Peb . 16, 2025 09:58 Back to list

G10083A05 high chrome throatbush

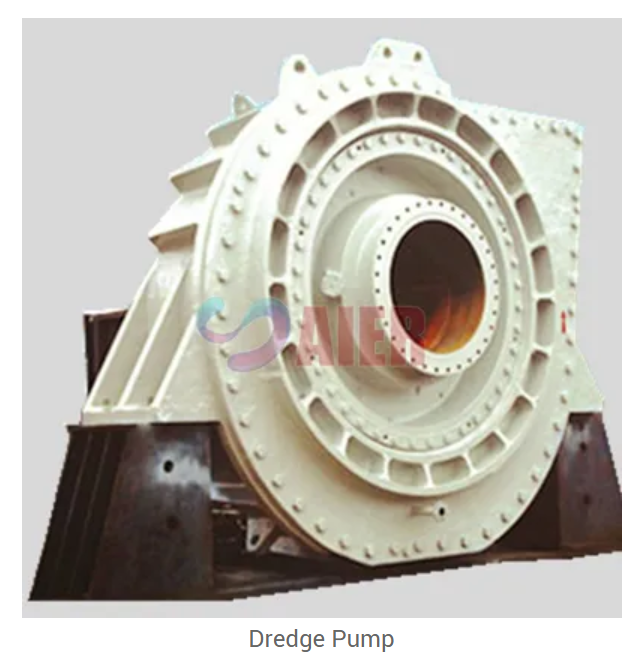

Selecting a high-quality dredge pump for sand can dramatically affect the success and efficiency of dredging operations. As an industry professional with years of experience, I have seen the transformative impact that state-of-the-art dredge pumps can have in various projects. Understanding the importance of these pumps and choosing the right one is crucial. This article will guide you through everything you need to know about high-quality dredge pumps for sand, ensuring your choice is informed, expertly guided, and authoritative.

Flow rate and efficiency are also paramount. A high-quality pump should deliver a steady, efficient flow of sand. Variable speed motors or hydraulic drive systems can optimize efficiency by enabling the pump to perform optimally under different conditions. When working on projects with fluctuating demands, such adaptability has crucially sustained operations without sacrificing performance or efficiency. While technological attributes are key to assessing a dredge pump’s quality, support, and service are equally important. Selecting a manufacturer or supplier with a reputation for excellence, backed by comprehensive support services, is indispensable. Reputable companies offer technical assistance, prompt service, and readily available spare parts, ensuring minimal operational interruptions. Experience has repeatedly confirmed the benefits of choosing well-regarded manufacturers, as their expertise significantly contributes to project success. Furthermore, environmental considerations are becoming increasingly paramount in dredging operations. Selecting a pump designed to operate efficiently with minimal environmental impact should be prioritized. Environmentally optimized pumps minimize energy consumption and reduce ecosystem disturbance, aligning with international standards and fostering sustainable practices. My involvement in numerous dredging projects has underscored the intrinsic responsibility we carry in preserving the environment. Incorporating eco-friendly, high-performance technology in dredging not only meets regulatory requirements but also tangibly reflects our commitment to sustainable engineering practices. In conclusion, selecting a high-quality dredge pump for sand requires careful evaluation of construction materials, impeller design, sealing systems, flow efficiency, and manufacturer support. The right pump integrates these features to deliver reliable, efficient, and sustainable operation. As an expert, my advice is to invest in quality and reliability from reputable sources, ensuring your operations benefit from cutting-edge technology and enduring professional support. Doing so can lead to remarkable improvements in performance and project outcomes, ultimately yielding long-term benefits both economically and environmentally.

Flow rate and efficiency are also paramount. A high-quality pump should deliver a steady, efficient flow of sand. Variable speed motors or hydraulic drive systems can optimize efficiency by enabling the pump to perform optimally under different conditions. When working on projects with fluctuating demands, such adaptability has crucially sustained operations without sacrificing performance or efficiency. While technological attributes are key to assessing a dredge pump’s quality, support, and service are equally important. Selecting a manufacturer or supplier with a reputation for excellence, backed by comprehensive support services, is indispensable. Reputable companies offer technical assistance, prompt service, and readily available spare parts, ensuring minimal operational interruptions. Experience has repeatedly confirmed the benefits of choosing well-regarded manufacturers, as their expertise significantly contributes to project success. Furthermore, environmental considerations are becoming increasingly paramount in dredging operations. Selecting a pump designed to operate efficiently with minimal environmental impact should be prioritized. Environmentally optimized pumps minimize energy consumption and reduce ecosystem disturbance, aligning with international standards and fostering sustainable practices. My involvement in numerous dredging projects has underscored the intrinsic responsibility we carry in preserving the environment. Incorporating eco-friendly, high-performance technology in dredging not only meets regulatory requirements but also tangibly reflects our commitment to sustainable engineering practices. In conclusion, selecting a high-quality dredge pump for sand requires careful evaluation of construction materials, impeller design, sealing systems, flow efficiency, and manufacturer support. The right pump integrates these features to deliver reliable, efficient, and sustainable operation. As an expert, my advice is to invest in quality and reliability from reputable sources, ensuring your operations benefit from cutting-edge technology and enduring professional support. Doing so can lead to remarkable improvements in performance and project outcomes, ultimately yielding long-term benefits both economically and environmentally.

Latest news

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025