يانۋار . 14, 2025 12:34 Back to list

interchangeable slurry pump

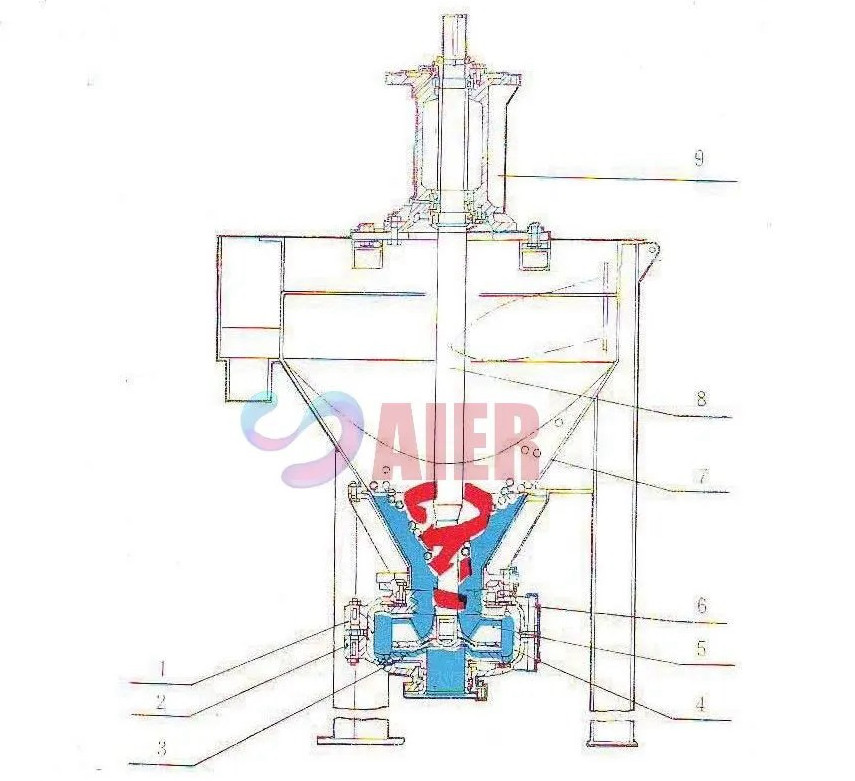

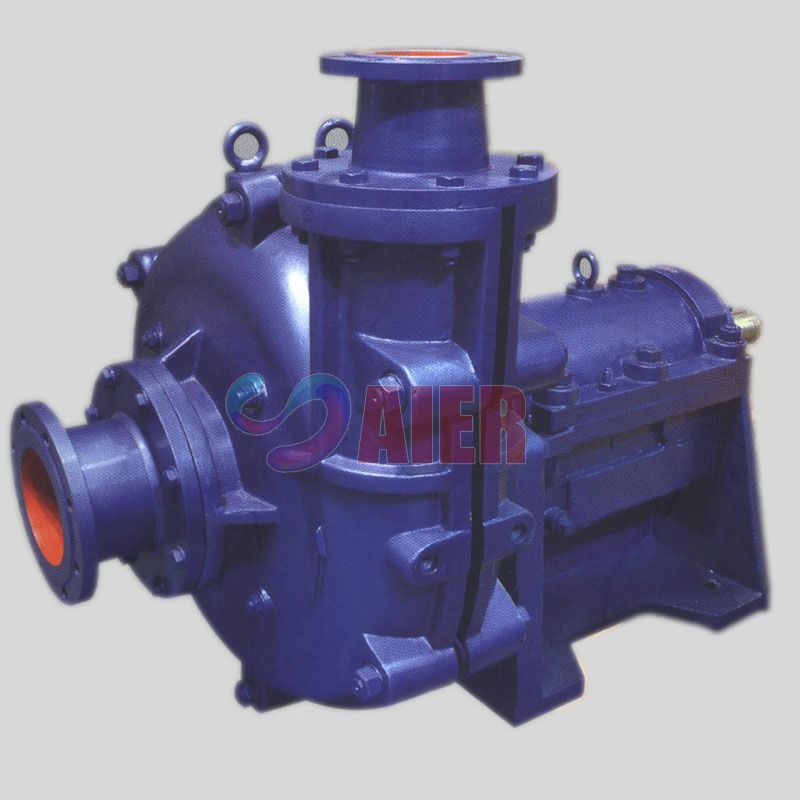

Interchangeable slurry pumps have become pivotal in industries requiring the efficient and reliable handling of abrasive, corrosive, and high-density slurries. These pumps maintain fluid dynamics across various sectors such as mining, mineral processing, construction, and wastewater treatment. A genuine understanding of interchangeable slurry pumps can significantly enhance operational efficiency and sustainable processes.

Building trustworthiness in the use of interchangeable slurry pumps involves transparent communication regarding the expected lifespan of wear parts under specified conditions. Providing accurate documentation and user guidance enhances customer confidence. The best manufacturers go a step further by offering comprehensive support services, including routine maintenance tips and guidelines for optimal operation of the interchangeable components. Furthermore, real-world experience indicates that integrating interchangeable slurry pumps into operations leads to a tangible reduction in long-term costs. Industry professionals testify to fewer interruptions in workflow due to the quick replacement of worn-out parts. Faster maintenance times equate to increased productivity, a crucial factor in high-demand industries. When-choice decisions prioritize interchangeable slurry pumps, businesses report improvements not just in operational continuity but also in the allocation of resources, as funds initially earmarked for extensive repairs can be redirected to other essential areas. Lastly, authentic case studies of successful implementation of interchangeable slurry pumps reinforce their value proposition. They expand on instances where mining operations, for instance, achieved substantial cost savings over time or where wastewater treatment plants significantly enhanced their operational capabilities. To conclude, interchangeable slurry pumps embody efficiency, reliability, and versatility. As industries continue to evolve with stringent productivity and sustainability goals, these pumps stand out as indispensable assets. The combination of advanced material science and mechanical engineering in their design makes them universally recognized in sectors dependent on robust slurry handling solutions.

Building trustworthiness in the use of interchangeable slurry pumps involves transparent communication regarding the expected lifespan of wear parts under specified conditions. Providing accurate documentation and user guidance enhances customer confidence. The best manufacturers go a step further by offering comprehensive support services, including routine maintenance tips and guidelines for optimal operation of the interchangeable components. Furthermore, real-world experience indicates that integrating interchangeable slurry pumps into operations leads to a tangible reduction in long-term costs. Industry professionals testify to fewer interruptions in workflow due to the quick replacement of worn-out parts. Faster maintenance times equate to increased productivity, a crucial factor in high-demand industries. When-choice decisions prioritize interchangeable slurry pumps, businesses report improvements not just in operational continuity but also in the allocation of resources, as funds initially earmarked for extensive repairs can be redirected to other essential areas. Lastly, authentic case studies of successful implementation of interchangeable slurry pumps reinforce their value proposition. They expand on instances where mining operations, for instance, achieved substantial cost savings over time or where wastewater treatment plants significantly enhanced their operational capabilities. To conclude, interchangeable slurry pumps embody efficiency, reliability, and versatility. As industries continue to evolve with stringent productivity and sustainability goals, these pumps stand out as indispensable assets. The combination of advanced material science and mechanical engineering in their design makes them universally recognized in sectors dependent on robust slurry handling solutions.

Next:

Latest news

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025