Jan . 14, 2025 10:24 Back to list

Mechanical Seals

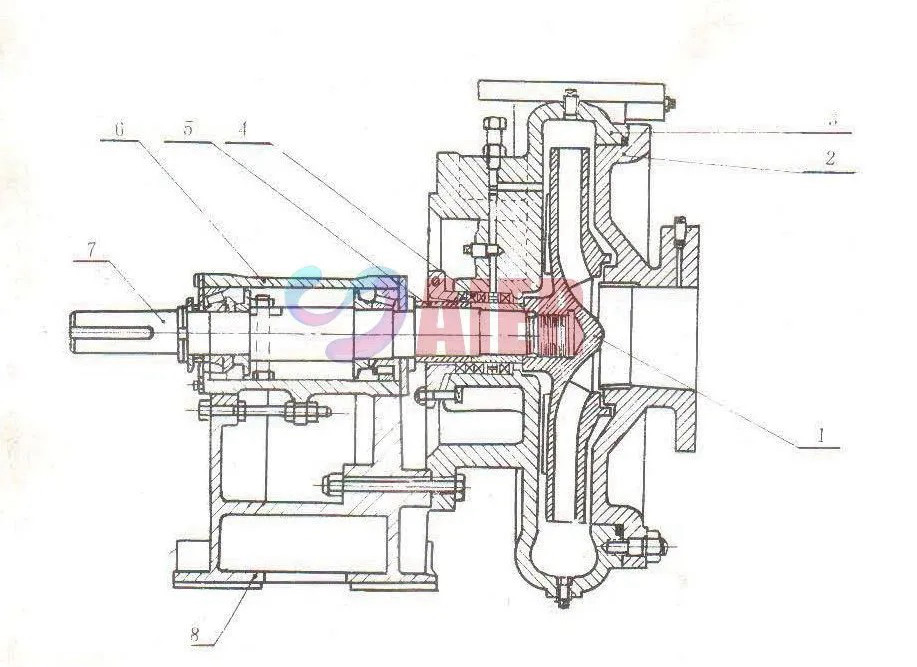

Selecting the right slurry pump seal is crucial for industries that deal with abrasive or corrosive materials. The seal ensures the longevity and efficiency of the pump, making it a vital component in maintaining operational integrity. Drawing from years of field experience and expert insights, this comprehensive guide will help you make informed decisions regarding slurry pump seals.

For applications that cannot accommodate seal leakage or require regular flushing, dynamic seals are an ideal solution. These seals operate without contact, reducing wear and consequently increasing their lifespan. However, the precise calibration required in their installation demands a high level of expertise. Consulting authoritative sources or equipment manufacturers ensures that these seals are optimized for specific operational conditions. Trustworthiness in product performance can be enhanced by paying attention to the manufacturer's reputation, customer reviews, and field performance data. Leading manufacturers often conduct extensive testing and offer warranties that speak to the reliability of their seals. Furthermore, engaging with community forums or industry groups can provide invaluable insights from those who have firsthand experience with these components in similar applications. Installing and maintaining the right slurry pump seal not only extends the life of the equipment but also optimizes energy efficiency. Properly sealed pumps prevent unnecessary power losses due to leaks, thus promoting sustainability and reducing operational costs. Routine maintenance checks, often guided by the manufacturer's recommendations, can spotlight issues before they escalate into system failures. In conclusion, the knowledge and authority vested in choosing the correct slurry pump seal can significantly impact both the operational budget and environmental footprint of a business. Understanding the intricate balance between seal type, material compatibility, and application-specific demands—alongside leveraging trusted sources—lays the groundwork for procurement decisions that champion durability, reliability, and efficiency.

For applications that cannot accommodate seal leakage or require regular flushing, dynamic seals are an ideal solution. These seals operate without contact, reducing wear and consequently increasing their lifespan. However, the precise calibration required in their installation demands a high level of expertise. Consulting authoritative sources or equipment manufacturers ensures that these seals are optimized for specific operational conditions. Trustworthiness in product performance can be enhanced by paying attention to the manufacturer's reputation, customer reviews, and field performance data. Leading manufacturers often conduct extensive testing and offer warranties that speak to the reliability of their seals. Furthermore, engaging with community forums or industry groups can provide invaluable insights from those who have firsthand experience with these components in similar applications. Installing and maintaining the right slurry pump seal not only extends the life of the equipment but also optimizes energy efficiency. Properly sealed pumps prevent unnecessary power losses due to leaks, thus promoting sustainability and reducing operational costs. Routine maintenance checks, often guided by the manufacturer's recommendations, can spotlight issues before they escalate into system failures. In conclusion, the knowledge and authority vested in choosing the correct slurry pump seal can significantly impact both the operational budget and environmental footprint of a business. Understanding the intricate balance between seal type, material compatibility, and application-specific demands—alongside leveraging trusted sources—lays the groundwork for procurement decisions that champion durability, reliability, and efficiency.

Next:

Latest news

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd | Gold Mining Equipment, Sand Dredging Machines

NewsAug.03,2025

-

Small Dredger & Marine Pontoon-Aier Machinery Hebei Co., Ltd|Industrial Equipment&Mining Machinery

NewsAug.03,2025

-

Small Dredger & Marine Pontoon Solutions-Aier Machinery Hebei Co., Ltd|Gold Mining Equipment, Industrial Dredging

NewsAug.03,2025

-

Warman Slurry Pump Bearing Assembly - Durable & Efficient

NewsAug.03,2025

-

Small Dredger and Marine Pontoon Solutions-Aier Machinery Hebei Co., Ltd|Marine Dredge Pump, Small Slurry Pump

NewsAug.02,2025

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd | Industrial Mining Equipment

NewsAug.02,2025