Oct . 07, 2025 08:40 Back to list

Submersible well pump manufacturer—ISO, fast delivery?

Inside a submersible and sewage pump shop: notes from the floor

If you’ve ever toured a busy pump factory, you know the smell of cutting fluid and the hiss of hydro-test rigs. I’ve spent enough time there to say this: choosing a submersible well pump manufacturer (or a wastewater specialist) isn’t just about datasheets—it’s about build discipline, field feedback, and how fast they solve problems at 2 a.m.

Product spotlight: KWP Non-clogging Sewage Pump (China)

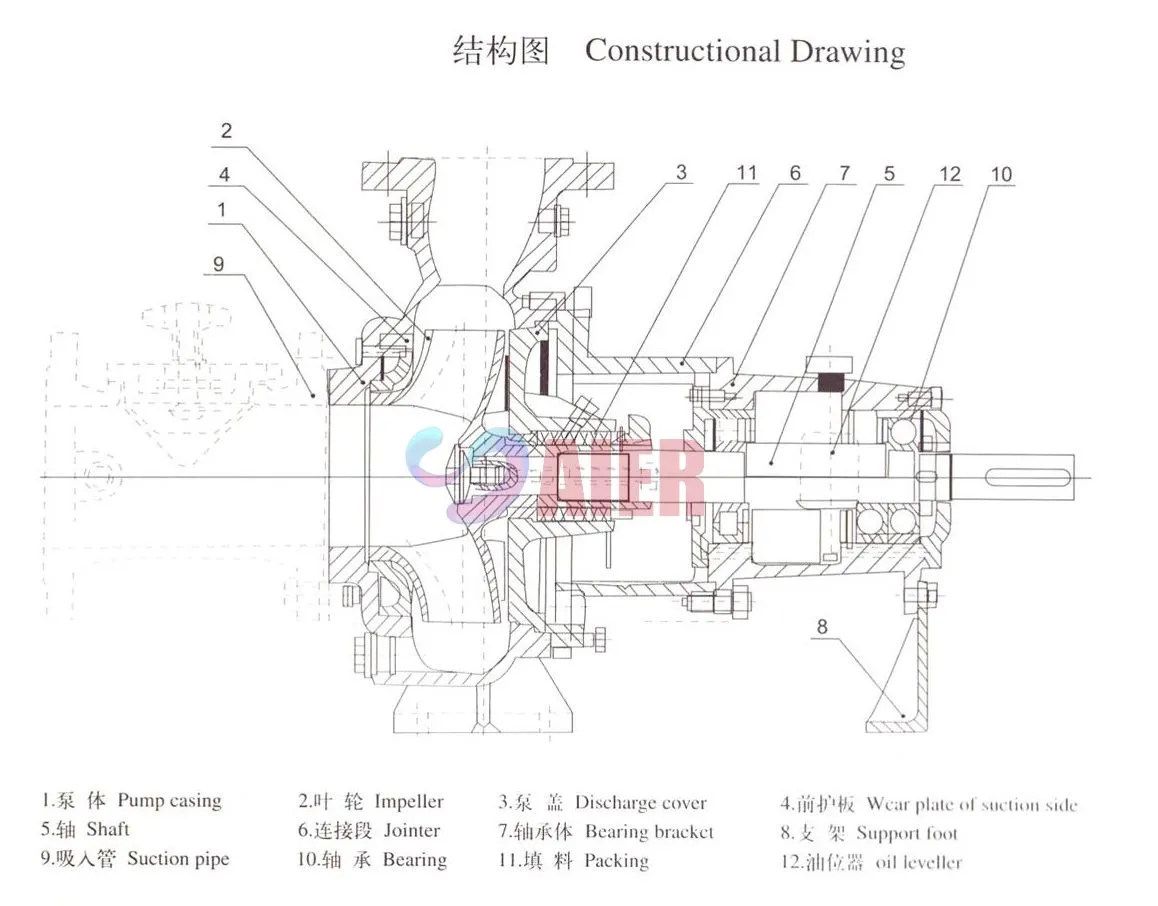

Meet the KWP Non-clogging Sewage Pump—built for city water supply, sewage and effluent treatment, and yes, the rough-and-tumble corners of chemicals, iron & steel, and the paper, sugar, and canned food industries. The back pull-out design is the practical star: you can remove the rotor without disturbing piping. Maintenance crews love that, and to be honest, so do planners staring down shutdown windows.

Why it matters in 2025

Two themes dominate: lifecycle efficiency and clog tolerance. Rag-laden municipal streams haven’t gotten any nicer. Non-clog hydraulics plus high-efficiency profiles can save surprising OPEX—many customers say they saw double-digit kWh reductions after swaps.

Key technical specifications (typical)

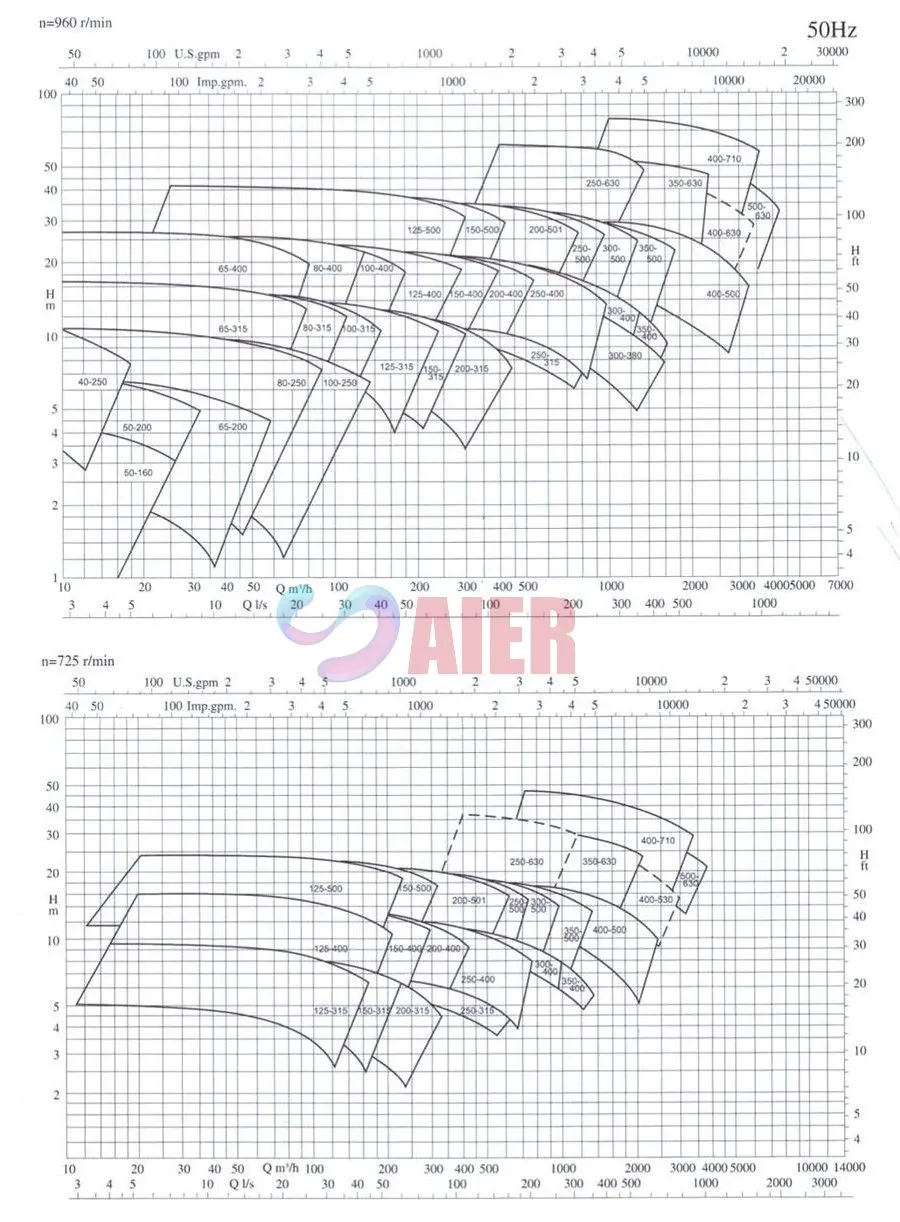

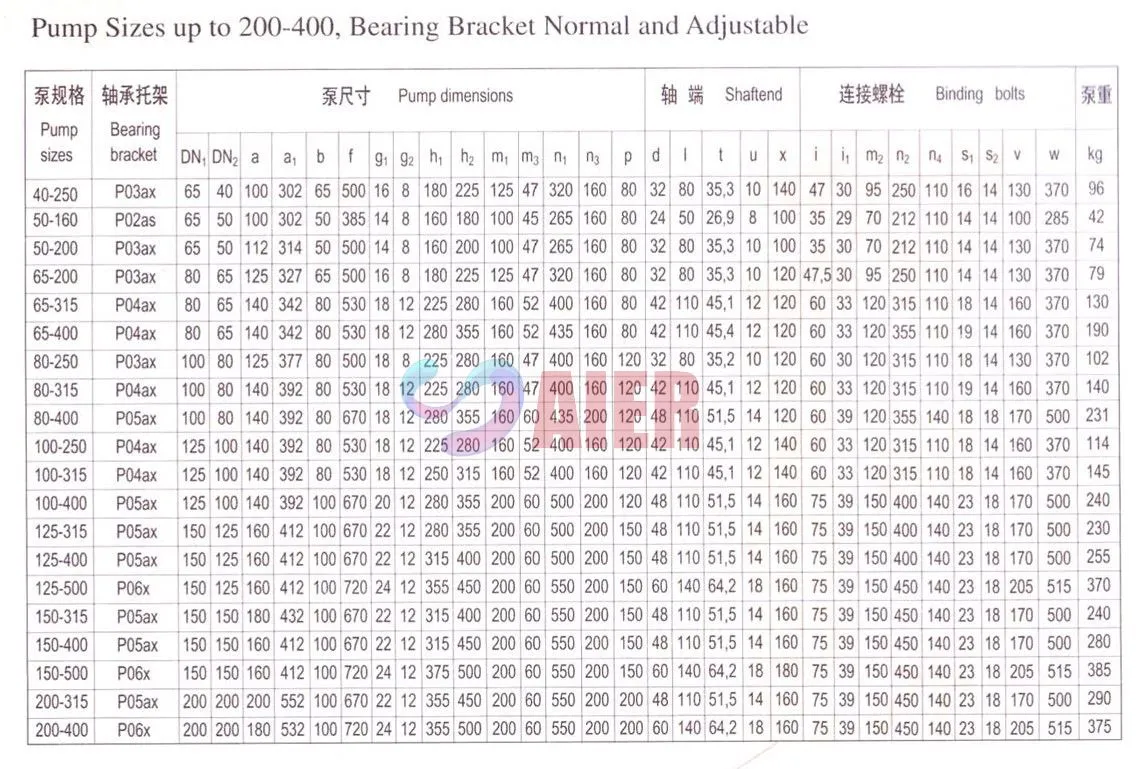

| Flow Range | ≈ 20–2,000 m³/h (real-world use may vary) |

| Head | ≈ 5–80 m |

| Materials | Cast iron, duplex options; wear-resistant coatings optional |

| Impeller | Non-clogging design; solids handling up to ≈ 100 mm |

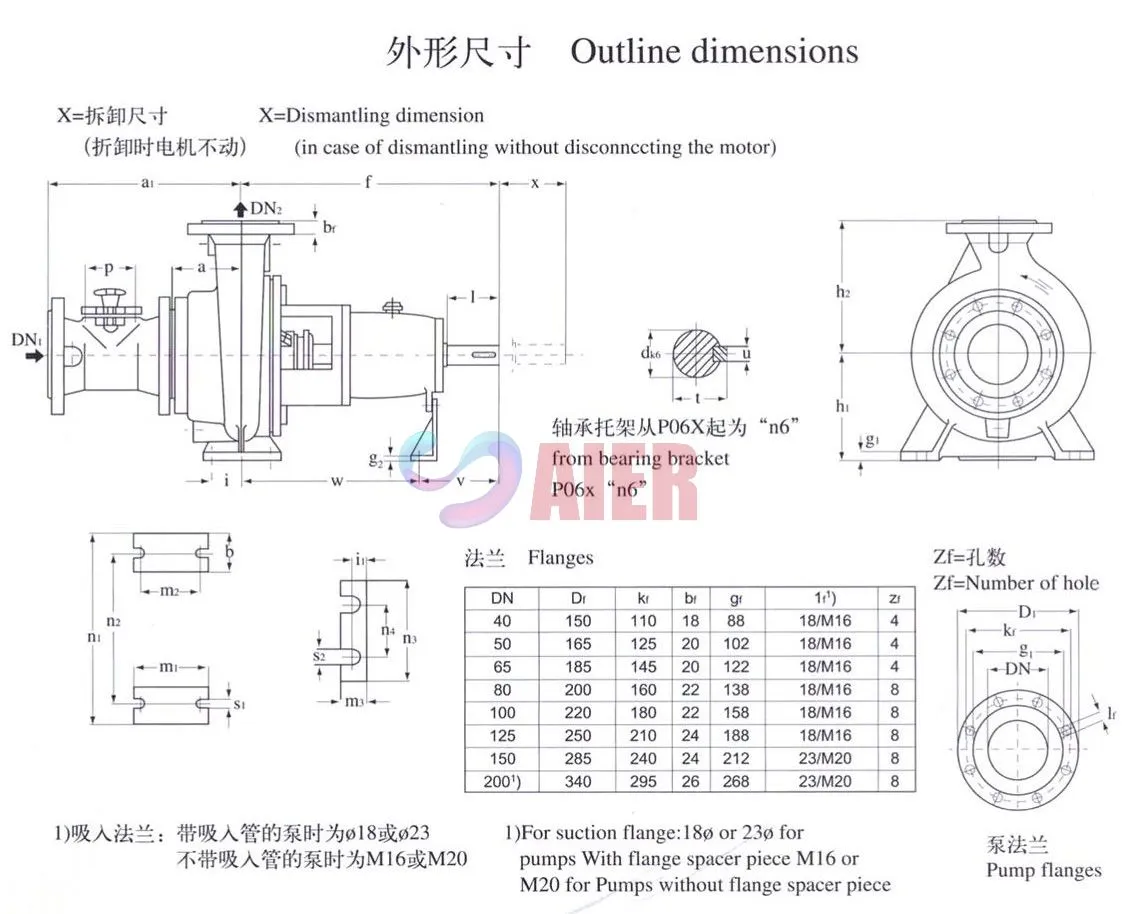

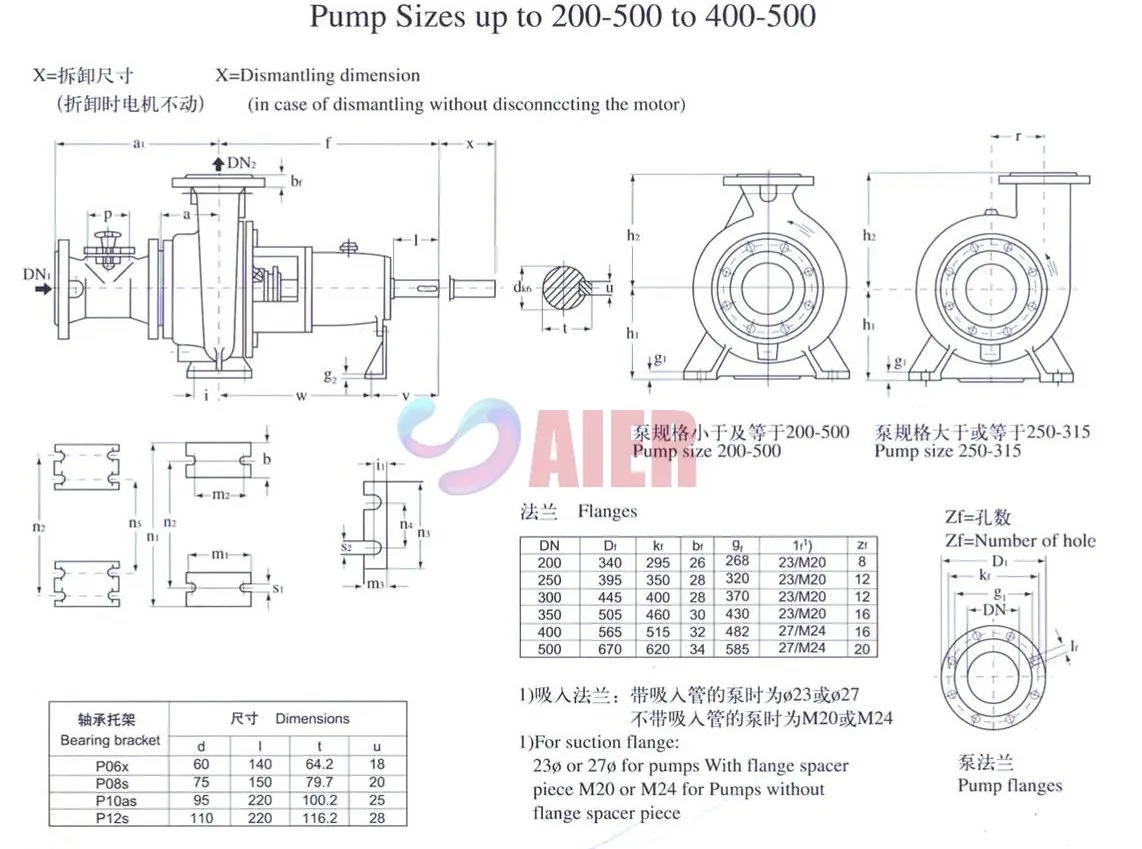

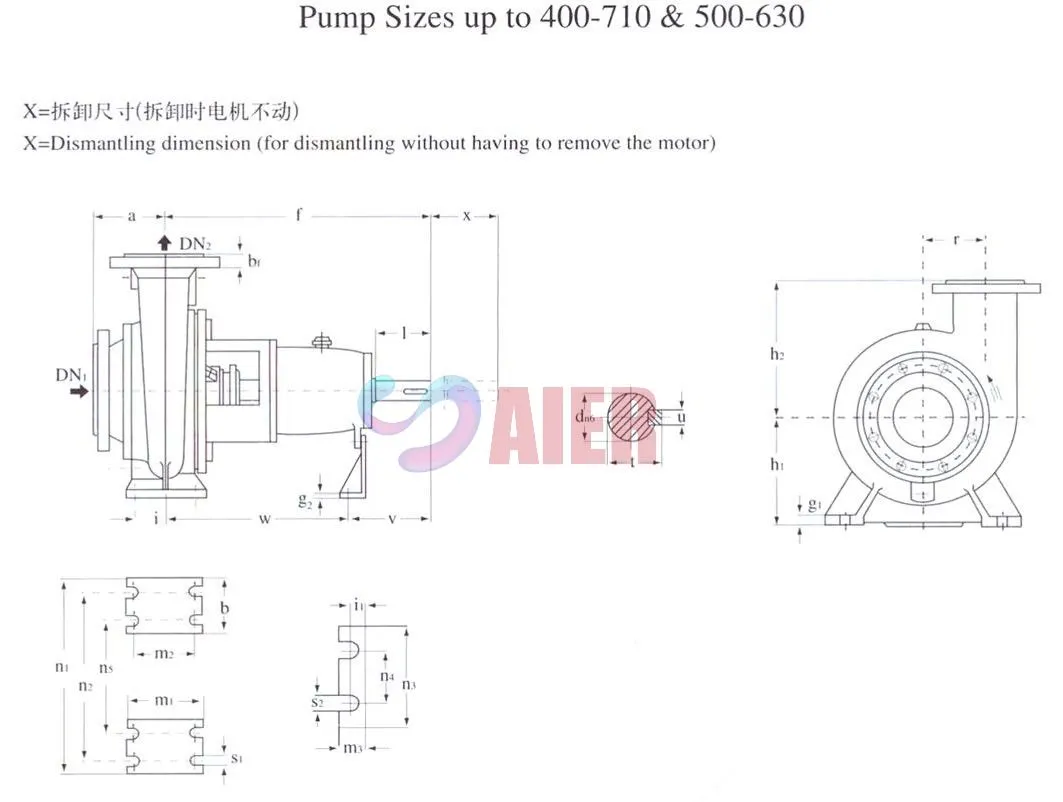

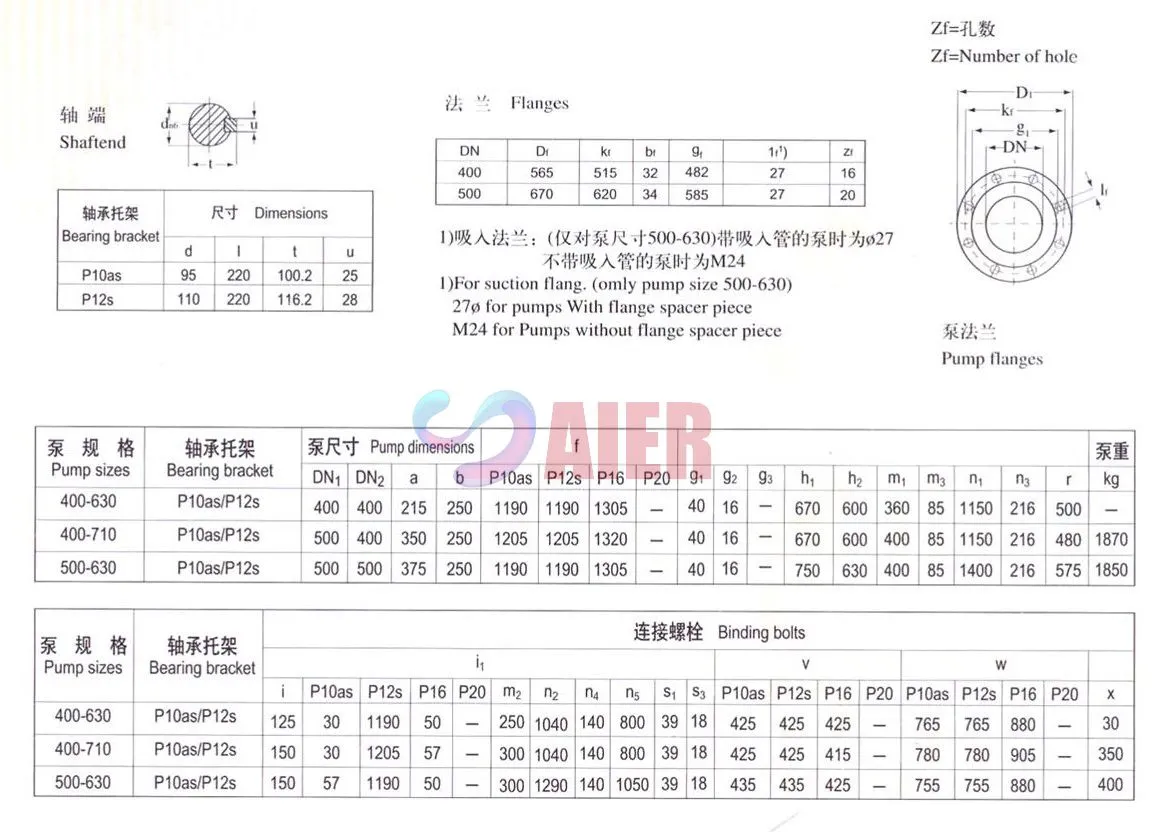

| Design | Back pull-out for fast service; ISO 2858 flanges where applicable |

| Testing | ISO 9906 acceptance; hydrostatic at 1.5× rated pressure |

Process and quality flow

- Materials: heat-treated castings, optional stainless internals; elastomers selected per media pH.

- Methods: CNC machining, dynamic balancing to ISO 1940 G6.3, precision fit-up.

- Testing: performance test per ISO 9906; vibration checks; seal integrity test.

- Service life: around 10–15 years with proper lubrication, alignment, and seal selection.

Applications and quick case notes

Municipal lift stations, industrial effluent, mill returns, and yes—sticky food plant waste. One city plant swapped aging units for KWP and reported ≈ 12% energy savings plus fewer rag-outs. A sugar mill noted faster rotor pulls (back pull-out) cut a weekend shutdown to a long Friday.

Vendor comparison (snapshot)

| Vendor | Certifications | Lead Time | Customization | Service |

|---|---|---|---|---|

| Aier (KWP) | ISO 9001; ISO 14001; ISO 9906-tested | ≈ 4–8 weeks | Materials, seals, coatings, curves | Remote commissioning, spare kits |

| Vendor B | ISO 9001; CE | 6–10 weeks | Limited impeller options | Basic hotline |

| Vendor C | ISO 9001/45001 | 8–12 weeks | Standard builds | Third-party service |

Customization and integration

Seal packs (single, double, cartridge), elastomer swaps, hardened wear rings, coated volutes, and curve tweaks for duty points. Integration tips: align NPSH margin ≥ 1 m, check solids size vs. impeller passage, and confirm VFD compatibility.

Field feedback and test data

- ISO 9906 Grade 2B performance curves; factory Q-H data archived per serial.

- Measured vibration typically ≤ 4.5 mm/s RMS at BEP on rigid base.

- Seal MTBF reports around 18–24 months in municipal duty (rag load varies).

Compliance and standards

Built under ISO 9001 with performance verification to ISO 9906. For explosion-risk zones, verify ATEX/IECEx options on request. Many utilities mandate HI (Hydraulic Institute) guidance for selection—this aligns well.

Buying checklist

- BEP near duty point; adequate NPSH margin.

- Solids size vs. passage; abrasives? consider hard-facing.

- Service plan: back pull-out spares and alignment kit.

Final thought: whether you’re vetting a submersible well pump manufacturer or a sewage specialist, look for transparent test data, fast parts logistics, and practical design touches. The KWP’s non-clog hydraulics and back pull-out tick boxes that, frankly, save weekends.

Authoritative citations

- ISO 9906: Rotodynamic pumps — Hydraulic performance acceptance tests.

- Hydraulic Institute Standards, Pump Application Guidelines (latest edition).

- ISO 1940-1: Mechanical vibration — Balance quality requirements.

- ISO 9001 / ISO 14001: Quality and Environmental Management Systems.

-

Leading FGD Pump Manufacturers for Reliable Flue Gas Desulfurization Solutions

NewsNov.24,2025

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025

-

Reliable China FGD Pump Suppliers for Effective Flue Gas Desulfurization | AiEr Pumps

NewsNov.22,2025