Th2 . 14, 2025 12:24 Back to list

high quality vertical sump pump parts

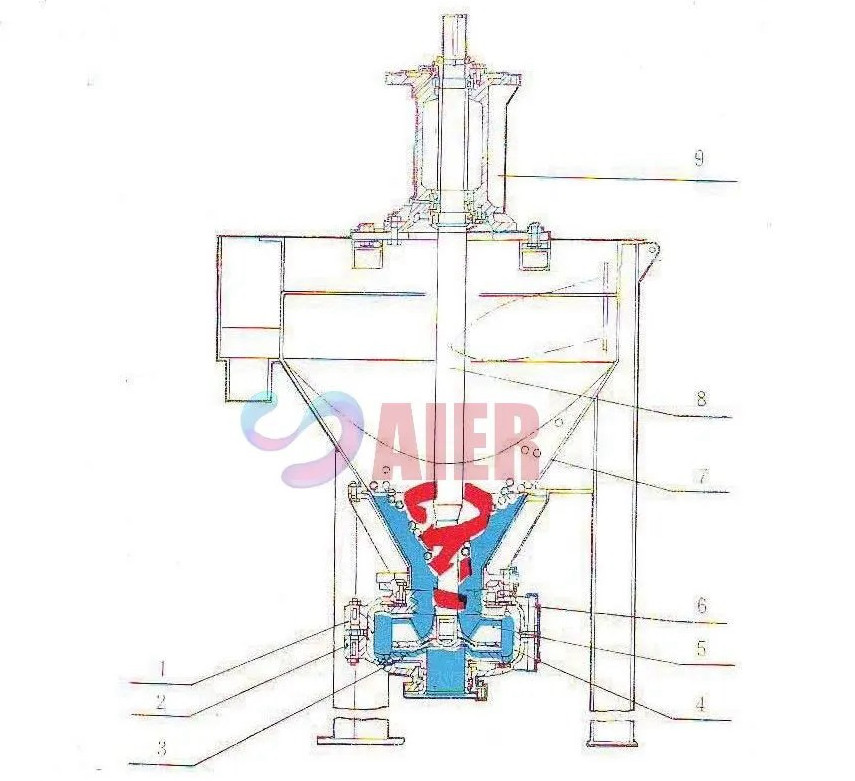

When it comes to maintaining an efficient and reliable pumping system in industrial settings, the importance of high quality vertical sump pump parts cannot be overstated. For industries such as mining, chemical processing, and wastewater management, these components are critical to ensuring the smooth operation of sump pumps, which are designed to handle fluids with high solid content or chemically aggressive substances. Acquiring superior parts not only extends the life of the pumps but also enhances their performance and reduces downtime, saving businesses significant time and resources.

Furthermore, the accessibility of expertise through customer service should not be overlooked. Reliable suppliers will offer robust support services, including detailed consultation and technical assistance, aiding customers in selecting the appropriate parts for their application. This personalized support ensures that each component performs at its best, contributing to the overall effectiveness of the pumping system. Trustworthiness encompasses more than just quality parts and service; it also involves adhering to ethical business practices and maintaining transparent communication with customers. Trusted suppliers are forthcoming about the specifications and origin of their parts, including detailing any certifications or compliance with industry standards. This honesty builds a foundation of trust with their clients, encouraging long-term business relationships. Experience in navigating the complexities of maintaining and upgrading vertical sump pumps reveals the importance of having a robust strategy for procuring parts. Those who have managed industrial pump systems can attest that unexpected failures or maintenance issues can halt production and incur significant costs. Planning ahead, maintaining a comprehensive stock of high-quality parts, and partnering with reliable suppliers can mitigate these risks and ensure continuous operation. Finally, businesses should consider implementing a preventative maintenance program that includes regular inspections and timely replacements of worn components. Consistent evaluation of pump performance and condition allows for the early detection of issues, facilitating timely replacements before a critical failure occurs. This proactive approach not only preserves pump longevity but also optimizes operational efficiency, reducing long-term costs and enhancing productivity. In conclusion, selecting high-quality vertical sump pump parts is paramount for businesses aiming to maintain uninterrupted operations in demanding industrial environments. By focusing on the quality of materials, engineering expertise, supplier reputation, and comprehensive customer service, companies can secure reliable and efficient pumping solutions. Investing in superior parts not only safeguards against operational disruptions but also supports a sustainable and cost-effective approach to industrial pump management.

Furthermore, the accessibility of expertise through customer service should not be overlooked. Reliable suppliers will offer robust support services, including detailed consultation and technical assistance, aiding customers in selecting the appropriate parts for their application. This personalized support ensures that each component performs at its best, contributing to the overall effectiveness of the pumping system. Trustworthiness encompasses more than just quality parts and service; it also involves adhering to ethical business practices and maintaining transparent communication with customers. Trusted suppliers are forthcoming about the specifications and origin of their parts, including detailing any certifications or compliance with industry standards. This honesty builds a foundation of trust with their clients, encouraging long-term business relationships. Experience in navigating the complexities of maintaining and upgrading vertical sump pumps reveals the importance of having a robust strategy for procuring parts. Those who have managed industrial pump systems can attest that unexpected failures or maintenance issues can halt production and incur significant costs. Planning ahead, maintaining a comprehensive stock of high-quality parts, and partnering with reliable suppliers can mitigate these risks and ensure continuous operation. Finally, businesses should consider implementing a preventative maintenance program that includes regular inspections and timely replacements of worn components. Consistent evaluation of pump performance and condition allows for the early detection of issues, facilitating timely replacements before a critical failure occurs. This proactive approach not only preserves pump longevity but also optimizes operational efficiency, reducing long-term costs and enhancing productivity. In conclusion, selecting high-quality vertical sump pump parts is paramount for businesses aiming to maintain uninterrupted operations in demanding industrial environments. By focusing on the quality of materials, engineering expertise, supplier reputation, and comprehensive customer service, companies can secure reliable and efficient pumping solutions. Investing in superior parts not only safeguards against operational disruptions but also supports a sustainable and cost-effective approach to industrial pump management.

Latest news

-

Reliable Submersible Well Pump Manufacturer – Quality & Durability

NewsJul.26,2025

-

Submersible Pump Shaft Manufacturer - High Quality Vertical and Ceramic Slurry Pumps

NewsJul.25,2025

-

Top Submersible Well Pump Manufacturer - Reliable & Durable Solutions

NewsJul.24,2025

-

Leading Submersible Well Pump Manufacturer – Reliable & Durable Pumps

NewsJul.23,2025

-

Submersible Well Pump Manufacturer: Reliable & Efficient Solutions

NewsJul.22,2025

-

China Slurry Pump Volute Liner Factory | Durable Spare Parts

NewsJul.21,2025