Oct . 28, 2025 12:05 Back to list

Submersible Well Pump Manufacturer | Durable, Efficient, OEM

Inside a Modern Submersible Supplier: YCT Vertical Spindle Ceramic Pump

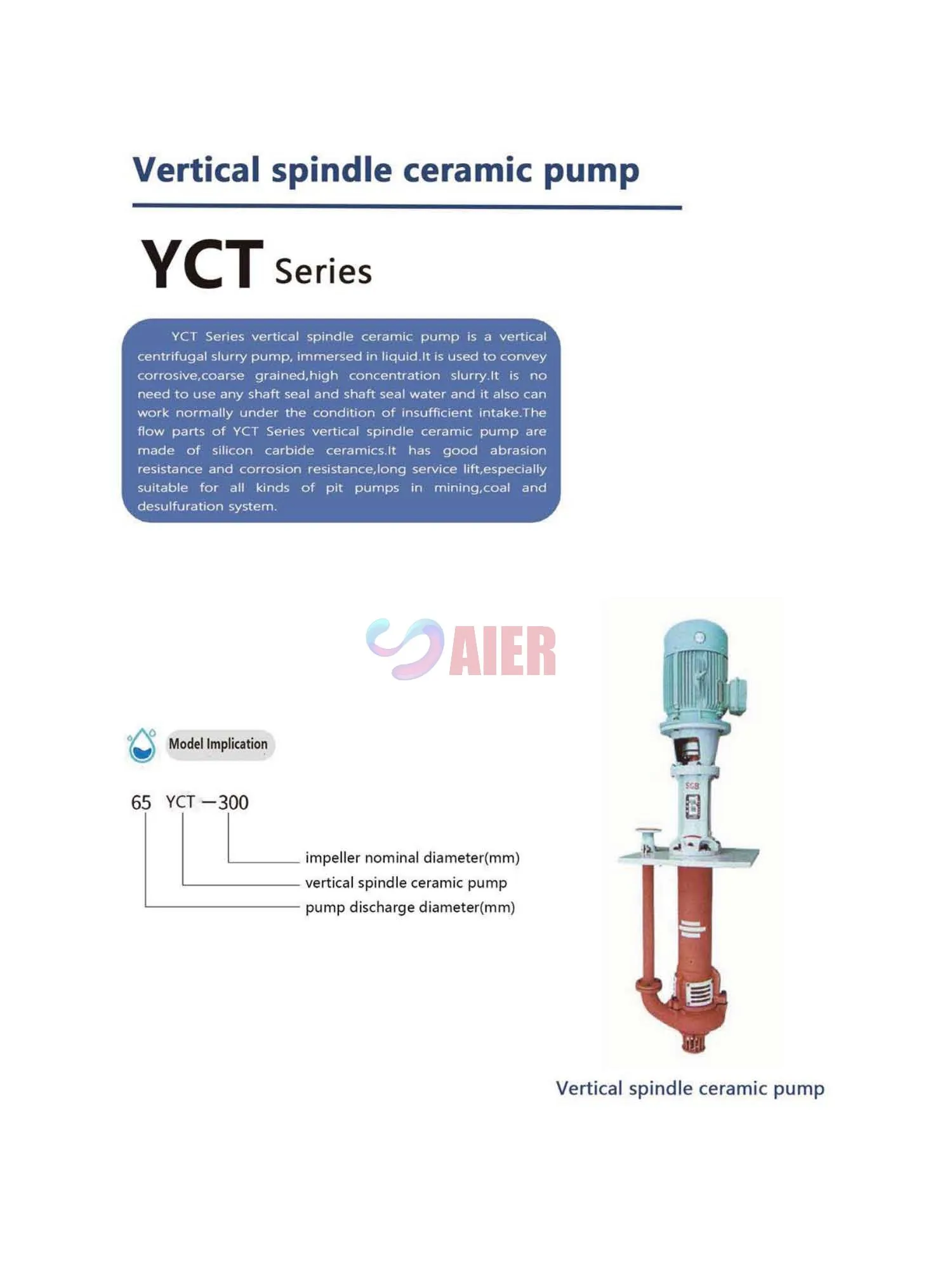

If you’ve ever stood over a sump full of abrasive slurry and thought, “there has to be a smarter way,” you’re not alone. I’ve been following the rise of ceramic-wetted pumps for years, and the shift is no fad. Meet the YCT Vertical Spindle Ceramic Pump from a seasoned Submersible Well Pump Manufacturer in China—built for corrosive, coarse-grained, high-solids duty where metal and rubber linings often tap out.

What’s changing in slurry and well pumping

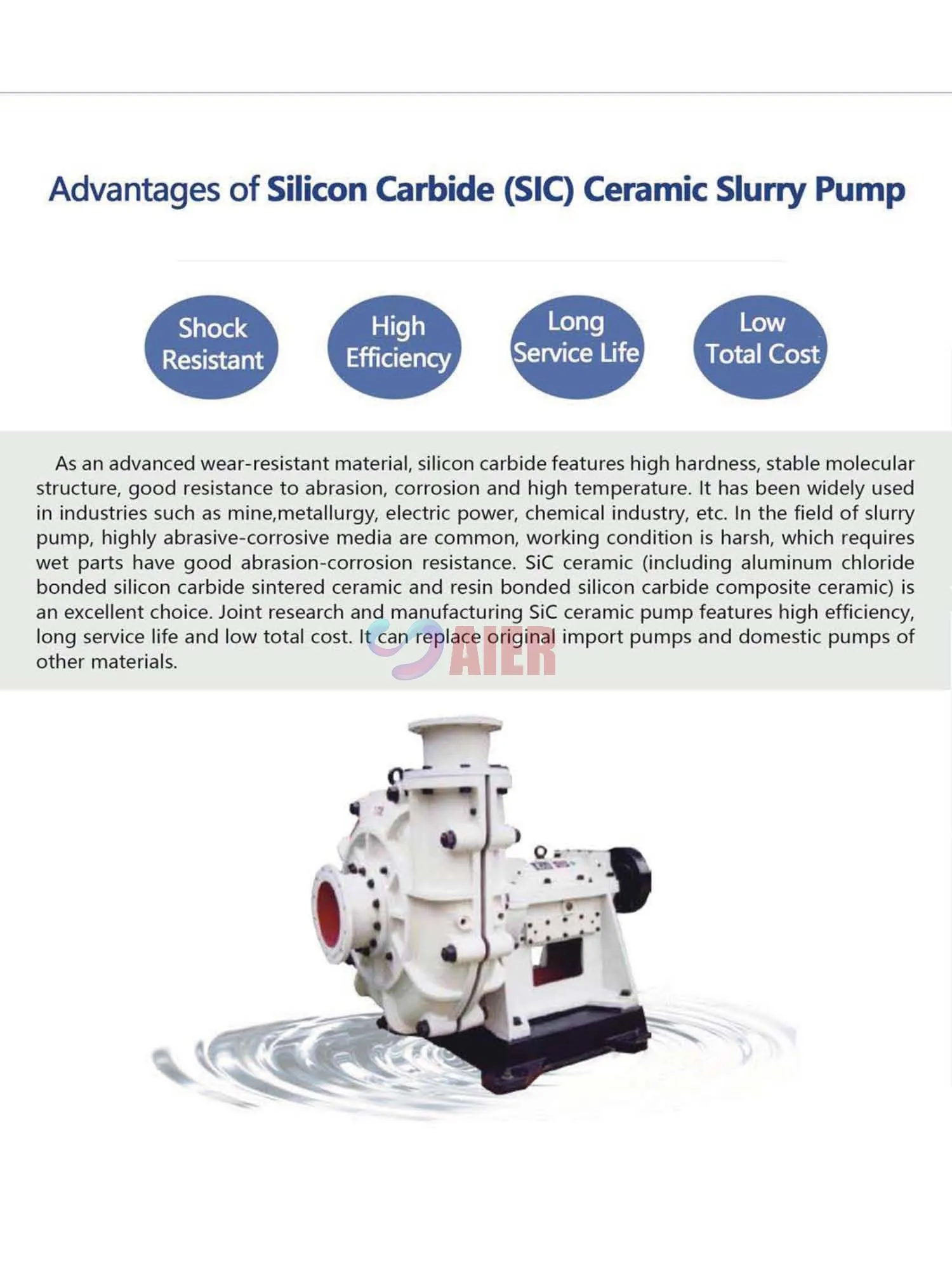

Frankly, the market is moving toward longer service life and fewer shutdowns. Ceramic components—especially silicon carbide (SiC)—are winning because they shrug off abrasion and nasty chemistry. To be honest, the upfront price can be a touch higher, but many customers say they get it back in saved maintenance and fewer crane calls.

YCT at a glance (origin: China)

The YCT vertical spindle ceramic pump is a vertical centrifugal slurry pump, immersed in liquid—no priming drama. Its wet end uses SiC ceramics for extreme abrasion and corrosion resistance. It’s become a staple for pit pumps in mining, coal prep, tailings, and FGD desulfurization systems.

| Spec (YCT Series) | Typical Range (≈ / real-world may vary) |

|---|---|

| Flow | ≈ 10–500 m³/h |

| Head | ≈ 5–45 m |

| Max solids size | ≈ 8–25 mm |

| Wetted parts | Silicon carbide ceramics (SiC) |

| pH window | ≈ 1–13 |

| Fluid temp | 0–80°C (higher on request) |

| Immersion depth | ≈ 0.6–3.5 m (custom shafts) |

| Motor power | ≈ 3–160 kW |

Process flow, materials, and testing

- Materials: pressure-formed SiC ceramic for volute, impeller, throatbush; stainless steel column and hardware.

- Methods: sintering, CNC grinding of sealing faces, dynamic balancing to ISO 1940 G6.3 or better.

- Performance tests: ISO 9906 acceptance (Grade 2B typical); hydrostatic pressure test; vibration checks.

- Wear benchmarking: ASTM G65 dry sand/rubber wheel abrasion—SiC shows drastically lower volume loss vs. high-chrome iron.

- Service life: field reports indicate 2–5× vs. metal in silica-heavy slurries (conditions matter).

- Certs: ISO 9001 QMS; CE/ATEX motor options available; GB/T 3216 alignment with ISO 9906.

Applications and real-world feedback

Use it in coal prep sumps, thickener underflow pits, mill scale trenches, and FGD absorber recirculation pits. Many operators tell me downtime drops fast. One northern Asia coal plant swapped a high-chrome sump pump for YCT: maintenance interval went from ~3 months to ~9 months; reported energy cut ≈12% at the duty point; spare parts spend down ~38% in year one. Your mileage may vary, of course.

Vendor comparison (quick take)

| Item | YCT Ceramic | Vendor A (Cast Iron) | Vendor B (Rubber-Lined) |

|---|---|---|---|

| Wetted material | SiC ceramic | High-chrome iron | Natural rubber |

| pH tolerance | ≈ 1–13 | ≈ 4–10 | ≈ 5–10 |

| Expected wear life | High in silica slurries | Medium | Low in sharp slurry |

| OPEX over 24 mo. | Lower (parts + labor) | Medium | Higher (liner wear) |

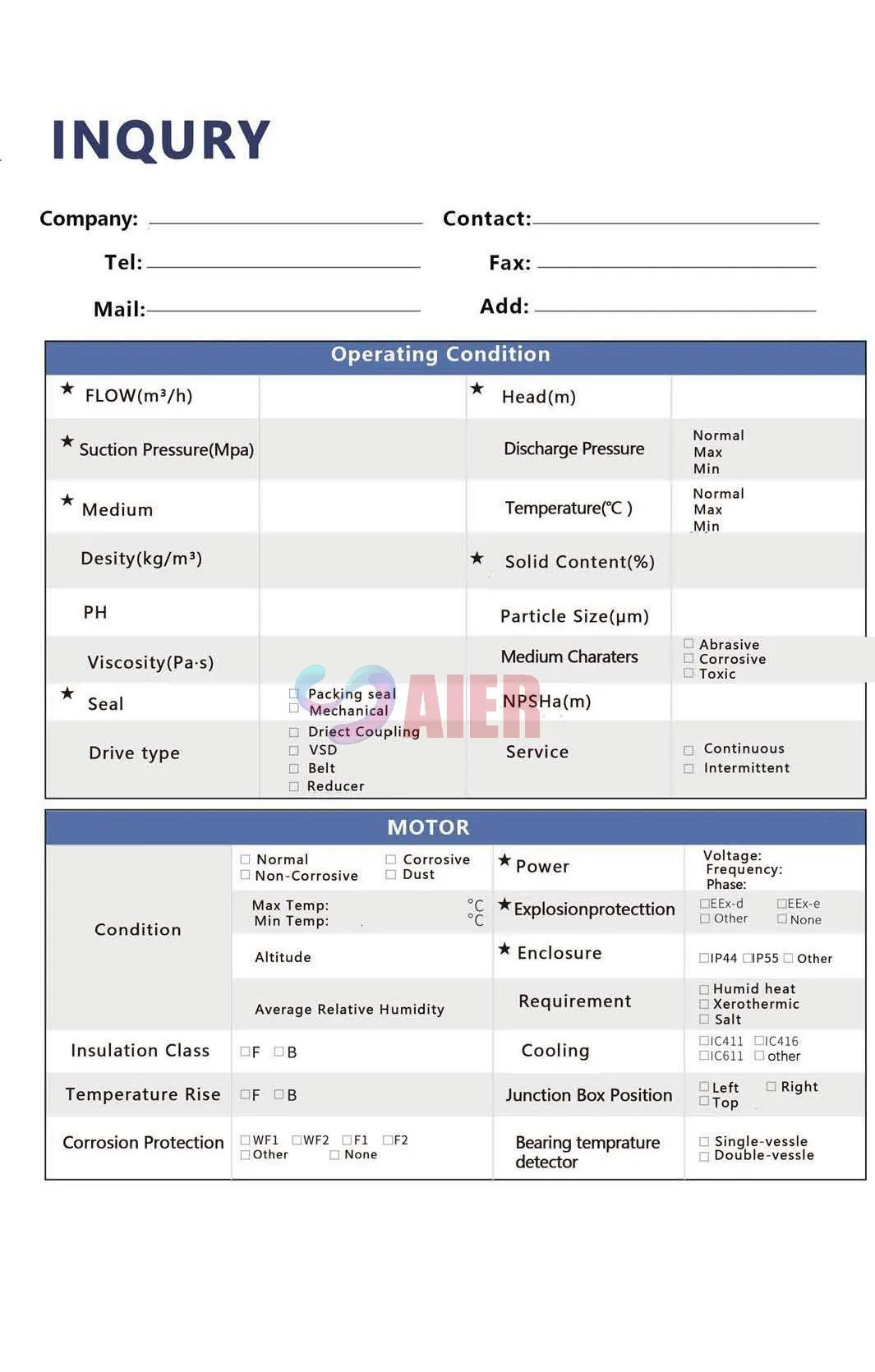

Customization and integration

- Shaft lengths, sump cover plates, discharge orientation, and flange standards (ANSI/DIN).

- Impeller trims for BEP targeting; clearances set for specific particle size distributions.

- Motors: IE3/IE4 efficiency, explosion-proof, VFD-ready; ATEX on request.

- Seals/bearings: upgraded bearing cartridges; FKM/EPDM elastomers depending on chemistry.

Installation note: avoid prolonged dry-running—ceramics like slurry lubrication. A simple level switch and VFD ramp can be a lifesaver.

Why this Submersible Well Pump Manufacturer keeps coming up

They’re pragmatic: fast ceramic spares, test curves to ISO 9906, and honest talk about limits. In fact, several engineers told me the sizing support alone saved them a weekend. If you’re juggling abrasive pits, a Submersible Well Pump Manufacturer that lives and breathes SiC is, I guess, worth shortlisting.

References

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025

-

Reliable China FGD Pump Suppliers for Effective Flue Gas Desulfurization | AiEr Pumps

NewsNov.22,2025

-

China FGD Pump: Durable & Efficient Solutions for Emission Control

NewsNov.21,2025