Novemba . 11, 2024 14:37 Back to list

sand slurry pump factories

Understanding Sand Slurry Pump Factories An Overview

In the world of industrial operations, the efficient handling and transportation of materials are of paramount importance. Among the various tools engineered for this purpose, sand slurry pumps hold a crucial position, particularly in industries like mining, construction, and wastewater treatment. This article delves into the significance of sand slurry pump factories, their manufacturing processes, and the vital role they play in various sectors.

What are Sand Slurry Pumps?

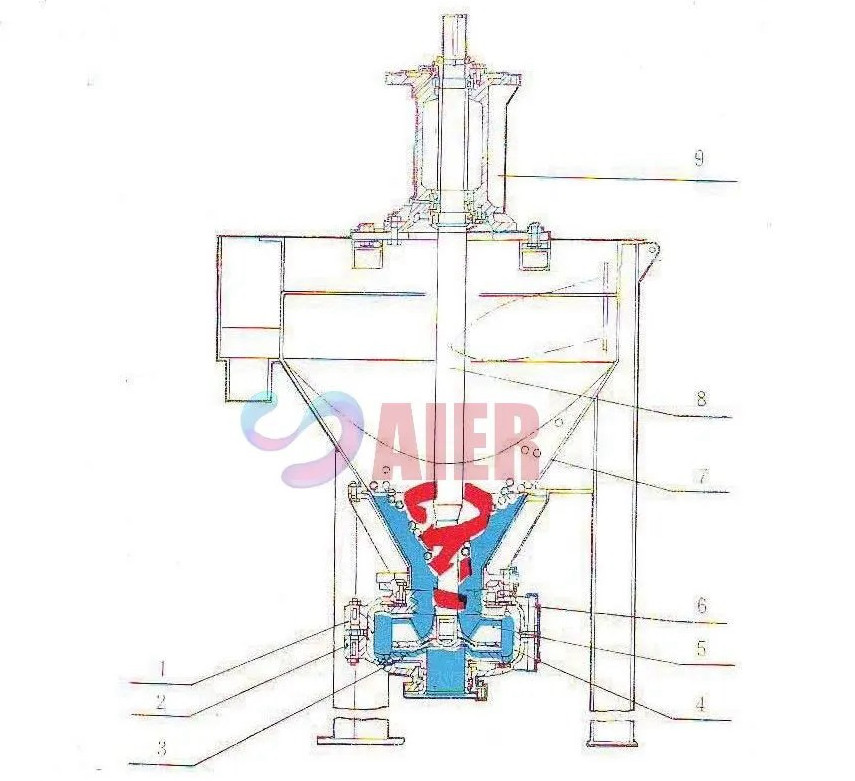

Sand slurry pumps are designed specifically to handle the transportation of sand particles amalgamated in a liquid medium, usually water. This mixture, commonly referred to as slurry, can be abrasive and dense, posing significant challenges for conventional pumps. Sand slurry pumps are engineered to withstand such harsh conditions, providing durability and efficiency in transferring materials over long distances or through challenging terrains.

The Role of Sand Slurry Pump Factories

Factories that specialize in the manufacturing of sand slurry pumps are equipped with advanced technology and skilled labor to produce reliable, high-quality pumps. These factories typically focus on several core aspects

1. Research and Development Innovation is key in any industry, and sand slurry pump factories invest in R&D to improve the performance and efficiency of their products. This involves the design of new materials, enhanced pump geometries, and improved sealing systems, which all contribute to better wear resistance and longer operational life.

2. Manufacturing Processes The production of sand slurry pumps involves several crucial steps, including casting, machining, assembling, and testing. Factories utilize sophisticated machinery to ensure that each pump part meets stringent quality standards. The casting process often involves the use of high-grade materials like cast iron or stainless steel to ensure toughness against abrasive substances.

3. Quality Control Maintaining high standards of quality is essential in the manufacturing of sand slurry pumps. Factories conduct rigorous testing of each pump to verify their performance under expected operating conditions. This might include checking flow rates, pressure levels, and wear resistance, ensuring that the products delivered to customers will meet or exceed their expectations.

sand slurry pump factories

4. Customization Different industries have varying requirements when it comes to sand slurry pumps. Factories often provide customization options, producing pumps tailored to specific applications. This can include modifications in size, material composition, and design features to accommodate particular operational needs.

5. Customer Support and Service A vital aspect of sand slurry pump factories is their post-purchase support. Providing maintenance services and spare parts is crucial to ensuring that purchased pumps operate efficiently throughout their expected lifespan. Factories typically have dedicated teams to assist clients with installation, troubleshooting, and repairs.

Industry Applications

Sand slurry pumps are utilized across a wide range of industries, each with specific demands. In the mining industry, for instance, these pumps are used to transport ore slurries, allowing for efficient extraction and processing of minerals. In construction, they facilitate the movement of sand and gravel, essential for concrete production. Moreover, in wastewater treatment plants, these pumps manage the transport of sludge and other byproducts of the treatment process.

Sustainability and Innovation

As industries become increasingly aware of their environmental impact, sand slurry pump factories are also focusing on sustainable practices. This includes developing pumps that require less energy to operate and have longer lifespans, thus reducing waste. The innovation of materials, such as ceramics and composites, can also reduce wear and extend pump life, further supporting sustainability goals.

Conclusion

In summary, sand slurry pump factories are pivotal in the functioning of various sectors that require the efficient and effective movement of abrasive materials. By investing in technology, quality control, and customer service, these factories are not only enhancing the performance of sand slurry pumps but also contributing to the growth and sustainability of the industries they serve. As industries continue to evolve, so too will the technologies and practices of sand slurry pump manufacturers, ensuring they remain at the forefront of material handling solutions.

-

China Slurry Pump Rubber Parts - Durable & Custom Solutions

NewsMay.20,2025

-

Heavy Duty Vertical Froth Pumps - China Factories & High-Quality Suppliers

NewsMay.20,2025

-

High-Quality Excavator Dredge Pump Suppliers China Manufacturers

NewsMay.19,2025

-

China Slurry Pump Rubber Parts - Durable & Custom Solutions

NewsMay.19,2025

-

China Electric Submersible Slurry Pump - Durable & High-Efficiency Solutions

NewsMay.19,2025

-

Heavy Duty Slurry Pump Manufacturers OEM & High-Quality Solutions

NewsMay.18,2025