse applications.

Core Manufacturing Process of Submersible Well Pumps

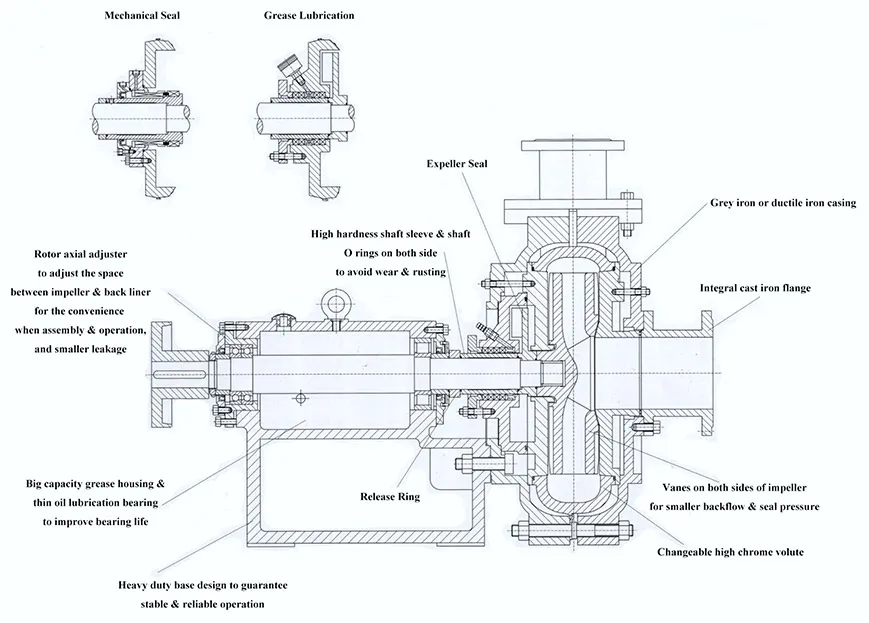

The production of a high-quality submersible well pump involves a series of meticulously controlled processes, beginning with advanced material selection to ensure longevity and optimal performance under challenging conditions. Typically, materials like stainless steel (e.g., SS304, SS316, Duplex 2205) are chosen for their superior corrosion resistance and strength, while specialized alloys are used for components exposed to highly abrasive or corrosive media. The manufacturing journey commences with precision casting or forging of critical components such as pump casings, impellers, and diffusers. This initial phase leverages sophisticated techniques to achieve precise metallurgical properties and dimensional accuracy, minimizing internal defects. Following this, advanced CNC machining is employed to achieve the tight tolerances required for hydraulic efficiency and seamless assembly. For instance, impeller balancing is critical to prevent vibration and ensure smooth operation, extending the pump's service life and maintaining optimal hydraulic performance across its operating range. This phase is crucial for transforming raw materials into finely engineered parts that will form the heart of the pump, showcasing the expertise of a dedicated manufacturer of submersible pump solutions.

Subsequent stages involve the precise assembly of the pump's hydraulic end, motor, and sealing systems. Each component, including the submersible pump shaft, is manufactured to rigorous standards, often incorporating advanced surface treatments for enhanced wear resistance. The motor, a vital part of an electrical submersible pump manufacturer's product, is sealed and filled with dielectric fluid to ensure proper cooling and insulation, allowing it to operate efficiently underwater. Comprehensive testing is integrated throughout the manufacturing process, adhering to international standards such as ISO 9001 for quality management and ANSI/HI (Hydraulic Institute) standards for pump performance. This includes hydrostatic pressure testing to verify casing integrity, performance curve testing to validate flow, head, and efficiency, and vibration analysis to ensure smooth operation. These stringent quality control measures are critical to guarantee the durability and reliability of the final product, especially for a centrifugal submersible pump manufacturer where hydraulic efficiency is paramount. The meticulous attention to detail at every step, from raw material inspection to final performance verification, underscores the commitment of a leading submersible pump part manufacturer to delivering superior pumping solutions for diverse and demanding applications like petrochemical, metallurgy, and water supply/drainage, where energy efficiency and corrosion resistance are key advantages.

Technical Parameters and Key Specifications

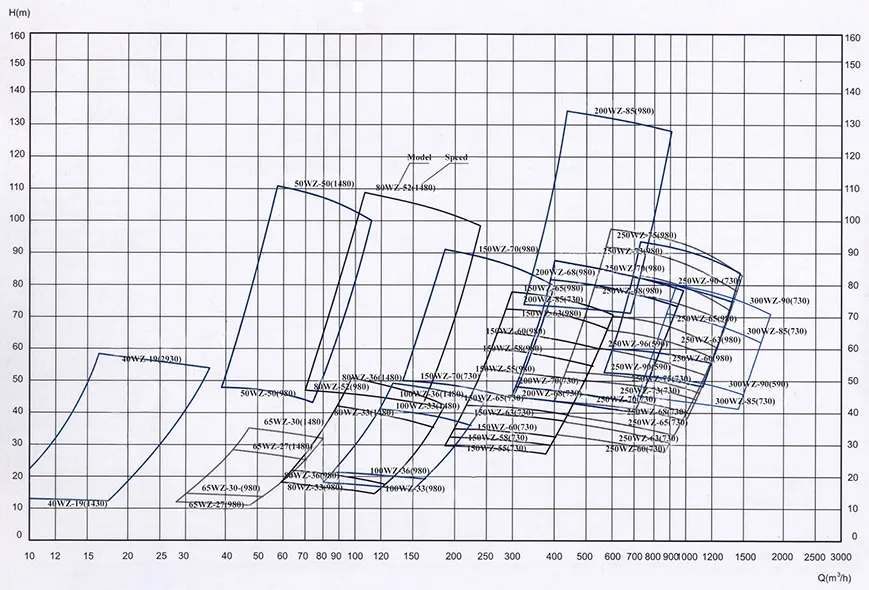

When selecting a submersible well pump, understanding the key technical parameters is crucial for optimal system design and performance. Leading manufacturers provide detailed specifications that allow engineers and procurement professionals to match the right pump to specific operational requirements. Core parameters include flow rate (Q), typically measured in cubic meters per hour (m³/h) or gallons per minute (GPM), which indicates the volume of fluid the pump can deliver. Head (H), expressed in meters (m) or feet (ft), represents the vertical distance the pump can lift the fluid. Power (P), specified in kilowatts (kW) or horsepower (HP), denotes the motor's output. Material selection is critical and includes options like ductile iron, various grades of stainless steel (e.g., 304, 316, Duplex, Super Duplex), and specialized alloys like CD4MCU for enhanced corrosion and abrasion resistance, reflecting the expertise of a robust submersible pump spares manufacturer. The maximum liquid temperature and maximum solid passage size are also vital, particularly for applications involving hot fluids or fluids with suspended solids, like those handled by a submersible sewage pump manufacturer.

| Parameter | Range/Description | Unit/Details |

|---|---|---|

| Flow Rate (Q) | 10 - 1500 | m³/h (or 44 - 6600 GPM) |

| Head (H) | 20 - 700 | m (or 65 - 2300 ft) |

| Motor Power (P) | 1.5 - 500 | kW (or 2 - 670 HP) |

| Operating Voltage | 380V, 460V, 660V (3-phase); 220V (1-phase) | AC, 50/60 Hz |

| Material Options | Cast Iron, SS304, SS316, Duplex SS, Bronze, CD4MCU | For different fluid types and corrosion resistance |

| Max Liquid Temperature | Up to 90 | °C (or 194 °F) |

| Protection Class | IP68 | Dust-tight and protected against continuous immersion |

| Insulation Class | F (or H for high temperature) | Defines maximum operating temperature of insulation |

| Efficiency (Max) | Typically 70 - 85 | % (Hydraulic Efficiency) |

The performance curve provided by a submersible well pump manufacturer is an indispensable tool, illustrating the relationship between flow rate, head, power consumption, and efficiency. This curve helps in determining the pump's Best Efficiency Point (BEP), which is crucial for energy optimization and minimizing operational costs over the pump's lifecycle. Moreover, understanding the Net Positive Suction Head Required (NPSHR) is vital, though less critical for fully submerged pumps as they inherently mitigate cavitation risks by operating under positive suction pressure. However, for a china submersible pump manufacturer or any global supplier, adhering to ISO and API standards for design, testing, and material traceability enhances trust and ensures interoperability. These detailed technical parameters, when thoroughly reviewed, empower clients to make informed decisions, ensuring the selected pump not only meets immediate operational needs but also offers long-term reliability and cost-effectiveness.

Versatile Application Scenarios and Key Advantages

Submersible well pumps are engineered for a vast array of demanding applications across multiple industries, demonstrating their versatility and robust design. In municipal water supply, they are indispensable for drawing potable water from deep aquifers, providing reliable and clean water to urban and rural populations. Their sealed design ensures water purity by preventing external contaminants from entering the system. For industrial applications, such as those in the petrochemical and mining sectors, specially designed submersible pumps handle abrasive slurries or corrosive chemicals, delivering consistent flow rates even under high-pressure conditions. The WZ High Efficiency Slurry Pump, for instance, represents a specialized category within this broader field, showcasing how advanced hydraulic designs and wear-resistant materials can be optimized for specific challenging media. An expert submersible pump part manufacturer can offer components tailored for such niche applications, enhancing pump longevity and performance.

Furthermore, in the agricultural sector, these pumps are crucial for irrigation systems, extracting water from wells and boreholes to nourish crops efficiently, contributing to food security. In wastewater management, specifically designed submersible sewage pumps handle raw sewage and industrial wastewater, often containing solids and fibrous materials, making them a cornerstone for sanitation infrastructure. A proficient submersible sewage pump manufacturer focuses on non-clogging designs and robust mechanical seals. The primary technical advantages of submersible pumps, particularly from a reputable submersible well pump manufacturer, include their inherent energy efficiency due to direct immersion, which eliminates the need for priming and minimizes suction lift losses. Their submerged operation also significantly reduces noise levels, making them suitable for residential and environmentally sensitive areas. Moreover, the robust construction, often incorporating corrosion-resistant materials and advanced sealing technologies, ensures a long service life and reduced maintenance requirements. These pumps are designed to be compact, saving valuable space, and their ability to operate without cavitation, given proper installation, ensures consistent and reliable fluid delivery, even in deep well applications.

Technical Superiority and Custom Solutions

Leading submersible well pump manufacturer companies distinguish themselves through continuous innovation and a commitment to technical superiority. This often manifests in advanced hydraulic designs, utilizing computational fluid dynamics (CFD) to optimize impeller and diffuser geometries for maximum efficiency and reduced energy consumption. State-of-the-art motor technology, including permanent magnet synchronous motors (PMSM) and high-efficiency induction motors, minimizes heat generation and maximizes power delivery, contributing to a lower total cost of ownership. Beyond design, the integration of advanced materials, such as duplex stainless steels for enhanced corrosion resistance and tungsten carbide for wear parts, significantly extends the pump's operational life in abrasive or chemically aggressive environments. For example, a reliable submersible pump shaft manufacturer will use high-grade materials and precise machining to ensure minimal runout and superior torsional strength, critical for transmitting power efficiently and reliably to the impeller stack. These technical advancements are not just theoretical; they translate directly into tangible benefits such as increased mean time between failures (MTBF) and significant operational savings for end-users, reflecting the expertise and authority of established manufacturers in the field.

A key differentiating factor for a premium submersible well pump manufacturer is the ability to provide bespoke solutions tailored to unique project requirements. Standard off-the-shelf pumps, while versatile, may not always deliver optimal performance for highly specific fluid properties, well dimensions, or energy constraints. Customization can involve modifying hydraulic components to achieve specific flow/head points, selecting specialized materials for extreme pH or temperature conditions, or integrating intelligent control systems for remote monitoring and variable speed operation. This client-centric approach, where engineers collaborate closely with customers to understand their precise needs, is indicative of a manufacturer's experience and trustworthiness. It allows for the development of pumps that are perfectly matched to the application, minimizing inefficiencies and maximizing return on investment. Furthermore, leading manufacturers offer comprehensive after-sales support, including installation guidance, maintenance services, and readily available submersible pump spares manufacturer parts, ensuring continuous and trouble-free operation throughout the pump's long service life, reinforcing the commitment to customer success and product reliability.

Insights from Application Cases and Industry Leadership

Real-world application cases underscore the practical effectiveness and reliability of pumps from a leading submersible well pump manufacturer. For example, in a large-scale agricultural project in arid regions, the deployment of high-efficiency submersible pumps facilitated significant water savings by optimizing irrigation schedules and delivering precise water volumes from deep boreholes, leading to enhanced crop yields and reduced operational costs for farmers. Another notable instance involves their use in dewatering operations for deep mines, where robust and abrasion-resistant submersible pumps effectively manage highly corrosive and abrasive mine water, preventing flooding and ensuring continuous extraction activities. These pumps, often supplied by a specialized submersible sewage pump manufacturer or a general manufacturer of submersible pump solutions, are critical for maintaining safe and productive working environments by handling difficult fluids with high solid content. Such scenarios highlight the resilience and adaptability of these engineered solutions to extreme operational demands, affirming their role as a backbone of modern industrial infrastructure and demonstrating the deep experience of the manufacturer in solving complex pumping challenges.

In the context of urban infrastructure, advanced submersible pumps have been instrumental in upgrading municipal water and wastewater treatment plants, enhancing treatment efficiency and reducing maintenance downtime. Consider an upgrade project for a metropolitan water supply system where older, less efficient pumps were replaced with modern, energy-efficient submersible units. This transition not only boosted the system's capacity to meet growing urban demands but also resulted in a substantial reduction in energy consumption and associated operational expenses, showcasing the long-term economic benefits. These pumps, often from an established china submersible pump manufacturer with a global footprint, are designed for longevity, typically offering a service life exceeding 15-20 years with proper maintenance, a testament to their robust construction and quality engineering. The continuous evolution in design, materials, and smart integration capabilities—from advanced sensor technology for predictive maintenance to remote monitoring systems for optimizing performance—cements the position of leading submersible well pump manufacturer entities as critical partners in ensuring sustainable water management and efficient fluid transfer across a spectrum of industrial and public utility applications worldwide.

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of a submersible well pump from a reputable manufacturer?

The typical lifespan of a high-quality submersible well pump can range from 10 to 20 years, provided it is properly installed, operated within its design parameters, and regularly maintained. Factors influencing longevity include material quality, fluid characteristics (e.g., abrasiveness, corrosiveness), motor efficiency, and power supply stability. Reputable manufacturers use advanced materials like stainless steel (e.g., SS316, Duplex) and robust mechanical seals to ensure maximum durability, even in challenging environments. Adherence to ISO standards during manufacturing and comprehensive quality control further extends the service life, ensuring a reliable product that minimizes long-term operational costs for the end-user.

Q2: How do submersible pumps contribute to energy efficiency?

Submersible pumps are inherently energy-efficient due to their design. Unlike surface pumps that require priming and expend energy overcoming suction lift, submersible pumps operate fully submerged, utilizing the positive pressure of the fluid column above them. This eliminates suction head losses and significantly reduces the risk of cavitation, a phenomenon that can severely reduce efficiency and damage the pump. Additionally, advanced submersible well pump manufacturer utilize high-efficiency motors (e.g., IE3/IE4 compliant, permanent magnet motors) and optimized hydraulic designs (impellers, diffusers) that minimize energy consumption for a given flow and head requirement, leading to substantial energy savings over the pump's operational lifespan, thereby lowering overall operating expenses.

Q3: What quality control measures are typically in place for a submersible pump manufacturer?

A leading submersible well pump manufacturer implements rigorous multi-stage quality control. This begins with material inspection, ensuring raw materials meet specified metallurgical properties. Throughout the manufacturing process, precise checks are performed after casting, machining (e.g., dimensional accuracy, surface finish), and assembly. Final testing involves comprehensive performance validation in dedicated test facilities, including hydrostatic pressure tests (to verify casing integrity), full load performance tests (to confirm flow, head, power, and efficiency against design curves), vibration analysis, and noise level checks. Adherence to international standards such as ISO 9001 for quality management systems and ANSI/HI for hydraulic performance testing is standard practice, ensuring every pump meets strict quality and performance criteria before dispatch.

Delivery and Warranty Commitment

A key aspect of trustworthiness for any submersible well pump manufacturer is their commitment to transparent delivery schedules and comprehensive warranty provisions. Typical delivery cycles for standard pump models usually range from 4 to 8 weeks, depending on the complexity and current production load. For custom-engineered solutions or pumps requiring specialized materials, lead times may extend slightly to accommodate design and manufacturing specificities. Reputable manufacturers provide clear communication regarding production progress and logistical updates to ensure clients are informed every step of the way. This proactive approach minimizes project delays and fosters strong client relationships, reflecting a customer-centric operational philosophy that extends beyond the point of sale.

Regarding quality assurance, a standard warranty period for industrial-grade submersible well pumps typically ranges from 12 to 24 months from the date of installation or 18 to 30 months from the date of shipment, whichever comes first. This warranty covers defects in materials and workmanship under normal use and service conditions, underscoring the manufacturer's confidence in their product quality. Furthermore, leading manufacturers offer robust after-sales support, including readily available spare parts, technical assistance for troubleshooting, and on-site maintenance services. This comprehensive support structure ensures that clients can rely on prompt and effective solutions should any issues arise, maximizing uptime and protecting their investment. This commitment to long-term support and accountability is a hallmark of a reliable and authoritative submersible well pump manufacturer, reinforcing their dedication to client satisfaction and product excellence throughout the pump's entire operational lifecycle.

References

- Hydraulic Institute. (2018). ANSI/HI 11.6 Rotodynamic Submersible Pumps for Slurry Transport.

- International Organization for Standardization. (2015). ISO 9906 Rotodynamic pumps - Hydraulic performance acceptance tests - Grades 1, 2 and 3.

- American Petroleum Institute. (2018). API 610: Centrifugal Pumps for Petroleum, Petrochemical and Natural Gas Industries.

- Elsevier. Journal of Fluid Mechanics and Engineering. Recent articles on advanced pump hydraulics and material science.

- Springer. Journal of Water Resource and Protection. Research on submersible pump applications in water management.

- MDPI. Energies. Studies on energy efficiency in pumping systems.

-

Wholesale Slurry Pump Spare Part Impeller - Rubber & Metal

NewsAug.27,2025

-

Submersible Well Pump Manufacturer: Quality Water & Sewage Pumps

NewsAug.26,2025

-

Manufacturer of Submersible Pumps & Slurry Impellers - Factory Direct

NewsAug.25,2025

-

Submersible Well Pump Manufacturer | Quality Water, Sewage & ESP

NewsAug.24,2025

-

Wholesale Slurry Pump Spare Part Impeller | Durable & High-Performance

NewsAug.23,2025

-

China Wear-Resistant Slurry Pump | Durable, Efficient Industrial Solutions

NewsAug.22,2025