Jan . 14, 2025 11:17 Back to list

centrifugal slurry pump manufacturers

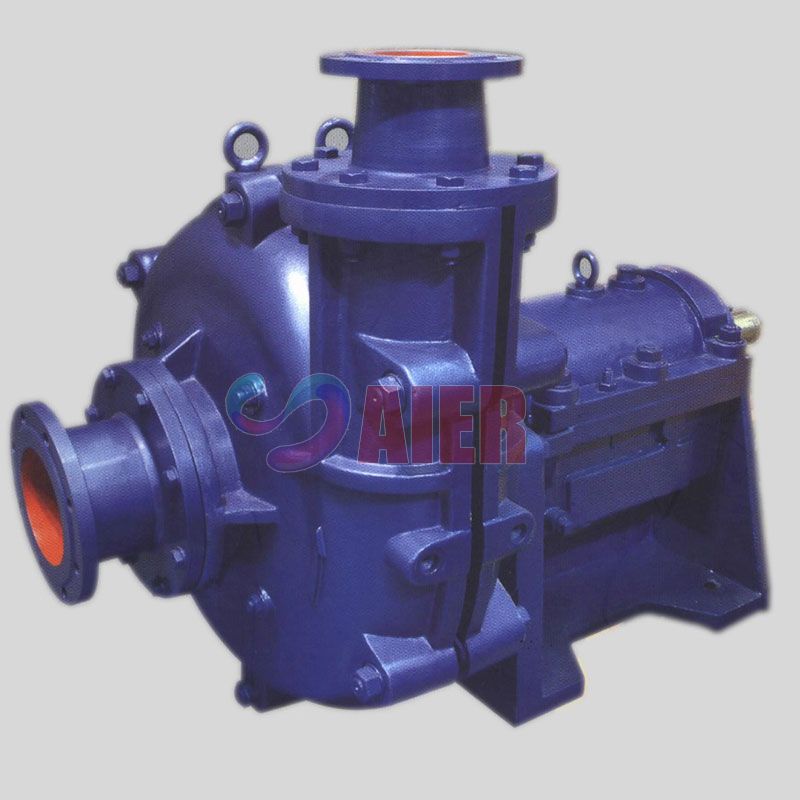

Finding the right centrifugal slurry pump manufacturer is crucial for industries handling abrasive and high-density slurries. These pumps are essential in mining, mineral processing, and power generation, among other sectors. Through personal experience and extensive research, it becomes evident that selecting the right manufacturer involves evaluating several critical factors to ensure reliable and efficient pump performance.

Building trust through authoritative partnerships is a hallmark of a distinguished pump manufacturer. Working with major industry players and gaining certifications from recognized bodies underscores a commitment to quality and reliability. ISO certifications, for example, provide assurance that manufacturing processes meet international standards. Such endorsements can guide potential clients in selecting a manufacturer whose reputation is backed by consistent performance and quality assurance. An exceptional user experience extends beyond the product. Reliable manufacturers have robust support systems, offering comprehensive after-sales service and technical support. This ongoing relationship ensures that any issues are swiftly addressed, minimizing operational disruptions. A dedicated support team with seasoned technicians and engineers further solidifies the trustworthiness of the manufacturer, ensuring clients that they are in capable hands long after the initial purchase. From a trust perspective, transparency in communication establishes credibility. Manufacturers who offer clear, detailed product information and documentation enable clients to make informed decisions. This openness is critical, especially when understanding the complexities involved in slurry applications. In summary, selecting the perfect centrifugal slurry pump manufacturer involves assessing expertise, innovation, efficiency, versatility, and support systems. These factors collectively ensure that industries receive not only high-performance products but also unmatched reliability and service. By prioritizing these elements, businesses can forge partnerships that drive success across their operations, ensuring seamless and sustainable industrial processes.

Building trust through authoritative partnerships is a hallmark of a distinguished pump manufacturer. Working with major industry players and gaining certifications from recognized bodies underscores a commitment to quality and reliability. ISO certifications, for example, provide assurance that manufacturing processes meet international standards. Such endorsements can guide potential clients in selecting a manufacturer whose reputation is backed by consistent performance and quality assurance. An exceptional user experience extends beyond the product. Reliable manufacturers have robust support systems, offering comprehensive after-sales service and technical support. This ongoing relationship ensures that any issues are swiftly addressed, minimizing operational disruptions. A dedicated support team with seasoned technicians and engineers further solidifies the trustworthiness of the manufacturer, ensuring clients that they are in capable hands long after the initial purchase. From a trust perspective, transparency in communication establishes credibility. Manufacturers who offer clear, detailed product information and documentation enable clients to make informed decisions. This openness is critical, especially when understanding the complexities involved in slurry applications. In summary, selecting the perfect centrifugal slurry pump manufacturer involves assessing expertise, innovation, efficiency, versatility, and support systems. These factors collectively ensure that industries receive not only high-performance products but also unmatched reliability and service. By prioritizing these elements, businesses can forge partnerships that drive success across their operations, ensuring seamless and sustainable industrial processes.

Next:

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025