ആഗ . 23, 2025 01:20 Back to list

Wholesale Slurry Pump Spare Part Impeller | Durable & High-Performance

Navigating the Market for High-Performance Slurry Pump Impellers

In demanding industrial applications, the efficiency and longevity of slurry pumping systems are critically dependent on the quality of their core components. Among these, the impeller stands out as the heart of the pump, directly influencing performance, energy consumption, and wear life. This comprehensive guide delves into the intricate world of the wholesale slurry pump spare part impeller, exploring its manufacturing, technical intricacies, and strategic importance for B2B stakeholders.

The global market for industrial pumps is experiencing steady growth, driven by expanding infrastructure, mining activities, and increasing demand from process industries. Within this landscape, the demand for robust and reliable wholesale slurry pump spare part impellers, including specialized variants like the wholesale slurry pump rubber impeller and those from reputable slurry pump parts impeller exporters, continues to rise. This growth is fueled by the need for more efficient and durable solutions to handle abrasive and corrosive slurries across diverse sectors.

The Advanced Manufacturing Process of Slurry Pump Impellers

Producing a high-quality wholesale slurry pump spare part impeller is a sophisticated process that combines advanced material science with precision engineering. The objective is to create a component that can withstand extreme abrasive wear, chemical corrosion, and high-impact forces, ensuring extended service life and optimal pump efficiency. The process involves several critical stages:

1. Material Selection

- High-Chrome Alloys: For severe abrasive applications, materials like A05 (27% Cr white iron) are commonly used. These alloys offer exceptional hardness and wear resistance, crucial for handling mineral slurries.

- Natural Rubber & Synthetics: For fine, highly abrasive, or corrosive slurries, materials such as natural rubber, neoprene, or polyurethane are selected. These provide superior resilience and impact absorption, characteristic of a slurry pump parts impeller rubber.

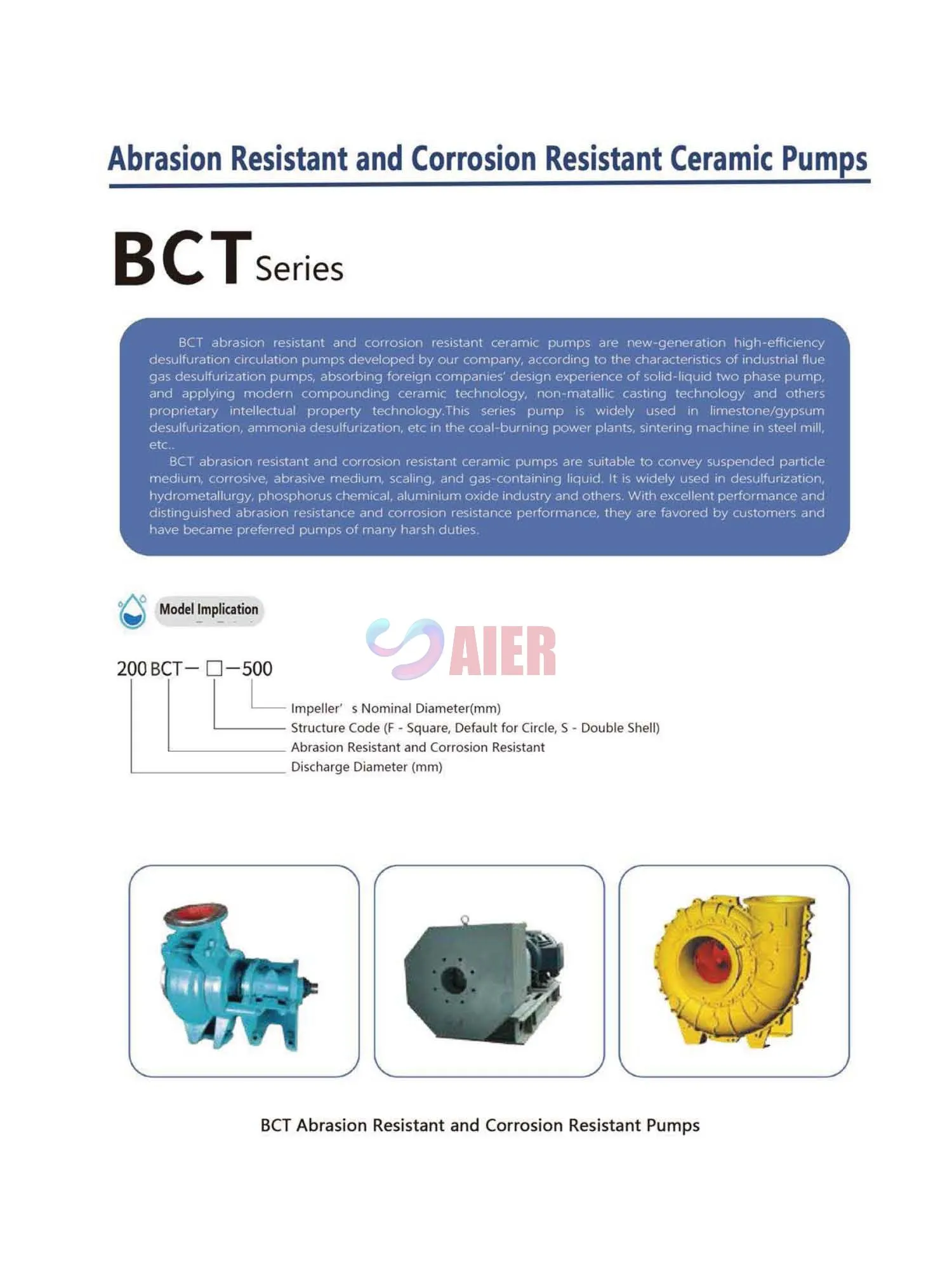

- Advanced Ceramics: For specialized applications requiring extreme chemical resistance and hardness beyond conventional alloys, materials like silicon carbide or alumina ceramics (as used in BCT Ceramic Slurry Pumps) are employed.

2. Manufacturing Processes

- Casting (for Metal Impellers): Precision sand casting or investment casting is utilized. Molten alloy is poured into molds, followed by controlled cooling to achieve desired metallurgical structures. This is critical for forming complex geometries like the wholesale slurry pump impeller vane.

- Molding/Vulcanization (for Rubber Impellers): Rubber compounds are compression or injection molded into the desired impeller shape, then cured (vulcanized) under heat and pressure to achieve optimal physical properties.

- Sintering (for Ceramic Impellers): Ceramic powders are pressed into shape and then heated to high temperatures (sintered) to fuse the particles, resulting in a dense, hard, and chemically inert component.

3. Machining & Finishing

Post-casting or molding, metallic impellers undergo CNC machining to achieve precise dimensions, surface finishes, and balancing. This ensures hydraulic efficiency and minimizes vibration. Rubber impellers may also require trimming and finishing. Ceramic impellers often demand diamond grinding due to their extreme hardness.

4. Quality Control & Testing

Rigorous testing is performed to ensure compliance with international standards such as ISO 9001 for quality management, and material-specific standards like ASTM A532 for abrasion-resistant cast irons or ISO 23207 for rubber and plastics. Key tests include:

- Dimensional Accuracy: CMM (Coordinate Measuring Machine) inspection.

- Material Hardness: Rockwell or Brinell hardness testing.

- Ultrasonic Testing: For internal defects or inclusions.

- Dynamic Balancing: To prevent vibration and extend bearing life.

- Hydrostatic Testing: For pressure integrity (where applicable).

These processes ensure that the resulting wholesale slurry pump spare part impeller offers an extended service life, often exceeding that of standard components by 30-50%, leading to reduced downtime and operational costs.

Technical Specifications and Material Science Excellence

The performance of a slurry pump impeller is defined by its hydraulic design, material composition, and manufacturing precision. Understanding these technical specifications is crucial for selecting the optimal wholesale slurry pump spare part impeller for any given application.

Impeller Types and Designs:

- Closed Impellers: Featuring shrouds on both sides of the vanes, wholesale slurry pump closed impeller designs offer high efficiency and are suitable for clean liquids or slurries with very fine solids. They provide excellent head and flow characteristics.

- Open Impellers: Lacking a front shroud, the slurry pump open impeller is ideal for slurries containing large or stringy solids, reducing the risk of clogging. While slightly less efficient, their non-clogging properties are invaluable in specific applications.

- Semi-Open Impellers: A hybrid design with a back shroud but no front shroud, offering a balance between efficiency and clog resistance.

- Expeller Impellers: A specialized type used in conjunction with expeller seals to reduce gland water requirements.

Key Material Properties:

- Abrasion Resistance: The ability of the material to resist wear caused by the impact and sliding of solid particles. Measured by hardness (e.g., Brinell Hardness Number for metals, Shore Hardness for rubbers).

- Corrosion Resistance: The material's capacity to resist chemical degradation from acidic or alkaline slurries. Achieved through specific alloy compositions (e.g., high-chromium content) or inert materials like ceramics.

- Impact Resistance: Essential for handling slurries with large, heavy particles where sudden impacts can occur. Rubber offers superior impact absorption compared to rigid metals or ceramics.

Typical Slurry Pump Impeller Specifications (High-Chrome Alloy)

| Parameter | Specification | Description |

|---|---|---|

| Material Grade | A05 (ASTM A532 Class III A) | High-Chrome White Iron for severe abrasion. |

| Hardness (HB) | ≥600 | Exceptional resistance to abrasive wear. |

| Tensile Strength | 300-400 MPa | Strength to withstand operational stresses. |

| Chrome Content | 25-30% | Key for wear and some corrosion resistance. |

| Surface Roughness | Ra ≤ 3.2 μm | Optimizes hydraulic efficiency and reduces friction. |

| Dynamic Balance | ISO 1940-1 Grade G6.3 | Ensures smooth operation and minimizes vibration. |

These specifications are crucial for B2B buyers evaluating wholesale slurry pump parts impeller options, ensuring they acquire components that meet the rigorous demands of their operations.

Diverse Application Scenarios and Technical Advantages

The versatility of slurry pump impellers, particularly high-performance wholesale slurry pump spare part impellers, makes them indispensable across a multitude of heavy industries. Their ability to efficiently move abrasive, corrosive, or high-density slurries is a testament to their advanced engineering.

Target Industries:

- Mining & Mineral Processing: Transporting ore slurries (e.g., iron, copper, gold), tailings, and mineral concentrates. Impellers here must withstand extreme abrasion.

- Power Generation: Handling fly ash and bottom ash slurries from coal-fired power plants, flue gas desulfurization (FGD) processes. Corrosion resistance is often paramount.

- Chemical Processing: Pumping aggressive chemical slurries, including acids, alkalis, and crystalline suspensions. Ceramic impellers, like those in BCT Ceramic Slurry Pumps, excel here due to superior chemical inertness.

- Dredging & Construction: Moving sand, gravel, and silt in dredging operations, land reclamation, and civil engineering projects. Large particle handling and high flow rates are key.

- Water & Wastewater Treatment: Transferring sludge, grit, and other suspended solids in treatment plants.

Demonstrable Advantages:

- Energy Saving: Optimized hydraulic designs and smoother surfaces (e.g., precision-machined alloys, polished ceramics) reduce friction and turbulence, leading to significant reductions in power consumption—often 5-15% compared to older designs.

- Corrosion Resistance: Specialized materials like high-chrome alloys or advanced ceramics effectively resist chemical attack, extending the life of the wholesale slurry pump parts impeller in aggressive environments.

- Abrasion Resistance: High hardness and specific material microstructures dramatically slow down wear from abrasive solids, minimizing component degradation and maintaining pump efficiency over longer periods.

- Extended Service Life: The combination of superior materials and precision manufacturing results in impellers that last significantly longer, reducing the frequency of replacements and associated labor costs.

- Reduced Downtime: Longer component life directly translates to less maintenance-related downtime, boosting overall plant productivity and operational continuity.

"Implementing advanced ceramic impellers in our FGD slurry pumps reduced our annual maintenance costs by 28% and increased our mean time between failures (MTBF) by over 60%. The initial investment was quickly recouped through operational efficiencies." - Senior Operations Manager, Thermal Power Plant.

Vendor Comparison and Customized Solutions

Selecting the right supplier for a wholesale slurry pump spare part impeller is a strategic decision that impacts long-term operational efficiency and cost. It goes beyond mere price comparison and involves evaluating expertise, manufacturing capabilities, and support services.

Key Considerations for Vendor Comparison:

- Material Expertise: Does the vendor offer a range of specialized materials (e.g., high-chrome, rubber, ceramics) tailored to different slurry conditions?

- Manufacturing Precision: Verification of ISO certifications, advanced machining capabilities (e.g., 5-axis CNC), and rigorous quality control protocols.

- Engineering Support: Ability to provide hydraulic analysis, material recommendations, and design optimization for specific applications.

- Lead Time & Logistics: Efficiency in production and global distribution networks for timely fulfillment, especially crucial for slurry pump parts impeller exporters.

- After-Sales Service: Availability of technical support, troubleshooting, and warranty provisions.

Impeller Material Comparison: Standard vs. Advanced (e.g., Ceramic)

| Feature | Standard High-Chrome (e.g., A05) | Natural Rubber (e.g., R55) | Advanced Ceramic (e.g., Alumina/SiC) |

|---|---|---|---|

| Primary Application | Coarse, highly abrasive slurries | Fine, corrosive/mildly abrasive slurries | Extreme abrasion, high corrosion, high temp. |

| Abrasion Resistance | Excellent | Good (for fine particles) | Superior (often 3-5x Hi-Chrome) |

| Corrosion Resistance | Good (pH 5-12) | Excellent (pH 2-12) | Exceptional (full pH range, aggressive chemicals) |

| Impact Resistance | Moderate | Excellent | Poor (brittle) |

| Typical Service Life Factor | 1.0 (Baseline) | 1.2 - 1.5 (for suitable applications) | 3.0 - 5.0 (significant improvement in wear) |

Customized Solutions:

Recognizing that no two slurry applications are identical, leading manufacturers offer customized wholesale slurry pump parts impeller solutions. This can include:

- Material Upgrades: Selecting a different alloy, rubber compound, or ceramic based on specific slurry characteristics (pH, particle size, temperature).

- Hydraulic Design Modifications: Adjusting vane geometry, number of vanes (e.g., wholesale slurry pump impeller vane optimization), or impeller diameter to achieve desired head, flow, or efficiency for unique system curves.

- Wear Part Integration: Designing impellers to work seamlessly with other pump components for overall system optimization and extended life.

A robust vendor relationship ensures access to engineering expertise that can translate operational challenges into effective, customized impeller solutions.

Real-World Application Case Studies

The tangible benefits of high-performance wholesale slurry pump spare part impellers are best illustrated through successful real-world applications. These case studies demonstrate how strategic impeller selection leads to significant operational improvements and cost savings.

Case Study 1: Mining Tailings Pond Management

- Client: Large-scale Copper Mine in South America.

- Challenge: Excessive wear on standard high-chrome impellers in their tailings pumps, leading to replacement every 3 months. The abrasive nature of the finely ground tailings, combined with fluctuating pH, resulted in high maintenance costs and frequent downtime. The complexity of warman slurry pump impeller removal and replacement further exacerbated the issue.

- Solution: Implemented specialized wholesale slurry pump rubber impellers, specifically designed for fine, abrasive particles and resistant to mild corrosive elements. The hydraulic design was optimized for improved flow.

- Results: Impeller service life increased from 3 months to 9 months, reducing annual impeller procurement by 66%. Maintenance labor costs decreased by 40%, and pump efficiency improved by 7%, leading to a 5% reduction in energy consumption for the pumping circuit.

Case Study 2: Flue Gas Desulfurization (FGD) at a Coal Power Plant

- Client: Major Thermal Power Producer in Europe.

- Challenge: Severe combined abrasion and corrosion in their FGD absorber recirculation pumps. Standard high-chrome impellers were failing within 6-8 weeks due to acidic slurry and gypsum crystal abrasion, causing unscheduled outages.

- Solution: Replaced standard impellers with BCT Ceramic Slurry Pumps' advanced ceramic impellers (silicon carbide). These impellers offered unparalleled resistance to both chemical attack and abrasion.

- Results: Impeller life extended to over 18 months, representing a 10-fold increase. Annual maintenance costs for impeller replacement dropped by over 85%. The plant reported a consistent 3% improvement in overall pump system efficiency due to the impeller's maintained hydraulic profile.

Ensuring Trust and Reliability: Our Commitment to Quality

Trustworthiness and authoritativeness are paramount in B2B transactions, especially when dealing with critical components like the wholesale slurry pump spare part impeller. Our commitment extends beyond product delivery to comprehensive support and adherence to the highest industry standards.

Certifications and Compliance:

- ISO 9001: Our manufacturing facilities are certified to ISO 9001 for quality management systems, ensuring consistent product quality from design to delivery.

- Material Certifications: All raw materials and finished impellers come with comprehensive material test certificates, complying with international standards such as ASTM, DIN, and JIS.

- Performance Guarantees: Our products are designed and tested to meet or exceed relevant industry performance standards (e.g., ANSI B73.1 for centrifugal pumps).

Experience and Partner Network:

With decades of experience in the pump industry, we have cultivated a deep understanding of diverse slurry applications. We partner with leading mining, power generation, and chemical companies globally, providing robust and reliable slurry pump parts impeller solutions. Our extensive track record and long-standing client relationships are a testament to our engineering prowess and commitment to excellence.

Frequently Asked Questions (FAQ)

Q1: How do I choose the correct material for my wholesale slurry pump spare part impeller?

A1: Material selection depends on slurry characteristics (particle size, hardness, concentration, pH), operating temperature, and required service life. High-chrome alloys are excellent for coarse, abrasive solids; natural rubber is preferred for fine, abrasive, and corrosive slurries; and ceramics excel in extremely abrasive and corrosive environments.

Q2: What is the typical lead time for a wholesale slurry pump parts impeller order?

A2: Standard high-wear parts typically have a lead time of 4-6 weeks, depending on inventory and production schedules. Custom-engineered impellers or specialized materials may require 8-12 weeks for design, manufacturing, and testing. We strive to maintain optimal inventory for common models to reduce lead times for urgent requirements.

Q3: Do you offer warranty on your slurry pump impellers?

A3: Yes, all our wholesale slurry pump spare part impellers are covered by a standard warranty against manufacturing defects. Specific warranty terms vary by product type and material, typically ranging from 6 to 12 months from installation or 18 months from shipment, whichever comes first. This warranty covers material and workmanship but excludes wear and tear under normal operating conditions.

Q4: Can your impellers be customized for specific pump models or challenging applications?

A4: Absolutely. We specialize in providing customized impeller solutions. Our engineering team works closely with clients to analyze their specific operational parameters and slurry properties, designing impellers that optimize performance, reduce wear, and improve efficiency for unique pump systems, including those requiring specific slurry pump parts impeller designs.

Logistics, Warranty, and After-Sales Support

Lead Time & Fulfillment:

Our robust supply chain and optimized manufacturing processes enable efficient order fulfillment. For in-stock standard wholesale slurry pump spare part impellers, dispatch can occur within 1-2 weeks. For made-to-order or highly customized components, typical lead times are communicated transparently at the quotation stage, usually ranging from 6 to 12 weeks depending on complexity and material availability. We utilize reliable global logistics partners to ensure timely and secure delivery worldwide.

Warranty Commitments:

We stand behind the quality and performance of our products. Each wholesale slurry pump spare part impeller is supplied with a comprehensive warranty covering defects in material and workmanship under normal operating conditions. Our technical team is available to assist with any warranty claims, ensuring a fair and prompt resolution process in line with our commitment to customer satisfaction.

Customer Support & After-Sales Service:

Our commitment to our clients extends far beyond the sale. We offer extensive after-sales support, including technical consultations, troubleshooting assistance, and expert advice on optimizing pump performance. Our dedicated service team is reachable via phone, email, and a secure online portal, ensuring that our partners receive timely and effective support for their operational needs, whether it's routine maintenance or complex challenges like warman slurry pump impeller removal and replacement.

Conclusion

The choice of a wholesale slurry pump spare part impeller is a pivotal decision that directly impacts operational efficiency, maintenance costs, and the overall reliability of slurry pumping systems. By focusing on advanced materials, precision manufacturing, and tailored hydraulic designs, businesses can unlock significant advantages in terms of energy savings, extended service life, and reduced downtime. Partnering with a knowledgeable and reputable supplier who emphasizes expertise, experience, authoritativeness, and trustworthiness is essential for navigating the complexities of severe-duty applications and achieving sustainable operational excellence.

References

- 1. International Organization for Standardization. ISO 9001:2015 - Quality management systems - Requirements.

- 2. American Society for Testing and Materials. ASTM A532/A532M - 19a Standard Specification for Abrasion-Resistant Cast Irons.

- 3. Hydraulic Institute. HI Standard 1.1-1.2, Centrifugal Pumps - Nomenclature, Definitions, Applications, and Operation.

- 4. Materials Science and Engineering: An Introduction. Callister, W. D., & Rethwisch, D. G. (2018). John Wiley & Sons.

-

Wholesale Slurry Pump Spare Part Impeller - Rubber & Metal

NewsAug.27,2025

-

Submersible Well Pump Manufacturer: Quality Water & Sewage Pumps

NewsAug.26,2025

-

Manufacturer of Submersible Pumps & Slurry Impellers - Factory Direct

NewsAug.25,2025

-

Submersible Well Pump Manufacturer | Quality Water, Sewage & ESP

NewsAug.24,2025

-

Wholesale Slurry Pump Spare Part Impeller | Durable & High-Performance

NewsAug.23,2025

-

China Wear-Resistant Slurry Pump | Durable, Efficient Industrial Solutions

NewsAug.22,2025