- ആഫ്രിക്കൻ

- അൽബേനിയൻ

- അംഹാരിക്

- അറബി

- അർമേനിയൻ

- അസർബൈജാനി

- ബാസ്ക്

- ബെലാറഷ്യൻ

- ബംഗാളി

- ബോസ്നിയൻ

- ബൾഗേറിയൻ

- കറ്റാലൻ

- സെബുവാനോ

- ചൈന

- ചൈന (തായ്വാൻ)

- കോർസിക്കൻ

- ക്രൊയേഷ്യൻ

- ചെക്ക്

- ഡാനിഷ്

- ഡച്ച്

- ഇംഗ്ലീഷ്

- എസ്പറാന്റോ

- എസ്റ്റോണിയൻ

- ഫിന്നിഷ്

- ഫ്രഞ്ച്

- ഫ്രിസിയൻ

- ഗലീഷ്യൻ

- ജോർജിയൻ

- ജർമ്മൻ

- ഗ്രീക്ക്

- ഗുജറാത്തി

- ഹെയ്തിയൻ ക്രിയോൾ

- ഹൌസ

- ഹവായിയൻ

- ഹീബ്രു

- ഇല്ല

- മിയാവോ

- ഹംഗേറിയൻ

- ഐസ്ലാൻഡിക്

- ഇഗ്ബോ

- ഇന്തോനേഷ്യൻ

- ഐറിഷ്

- ഇറ്റാലിയൻ

- ജാപ്പനീസ്

- ജാവനീസ്

- കന്നഡ

- കസാഖ്

- ഖെമർ

- റുവാണ്ടൻ

- കൊറിയൻ

- കുർദിഷ്

- കിർഗിസ്

- ടി.ബി

- ലാറ്റിൻ

- ലാത്വിയൻ

- ലിത്വാനിയൻ

- ലക്സംബർഗ്

- മാസിഡോണിയൻ

- മൽഗാഷി

- മലയാളി

- മലയാളം

- മാൾട്ടീസ്

- മാവോറി

- മറാത്തി

- മംഗോളിയൻ

- മ്യാൻമർ

- നേപ്പാളി

- നോർവീജിയൻ

- നോർവീജിയൻ

- ഓക്സിറ്റാൻ

- പാഷ്തോ

- പേർഷ്യൻ

- പോളിഷ്

- പോർച്ചുഗീസ്

- പഞ്ചാബി

- റൊമാനിയൻ

- റഷ്യൻ

- സമോവൻ

- സ്കോട്ടിഷ് ഗാലിക്

- സെർബിയൻ

- ഇംഗ്ലീഷ്

- ഷോണ

- സിന്ധി

- സിംഹള

- സ്ലോവാക്

- സ്ലോവേനിയൻ

- സോമാലി

- സ്പാനിഷ്

- സുന്ദനീസ്

- സ്വാഹിലി

- സ്വീഡിഷ്

- ടാഗലോഗ്

- താജിക്ക്

- തമിഴ്

- ടാറ്റർ

- തെലുങ്ക്

- തായ്

- ടർക്കിഷ്

- തുർക്ക്മെൻ

- ഉക്രേനിയൻ

- ഉർദു

- ഉയിഗർ

- ഉസ്ബെക്ക്

- വിയറ്റ്നാമീസ്

- വെൽഷ്

- സഹായം

- യദിഷ്

- യൊറൂബ

- സുലു

ആഗ . 29, 2025 01:40 പട്ടികയിലേക്ക് മടങ്ങുക

Submersible Well Pump Manufacturer | Durable & Efficient Solutions

The Core of Subterranean Water Management: Navigating the Role of a മുങ്ങിക്കാവുന്ന കിണർ പമ്പ് നിർമ്മാതാവ്

In the critical infrastructure of water supply, agriculture, and industrial processes, the reliability and efficiency of water pumping systems are paramount. At the heart of subterranean water extraction lies the submersible well pump, a device engineered to operate fully immersed in water. As a leading മുങ്ങിക്കാവുന്ന കിണർ പമ്പ് നിർമ്മാതാവ്, we understand the intricate demands of these applications, from ensuring potable water supply to facilitating complex industrial cooling systems. This article delves into the technical prowess, manufacturing excellence, and application versatility that define modern submersible pump technology, offering insights for B2B decision-makers seeking robust and sustainable solutions.

The global market for submersible pumps is experiencing significant growth, driven by increasing urbanization, agricultural demands, and industrial expansion. According to recent industry reports, the market is projected to reach over USD 15 billion by 2028, with a Compound Annual Growth Rate (CAGR) exceeding 6%. This growth underscores the increasing reliance on efficient and durable pumping solutions, making the selection of a reputable സബ്മെർസിബിൾ വാട്ടർ പമ്പ് നിർമ്മാതാവ് more critical than ever.

Industry Trends Shaping Submersible Pump Technology

The landscape for submersible pump manufacturing is continuously evolving, shaped by technological advancements, environmental regulations, and shifting market demands. Key trends include:

- Energy Efficiency: Driven by rising energy costs and environmental concerns, there's a strong push towards high-efficiency motors (IE3/IE4 standards) and variable frequency drive (VFD) integration to optimize power consumption and reduce operational costs.

- Smart Pumping Systems: Integration of IoT, sensors, and remote monitoring capabilities allows for predictive maintenance, real-time performance tracking, and automated adjustments, enhancing system reliability and reducing downtime.

- Advanced Materials: Development of more durable, corrosion-resistant materials (e.g., Duplex Stainless Steel, specialized alloys) extends service life, particularly in harsh environments involving abrasive fluids or corrosive chemicals. This is particularly relevant for a സബ്മേഴ്സിബിൾ മലിനജല പമ്പ് നിർമ്മാതാവ്.

- Modularity and Customization: An increasing demand for modular designs that allow for easier maintenance, replacement of സബ്മെർസിബിൾ പമ്പ് സ്പെയർ നിർമ്മാതാവ്, and customized configurations to meet specific application requirements.

- Sustainability and Lifecycle Focus: Emphasis on the entire product lifecycle, from eco-friendly manufacturing processes to end-of-life recycling, aligning with global sustainability initiatives.

The Manufacturing Process: Precision and Durability

The production of high-quality submersible pumps is a multi-stage process demanding meticulous attention to detail, adherence to stringent quality control, and the use of advanced manufacturing technologies. As a proficient സബ്മെർസിബിൾ പമ്പിന്റെ നിർമ്മാതാവ്, our process is designed to ensure maximum performance and longevity.

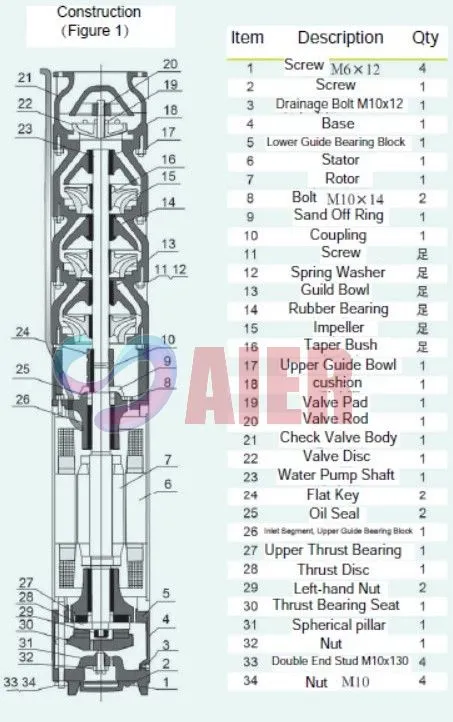

Manufacturing Process Flow of QJ Submersible PUMP:

1. Material Selection & Procurement

High-grade stainless steel (304, 316, Duplex) for pump casing, impeller, diffuser, and സബ്മെർസിബിൾ പമ്പ് ഷാഫ്റ്റ് നിർമ്മാതാവ്. High-quality copper wire for motor windings. Rubber and polymers for seals and bearings. All materials sourced from ISO-certified suppliers, adhering to ASTM/DIN standards for metallurgy.

2. Component Fabrication

- Casting/Forging: Impellers, diffusers, and certain pump parts are cast or forged for optimal mechanical properties.

- CNC Machining: Precision machining of shafts, housings, and other critical സബ്മെർസിബിൾ പമ്പ് ഭാഗങ്ങളുടെ നിർമ്മാതാവ് ensures tight tolerances and perfect fit.

- Motor Winding: Automated winding processes for electric motors, followed by vacuum impregnation with varnish for insulation.

3. Assembly & Sealing

Careful assembly of impellers, diffusers, motor, and housing. Critical sealing points are meticulously installed using high-grade mechanical seals (e.g., silicon carbide/graphite) to prevent water ingress into the motor chamber, ensuring operational integrity for an ഇലക്ട്രിക്കൽ സബ്മേഴ്സിബിൾ പമ്പ് നിർമ്മാതാവ്.

4. Testing & Quality Control

- Hydrostatic Testing: Pressure testing of pump housing for leak integrity.

- Performance Testing: Each pump undergoes rigorous performance testing (flow rate, head, efficiency, power consumption) according to ISO 9906 (Grade 2B) and ANSI/HI standards.

- Electrical Testing: Motor insulation resistance, continuity, and high-pot tests.

- Vibration Analysis: Ensuring smooth operation and extended bearing life.

5. Finishing & Packaging

Surface treatment, protective coatings, and final inspection. Robust packaging designed for safe transportation and long-term storage, often customized for international shipping as a ചൈന സബ്മെർസിബിൾ പമ്പ് നിർമ്മാതാവ്.

Our adherence to international standards such as ISO 9001 for quality management and ISO 14001 for environmental management ensures that every product, including our QJ Submersible PUMP series, meets the highest benchmarks for reliability and sustainability. The service life of our pumps is typically 8-15 years, depending on application severity and maintenance.

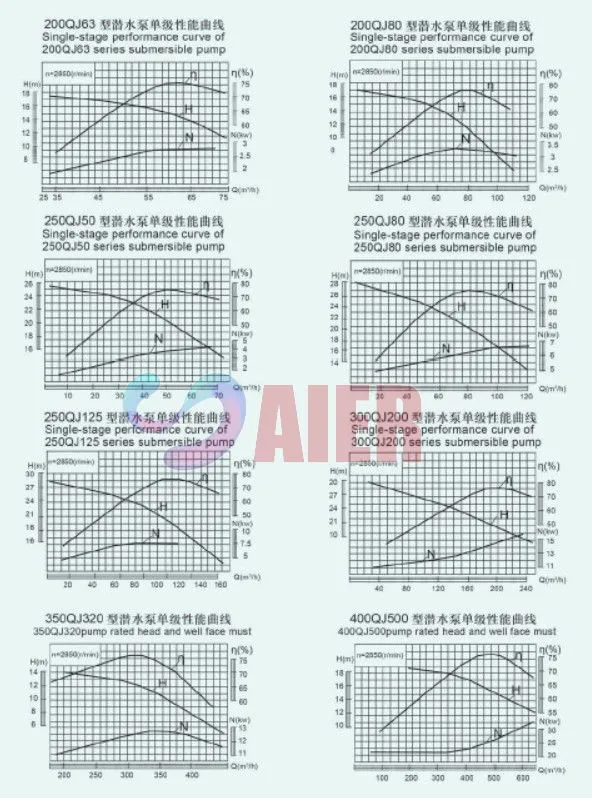

QJ Submersible PUMP: Technical Specifications and Advantages

The QJ Submersible PUMP series is engineered for deep well applications, characterized by its robust construction, high efficiency, and reliable operation. This സെൻട്രിഫ്യൂഗൽ സബ്മെർസിബിൾ പമ്പ് നിർമ്മാതാവ് series is designed to handle clean water effectively, delivering high head and flow rates required for municipal, agricultural, and industrial water supply.

Key Technical Parameters (QJ Series Example)

| Parameter | Value/Description |

|---|---|

| Flow Rate (Q) | 10 – 500 m³/h |

| Head (H) | 20 – 500 m |

| Motor Power | 2.2 kW – 300 kW |

| Voltage | 380V/50Hz, 460V/60Hz (customizable) |

| Max. Fluid Temperature | Up to 30°C (86°F) standard, higher upon request |

| Outlet Diameter | DN80 – DN300 (3 – 12 inches) |

| Material (Standard) | Cast Iron (HT200) for casing, Stainless Steel (304/316) for shaft & impellers |

| Protection Class | IP68 |

| Insulation Class | Class B (standard), Class F (optional) |

Technical Advantages:

- High Efficiency Hydraulics: Optimized impeller and diffuser designs reduce hydraulic losses, translating to significant energy savings (up to 15-20% compared to older designs).

- Robust Motor Design: Hermetically sealed, water-filled or oil-filled motors ensure excellent cooling and long-term reliability even under continuous operation.

- Wear Resistance: Multi-stage impellers made from high-chrome cast iron or stainless steel offer superior resistance to abrasive particles (e.g., sand content up to 50mg/L). For more aggressive media, specialized materials are offered.

- Corrosion Resistance: Options for full stainless steel construction (304, 316, or Duplex) provide exceptional corrosion resistance in aggressive water environments, extending pump lifespan.

- Integrated Protection: Optional features like motor overheating protection, dry-running protection, and overcurrent protection safeguard the pump and prolong its operational life.

Versatile Application Scenarios for Submersible Pumps

The versatility of submersible pumps makes them indispensable across numerous industries. Our QJ series, developed as a leading മുങ്ങിക്കാവുന്ന കിണർ പമ്പ് നിർമ്മാതാവ്, is specifically designed to excel in various demanding applications:

- Municipal Water Supply: Extracting potable water from deep boreholes for urban and rural communities, ensuring consistent pressure and flow.

- Agricultural Irrigation: Supplying water for large-scale irrigation projects, critical for crop cultivation and livestock watering, especially in regions with deep water tables.

- Industrial Water Treatment: Providing raw water for industrial processes, cooling systems, and specialized applications where reliable water sourcing is crucial.

- Mining & Dewatering: Pumping water from mines, construction sites, and excavation areas to maintain dry working conditions, often involving abrasive slurries (requiring specialized pump variants).

- Fire Fighting Systems: Serving as emergency water sources for fire suppression systems in industrial and commercial complexes due to their high head capabilities.

- Fountain & Water Features: Used in large public fountains and aesthetic water features where quiet operation and submerged installation are desirable.

Vendor Comparison: Choosing the Right Submersible Pump Partner

Selecting a മുങ്ങിക്കാവുന്ന കിണർ പമ്പ് നിർമ്മാതാവ് is a strategic decision that impacts long-term operational efficiency and cost. A comprehensive evaluation involves more than just price; it encompasses product quality, technical support, customization capabilities, and after-sales service.

Submersible Pump Manufacturer Comparison Matrix (Illustrative)

| Feature/Criterion | Aier Pumps (QJ Series) | Competitor X | Competitor Y |

|---|---|---|---|

| Material Options | Cast Iron, SS304, SS316, Duplex SS | Cast Iron, SS304 | SS304, SS316 |

| Efficiency (IE Class) | IE3/IE4 options available | IE2/IE3 | IE3 |

| Customization Scope | High (materials, voltage, flow/head adjustment) | Moderate (standard models only) | Limited (minor adjustments) |

| Certifications | ISO 9001, CE, local certifications | ISO 9001 | ISO 9001, UL |

| Warranty Period | 12-18 Months (Standard) | 12 Months | 12 Months |

| Technical Support | 24/7 online, field support, spare parts | Business hours online, limited field | Online support only |

This illustrative comparison highlights the importance of evaluating various factors beyond just the initial purchase price. A robust warranty, comprehensive technical support, and the ability to provide customized solutions often lead to lower total cost of ownership (TCO) over the pump's operational lifespan.

Customized Solutions and Application Case Studies

Tailored Engineering for Unique Challenges

Recognizing that standard products may not always fit every unique operational parameter, as an experienced മുങ്ങിക്കാവുന്ന കിണർ പമ്പ് നിർമ്മാതാവ്, we specialize in providing customized solutions. This includes:

- Material Adaptation: Engineering pumps with specific materials (e.g., higher grades of stainless steel, bronze, specialized alloys) to withstand corrosive fluids or extremely abrasive conditions.

- Hydraulic Optimization: Customizing impeller and diffuser geometry to achieve precise flow and head requirements for specific well characteristics or system demands.

- Motor & Electrical Modifications: Adapting motor power, voltage, frequency, and control systems (e.g., integrated VFDs, specialized sensors) to comply with local electrical standards and operational needs.

- Accessory Integration: Supplying complete pumping stations including control panels, level sensors, discharge piping, and other ancillary equipment, pre-engineered for seamless integration.

Application Case Studies: Proving Our Expertise

Case Study 1: Municipal Water Supply Upgrade (Middle East)

A major municipality faced challenges with aging pumps leading to insufficient water pressure and high energy consumption. We provided 10 units of customized QJ Series pumps (SS316 construction for brackish water, 150 kW, 300 m³/h at 250m head) integrated with smart VFD control systems. This upgrade resulted in a 22% reduction in energy costs and a 30% improvement in water delivery efficiency, meeting peak demand without strain.

Case Study 2: Agricultural Irrigation Project (Southeast Asia)

A large-scale agricultural cooperative required a robust solution for irrigating 500 hectares from deep wells. Our team designed and supplied 5 high-capacity QJ pumps (250 kW, 400 m³/h at 180m head) with enhanced sand-handling capabilities. The project achieved a consistent water supply throughout the dry season, leading to a significant increase in crop yield and an estimated 5-year payback period on the pump investment due to increased efficiency.

Trustworthiness & Customer Assurance

Frequently Asked Questions (FAQ)

Q: What is the typical lead time for a QJ Submersible PUMP order?

A: Standard models typically have a lead time of 2-4 weeks, depending on inventory and order volume. Customized orders may range from 6-10 weeks, factoring in design, material procurement, and specific manufacturing processes. We prioritize efficient order fulfillment while maintaining stringent quality control.

Q: What warranty does your company offer on submersible pumps?

A: We offer a standard 12 to 18-month warranty from the date of purchase or 1000 operating hours, whichever comes first, against manufacturing defects. Extended warranty options are available upon request for specific projects.

Q: How do you handle after-sales support and spare parts?

A: Our dedicated after-sales support team is available 24/7 to assist with technical queries, troubleshooting, and maintenance guidance. We maintain a comprehensive stock of genuine സബ്മെർസിബിൾ പമ്പ് സ്പെയർ നിർമ്മാതാവ് and replacement components to ensure prompt availability and minimize downtime for our clients globally.

Q: Can your pumps handle abrasive fluids or corrosive chemicals?

A: While the standard QJ series is designed for clean water, we offer specialized versions with enhanced material specifications (e.g., Duplex stainless steel, wear-resistant coatings, ceramic bearings) suitable for mildly abrasive fluids or corrosive environments. We recommend consulting our engineering team for detailed material selection based on fluid analysis.

Commitment to Service and Reliability

Our commitment extends beyond providing high-quality submersible pumps; it encompasses a complete lifecycle support system. We leverage decades of experience in the pump industry, working with a diverse portfolio of clients across petrochemical, metallurgy, municipal water supply & drainage, and agricultural sectors. Our authoritative certifications, including ISO 9001, CE, and country-specific approvals, validate our adherence to global quality and safety standards. Each pump undergoes stringent factory acceptance tests (FAT) to ensure performance matches specifications before dispatch, reinforcing our position as a trusted മുങ്ങിക്കാവുന്ന കിണർ പമ്പ് നിർമ്മാതാവ്.

Conclusion

The choice of a മുങ്ങിക്കാവുന്ന കിണർ പമ്പ് നിർമ്മാതാവ് is pivotal for the operational success and longevity of any water management system. With a focus on advanced engineering, rigorous quality control, and comprehensive customer support, we are dedicated to delivering submersible pump solutions that are not only efficient and durable but also perfectly tailored to the evolving needs of our global clientele. Our QJ Submersible PUMP series embodies this commitment, offering unparalleled performance and reliability for critical water extraction challenges.

References:

- Grand View Research. "Submersible Pumps Market Size, Share & Trends Analysis Report." Published [Year of latest report, e.g., 2023].

- International Organization for Standardization (ISO). "ISO 9906: Rotodynamic pumps - Hydraulic performance acceptance tests - Grades 1, 2 and 3."

- Hydraulic Institute. "ANSI/HI 1.6-2000 - Rotodynamic (Centrifugal) Pump Tests."

- Mordor Intelligence. "Submersible Pump Market - Growth, Trends, COVID-19 Impact, and Forecasts (2023 - 2028)."

-

Submersible Well Pump Manufacturer | Durable & Efficient Solutions

വാർത്തAug.29,2025

-

Small Dredge Pump Applications in Aquaculture and Ponds

വാർത്തAug.28,2025

-

Portable Sump Pumps for Emergency Flood Situations

വാർത്തAug.28,2025

-

Metal Slurry Pump Applications in Mining Industry

വാർത്തAug.28,2025

-

Hydraulic Performance Testing for Centrifugal Vertical Slurry Pumps

വാർത്തAug.28,2025

-

Froth Pump Automation Trends in Modern Industry

വാർത്തAug.28,2025