Dec . 04, 2024 16:03 Back to list

Manufacturer of Rubber Components for Slurry Pump Spare Parts

The Importance of High-Quality Rubber Parts in Slurry Pump Spare Parts

In the world of industrial machinery, slurry pumps play a critical role in transporting mixtures of liquids and solids, often in challenging environments. These pumps are widely used in various sectors, including mining, construction, and wastewater treatment. To ensure optimal performance and longevity of slurry pumps, attention must be given to their spare parts, particularly rubber components, which are vital for seamless operation. This article explores the significance of high-quality rubber parts in slurry pump spare parts and the attributes that define an excellent manufacturer in this niche.

Understanding Slurry Pumps and Their Components

Slurry pumps are designed to handle abrasive, corrosive, and viscous liquids, which means that the quality of their components can significantly affect their efficiency and durability. Among the various parts, rubber components such as liners, impellers, gaskets, and seals are crucial. These rubber parts are responsible for maintaining the integrity of the pump, preventing leaks, and providing a buffer against wear and tear caused by abrasive materials.

The Role of Rubber Parts in Slurry Pumps

Rubber parts in slurry pumps serve multiple functions

1. Wear Resistance Given the abrasive nature of the materials being pumped, high-quality rubber is essential to withstand wear and extend the lifespan of the pump.

2. Sealing Properties Proper sealing is critical in preventing leaks and ensuring that the pump operates efficiently. Quality rubber compounds provide excellent sealing capabilities, which is vital for maintaining the system's pressure and preventing contamination.

3. Flexibility and Elasticity Rubber components can absorb shocks and vibrations, thereby protecting other mechanical parts from damage. This flexibility is especially important in heavy-duty applications where pumps experience varying pressure and flow rates.

4. Corrosion Resistance Many rubber compounds are engineered to resist corrosive substances that may be present in slurries. This property helps in maintaining the performance and safety of the pumping system.

slurry pump spare parts rubber parts manufacturer

Choosing the Right Manufacturer

Given the importance of rubber parts in slurry pumps, selecting a reliable manufacturer is crucial. Here are some factors to consider

1. Material Quality A reputable manufacturer should utilize high-grade rubber materials that meet industry standards. This ensures durability and performance in harsh operating conditions.

2. Customization Options Different applications may require specific rubber formulations and designs. A good manufacturer should offer custom solutions tailored to meet the unique needs of their clients.

3. R&D Capabilities Investing in research and development enables manufacturers to innovate and improve their products continually. This can lead to the development of advanced rubber compounds that enhance the longevity and efficiency of slurry pumps.

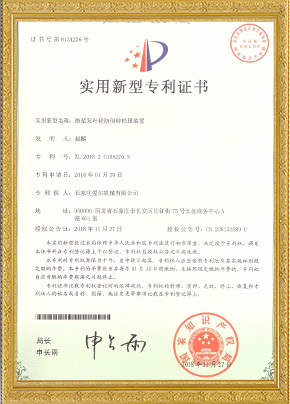

4. Certification and Standards Ensure that the manufacturer adheres to international standards and certifications. This not only guarantees the quality of the rubber parts but also ensures compliance with safety regulations.

5. Expertise and Experience A manufacturer with extensive experience in producing slurry pump rubber parts will have a deeper understanding of the challenges faced in the industry, allowing for better product development and customer service.

Conclusion

In summary, the significance of high-quality rubber parts in slurry pump spare parts cannot be overstated. They play an essential role in ensuring the efficiency, reliability, and longevity of slurry pumps. By choosing a skilled manufacturer that prioritizes quality materials, customization, and innovation, industry professionals can protect their investments and enhance operational efficiency. Regular maintenance and timely replacement of worn-out parts will further optimize performance, making quality rubber components indispensable in the world of slurry pumping.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025