Oct . 06, 2025 00:25 Back to list

Submersible Well Pump Manufacturer: Efficient, Durable—Why?

Inside a Modern Pump Shop: Notes from a Field Visit to a Submersible (and Slurry) Specialist

Last spring I walked the factory floor of a submersible well pump manufacturer in China that also builds heavy-duty slurry equipment. What stood out? The same engineering rigor used for deep-well submersibles shows up in their gravel pumps too—particularly the WS, WSG Gravel Sand Pump line. Different battlefield, same discipline.

Industry trends (and a few honest takeaways)

Dredging, tailings reprocessing, and river-course remediation are all pushing pumps harder—coarser solids, higher duty cycles, tighter HSE rules. Buyers want measurable life-cycle value: longer wear parts, real ISO 9906 test curves, faster rebuilds. To be honest, flashy brochures don’t cut it anymore; field data does.

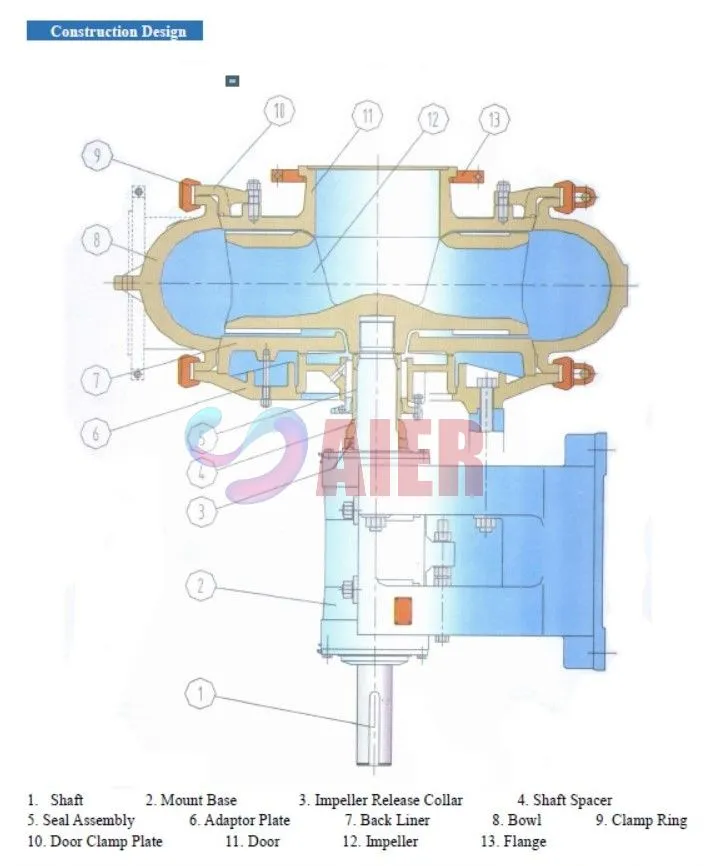

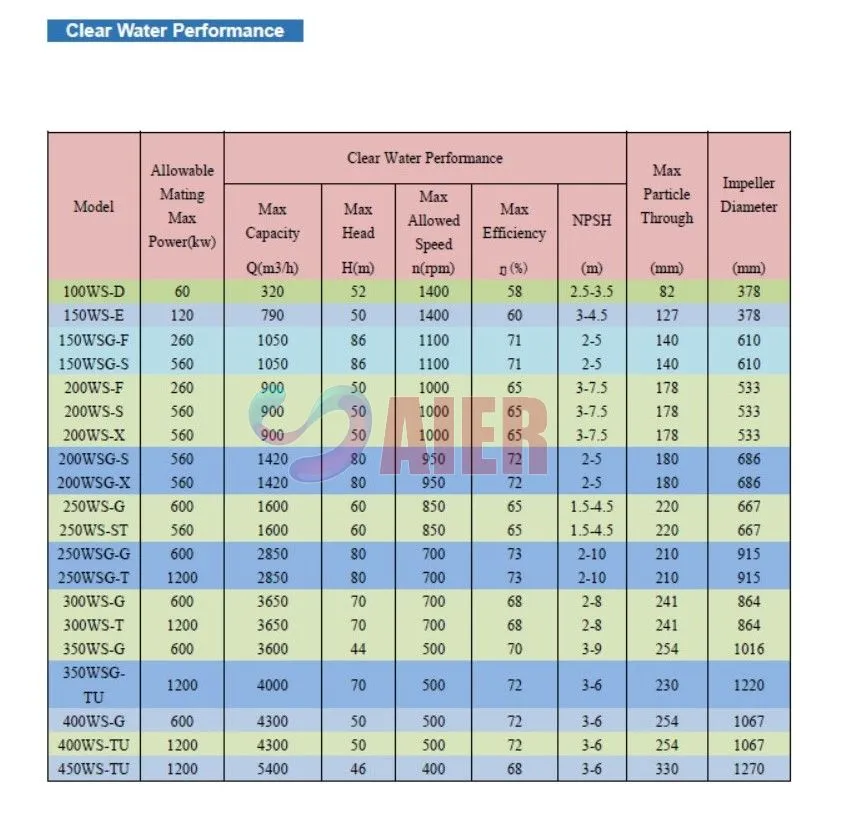

Product snapshot: WS, WSG Gravel Sand Pump

The WS/WSG pumps are built for continuous handling of highly abrasive slurry with big solids—think dredging barges, explosive sludge in smelting, or mining pits. The WSG versions are the high-head variants. Materials are typically Hi-Chrome white iron (ASTM A532, A05/A49) with optional duplex stainless in corrosive blends. Impellers and volutes are beefy; tolerances are practical rather than delicate—on purpose.

Indicative Specifications (real-world use may vary)

| Model | Flow (m³/h) | Head (m) | Max Solids (mm) | Material | Efficiency η (≈) |

|---|---|---|---|---|---|

| WS 200 | 400–1200 | 20–45 | 90 | Hi-Chrome A05 | 60–68% |

| WS 300 | 900–2200 | 18–40 | 110 | A05/A49 | 62–70% |

| WSG 300 (High Head) | 800–1800 | 35–80 | 100 | Hi-Chrome/Optional Duplex | 58–66% |

Manufacturing and test flow (how it’s actually built)

- Materials: ASTM A532 Hi‑Chrome white iron (A05/A49), optional duplex SS for chloride-rich slurry, elastomer liners in select sizes.

- Methods: precision sand casting, heat treatment, CNC machining, hardfacing on critical wear paths, dynamic balancing per ISO 1940‑1 (G6.3 or better).

- Performance testing: ISO 9906 Grade 2B acceptance; hydrostatic to 1.5× MAWP; runout and vibration logs archived.

- Service life: in 10–15% silica (0.3–0.8 mm), field feedback shows impeller life ≈ 1,800–4,000 hours; obviously site-dependent.

- Certifications: ISO 9001 QMS; CE marking for relevant assemblies; material certs kept on heat number.

Where these pumps actually work

- Mining slurry transfer, sand and gravel pits, cutter-suction dredgers, river desilting, and metallurgical sludge. Many customers say the WS/WSG units handle “too-big” solids their previous pumps choked on. I guess that’s the impeller passage design doing the heavy lifting.

Vendor snapshot (because choice matters)

| Vendor | Design & Materials | Testing & Docs | Lead Time | Notes |

|---|---|---|---|---|

| Aier (WS/WSG) | Hi‑Chrome, optional duplex; hydraulics tuned for coarse solids | ISO 9906 curves, hydrostatic, balance reports | ≈ 3–6 weeks for common sizes | Strong spares kit and rebuild guidance |

| Importer B | Mixed alloys; generic patterns | Basic factory run test only | Varies (stock-based) | Lower entry price, less traceability |

| Regional C | Good alloys, localized tweaks | Partial ISO reporting | 4–10 weeks | Decent service locally |

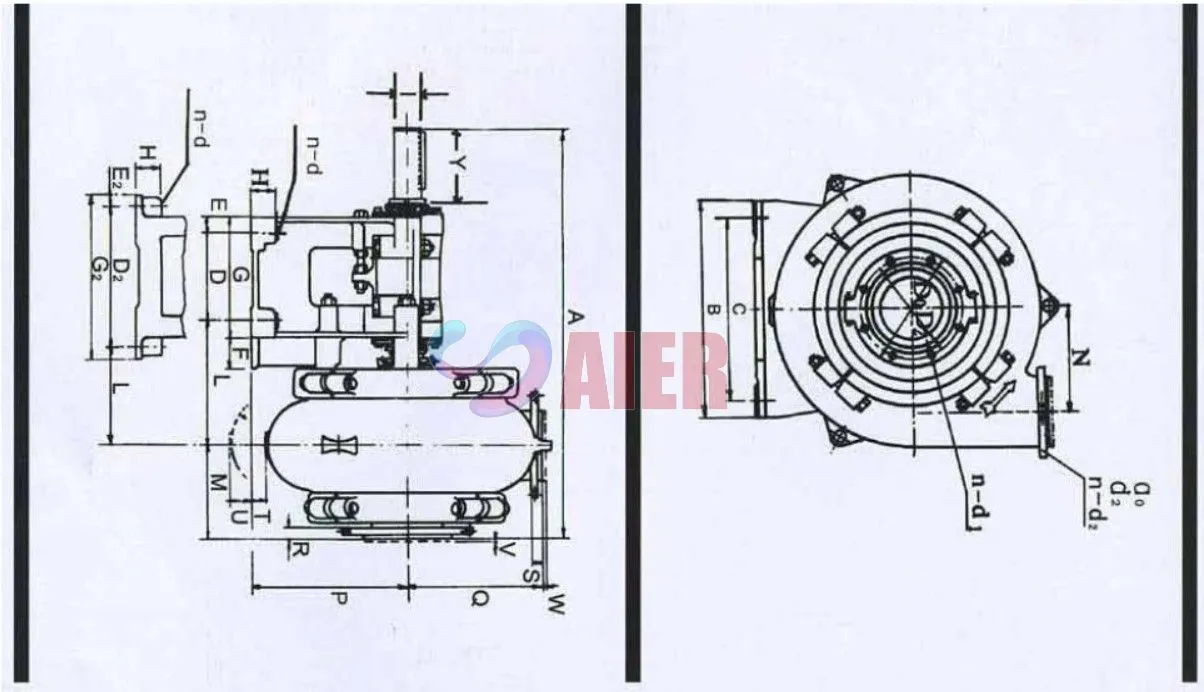

Customization and integration

Options include elastomer-lined casings for specific sands, adjustable throatbush, expeller or mechanical seal packages, and protective coatings. Integration with dredger PLCs is straightforward; VFD duty motors are common. For submersible well lines from the same shop, the control philosophy overlaps—nice if you want a single submersible well pump manufacturer to handle mixed fleets.

Case note: river dredging barge, Southeast Asia

A barge operator swapped two older pumps for one WSG 300. Flow increased from ≈ 950 to 1,350 m³/h at similar head; fuel per ton moved dropped around 12%. After 10 weeks on medium silica, the impeller wear was within predicted limits. The skipper’s feedback was simple: fewer clogs, better mornings.

Final thought

If you’re shortlisting a submersible well pump manufacturer that also understands brutal slurry duty, the WS/WSG line is worth a look. Not glamorous, but tough, documented, and—surprisingly—serviceable.

Authoritative references

- ISO 9906:2012 – Rotodynamic pumps — Hydraulic performance acceptance tests.

- ISO 1940-1:2003 – Mechanical vibration — Balance quality requirements for rotors.

- ASTM A532 – Standard Specification for Abrasion-Resistant Cast Irons.

- ISO 9001 – Quality management systems — Requirements.

-

Leading FGD Pump Manufacturers for Reliable Flue Gas Desulfurization Solutions

NewsNov.24,2025

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025

-

Reliable China FGD Pump Suppliers for Effective Flue Gas Desulfurization | AiEr Pumps

NewsNov.22,2025