Dec . 04, 2024 16:05 Back to list

China Supplier of Centrifugal Slurry Pump Components and Replacement Parts

China Centrifugal Slurry Pump Parts Supplier A Comprehensive Overview

In the world of industrial applications, centrifugal slurry pumps play a critical role in transporting abrasive and viscous materials across various sectors, including mining, minerals processing, and wastewater treatment. The efficiency and reliability of these pumps largely depend on the quality of their components. As a result, sourcing high-quality parts from reputable suppliers is essential for optimal performance and longevity. Among the leading markets for these products is China, which has established itself as a prominent supplier of centrifugal slurry pump parts.

The Importance of Quality Parts

Centrifugal slurry pumps are designed to handle corrosive and abrasive slurries, which makes the choice of materials and construction critical. The components that make up these pumps, such as the impellers, volutes, liners, and bearing assemblies, must withstand high wear rates and pressures. Consequently, suppliers must prioritize high-grade materials like stainless steel and high-chrome iron to ensure durability and efficiency. Chinese manufacturers have made significant strides in producing reliable and high-performance parts that meet international standards.

Key Components of Slurry Pumps

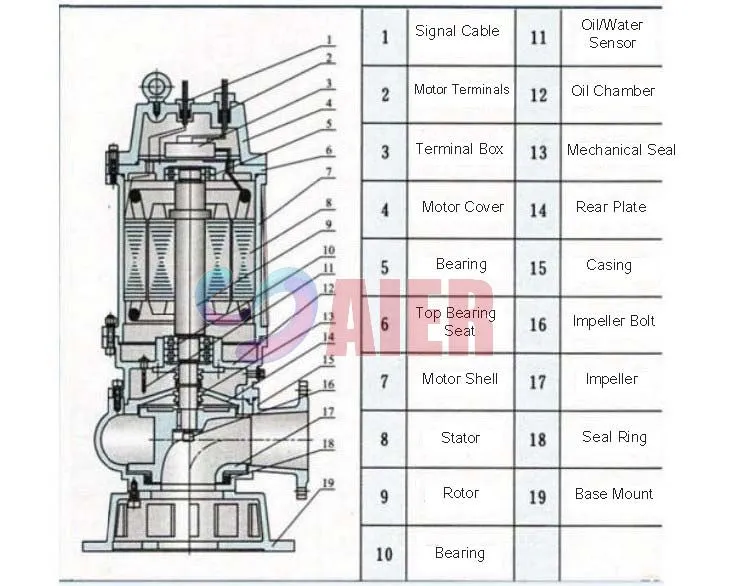

1. Impellers As the heart of the pump, impellers are responsible for converting mechanical energy into kinetic energy of the slurry. The design and material of the impeller significantly affect the pump's performance, efficiency, and lifespan.

2. Volutes These casing components direct the slurry flow and help convert kinetic energy into pressure. The design of volutes must account for different operational conditions, and high-quality materials are crucial for preventing wear and corrosion.

3. Liners Liners are protective coatings that shield the pump casing from the slurry's abrasive nature. Replacing worn liners periodically can extend the pump's service life and maintain efficiency.

4. Bearings They support the rotating parts of the pump. High-quality bearings minimize friction and wear, ensuring smooth operation and reducing maintenance costs.

Benefits of Sourcing from China

Chinese suppliers of centrifugal slurry pump parts offer several advantages

- Cost-Effectiveness Due to lower manufacturing and labor costs, Chinese suppliers can provide competitive pricing without compromising on quality. This is particularly beneficial for companies looking to optimize their operational budgets.

china centrifugal slurry pump parts supplier

- Diverse Product Range China boasts a vast array of manufacturers specializing in various types of pump components. This diversity allows clients to source specialized products tailored to their specific needs, ensuring compatibility and performance.

- Technological Advancements Many Chinese manufacturers are investing in advanced technologies and machinery to improve production processes and product quality. This commitment to innovation allows them to meet the ever-evolving demands of the global market.

- Easy Accessibility The widespread digitalization and e-commerce platforms enable international customers to easily access a multitude of suppliers, compare products, and make informed purchasing decisions.

Considerations When Choosing a Supplier

While there are many benefits to sourcing from China, businesses should remain vigilant when selecting a supplier. Here are some points to consider

- Reputation and Reliability Researching the supplier's background, customer reviews, and industry reputation can help ensure you are dealing with a reputable manufacturer.

- Quality Assurance Look for suppliers who adhere to international quality standards, such as ISO certifications. This can serve as a testament to their commitment to quality.

- Communication and Support Effective communication is essential for a smooth purchasing process. Ensure that the supplier is responsive and ready to provide after-sales support.

- Customization Options Depending on specific operational requirements, the ability to customize parts can be a significant advantage.

Conclusion

As industries continue to evolve and the demand for efficient slurry transport grows, finding a reliable supplier of centrifugal slurry pump parts is more critical than ever. China has positioned itself as a leading market due to its competitive pricing, diverse product offerings, and commitment to quality. By carefully selecting suppliers and prioritizing high-quality components, companies can enhance their operational efficiency and the longevity of their equipment. Investing in the right parts today can translate into significant savings and improved performance in the long run.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025