- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Sep . 02, 2025 10:56 Back to list

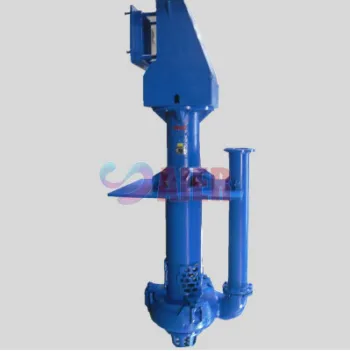

Rubber Slurry Pump: Ideal for Transporting Corrosive Slurry

In industrial production, transporting slurry containing corrosive media has always been a challenge, and Rubber Slurry Pump, with its unique material and design, has become an important equipment to solve this problem, playing a key role in multiple fields.

The structural design of Rubber Slurry Pump fully embodies pertinence and practicality

The core components of the 8/6 rubber slurry pump, such as the pump body and impeller, are mainly made of high-quality wear-resistant rubber. This rubber has excellent elasticity and corrosion resistance, and can effectively resist the erosion of corrosive media such as acid and alkali. The casing of the pump is often made of high-strength metal materials, providing solid protection for the internal rubber components and ensuring the overall stability of the equipment. At the same time, a reasonable flow channel design allows the slurry to flow more smoothly inside the pump, reducing resistance and wear, and improving conveying efficiency.

The performance advantages of Rubber Slurry Pump are particularly prominent in the transportation of corrosive slurries

Rubber slurry pump parts have extremely strong corrosion resistance and can adapt to different concentrations of acidic and alkaline slurries as well as media containing chemical impurities, greatly expanding their application range. Moreover, the elasticity of rubber material provides a certain buffering effect on solid particles in the slurry during the operation of the pump, reducing the impact and wear of particles on the pump body and extending the service life of the equipment. In addition, the pump operates with relatively low noise and gentle vibration, providing better protection for the production environment.

Rubber Slurry Pump has a wide range of application scenarios

In the chemical industry, ahr rubber slurry pumps are commonly used to transport chemical slurries containing acidic and alkaline components, meeting the needs of material transportation in chemical production; In the metallurgical industry, it is possible to transport waste slurry containing corrosive substances generated during the smelting process, which helps to facilitate the smooth progress of metallurgical production; In the field of environmental protection, it can effectively transport corrosive sludge generated during the sewage treatment process, ensuring the stable operation of the sewage treatment system; In the mining industry, Rubber Slurry Pump is also an ideal conveying equipment for some slurry containing corrosive components.

With the continuous advancement of industrial technology, Rubber Slurry Pump is also constantly improving and developing

The research and application of new rubber materials have further improved the corrosion resistance, wear resistance, and high temperature resistance of pumps, enabling open rubber slurry pump impellers to adapt to more complex working conditions. At the same time, intelligent technology is gradually being integrated into it. By installing sensors and intelligent control systems, the operating status of the pump can be monitored in real time, such as flow rate, pressure, temperature and other parameters, and potential faults can be detected and warned in a timely manner, improving the reliability and safety of equipment operation.

In summary, Rubber Slurry Pump occupies an important position in the field of corrosive slurry transportation due to its excellent corrosion resistance, unique structural design, wide application scenarios, and continuous technological innovation. It not only provides stable and reliable transportation guarantees for the production of various industries, but also promotes the development of related industries to a certain extent. In the future, with continuous technological breakthroughs, Rubber Slurry Pump will develop towards greater efficiency, durability, and intelligence, bringing greater assistance to industrial production.

Rubber Slurry Pump

What is the main purpose of Rubber Slurry Pump?

Rubber Slurry Pump is mainly used for conveying media containing solid particles and high concentration abrasive slurries, commonly found in industries such as mining, metallurgy, power, and chemical. Its rubber material has excellent wear and corrosion resistance, making it suitable for handling highly abrasive slurries.

What are the advantages of Rubber Slurry Pump compared to metal pumps?

Wear resistance: Rubber (such as natural rubber or synthetic rubber) has a stronger buffering ability against particle impact and a lower wear rate than metal.

Corrosion resistance: better adaptability to corrosive media such as acid and alkali.

Lightweight: easier to install and maintain.

Noise reduction and shock absorption: Rubber can absorb vibrations and reduce operating noise.

Common faults and solutions of Rubber Slurry Pump?

Problem: Rubber lining peeling or cracking

Reason: Excessive slurry impact or chemical corrosion.

Solution: Check if the characteristics of the slurry match the rubber material, and replace it with a higher grade of rubber (such as acid resistant rubber) if necessary.

Problem: Decreased traffic

Reason: Impeller or pipeline blockage, lining wear leading to increased clearance.

Solution: Stop the machine to clean blockages or replace worn parts.

How to extend the service life of Rubber Slurry Pump?

Regularly inspect the wear of vulnerable parts such as rubber lining and impeller.

Avoid prolonged idling or overloaded operation.

Select the appropriate rubber material based on the characteristics of the slurry, such as particle size and pH value.

Thoroughly clean the residual slurry inside the pump during shutdown to prevent solidification and corrosion.

What parameters should be considered when selecting Rubber Slurry Pump?

Medium characteristics: particle concentration, hardness, corrosiveness, etc.

Flow rate and head: Match the performance curve of the pump according to the working condition requirements.

Rubber types: such as natural rubber (suitable for weak acids), chloroprene rubber (oil resistant and oxidation resistant), etc.

Installation method: horizontal or vertical, taking into account on-site space and pipeline layout.

-

Essential Guide to FGD Pump Supplies – Efficiency and Sustainability for Industrial Emission Controls

NewsNov.24,2025

-

Leading FGD Pump Manufacturers for Reliable Flue Gas Desulfurization Solutions

NewsNov.24,2025

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025