Oct . 11, 2024 08:09 Back to list

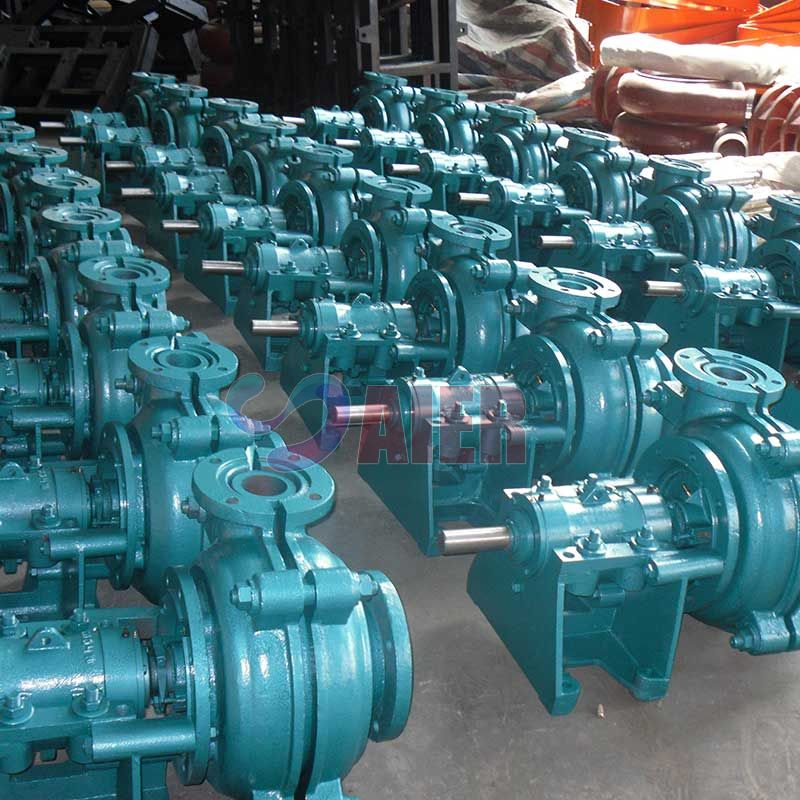

high quality thick slurry pump

The Importance of High-Quality Thick Slurry Pumps

In various industrial sectors, the transportation of thick slurries plays a crucial role in operational efficiency and process optimization. Thick slurries, which are mixtures of solid particles and liquids, are common in mining, mineral processing, wastewater treatment, and many other applications. As these thick slurries can be highly abrasive and corrosive, using the right equipment becomes paramount. One of the most essential pieces of equipment for this task is the high-quality thick slurry pump.

Understanding Slurry Pumps

Slurry pumps are specifically designed to handle mixtures of liquids and solids, unlike standard pumps that may struggle with such demanding conditions. These pumps must be robust enough to manage the high viscosity and density of the materials being transported. A high-quality thick slurry pump is engineered to withstand wear and tear caused by abrasive solids, reducing maintenance needs and extending the pump’s lifespan.

Key Features of High-Quality Thick Slurry Pumps

1. Durable Materials High-quality slurry pumps are typically constructed from wear-resistant materials such as High-Chrome alloys or rubber linings. These materials are specifically chosen to withstand erosion from the abrasive particles in the slurry.

2. Efficient Design A well-designed slurry pump optimizes fluid flow and minimizes energy consumption. Features such as a robust impeller design and well-engineered volute casing allow for effective handling of thick mixtures, reducing the risk of clogging and operational failures.

3. Versatility High-quality slurry pumps can handle various slurry types, including coarse, fine, abrasive, and corrosive slurries. This versatility makes them ideal for multiple applications across different industries.

high quality thick slurry pump

4. Reliable Performance Reliable performance is crucial when dealing with thick slurries, particularly in environmentally sensitive operations. High-quality thick slurry pumps are designed to deliver consistent performance, ensuring that operations run smoothly and efficiently.

5. Ease of Maintenance Regular maintenance is essential for the longevity of any pumping equipment. High-quality thick slurry pumps often feature design elements that facilitate easy access for maintenance, such as quick-release casings and modular components.

Applications of Thick Slurry Pumps

Thick slurry pumps are extensively used in several applications. In the mining industry, they transport mineral slurries, tailings, and concentrates. In mineral processing, they play a vital role in the separation and processing of minerals. Additionally, in wastewater treatment, these pumps are essential for handling sludge, ensuring that facilities can operate efficiently while maintaining environmental standards.

Conclusion

The choice of a thick slurry pump can significantly impact the efficiency and effectiveness of operations. High-quality pumps not only improve the transport of thick slurries, but they also enhance overall productivity and reduce operational costs. Therefore, industries dealing with slurries must prioritize the selection of high-quality, reliable pumps to ensure optimal performance.

Investing in a high-quality thick slurry pump is not merely a purchase; it is a strategic decision that can lead to long-term benefits in operational efficiency and machinery reliability. When choosing the right pump, organizations should consider not only the initial cost but also factors such as durability, maintenance, and overall performance in handling the specific type of slurry they deal with.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025