Oct . 24, 2025 11:40 Back to list

Wholesale Slurry Pump Spare Part Impeller | OEM, Warman-fit

Wholesale Slurry Pump Spare Part Impeller: What Buyers Are Actually Asking in 2025

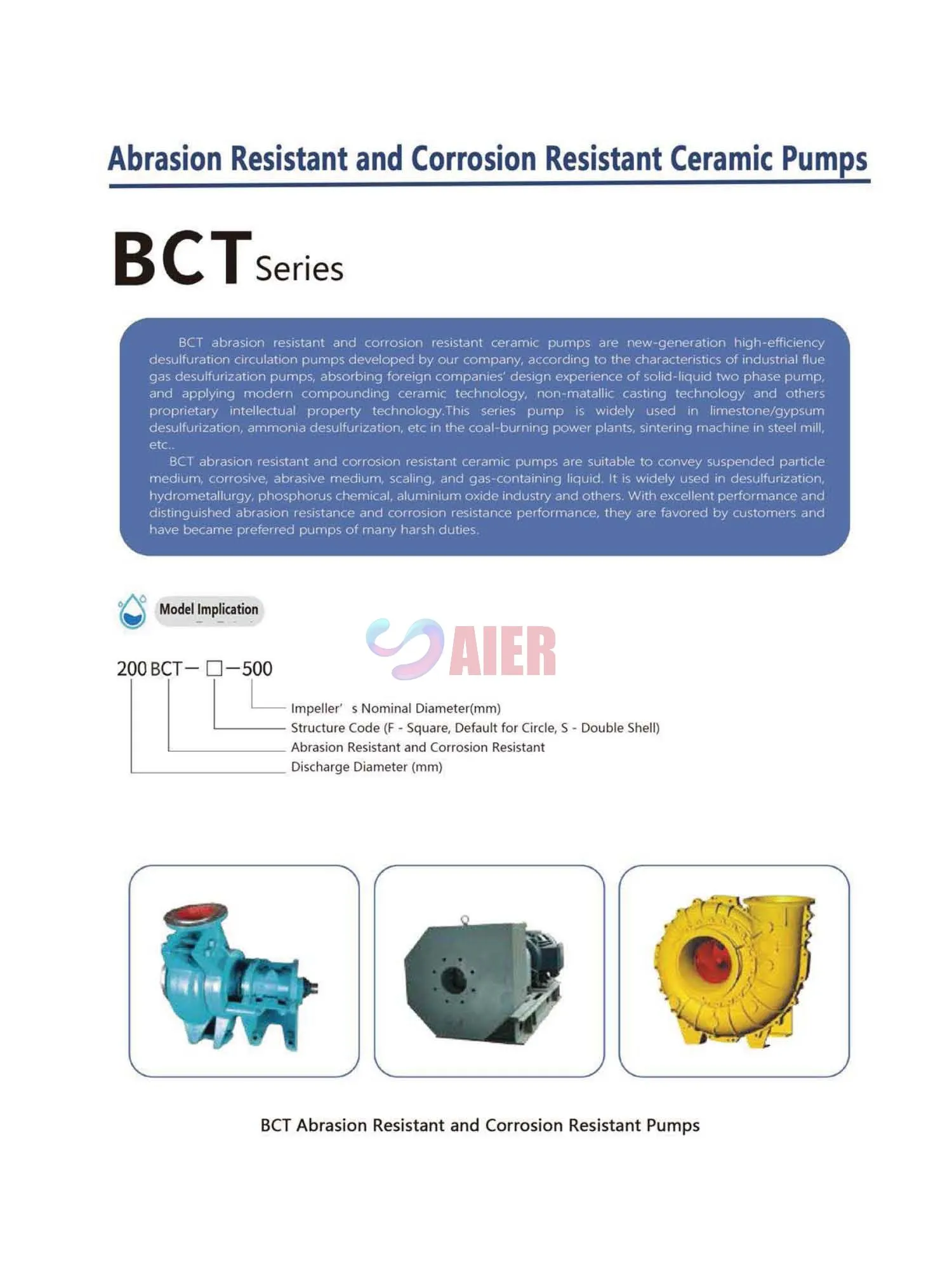

If you’re sourcing a Wholesale Slurry Pump Spare Part Impeller for harsh FGD or hydromet applications, you’ve likely heard the buzz around ceramic wet-end kits. To be honest, I was skeptical the first time I toured a plant in Shandong that runs BCT Ceramic Slurry Pumps day and night. But the data—wear scans, outage logs—was hard to argue with.

Why ceramic impellers matter right now

The BCT abrasion- and corrosion-resistant ceramic architecture—born in China and now seen in power plant desulfurization, sintering lines, and phosphorus chemical loops—targets the two things that ruin impellers: slurry abrasion and low-pH corrosion. Many customers say these impellers simply “refuse to pit” where high-chrome struggles. That’s a bold claim, sure, but field records back it up more often than not.

Quick specs (typical BCT ceramic impeller set)

| Parameter | Spec (≈, real-world use may vary) |

|---|---|

| Material options | ZTA (Zirconia Toughened Alumina), Reaction-bonded SiC |

| Hardness | ≈ HV 1100–1400 (SiC); ≈ HV 1000–1200 (ZTA) |

| pH range | ≈ 2–12 (continuous) |

| Max temp | ≈ 120–150°C (application-dependent) |

| Balance grade | ISO 1940-1 G6.3 or tighter |

| Service life | ≈ 2–6× vs. HiCr in abrasive FGD limestone slurry |

| Interchangeability | Custom to drawing; retrofit patterns available |

Applications: limestone/gypsum FGD loops, ammonia desulfurization, hydrometallurgy, alumina refineries, and gas-containing slurries where cavitation scars traditional alloys.

How the parts are made (short version)

- Materials: ZTA or SiC powders with controlled grain size and binders.

- Forming: isostatic pressing or slip casting; complex vane geometry via green machining.

- Sintering: high-temperature cycles; optional HIP for density.

- Finishing: diamond grinding on shroud/eye; tolerance ≈ ±0.2–0.5 mm.

- Balancing: per ISO 1940-1; dye penetrant and ultrasonic checks on critical sections.

- Testing: ASTM G65 abrasion rigs; hydro test in assembled pump; CMM for QA.

Vendor landscape (my field-notes take)

| Vendor | Material breadth | Lead time | Certs | Notes |

|---|---|---|---|---|

| Aier Pumps (China) | ZTA, SiC | ≈ 3–6 weeks | ISO 9001 | Strong in FGD, competitive MOQ |

| Vendor M (EU) | SiC mainly | ≈ 6–10 weeks | ISO 9001, PED | Premium pricing, good documentation |

| Vendor S (Global) | HiCr + ceramic inserts | ≈ 4–8 weeks | ISO 9001 | Hybrid approach, easier retrofits |

Real-world snapshots

- 2×135 MW power plant FGD: ceramic impeller runtime extended from 6 to 18 months; outage savings surprised even finance.

- Alumina refinery: fewer vane edge chips after switching to ZTA grade; operators reported smoother startup.

- Phosphorus chemical loop: cavitation pitting reduced visibly; vibration stayed within ISO G6.3 limits.

Standards, data, and what to request in RFQs

Ask for: material certificate (ZTA/SiC), balance report to ISO 1940-1, abrasion test summary per ASTM G65, QA plan (ISO 9001), and dimensional report. Also clarify pH/temperature envelope, shaft fit, and vane count. For a Wholesale Slurry Pump Spare Part Impeller, drawings with tolerances save weeks.

What users keep telling me

“It just lasts longer” comes up a lot. Some do note ceramics are less forgiving to impact during installation—fair point—so proper handling is key. Overall, the BCT ceramic approach feels like the practical sweet-spot for tough slurries, especially when a Wholesale Slurry Pump Spare Part Impeller must survive both abrasion and acid.

Origin: China. Product family: BCT Ceramic Slurry Pumps (wet-end spares, including Wholesale Slurry Pump Spare Part Impeller). If you’re migrating from high-chrome, consider a staged retrofit to validate life-cycle cost. I guess conservative is smart when production can’t blink.

Citations

- ISO 1940-1: Mechanical vibration — Balance quality requirements for rotors.

- ASTM G65: Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus.

- ASTM C1161: Standard Test Method for Flexural Strength of Advanced Ceramics.

- ISO 9001: Quality management systems — Requirements.

- EU 2014/68/EU (PED): Pressure Equipment Directive (documentation guidance for assemblies/components).

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025

-

Reliable China FGD Pump Suppliers for Effective Flue Gas Desulfurization | AiEr Pumps

NewsNov.22,2025

-

China FGD Pump: Durable & Efficient Solutions for Emission Control

NewsNov.21,2025