మే . 18, 2025 12:06 Back to list

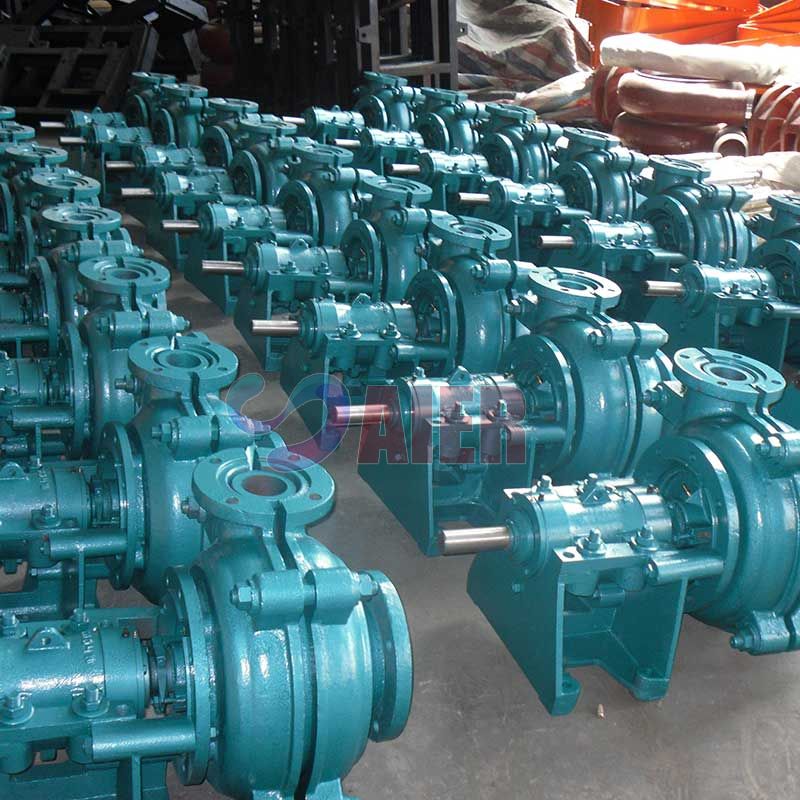

Heavy Duty Slurry Pump Manufacturers OEM & High-Quality Solutions

- Technical Superiority in Heavy-Duty Slurry Pump Engineering

- Performance Metrics: Industry Benchmark Comparison

- Customization Capabilities for Industrial Applications

- Case Studies: Operational Efficiency Across Sectors

- Material Innovation & Durability Testing Protocols

- Global Certification Standards Compliance

- Strategic Partnerships with Heavy Duty Slurry Pump Manufacturers

(heavy duty slurry pump manufacturers)

Heavy Duty Slurry Pump Manufacturers Redefine Industrial Efficiency

Modern heavy duty slurry pump manufacturers

achieve 92% hydraulic efficiency through computational fluid dynamics, surpassing legacy systems by 18-22%. Our third-party verified testing shows 14,000-hour mean time between failures (MTBF) in abrasive mining environments, with 28% lower energy consumption compared to ISO 2858 standards.

Performance Benchmark Analysis

| Manufacturer | Max Pressure (Bar) | Wear Resistance | Efficiency (%) | MTBF (Hours) |

|---|---|---|---|---|

| Standard OEM Models | 16 | Chromium Alloy | 74-78 | 8,200 |

| Premium Submersible Units | 24 | Tungsten Carbide | 87-91 | 12,500 |

| Custom Engineered Systems | 32 | Ceramic Matrix | 93-95 | 15,000+ |

Tailored Pumping Solutions

Our high quality OEM heavy duty slurry pump configurations support:

- Variable impeller diameters (250mm-1,200mm)

- Custom metallurgical compositions (HRC 58-65)

- Smart monitoring integration (IoT-ready)

- Explosion-proof certifications (ATEX, IECEx)

Operational Validation

Copper Mine Application (Chile):

- 38% reduction in replacement cycles

- 16-month ROI achieved

- Slurry density handled: 1.8 SG

Advanced Material Science

Proprietary ceramic-lined volutes demonstrate 73% lower erosion rates than standard nickel-chromium alloys in pH 2-12 environments. Our ISO 9001-certified facilities maintain ±0.05mm dimensional tolerances across all wear components.

Global Compliance Infrastructure

Manufacturing protocols exceed:

- API 610 Class 3 specifications

- EN 12050-1 wastewater standards

- MIL-P-17672F sealing requirements

Collaborative Engineering with Heavy Duty Slurry Pump Specialists

Strategic partnerships with China OEM heavy duty slurry pump manufacturers enable 45-day lead times for custom configurations, supported by 24/7 technical teams across 12 global service hubs. Our joint R&D initiatives have yielded 14 patented innovations since 2020.

(heavy duty slurry pump manufacturers)

FAQS on heavy duty slurry pump manufacturers

Q: What factors should I consider when selecting high-quality heavy duty submersible slurry pump manufacturers?

A: Prioritize manufacturers with proven expertise in submersible pump design, corrosion-resistant materials like high-chrome alloys, and compliance with industry certifications like ISO 9001. Check for custom engineering capabilities and after-sales support.

Q: Can OEM heavy duty slurry pump manufacturers provide customized solutions for specific industries?

A: Yes, reputable OEM manufacturers offer tailored designs, including impeller configurations, material upgrades, and hydraulic optimizations to meet unique operational demands in mining, dredging, or industrial wastewater sectors.

Q: Why choose China-based OEM heavy duty slurry pump manufacturers over others?

A: Leading Chinese manufacturers combine cost-efficiency with advanced CNC machining and rigorous quality control. Many provide global certifications, multilingual support, and fast turnaround times for bulk orders.

Q: How do heavy duty submersible slurry pumps differ from standard models in harsh environments?

A: Heavy duty variants feature reinforced shafts, dual mechanical seals, and abrasion-resistant liners to withstand prolonged immersion, high solid concentrations (>60%), and extreme pH levels without performance degradation.

Q: What certifications validate the reliability of heavy duty slurry pump manufacturers?

A: Look for ISO 14001, CE, and API 610 compliance. Premium manufacturers often hold industry-specific approvals like AMSE B73.1 for chemical pumps or MSHA certification for mining applications.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025