Jan . 16, 2025 03:10 Back to list

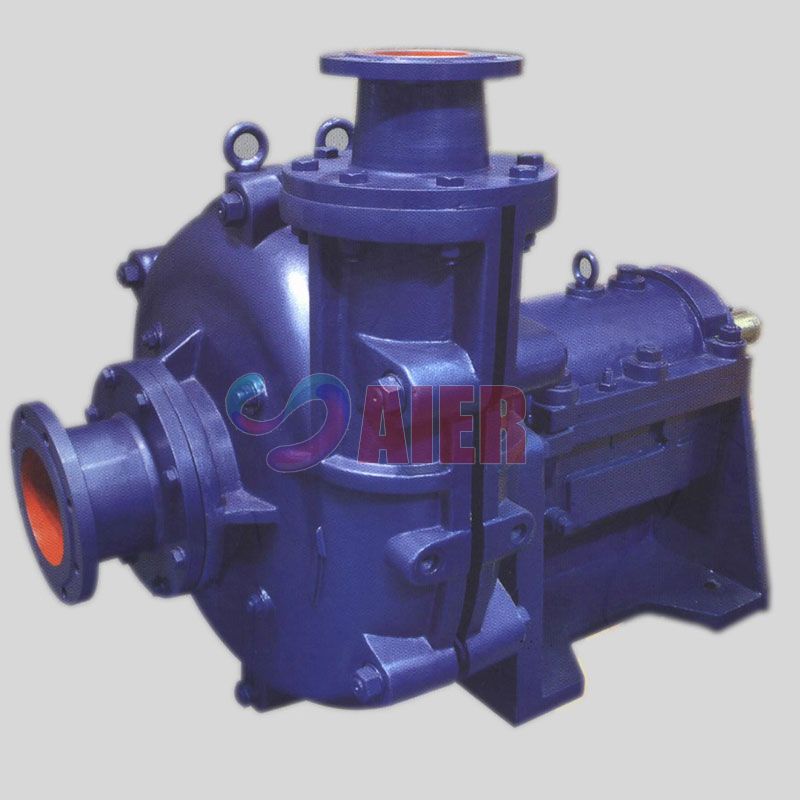

slurry sump pump and spare parts

The world of industrial applications often requires robust and reliable solutions for managing slurry, an abrasive mixture of solids and liquids. At the forefront of this necessity is the sump slurry pump, a critical piece of equipment engineered to handle the harshest conditions with efficiency and durability. This article will delve into the importance, functionality, and selection criteria of sump slurry pumps, aiming to provide unparalleled insights that enhance your understanding and guide procurement decisions.

For potential buyers, authoritativeness in sump slurry pump selection rests on understanding the specific requirements of your application. Key factors to consider include the solid content, particle size, and abrasiveness of the slurry. A common mistake is overlooking the pump's material compatibility with these factors, which can lead to premature wear and frequent maintenance needs. Consulting with manufacturers who provide comprehensive technical support can illuminate these variables, ensuring that your choice of pump aligns perfectly with your operational needs. Trustworthiness is critical when choosing a supplier for sump slurry pumps. Reputable manufacturers not only provide high-quality products but also offer extensive after-sales support, including maintenance services and spare parts availability. Establishing a relationship with such suppliers fosters a reliable source of technical support, which is crucial for resolving issues promptly and maintaining uninterrupted operations. In conclusion, sump slurry pumps are more than just machinery; they are crucial allies in industrial processes requiring the movement of abrasive slurry materials. Investing in a sump slurry pump is an exercise in balancing efficiency, durability, and reliability—attributes that are achievable with informed decision-making and expert guidance. Evaluate your operational requirements meticulously, leverage the expertise of industry leaders, and cultivate a strong partnership with trusted suppliers. By doing so, you not only enhance the operational efficacy of your processes but also ensure that your investment in a sump slurry pump offers substantial long-term benefits.

For potential buyers, authoritativeness in sump slurry pump selection rests on understanding the specific requirements of your application. Key factors to consider include the solid content, particle size, and abrasiveness of the slurry. A common mistake is overlooking the pump's material compatibility with these factors, which can lead to premature wear and frequent maintenance needs. Consulting with manufacturers who provide comprehensive technical support can illuminate these variables, ensuring that your choice of pump aligns perfectly with your operational needs. Trustworthiness is critical when choosing a supplier for sump slurry pumps. Reputable manufacturers not only provide high-quality products but also offer extensive after-sales support, including maintenance services and spare parts availability. Establishing a relationship with such suppliers fosters a reliable source of technical support, which is crucial for resolving issues promptly and maintaining uninterrupted operations. In conclusion, sump slurry pumps are more than just machinery; they are crucial allies in industrial processes requiring the movement of abrasive slurry materials. Investing in a sump slurry pump is an exercise in balancing efficiency, durability, and reliability—attributes that are achievable with informed decision-making and expert guidance. Evaluate your operational requirements meticulously, leverage the expertise of industry leaders, and cultivate a strong partnership with trusted suppliers. By doing so, you not only enhance the operational efficacy of your processes but also ensure that your investment in a sump slurry pump offers substantial long-term benefits.

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025