Oct . 21, 2025 11:20 Back to list

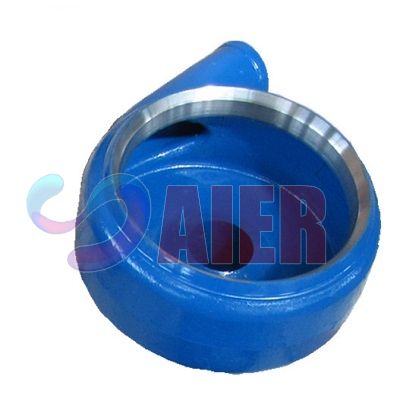

Slurry Pump Spare Parts Volute Liner Factory | OEM & Durable

Inside the Slurry Pump Spare Parts Volute Liner Factory: What Buyers Actually Need to Know

If you’ve ever stood next to a hard‑working slurry pump on a mine site, you know the volute liner takes a beating. To be honest, that’s where the real money is saved (or lost): in the wear parts. Lately I’ve been talking with maintenance managers who swear by high‑chrome liners, particularly the E4110A05 type made in China. And, yes, I’ve seen enough labs, foundries, and dusty pump bays to say: the details matter more than the brochure.

Market trends I keep hearing on site

- Shift to higher Cr content and tighter heat treatment windows for predictable wear.

- Shorter lead times with foundries that hold near‑net molds and common patterns in stock.

- More QC data in the box: spectro printouts, hardness maps, even G65 abrasion numbers—buyers are asking for proof, not promises.

Product snapshot: E4110A05 high chrome volute liner

Origin: China. Material: high chrome white iron (A05). Useful where silica‑rich slurries chew through lesser alloys. It’s meant for heavy‑duty slurry duty—mine tailings, sand & aggregate, ash handling—where uptime is currency.

| Spec | Value (≈ real-world) |

|---|---|

| Part code | E4110A05 |

| Material grade | High Chrome White Iron A05 (≈26–28% Cr), per ASTM A532 [1] |

| Hardness | HRC 62 ± 2 (ASTM E18) |

| Abrasion test | ASTM G65 Proc. A: ≈ 90–130 mm³ loss (typical) |

| Dimensional tolerance | ±0.8–1.2 mm critical faces (CMM verified) |

| Compatibility | Selected 6/4E‑size AH‑type slurry pumps; confirm against drawing |

| Expected service life | ≈ 1.5–3× mild steel baseline; 3–12 months depending on slurry PSD, % solids, pH |

| Certificates | ISO 9001:2015, EN 10204 3.1 material certs |

How a good liner is actually made

- Materials: low‑S/low‑P charge, FeCr, returns. Spectrometer checks at tap and final.

- Methods: medium‑frequency induction melt; resin‑bonded sand molds; riser/feeder design tuned to minimize shrink porosity.

- Heat treatment: controlled hardening/tempering curve to get M7C3 carbides dispersed in a tough matrix (the sweet spot).

- Testing: chemistry per A532, hardness grid, dye penetrant on sealing faces, CMM on fit surfaces, and (in better shops) ASTM G65 samples poured with the batch.

Where it’s used (and why it lasts)

Mining tailings lines, cyclone feed, dredging sand slurries, coal prep, and even aggressive mineral sands. High‑chrome resists sliding abrasion; not magic against severe impact or corrosion—though many customers say their maintenance windows stretched nicely once pH was stabilized.

Vendor comparison (what I look for)

| Vendor | Material/HT | QC pack | Lead time | Certs |

|---|---|---|---|---|

| Aier Pumps Factory (E4110A05) | A05, tightly controlled; HRC 62±2 | Chem + hardness map + G65 (on request) | ≈ 2–4 weeks if pattern in stock | ISO 9001, EN 10204 3.1 |

| Generic Foundry A | A05, wider HT window | Chem + hardness spot | 4–6 weeks | ISO 9001 |

| Overseas Trader B | Claimed A05 (verify) | Basic COA only | 6–10 weeks | Varies |

Customization that actually helps

- Geometry tweaks for localized washout zones (I’ve seen 8–12% life gains).

- Corrosion‑assist: chrome‑moly tweaks or bi‑metal overlays where pH dips.

- Traceability: heat ID, pour date, and QR linking to test data.

Mini case study

A silica sand plant swapped to the E4110A05 from a mixed supplier set. Same duty, 38–45% solids, d50 ≈ 250 μm. After two quarters, average liner changeout moved from every 10 weeks to 14 weeks. Not dramatic, but it stabilized maintenance planning—operators loved that. Feedback note: they tightened suction side alignment and saw fewer edge failures—setup matters.

Slurry Pump Spare Parts Volute Liner Factory buyers, in my experience, don’t just want a part; they want evidence. If you get chemistry, hardness grids, and even a one‑off G65 coupon with your shipment, you’re dealing with a serious shop.

Standards and references

- ASTM A532/A532M – Abrasion-Resistant Cast Irons.

- ASTM G65 – Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus.

- ISO 9001:2015 – Quality Management Systems.

- EN 10204:2004 – Metallic products, Types of inspection documents.

- ISO 5199 – Technical specifications for centrifugal pumps (process pumps) — for dimensional/fit guidance in related installs.

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025

-

Reliable China FGD Pump Suppliers for Effective Flue Gas Desulfurization | AiEr Pumps

NewsNov.22,2025

-

China FGD Pump: Durable & Efficient Solutions for Emission Control

NewsNov.21,2025