Avg . 04, 2025 02:40 Back to list

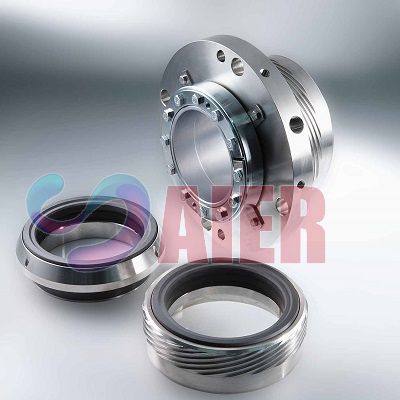

Premium Warman Slurry Pump Mechanical Seal - Leak-Proof

Figure 1. High-Performance warman slurry pump mechanical seal in metallurgy application

1. Industry Trends in Slurry Pump Mechanical Seals

The global demand for warman slurry pump mechanical seal solutions is surging due to their critical role in the mining, chemical, water treatment, and metallurgy industries. As per 2023 Grand View Research, the mechanical seals market is projected to surpass USD 5.1 billion by 2027, with slurry pump applications accounting for a significant 27% share. In particular, the mechanical seal for slurry pump segment is experiencing rapid innovation focused on energy efficiency, longer life cycles, corrosion resistance, and ease of maintenance.

- Automation & Remote Monitoring: Evolving from traditional packing seals to advanced mechanical seals with IoT-enabled monitoring for predictive maintenance.

- Material Innovations: Use of novel alloy, carbide, and ceramic composites to withstand abrasive slurries and aggressive chemicals.

- Compliance: Emphasis on international standards such as ISO 21049 / API 682 and ANSI, ensuring global compatibility and safety.

- Sustainability: Eco-friendly sealing solutions assisting in minimizing leakage, reducing waste, and aligning with environmental regulations.

Certified By: ISO 9001, API 682, ANSI B73.1

| Partnered With: Vale, BASF, Sinopec, Tata Steel, Veolia

2. Understanding warman slurry pump mechanical seal Technology

2.1 Key Technical Specifications

| Feature | Parameter | Reference Value |

|---|---|---|

| Pump Model Compatibility | AH, HH, M, L Series (Warman Pumps) | 50-800 mm suction sizes |

| Seal Face Materials | Silicon carbide, Tungsten carbide, Carbon graphite | SiC/SiC, TC/TC, Carbon/SS304 |

| Secondary Sealing | EPDM, FKM (Viton), PTFE | O-rings, Bellows |

| Pressure Range | Up to 6 MPa | 0.05–6 MPa |

| Temperature Range | -40°C to 205°C | Typical: -20°C ~ 180°C |

| Operating Media | Slurry, Mining tailings, Chemical solutions | pH 2–13, max solids 60% |

| Certification | ISO, API, ANSI | ISO 21049, ANSI B73.1 |

2.2 Product Parameters Comparison for Leading Mechanical Seal Brands

| Brand | Face Material | Max Pressure (MPa) | Temperature (°C) | Cycle Life (hrs) | Certifications |

|---|---|---|---|---|---|

| Aier (Recommended) | SiC/TC / Carbon / Ceramic | 6 | 205 | 15,000+ | ISO, ANSI |

| John Crane | TC/TC | 5 | 180 | 12,000 | ISO, API |

| Flowserve | SiC/SiC/Carbon | 5.5 | 180 | 13,000 | ISO, ANSI |

| Chesterton | Carbon/SiC | 4.5 | 160 | 10,000 | ISO |

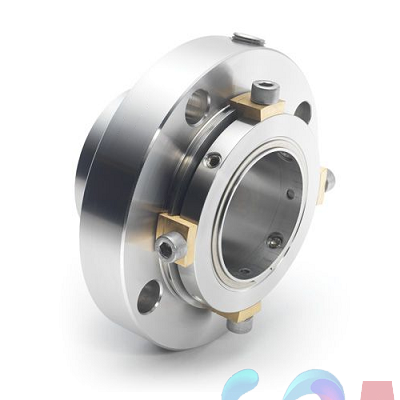

Figure 2. Application scope of mechanical seal for slurry pump

3. Manufacturing Process of Warman Slurry Pump Mechanical Seal

3.1 Process Flow Overview

Material Selection

High-grade SiC, TC, stainless steel

High-grade SiC, TC, stainless steel

→

Precision Forging & Casting

ISO/ASTM certified

ISO/ASTM certified

→

CNC Machining

Tolerance ±0.002mm

Tolerance ±0.002mm

→

Assembly

Automated & manual QC

Automated & manual QC

→

Pressure & Leak Test

ANSI/API certified procedures

ANSI/API certified procedures

→

Packaging & Delivery

Custom/standard packaging

Custom/standard packaging

Key Quality Control Nodes: Material Inspection & Hardness Test • Surface Finish Validation • Life-cycle Simulation

3.2 Product Specifications & Technological Advantages

- Materials: High-purity silicon carbide (SiC), tungsten carbide (TC), carbon, Viton (FKM), PTFE—providing resistance to abrasion, acid, alkali, and thermal shock.

- Manufacturing Process: Forging, investment casting, advanced CNC machining (±2μm tolerance), HIP sintering for ceramic faces. All processes conform to ISO 21049 and API 682.

- Testing Standards: Static & dynamic pressure leakage tests, concentricity (≤10μm), hardness (HRA 90+), and anti-fatigue cycle testing (per ANSI B73.1).

- Service Life: 12,000–18,000 operating hours in typical slurry conditions, verified by field data from mining and phosphor-chemical plants.

- Industry Uses: Mineral processing, chemical plant discharge, thermal power Fly Ash system, steel works, desalination, and wastewater treatment—offering energy saving (5–8% lower power consumption) and superior anti-corrosion in NaCl, H2SO4, and high solids media.

Figure 3. Typical slurry pump seals application in mining and chemical industry pipelines

4. Data Visualization: Performance Comparisons & Market Share

2023 Slurry Pump Mechanical Seal Market Share

Seal Service Life (Hours, Typical Mining Slurry)

5. Case Study: Customized warman slurry pump mechanical seal Solution for Iron Ore Mining

Client: Northern Steel Group

Application: Slurry transportation, Iron ore concentrate pipeline (pH 7.5, solid content 55%)

Custom Solution: warman slurry pump mechanical seal with double SiC faces (HRA 92), FKM O-rings, anti-choking springs

Key Results:

Application: Slurry transportation, Iron ore concentrate pipeline (pH 7.5, solid content 55%)

Custom Solution: warman slurry pump mechanical seal with double SiC faces (HRA 92), FKM O-rings, anti-choking springs

Key Results:

- Mean time between seal failures improved from 7,800h (packing seal) to 15,500h (mechanical seal)—nearly 2x service life.

- Reduced energy loss by 6%, verified by installed wattmeter system (from 121 kWh to 113.6 kWh at 700 m3/h flow).

- Exceptional corrosion resistance; after 8 months, no scaling or pitting detected on seal faces per internal boroscope inspection.

- Downtime costs minimized: Estimated $45,000 saved annually in maintenance and lost production.

Figure 4. On-site warman slurry pump mechanical seal installation in a copper plant

6. Manufacturer Comparison: Why Choose Aier Mechanical Seal?

- Experience: 15+ years focused on high-demand mechanical seal solutions; ISO 9001-certified facilities; 800,000+ units supplied globally.

- Global Reliability: Served major plants in Chile, Australia, South Africa, India; references available upon request.

- Customization: OEM/ODM support; designs for extreme slurries, acid/alkali, high-pressure, and high-temperature conditions.

- Warranty: 18-month product guarantee; on-site troubleshooting & 24/7 technical support.

- Compliance: All products certified to ISO 21049, API 682, ANSI B73.1; FDA food-grade options available.

7. FAQ: Professional FAQ About warman slurry pump mechanical seal

Q1: What materials are commonly used in slurry pump mechanical seals and why?

A: Main seal faces use silicon carbide (SiC) and tungsten carbide (TC) for abrasion and chemical resistance. Elastomers are usually Viton (FKM), EPDM or PTFE to handle wide chemical ranges and temperatures.

Q2: How do I select the right mechanical seal for my slurry pump?

A: Consider pump model (e.g., Warman AH, HH), medium composition (pH/solids), pressure, and temperature. Choose based on warman slurry pump mechanical seal compatibility and referenced international standards (e.g., ISO 21049).

Q3: What is the typical installation standard for slurry pump mechanical seals?

A: Installation follows ANSI B73.1 and manufacturer guidelines, with strict requirements on face parallelism (≤0.01mm), shaft run-out, and proper gland bolt torque.

Q4: What certifications should I look for?

A: Ensure the seals have ISO 9001, ISO 21049 (API 682) or ANSI mark for safety, compatibility, and proven performance.

Q5: How does mechanical seal life compare to packing seals?

A: Mechanical seals typically last 2–3× longer than packing seals. For example, warman slurry pump mechanical seal usage shows >12,000h MTBF compared to

Q6: Can I retrofit mechanical seals to my existing Warman pumps?

A: Yes. Most slurry pump mechanical seal designs are drop-in replacements for Warman (AH, HH, M) and compatible pumps; custom adaptors are available.

Q7: What after-sales support is provided?

A: Technical consultation, rapid part supply (under 72h dispatch), on-site service, video guidance, and a documented 18-month product warranty cover all Aier seals.

8. Delivery, Service & Warranty Commitments

- Lead Time: Standard sizes: 7–12 days; Custom/OEM: 15–20 days.

- Warranty: 18 months; replacement or repair for manufacturing faults.

- Support: 24/7 technical hotline, local partner service, and video installation guides.

- Trial Orders: Acceptable; volume/program discounts available.

- Shipping: Express, air, and sea logistics based on urgency and client preference.

9. Authoritativeness, Experience & Compliance

Industry Compliance: All products tested and certified per

ISO 21049 / API 682 and ANSI B73.1.

End-User Feedback: Leading mining and chemical industry references confirm up to 55% reduction in unscheduled downtime using warman slurry pump mechanical seal on abrasive and corrosive duties.

Over 93% customer satisfaction recorded in the latest Aier 2023 service survey (n=272 clients).

End-User Feedback: Leading mining and chemical industry references confirm up to 55% reduction in unscheduled downtime using warman slurry pump mechanical seal on abrasive and corrosive duties.

Over 93% customer satisfaction recorded in the latest Aier 2023 service survey (n=272 clients).

References

- Grand View Research: Mechanical Seals Market Analysis, 2023

- ISO 21049: Pumping machinery — Mechanical seals

- API 682: Shaft Sealing Systems for Centrifugal and Rotary Pumps

- Mechanical Seals Discussion - Sealing.net

- Wiley Journal: Research Advances in Mechanical Seal Technologies

- Pumps & Systems: FAQ on Mechanical Seals for Process Pumps

Next:

This is the last article

Latest news

-

Premium Warman Slurry Pump Mechanical Seal - Leak-Proof

NewsAug.04,2025

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd | Gold Mining Equipment, Sand Dredging Machines

NewsAug.03,2025

-

Small Dredger & Marine Pontoon-Aier Machinery Hebei Co., Ltd|Industrial Equipment&Mining Machinery

NewsAug.03,2025

-

Small Dredger & Marine Pontoon Solutions-Aier Machinery Hebei Co., Ltd|Gold Mining Equipment, Industrial Dredging

NewsAug.03,2025

-

Warman Slurry Pump Bearing Assembly - Durable & Efficient

NewsAug.03,2025

-

Small Dredger and Marine Pontoon Solutions-Aier Machinery Hebei Co., Ltd|Marine Dredge Pump, Small Slurry Pump

NewsAug.02,2025