Jan . 14, 2025 10:11 Back to list

close impeller type slurry pump factory

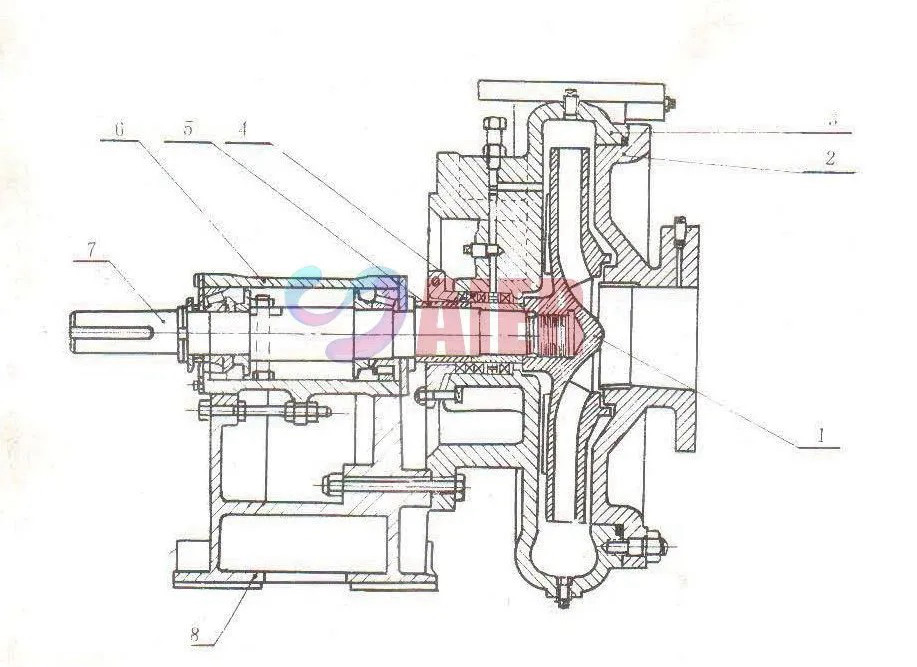

Slurry pump components are pivotal to the seamless operation of various industrial systems. These components ensure that the pump functions efficiently, extending its lifespan and maintaining its effectiveness. Here, we explore the essential components, offering insights into their roles, significance, and impact on overall system performance, providing knowledge derived from extensive experience and industry expertise.

The shaft sleeve, though often overlooked, plays a crucial role in protecting the shaft from the abrasive and corrosive qualities of the slurry. This replaceable component ensures that the main shaft retains its integrity, reducing maintenance costs and extending the pump’s operational life. Experts with decades of experience understand the value of regular checks and replacements, reinforcing that a frail shaft sleeve often leads to extensive repairs elsewhere in the pump assembly. Lastly, the base plate or mounting assembly is foundational for maintaining the structural integrity of the entire pump system. It needs to provide a stable and robust platform that can withstand the operational stresses and vibrations that characterize slurry transport. Proper alignment and secure anchoring are crucial, as misalignments can lead to inefficiency and premature wear of other components. Professionals who have dedicated their careers to slurry pump maintenance and optimization stress the importance of understanding these components within the context of the entire pump system. With expertise spanning various applications and environments, it becomes clear that the synergy between components is what dictates the efficiency and reliability of slurry pumps. The awareness and understanding of slurry pump components can greatly enhance system performance, optimize life-cycle costs, and reduce environmental impacts, reflecting an intersection of technical expertise and practical, experienced-based insight. By focusing on these aspects, businesses can ensure their operational longevity and sustainability — a testament to the authoritative and trustworthy nature of seasoned industry professionals.

The shaft sleeve, though often overlooked, plays a crucial role in protecting the shaft from the abrasive and corrosive qualities of the slurry. This replaceable component ensures that the main shaft retains its integrity, reducing maintenance costs and extending the pump’s operational life. Experts with decades of experience understand the value of regular checks and replacements, reinforcing that a frail shaft sleeve often leads to extensive repairs elsewhere in the pump assembly. Lastly, the base plate or mounting assembly is foundational for maintaining the structural integrity of the entire pump system. It needs to provide a stable and robust platform that can withstand the operational stresses and vibrations that characterize slurry transport. Proper alignment and secure anchoring are crucial, as misalignments can lead to inefficiency and premature wear of other components. Professionals who have dedicated their careers to slurry pump maintenance and optimization stress the importance of understanding these components within the context of the entire pump system. With expertise spanning various applications and environments, it becomes clear that the synergy between components is what dictates the efficiency and reliability of slurry pumps. The awareness and understanding of slurry pump components can greatly enhance system performance, optimize life-cycle costs, and reduce environmental impacts, reflecting an intersection of technical expertise and practical, experienced-based insight. By focusing on these aspects, businesses can ensure their operational longevity and sustainability — a testament to the authoritative and trustworthy nature of seasoned industry professionals.

Latest news

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025