Oct . 27, 2025 11:25 Back to list

Submersible Well Pump Manufacturer | Durable, Efficient OEM

What to Look for in a Submersible Well Pump Partner (from someone who’s been in the pump room)

If you’re shortlisting a Submersible Well Pump Manufacturer, the badge on the nameplate matters less than the engineering under the hood. To be honest, that’s the quiet truth you learn after a few site visits, some muddy test pits, and a couple of midnight callouts. The right vendor blends materials science, test discipline, and boringly reliable after-sales.

Industry trends I see in the field

- High-efficiency hydraulics paired with VFD-ready motors (amp draw data actually backs the claims).

- IoT-ish monitoring—nothing fancy; just clean pressure, kW, and run-hours data that techs can trust.

- Materials upgrade path: 304 → 316L → duplex/CF3M where chlorides bite; nitrile to FKM as temps climb.

- Faster modular servicing—pull-out stages, cartridge seals, and smarter cable entries that don’t wick.

A quick (and relevant) product spotlight

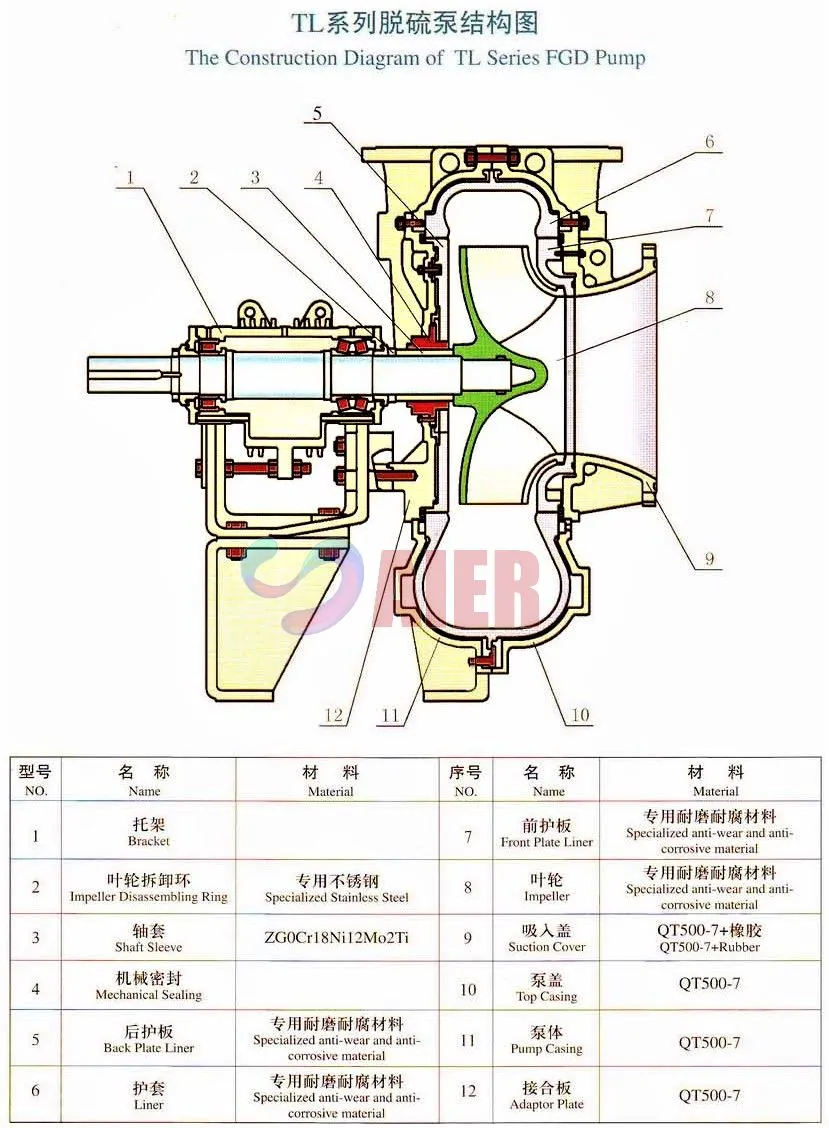

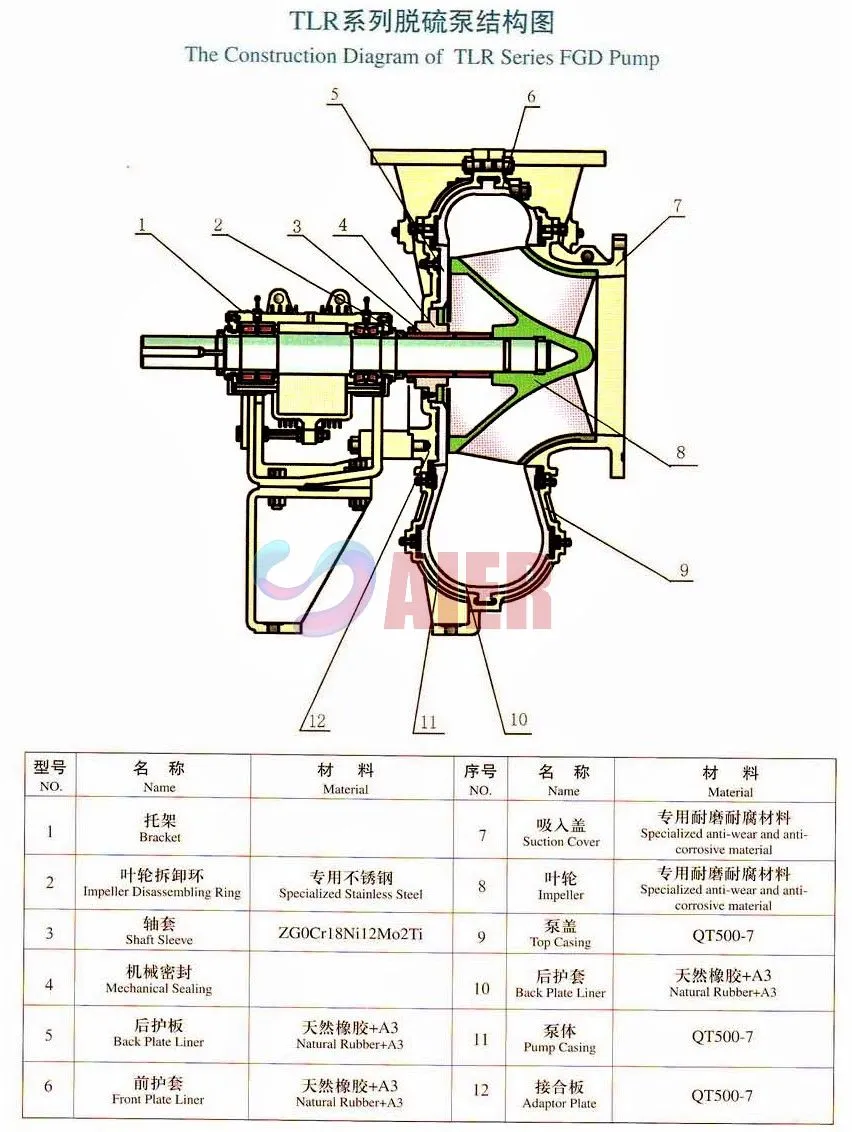

While I’m talking wells, I’ll point at an adjacent benchmark for build quality: the TL, TLR FGD Pump from China—single-stage, single-suction horizontal centrifugal gear used as absorbent tower circulation in FGD. Not a submersible, sure, but its abrasion/corrosion DNA says a lot about the shop behind it. In fact, many customers say the material know-how transfers well into deep-well lines.

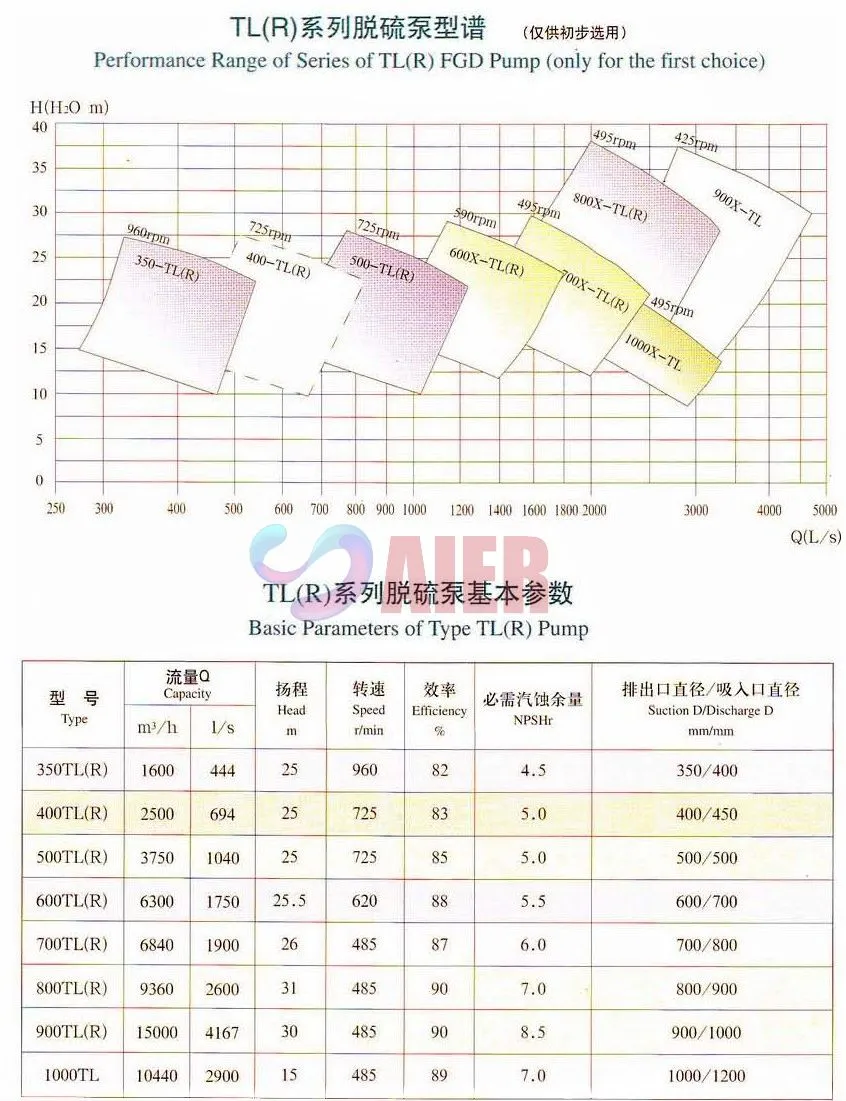

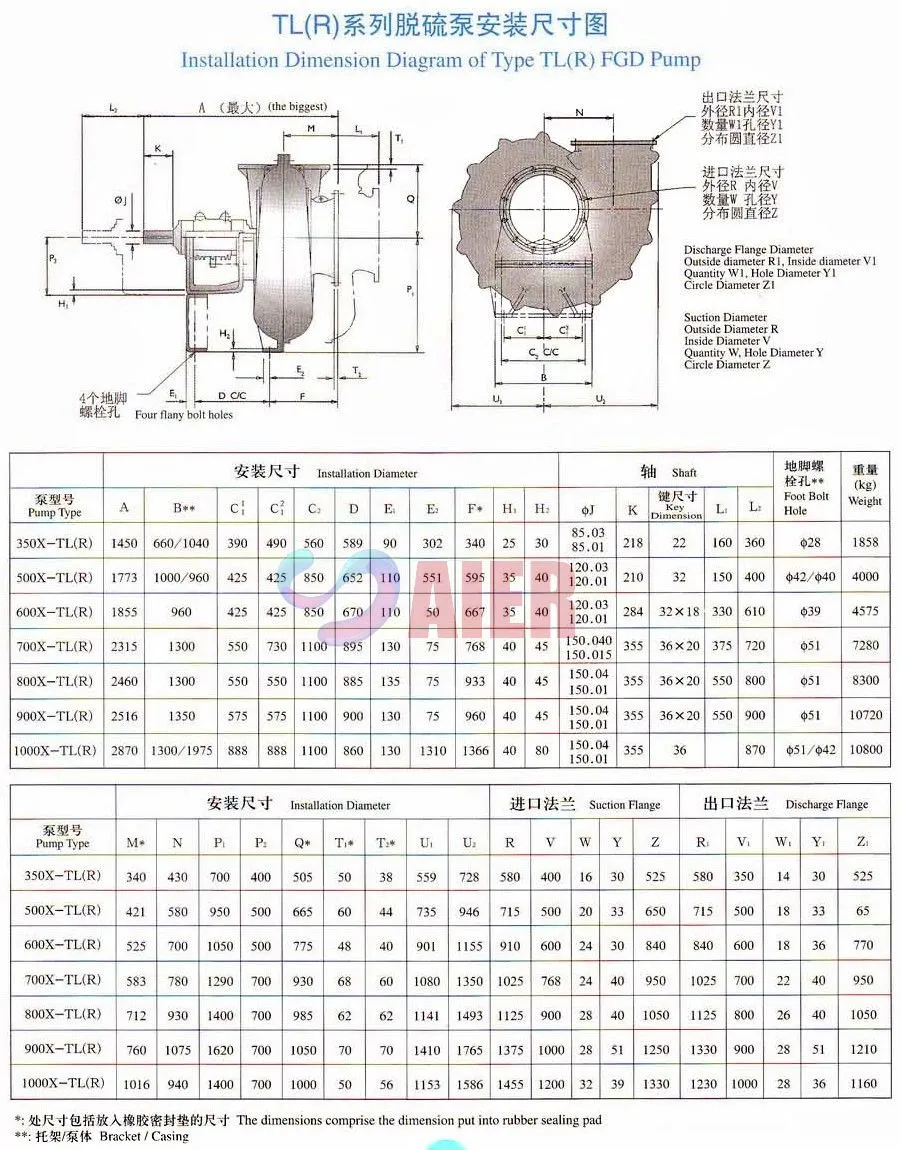

| Item | TL, TLR FGD Pump (reference) |

|---|---|

| Type | Single-stage, single-suction horizontal centrifugal |

| Flow | ≈150–7000 m³/h (real-world use may vary) |

| Head | ≈12–65 m |

| Materials | High-chrome iron, duplex SS, rubber-lined (TLR) |

| Efficiency | Up to ≈82% hydraulics |

| Seal | Expeller + mechanical seal options |

| Origin | China |

Where submersible well pumps shine

Domestic and municipal wells, irrigation pivots, mining dewatering, geothermal injection. Typical 4–10 inch units push 5–300 m³/h at heads of 40–300 m, with motors from 0.75–150 kW. Sand-handling design (floating impellers, wear rings) is the quiet hero here.

How good manufacturers build them

- Materials: 304/316L or duplex bowls/shafts; bronze/SS impellers; FKM/NBR elastomers; potable elastomers per NSF/ANSI/CAN 61.

- Methods: investment casting, precision machining; dynamic balancing to ISO 1940 G6.3 (some go G2.5); stator resin potting.

- Testing: performance per ISO 9906 (Grade 2B or 1B); hydro to 1.5× MAWP; motors to IEC 60034; dielectric and surge tests.

- Service life: around 20,000–40,000 h in clean water; derate where sand >50 ppm unless protection stages are used.

Vendor snapshot (comparing apples to… well, close enough)

| Vendor | Core strength | Typical kW range | Test standard | Potable cert | Notes |

|---|---|---|---|---|---|

| Aier Pumps (China) | Materials and slurry know-how from FGD line | ≈0.75–150 | ISO 9906, HI 14.6 | NSF/ANSI/CAN 61 on request | Lean X-bracket designs save space |

| Grundfos | Efficient SP hydraulics, global service | ≈0.37–250 | ISO 9906 | Often available | Strong VFD pairing |

| Franklin Electric | Submersible motors + pump packages | ≈0.37–300 | UL 778, ISO 9906 | Often available | Good distributor network |

| Local OEM | Custom diameters, fast spares | ≈0.75–55 | Varies | Varies | Check test bench data |

Customization, testing, and the boring stuff that saves money

Spec the cable length and metallurgy early; ask for ISO 9906 curves with measurement uncertainty. Request motor insulation class F, 1.15 S.F., and sand-handling clearances. For potable wells, insist on NSF/ANSI/CAN 61 or equivalent (WRAS). I guess it seems fussy—until energy and pull costs hit the ledger.

Quick case snapshots

- Municipal wellfield (8-inch, 37 kW, 120 m head): post-VFD tuning, site kWh down ≈11% vs. nameplate. Noise and harmonics within utility limits.

- FGD plant (TL/TLR reference): limestone slurry ~30% solids; 18 months continuous duty; one planned seal swap, bearings within spec at teardown.

Customer feedback? “Quieter than expected” and “spares landed fast”—not glamorous, but that’s what ops teams remember.

If you’re weighing a Submersible Well Pump Manufacturer, kick the tires on test standards, materials, and curve honesty. And yes, ask for real bench data, not brochure poetry.

Authoritative references

- ISO 9906:2012 – Rotodynamic pumps—Hydraulic performance acceptance tests. https://www.iso.org/standard/52052.html

- ANSI/HI 14.6 – Rotodynamic Pumps for Hydraulic Performance Tests. https://www.pumps.org

- NEMA MG 1 – Motors and Generators (submersible motor sections). https://www.nema.org

- NSF/ANSI/CAN 61 – Drinking Water System Components—Health Effects. https://www.nsf.org

- UL 778 – Motor-Operated Water Pumps. https://www.ul.com

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025

-

Reliable China FGD Pump Suppliers for Effective Flue Gas Desulfurization | AiEr Pumps

NewsNov.22,2025

-

China FGD Pump: Durable & Efficient Solutions for Emission Control

NewsNov.21,2025