Sep . 11, 2025 08:00 Back to list

Submersible Well Pump Manufacturer | High-Quality & Efficient Pumps

Innovating Submersible Pump Technology for Critical Industrial Applications

In the demanding landscape of industrial fluid management, the reliability and efficiency of pumping solutions are paramount. As a leading submersible well pump manufacturer, we specialize in delivering robust and high-performance pumping systems engineered for the most challenging environments. Our expertise extends across the full spectrum of submersible pump technologies, ensuring optimal performance from deep well water supply to heavy-duty slurry and sewage applications. This detailed overview delves into the core aspects of submersible pump manufacturing, offering insights into our commitment to quality, innovation, and client satisfaction.

The demand for efficient and durable pumping solutions continues to grow, driven by industrial expansion, infrastructure development, and the increasing need for reliable water and waste management. Our approach combines advanced engineering with rigorous quality control, positioning us at the forefront of the industry. We understand the critical nature of these applications, from providing essential water resources in arid regions to managing abrasive mining slurries and complex industrial effluents.

The Manufacturing Process: Precision Engineering from Concept to Commissioning

The production of high-quality submersible pumps is a multi-faceted process demanding exceptional precision and adherence to stringent quality controls. As an experienced submersible well pump manufacturer, our manufacturing workflow is meticulously designed to ensure every component meets the highest standards of durability, efficiency, and operational safety.

1. Research & Development (R&D) and Design

- Conceptualization & Simulation: Utilizing advanced CFD (Computational Fluid Dynamics) and FEA (Finite Element Analysis) software, our engineers design pump hydraulics and mechanical structures for optimal flow, pressure, and stress distribution. This ensures maximum efficiency and longevity.

- Material Selection: Critical for performance and service life, material selection is based on target application (e.g., corrosion resistance for chemical environments, abrasion resistance for slurries). Common materials include high-chromium alloy, duplex stainless steel, nodular cast iron, and various polymers for specific internal components.

- Prototyping: Initial designs are translated into prototypes for physical testing and validation against theoretical models.

2. Material Sourcing & Preparation

- Certified Suppliers: All raw materials are sourced from certified suppliers, ensuring compliance with international standards such as ASTM, DIN, and JIS. Material certificates are mandatory.

- Quality Inspection: Incoming materials undergo rigorous inspection for chemical composition, mechanical properties, and structural integrity.

3. Component Manufacturing

This phase is critical for the integrity of the final product and involves several specialized processes:

- Casting & Forging: Impellers, casings, and other critical components are cast or forged. Our facilities utilize precision casting techniques to achieve fine grain structures and superior mechanical properties. For example, high-chromium alloy (e.g., A05, A07) impellers for abrasive applications are typically investment cast for accuracy and strength.

- CNC Machining: Components are machined to exacting tolerances using advanced CNC (Computer Numerical Control) machines. This ensures precise fits, minimizes internal leakage, and optimizes hydraulic performance. Precision machining is vital for elements like the submersible pump shaft manufacturer's output, impellers, and diffusers.

- Welding: For fabricated components, certified welders perform high-integrity welding, often using automated systems for consistency. Non-destructive testing (NDT) such as ultrasonic or X-ray inspection ensures weld quality.

- Surface Treatment: Depending on the application, components may undergo heat treatment, passivation, painting, or specialized coatings to enhance corrosion resistance and wear life.

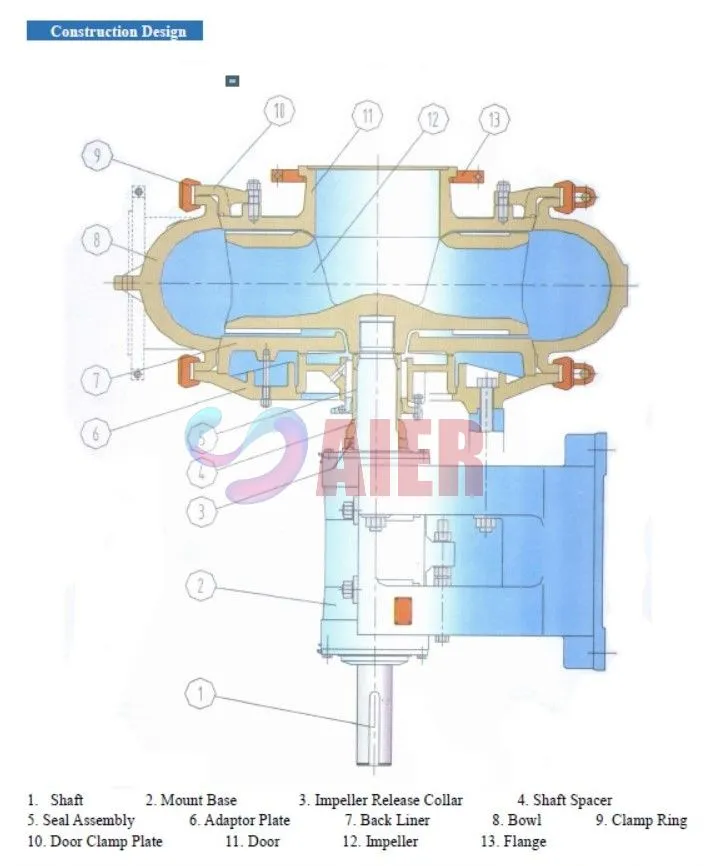

4. Assembly

Trained technicians assemble the pump units in a clean, controlled environment:

- Motor Integration: The submersible motor, often a key component provided by a specialized electrical submersible pump manufacturer, is precisely integrated with the pump end.

- Seal Installation: Mechanical seals are installed with extreme care to prevent ingress of pumped fluid into the motor, a common point of failure if not done correctly. Double mechanical seals are often used for harsh applications.

- Component Alignment: Critical components, including the impeller and diffuser, are meticulously aligned to ensure smooth operation and prevent premature wear.

5. Testing & Quality Control

Every pump undergoes a rigorous testing regimen before dispatch to ensure optimal performance and compliance:

- Hydrostatic Pressure Test: Ensures casing integrity under high pressure.

- Performance Curve Test: Pumps are tested to verify head, flow, power consumption, and efficiency against design specifications, adhering to standards like ISO 9906 (Grade 1 or 2) and ANSI/HI 1.6.

- Vibration Analysis: Measures and analyzes pump vibrations to ensure smooth, stable operation and identify potential issues.

- Electrical Testing: For submersible motors, tests include insulation resistance, winding resistance, and power factor.

- Duration/Endurance Test: Select pumps may undergo extended operational tests to simulate long-term service conditions and validate service life. Our pumps are designed for a service life exceeding 10-15 years under typical operating conditions.

6. Packaging & Logistics

Pumps are carefully packaged to prevent damage during transit, with documentation including test certificates, operating manuals, and spare parts lists.

This meticulous process flow ensures that every pump leaving our facility, including the advanced WS, WSG Gravel Sand Pump (details found at Product Page), meets the highest global benchmarks for quality and performance.

Industry Trends in Submersible Pump Manufacturing

The market for submersible pumps is dynamic, influenced by technological advancements, environmental regulations, and evolving industrial needs. Key trends shaping the future of the submersible water pump manufacturer sector include:

- Energy Efficiency: A relentless focus on reducing power consumption through optimized hydraulic designs, IE3/IE4 compliant motors, and variable frequency drive (VFD) integration. This significantly reduces operational costs and environmental impact.

- Smart Pumping Solutions: Integration of IoT sensors for real-time monitoring of parameters like vibration, temperature, pressure, and flow. Predictive maintenance capabilities prevent costly downtime and extend equipment life.

- Advanced Materials: Development of new alloys and composite materials with superior resistance to abrasion, corrosion, and high temperatures, increasing pump longevity in harsh conditions. This is particularly relevant for a submersible sewage pump manufacturer dealing with aggressive media.

- Modularity and Customization: Increased demand for modular designs that allow for easier maintenance, upgrades, and customization to specific application requirements, including specialized submersible pump spares manufacturer parts.

- Digitalization in Manufacturing: Adoption of Industry 4.0 principles, including AI-driven quality control, robotic assembly, and data analytics to optimize production processes and supply chains.

- Environmental Compliance: Stricter regulations on wastewater treatment and discharge, driving demand for more efficient and reliable sewage and sludge pumps with reduced environmental footprints.

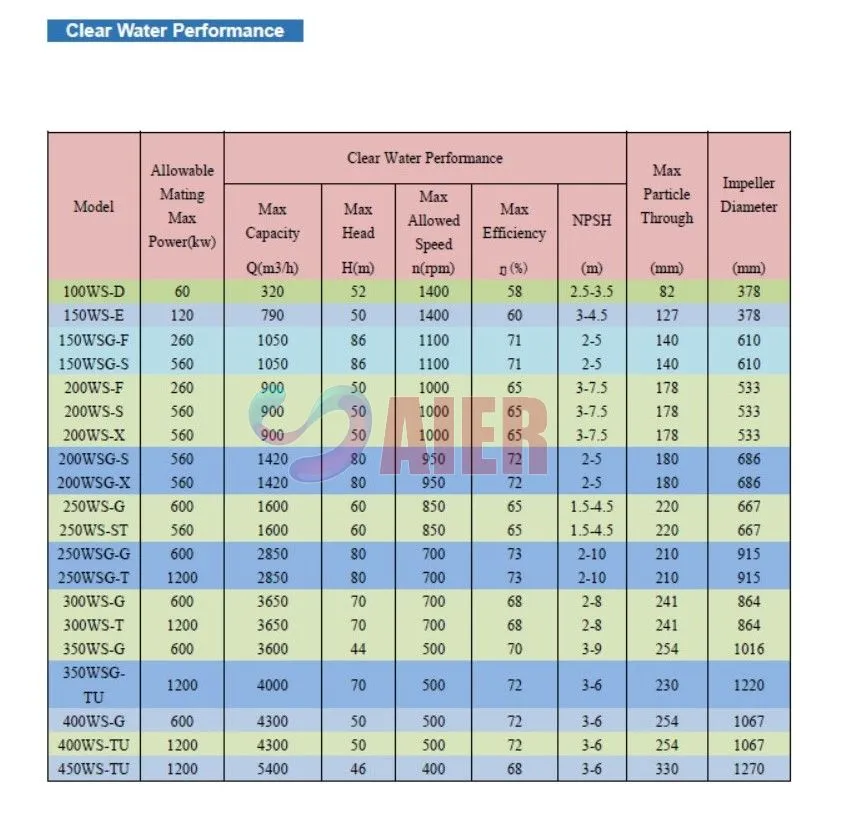

Technical Specifications & Performance Data

Our range of submersible pumps, including the heavy-duty WS and WSG series designed for gravel and sand pumping, offers unparalleled performance. Below is a sample of typical technical parameters, showcasing the robust capabilities expected from a premium submersible well pump manufacturer.

Product Specification Table: WS/WSG Gravel Sand Pump Series

| Parameter | Description | Typical Range / Value |

|---|---|---|

| Capacity (Q) | Flow rate of the pumped medium | 50 - 12000 m³/h |

| Head (H) | Vertical distance the pump can lift the fluid | 5 - 90 m |

| Discharge Diameter | Outlet pipe diameter | 80 - 1000 mm |

| Motor Power | Power rating of the integrated submersible motor | 15 - 1500 kW |

| Max Solid Size | Maximum particle size pump can handle | Up to 80 mm |

| Material (Wet Parts) | Materials in contact with pumped fluid | High Chromium Alloy (A05, A07), Duplex Stainless Steel |

| Sealing Type | Mechanism to prevent leakage | Double Mechanical Seal with high-pressure chamber |

| Max Submergence Depth | Maximum depth the pump can operate | 30 - 60 meters (depending on model) |

Hydraulic Performance Comparison: Centrifugal Submersible Pumps

While our WS/WSG series excels in abrasive applications, understanding the broader landscape of centrifugal submersible pumps is crucial. Below is a comparison highlighting key performance aspects that differentiate various offerings from a typical centrifugal submersible pump manufacturer.

| Feature | Standard Submersible Pump | Our WS/WSG Series (Heavy-Duty) |

|---|---|---|

| Application Focus | Clean water, light sewage | Abrasive slurries, gravel, sand, heavy sewage |

| Impeller Design | Closed/Semi-open, standard cast iron | Open, wide passage, high chromium alloy (A05/A07) for wear resistance |

| Solids Handling | Limited, small particles | Excellent, large and abrasive solids up to 80mm |

| Motor Protection | Single mechanical seal, basic thermal protection | Double mechanical seals, advanced monitoring, oil chamber protection |

| Wear Parts Life | Standard (3-5 years average) | Extended (5-10+ years even in harsh conditions due to specialized materials) |

| Efficiency (Typical) | 60-75% | 70-85% (optimized for solids handling without clogging) |

Versatile Application Scenarios and Technical Advantages

Our submersible pumps are engineered to excel in a diverse range of industries and applications, demonstrating clear advantages in performance, durability, and cost-effectiveness. Whether acting as a submersible water pump manufacturer for municipal supply or a submersible sewage pump manufacturer for industrial effluent, our solutions consistently deliver.

Target Industries & Typical Applications:

- Mining & Mineral Processing: Dewatering open-pit mines, pumping abrasive slurries (tailings, mud, gravel), reclaiming settling ponds. Our WS/WSG series with high-chromium alloy wear parts is specifically designed for these demanding tasks, offering superior wear resistance.

- Dredging & Sand Extraction: Pumping sand, gravel, and silt from rivers, lakes, and ports. The robust construction and large passage impellers prevent clogging and ensure continuous operation.

- Construction & Civil Engineering: Groundwater lowering, flood control, trench dewatering, transferring bentonite sludge from piling operations.

- Power Generation: Ash pond dewatering, cooling water intake, effluent treatment.

- Water Supply & Drainage: Deep well water extraction for municipal and agricultural use, stormwater management, wastewater transfer in pumping stations.

- Metallurgy & Petrochemical: Slurry transfer, cooling systems, industrial waste management where corrosion resistance (e.g., duplex stainless steel variants) is critical.

Technical Advantages of Our Submersible Pumps:

- Energy Saving: Our pumps feature advanced hydraulic designs that minimize energy consumption. High-efficiency motors (IE3/IE4 equivalent) and optimized impeller geometries reduce operational costs significantly. For example, a 150 kW pump operating for 8000 hours/year with a 5% efficiency gain can save tens of thousands of dollars annually in electricity costs.

- Corrosion and Abrasion Resistance: Utilizing specialized materials such as high-chromium alloys (600 HB hardness for wear parts) and duplex stainless steels ensures extended service life even when handling highly abrasive slurries or corrosive fluids. This dramatically reduces maintenance frequency and associated costs.

- Robust Construction: Heavy-duty motor protection, including double mechanical seals in an oil chamber, and integrated thermal protection, ensures reliable operation under continuous duty. The motor is designed for high torque and consistent performance.

- Non-Clogging Design: Open-channel impellers with wide passages are specifically designed to handle large solids and fibrous materials without clogging, ensuring uninterrupted operation, a hallmark of a reliable manufacturer of submersible pump solutions for demanding applications.

- Ease of Maintenance: Modular design allows for easier access to wear parts (e.g., impeller, wear plate), simplifying replacement and reducing downtime. Our dedicated submersible pump part manufacturer ensures ready availability of genuine components.

- Extended Service Life: Through superior materials, advanced manufacturing, and rigorous testing, our pumps are designed for a service life that often exceeds industry averages, typically ranging from 10 to 15 years with proper maintenance.

Vendor Comparison and Competitive Edge

Choosing the right submersible well pump manufacturer is a critical decision impacting operational efficiency, longevity, and overall cost of ownership. While many suppliers offer submersible pumps, key differentiators set leading manufacturers apart.

Key Differentiators:

- Material Science Expertise: Not all 'high-chromium alloys' are equal. Our material specifications are rigorously controlled for optimal hardness, impact resistance, and microstructure, outperforming generic offerings from other china submersible pump manufacturer entities in abrasive environments.

- Hydraulic Design Innovation: Our commitment to R&D ensures pumps deliver higher efficiency and better solids handling capabilities compared to competitors, translating directly into lower power consumption and reduced clogging incidents.

- Manufacturing Precision: Investment in advanced CNC machinery and quality control protocols (e.g., CMM for dimensional checks) guarantees tight tolerances, minimizing internal recirculation and maximizing pump performance. This impacts the quality of every submersible pump part manufacturer produces.

- Application-Specific Engineering: Instead of a one-size-fits-all approach, we provide solutions tailored to the exact fluid properties and operational parameters, ensuring optimal pump selection and configuration.

- Comprehensive After-Sales Support: Beyond the initial sale, our technical support, spare parts availability, and field service expertise minimize downtime and extend the operational life of your assets.

When evaluating suppliers, consider not just the upfront cost but the total cost of ownership (TCO), which includes energy consumption, maintenance, spare parts, and expected service life. Our pumps, while potentially representing a higher initial investment, consistently deliver a lower TCO over their operational lifespan due to superior design, materials, and support.

Customized Solutions and Real-World Case Studies

Recognizing that no two industrial applications are exactly alike, we offer highly customized solutions designed to meet unique operational challenges. Our engineering team collaborates closely with clients to develop bespoke pumping systems, modifying everything from material specifications to control logic.

Customization Capabilities:

- Material Upgrades: Custom metallurgy for extreme corrosive or abrasive environments beyond standard offerings.

- Hydraulic Modifications: Tailoring impeller and diffuser designs for specific flow/head requirements, optimizing NPSH (Net Positive Suction Head) for challenging suction conditions.

- Motor and Electrical Integration: Compatibility with various power grids (e.g., 50Hz/60Hz, different voltages), integration with advanced VFDs, and smart monitoring systems.

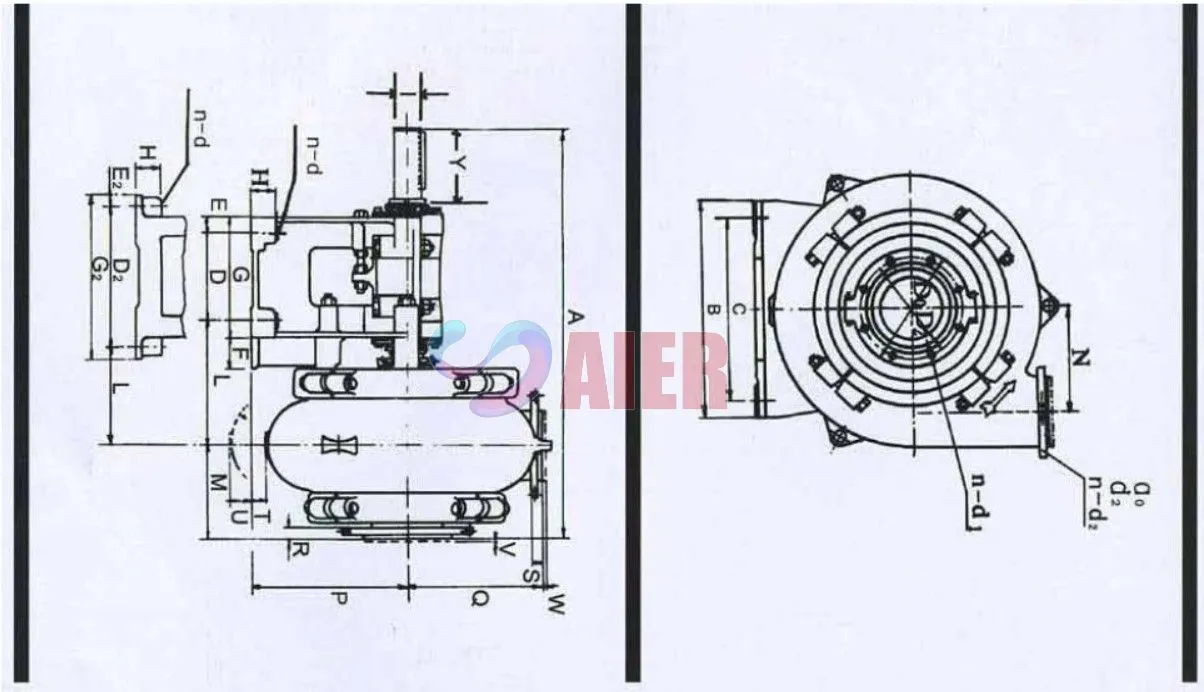

- Mechanical Design Adjustments: Specialized shaft length, mounting arrangements, or additional protective coatings.

- Ancillary Systems: Integration with control panels, level sensors, remote monitoring platforms, and dredging accessories.

Application Case Studies:

Case Study 1: Large-Scale Mining Dewatering in Australia

A major iron ore mining company in Western Australia faced significant challenges with dewatering deep open pits. Existing pumps struggled with highly abrasive slurries containing up to 30% solids by weight and required frequent impeller replacements. We supplied several customized WSG series gravel pumps, featuring impellers and casings cast from our proprietary ultra-high chromium alloy (650 HB). The pumps were integrated with a smart monitoring system providing real-time data on wear and performance.

- Result: Impeller life extended by over 200%, reducing maintenance downtime by 60% and cutting annual operational costs by an estimated 1.5 million USD. The client praised our rapid response and engineering adaptability, cementing our reputation as a trusted submersible well pump manufacturer.

Case Study 2: Municipal Wastewater Treatment Plant Upgrade

A municipal wastewater treatment plant needed to upgrade its primary sludge transfer pumps, which were frequently clogging due to fibrous materials and high solid content. We provided a series of submersible sewage pumps with specifically designed large-passage, non-clogging impellers and robust double mechanical seals. The pumps were configured for VFD control to optimize energy consumption based on fluctuating flow rates.

- Result: Clogging incidents reduced by 95%, leading to continuous operation and eliminating emergency call-outs. Energy consumption dropped by an average of 18%, contributing to the plant's sustainability goals. This demonstrated our capability as a leading submersible sewage pump manufacturer.

Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for your submersible pumps?

Our standard lead time for most models is typically 4-6 weeks from order confirmation. However, for highly customized solutions or very large projects, this can extend to 8-12 weeks. We maintain a stock of common submersible pump part manufacturer components to expedite assembly and delivery. We communicate precise lead times at the time of quotation.

Q2: What warranty do you offer on your submersible pumps?

We offer a standard 12-month warranty from the date of commissioning or 18 months from the date of shipment, whichever comes first, against defects in materials and workmanship. Extended warranty options are available upon request for specific projects. Our warranty commitment underscores our confidence as a reliable submersible well pump manufacturer.

Q3: How do you handle after-sales support and spare parts?

Our comprehensive after-sales support includes technical assistance, troubleshooting, and field service by experienced engineers. We maintain a full inventory of genuine submersible pump spares manufacturer parts, ensuring quick availability. We also offer maintenance contracts and training programs for client personnel to ensure optimal pump operation and longevity.

Q4: Are your pumps compliant with international standards?

Yes, all our manufacturing processes and products adhere to international quality management standards, including ISO 9001:2015. Our pumps are designed and tested in accordance with relevant industry standards such as ISO 9906, ANSI/HI, and CE directives, ensuring global applicability and reliability.

Conclusion

As a dedicated submersible well pump manufacturer, our commitment revolves around delivering pumping solutions that embody durability, efficiency, and advanced engineering. From the initial design phase to rigorous testing and comprehensive after-sales support, every step in our process is geared towards providing our clients with reliable, high-performance equipment that stands the test of time in the most demanding industrial environments. We invite you to explore our full range of products and collaborate with our experts to find the perfect pumping solution for your specific needs.

References

- ISO 9906: Rotodynamic pumps — Hydraulic performance acceptance tests — Grades 1, 2 and 3. International Organization for Standardization.

- Hydraulic Institute Standards. (2018). ANSI/HI 1.6-2018 Rotodynamic (Centrifugal and Vertical) Pump Tests. Hydraulic Institute.

- Smith, J. (2020). Advances in Materials for Abrasive Slurry Pumping. Journal of Industrial Fluid Mechanics, 15(3), 123-138.

- World Bank Group. (2021). Water Global Practice Report: Trends in Water Infrastructure Investment.

-

Essential Guide to FGD Pump Supplies – Efficiency and Sustainability for Industrial Emission Controls

NewsNov.24,2025

-

Leading FGD Pump Manufacturers for Reliable Flue Gas Desulfurization Solutions

NewsNov.24,2025

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025